- 12/3/18

- 37,544

- 80,351

- 113

Greetings fellow watch bros!

I had some parts lying around doing nothing so I decided to mod a couple of DJ41s. This is the watch to be modded, an old Noob DJ41 with 2836 that was probably about $268 back in the day. It’s a decent case and while the dial is beautiful in its own right, it really isn’t very gen-like.

So the 3235 parts I had were: datewheel, dial, hands, crystal and crown.

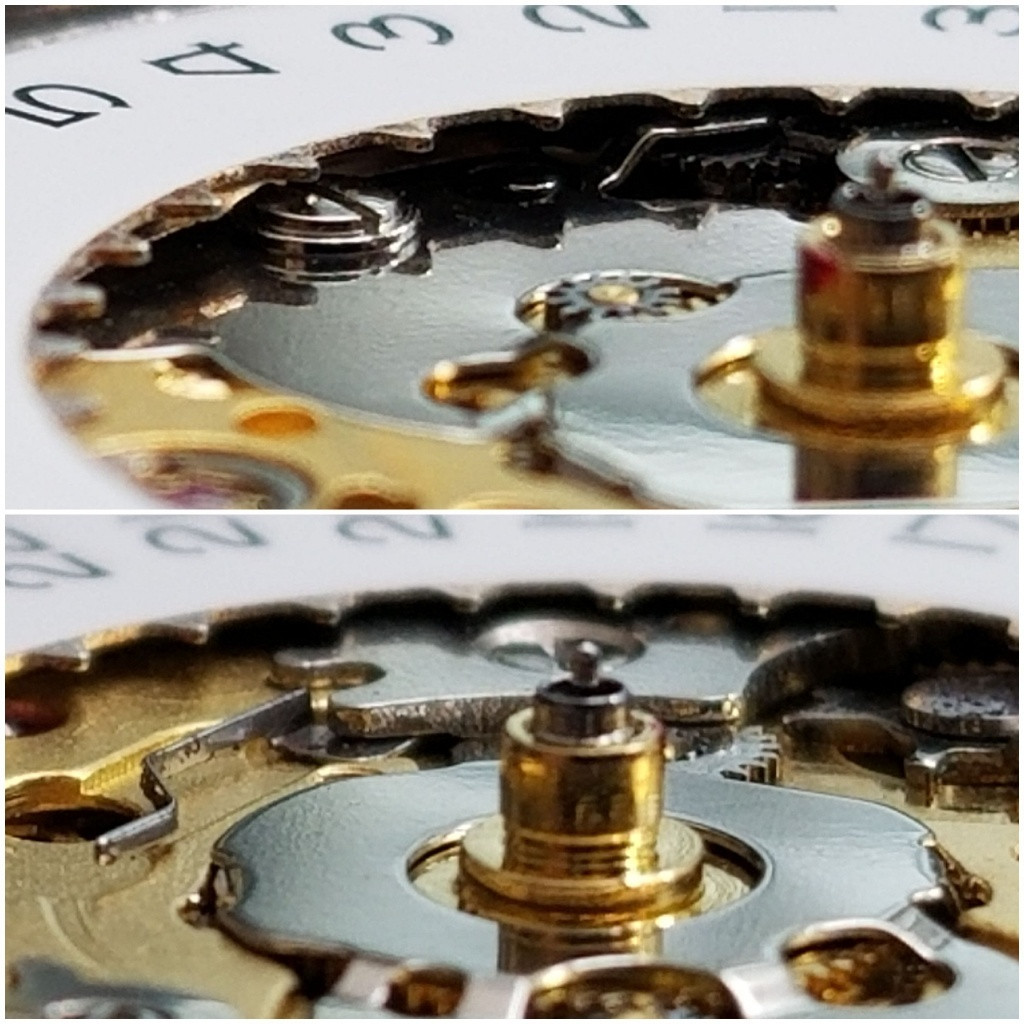

Datewheel

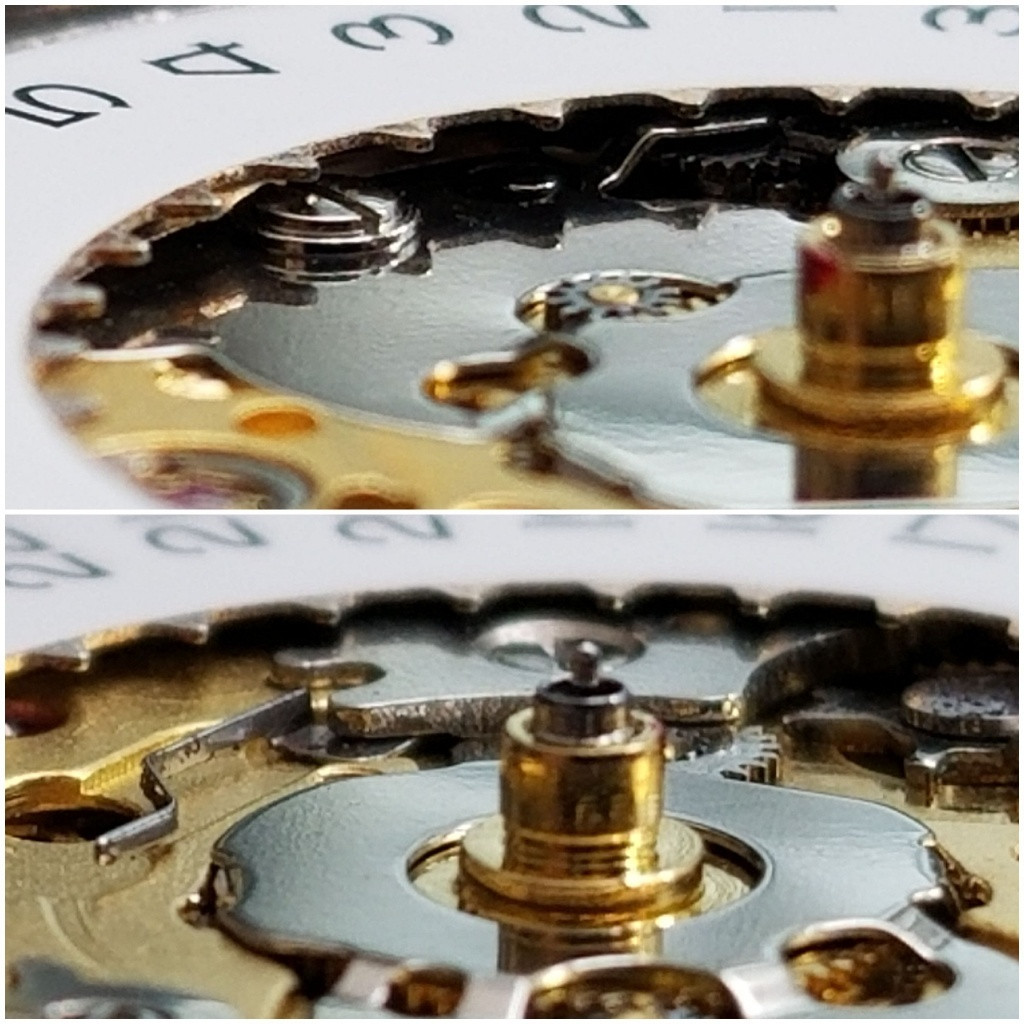

This was the easiest mod since the 2836 has plenty of room beneath the dial. This can also be done with a 2824 but is more challenging and often requires grinding the teeth off the 3235 DW to use it as a DWO. Just add some epoxy ribbons to the existing DW and set it in place.

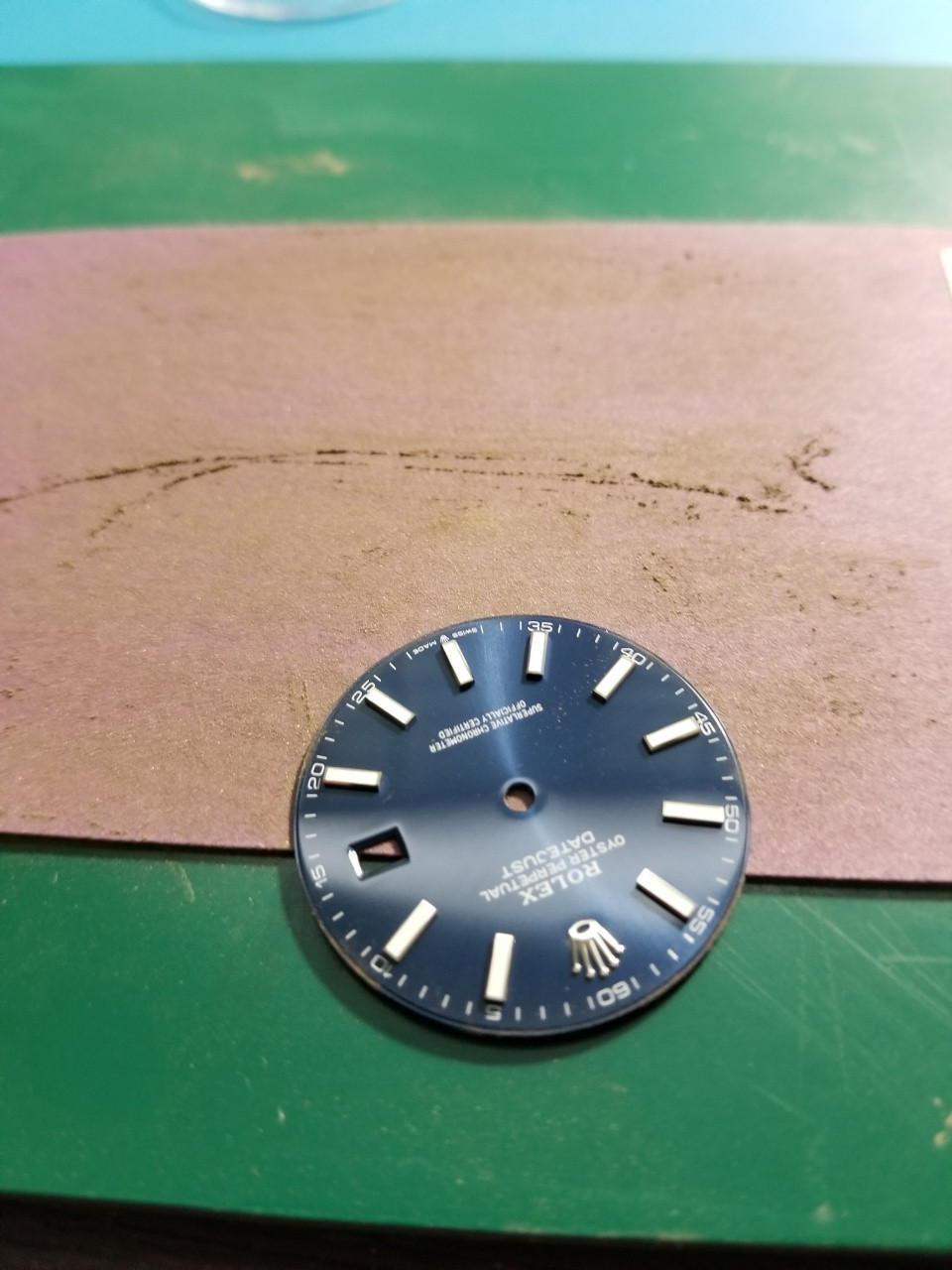

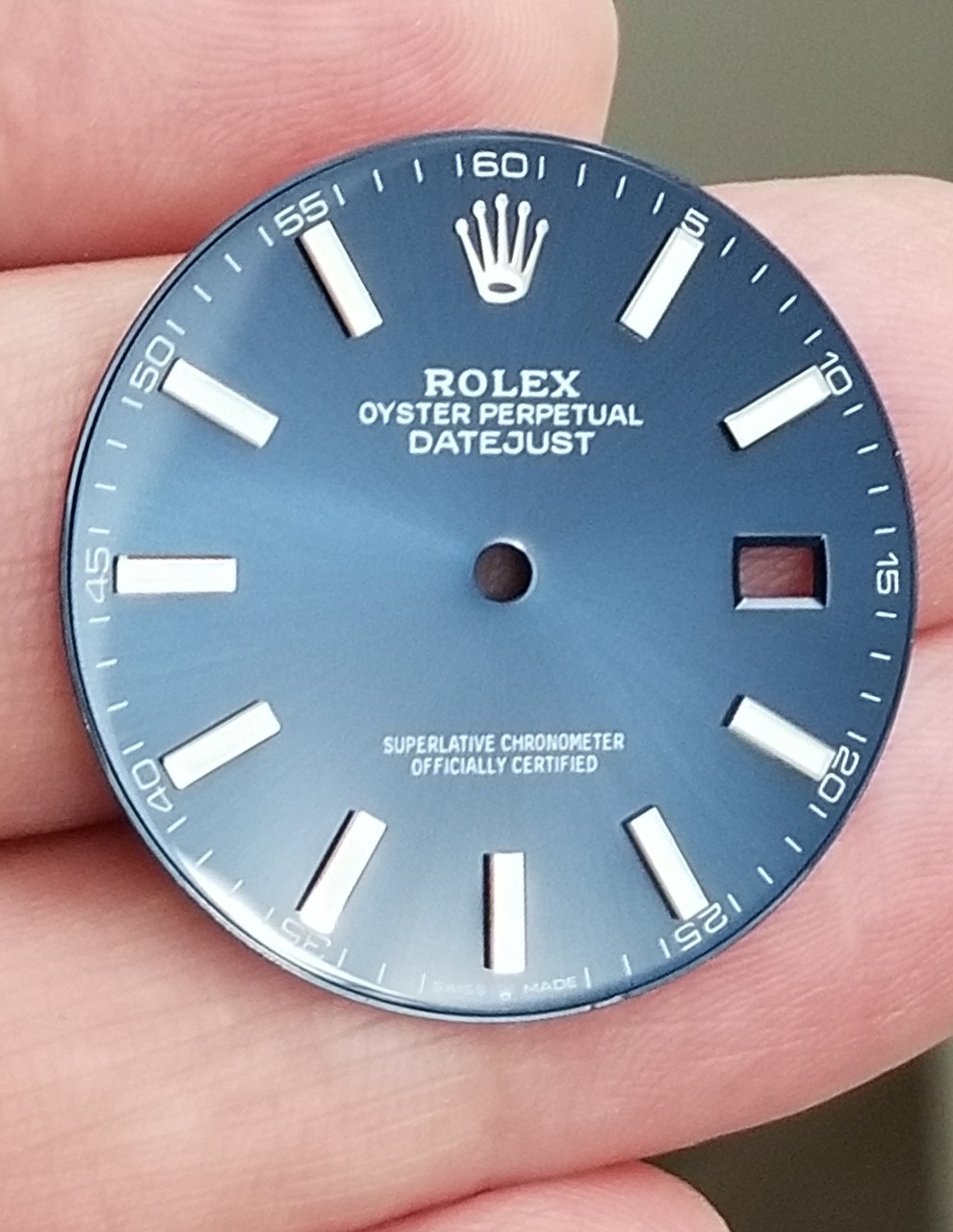

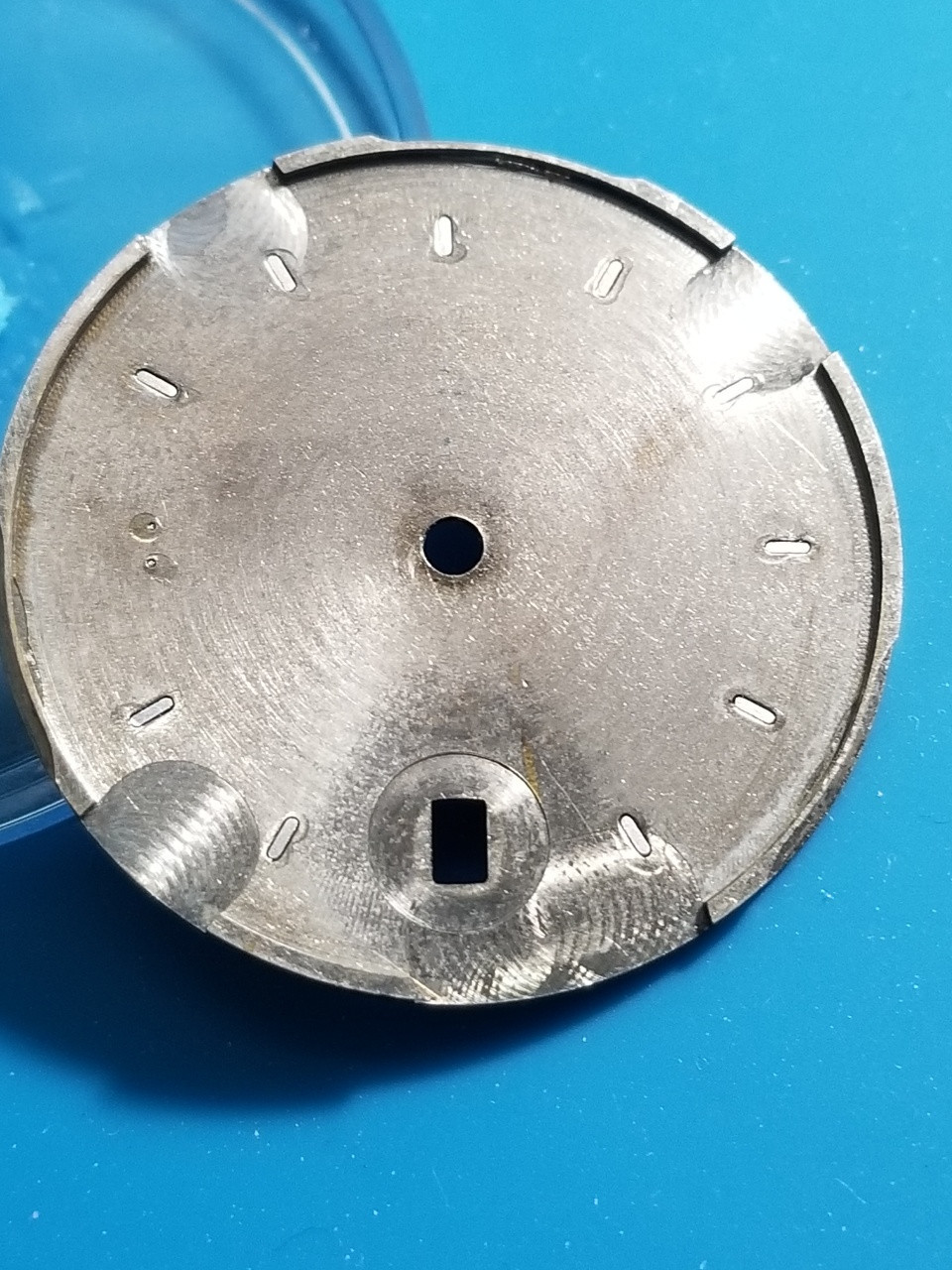

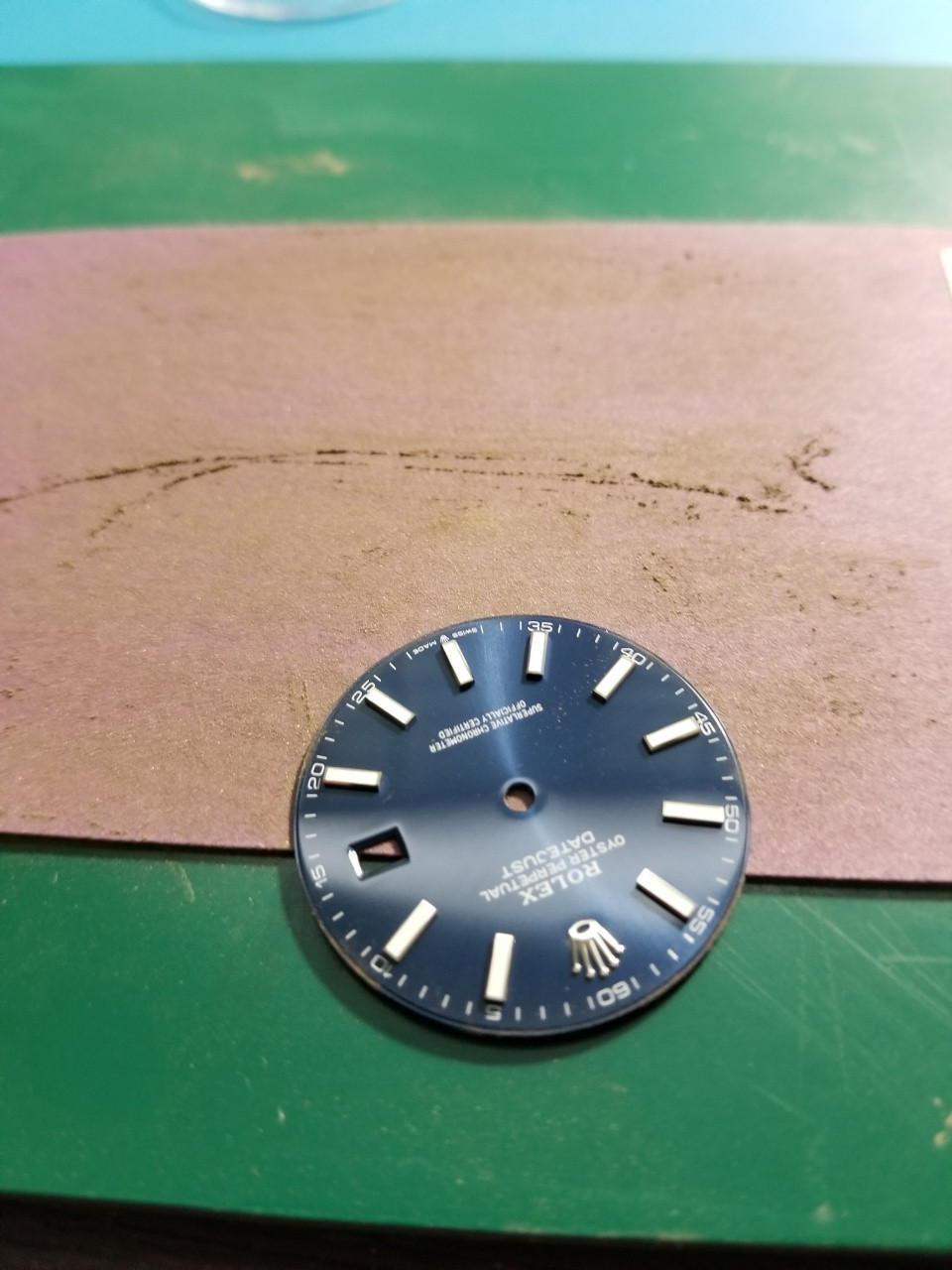

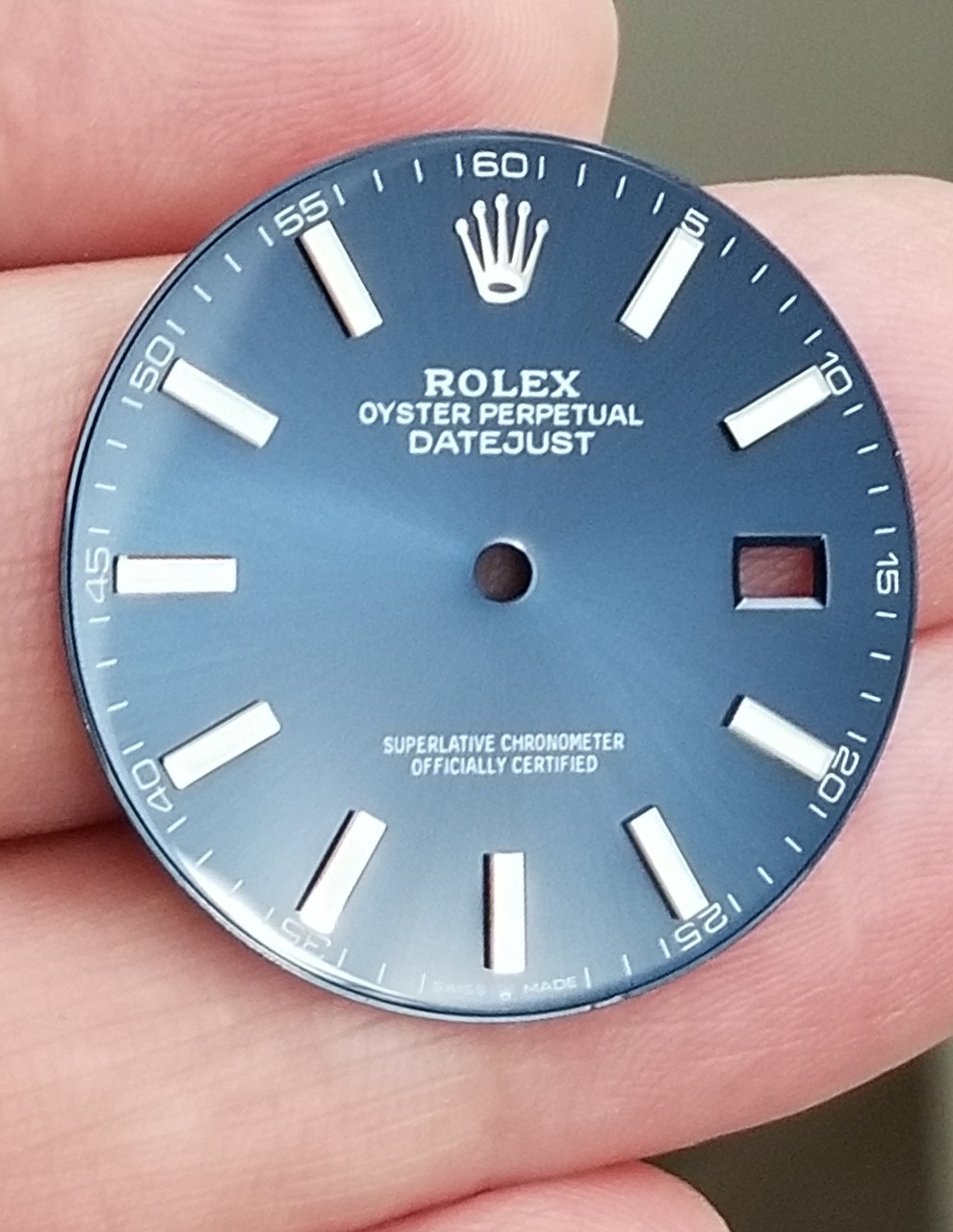

Dial

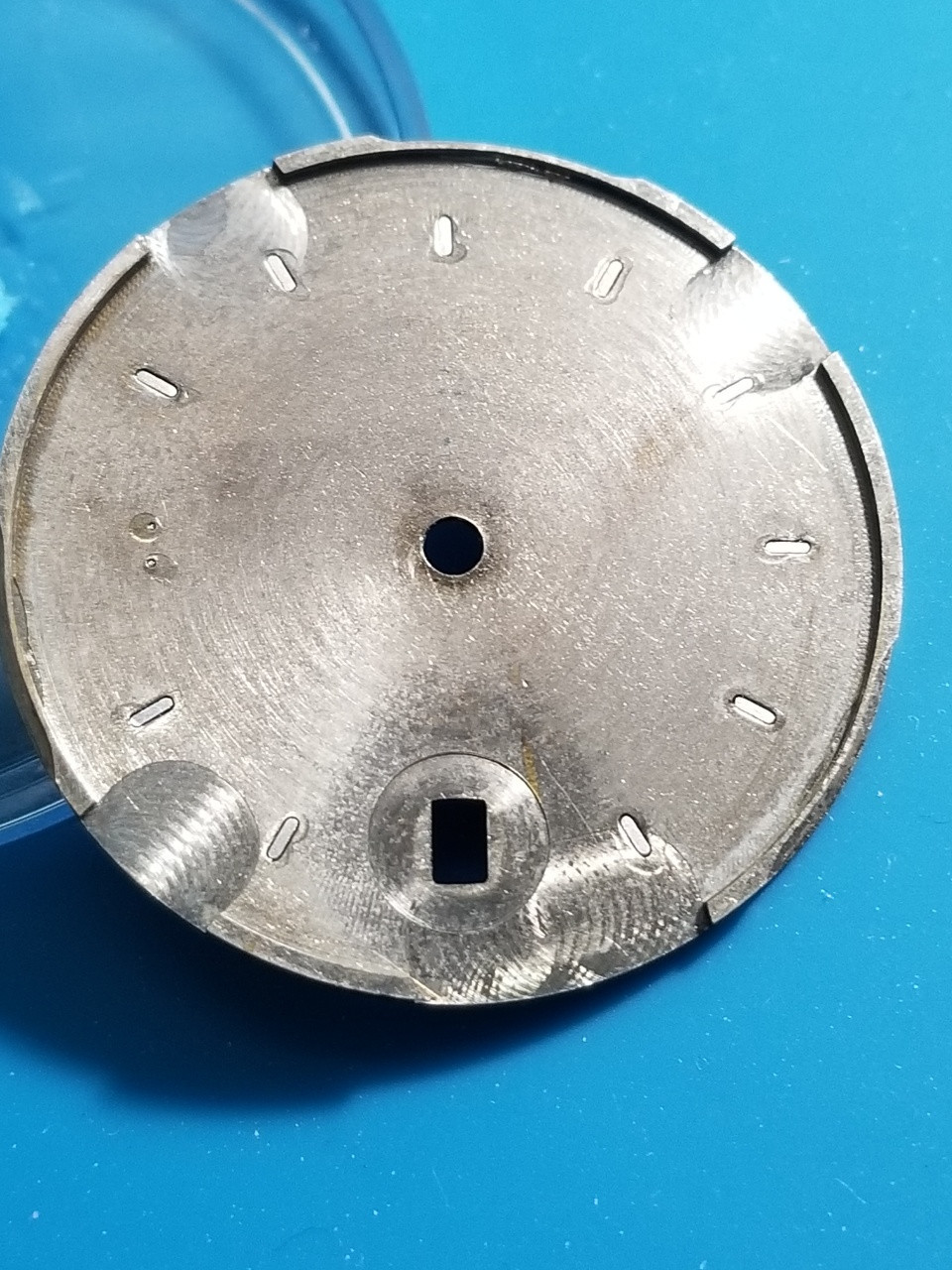

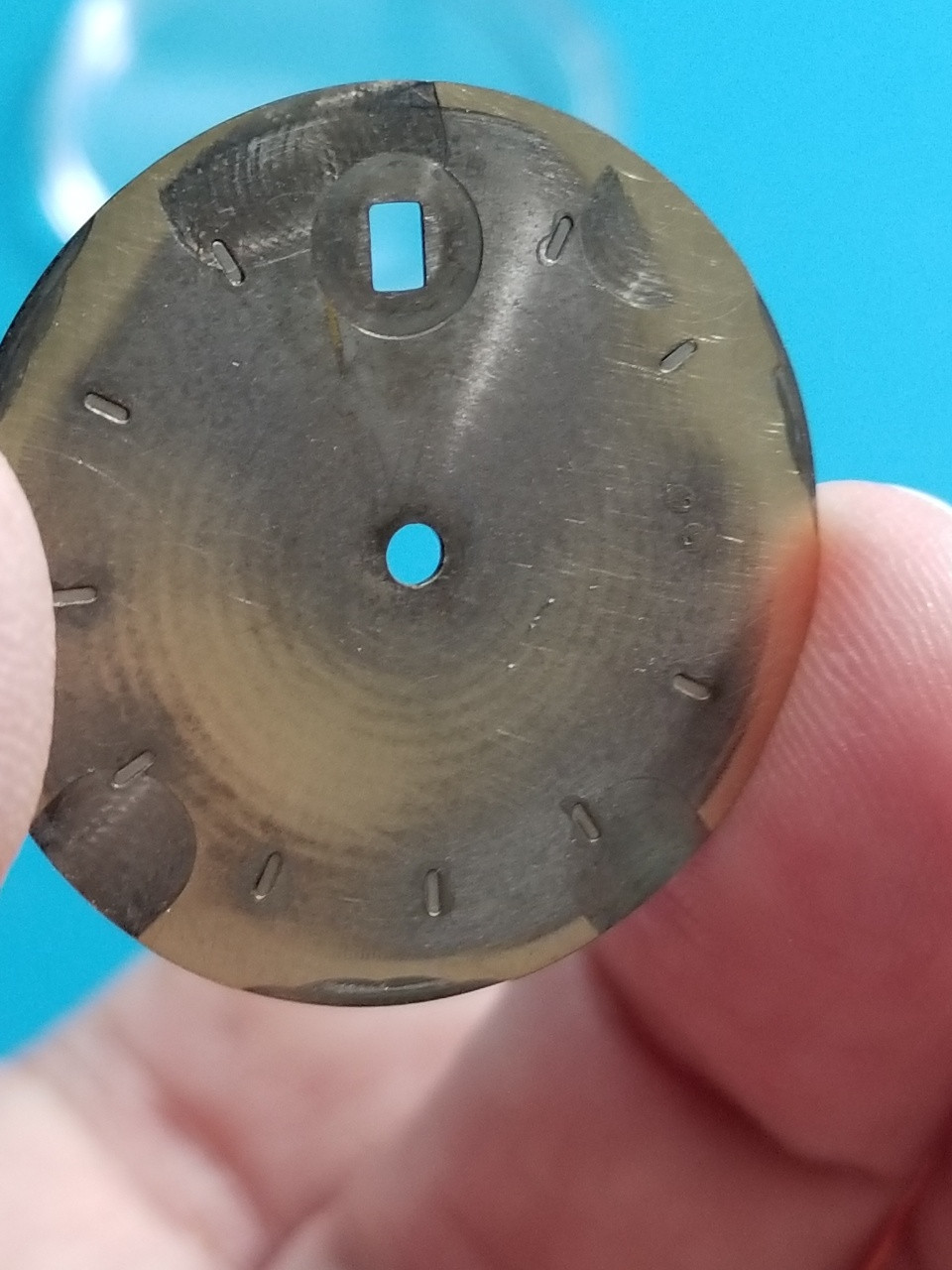

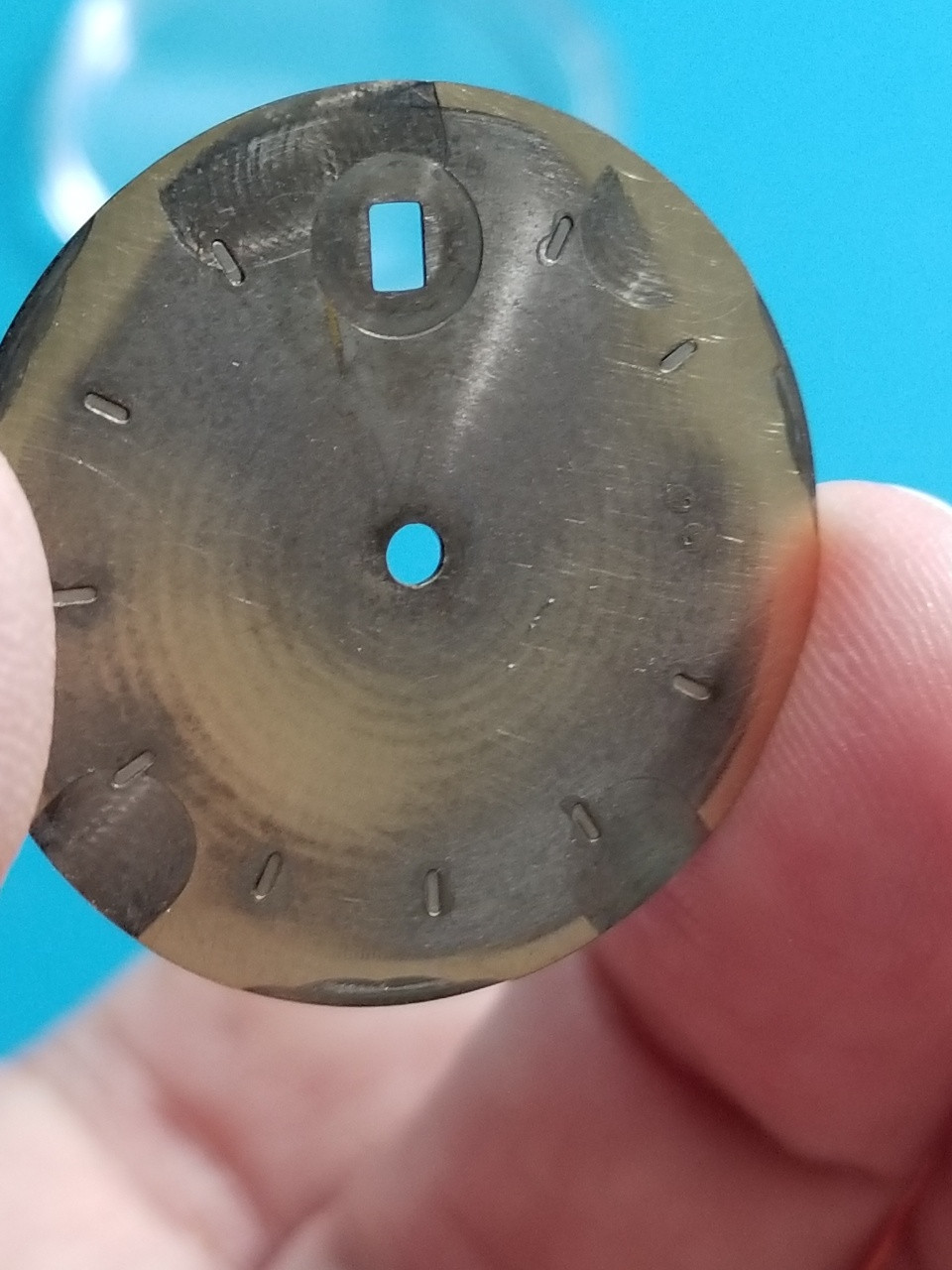

Here is the CF 3235 dial. Since it has no feet and some underside rims, those will have to be sanded or grinded down. I opted to sand the rims down, though a grinding bit on a dremel could also work.

I covered the dial front with some plastic and then painter’s tape. Then taped it to a die. After that it’s just a few minutes of rubbing. Rotate often to keep it even.

Next the dial gets a bath and blow dry.

The ETA DJ41s have a very wide movement holder that has feet holes but since the dial has no feet and gluing new ones on would mean notching the holder to account for the foot bases, I just epoxied the dial onto the holder. This is a little less convenient to remove if you have to but easy enough. I did have to completely undo it and redo it once because for some still unknown reason to me the dates ended up sitting high so I had to fix that. The cured epoxy slices off from both pieces cleanly, then just wipe with alcohol.

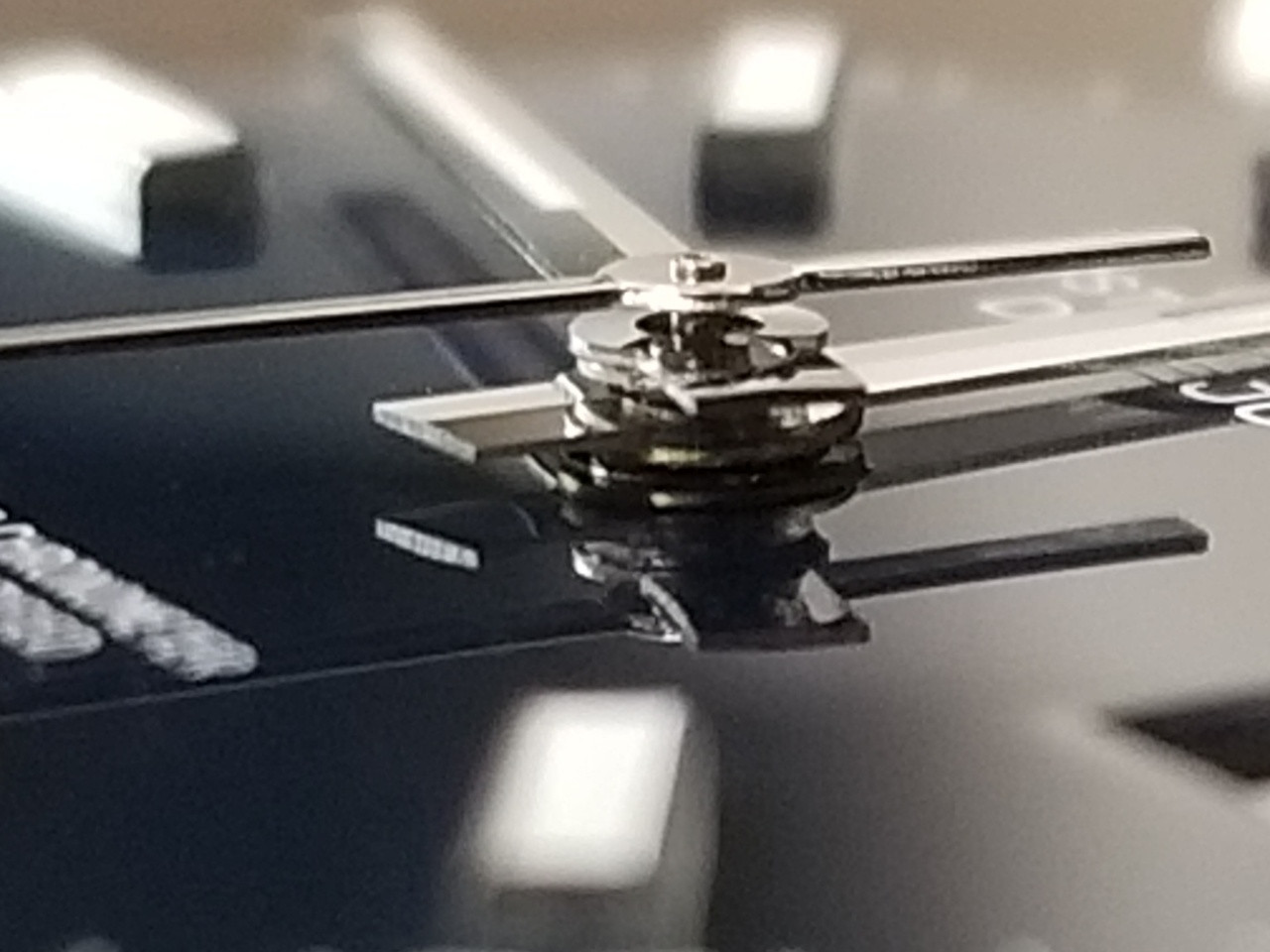

Hands

This was the most challenging part. All the 3235 hands holes had to be modded.

3235 HMS 140/100/20 mm

2836 HMS 150/90/25 mm

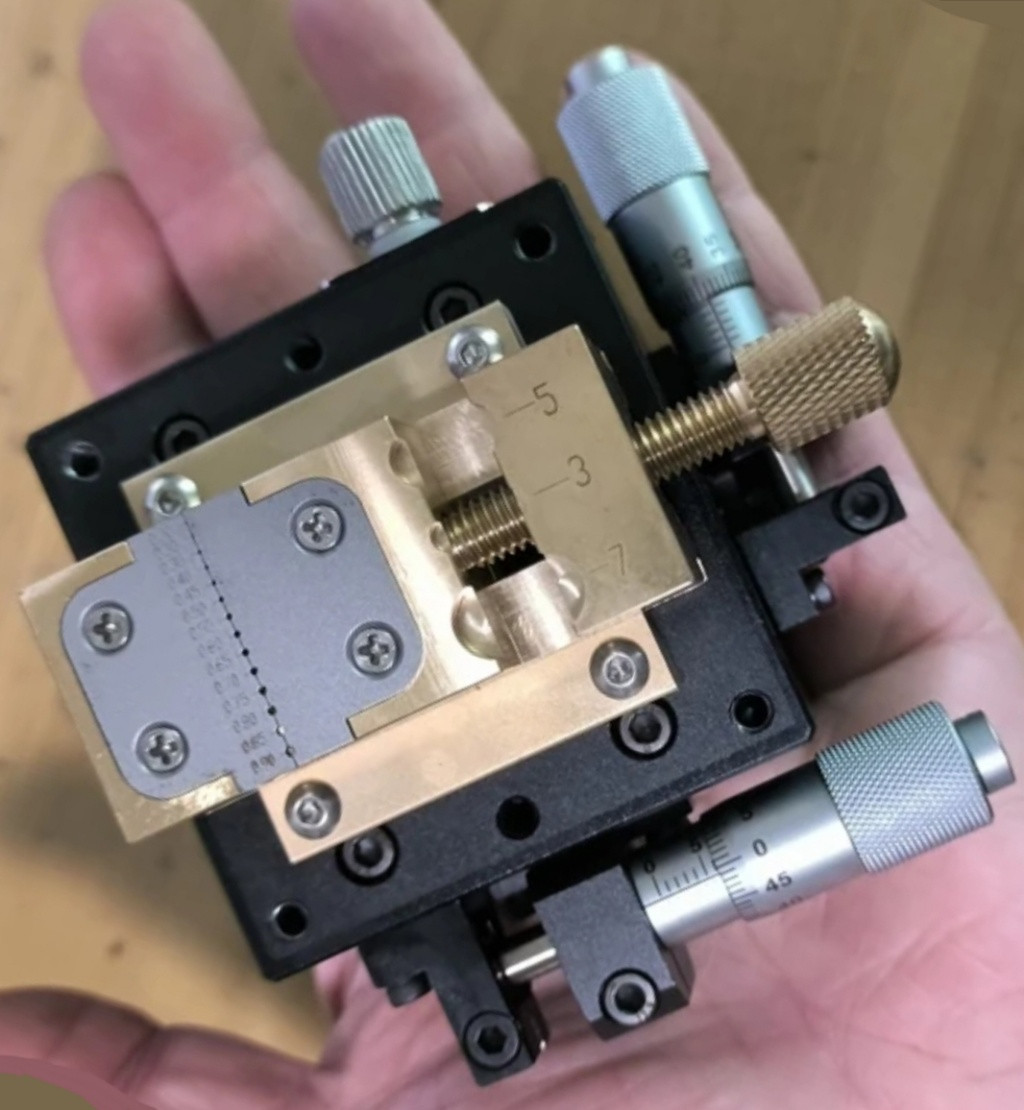

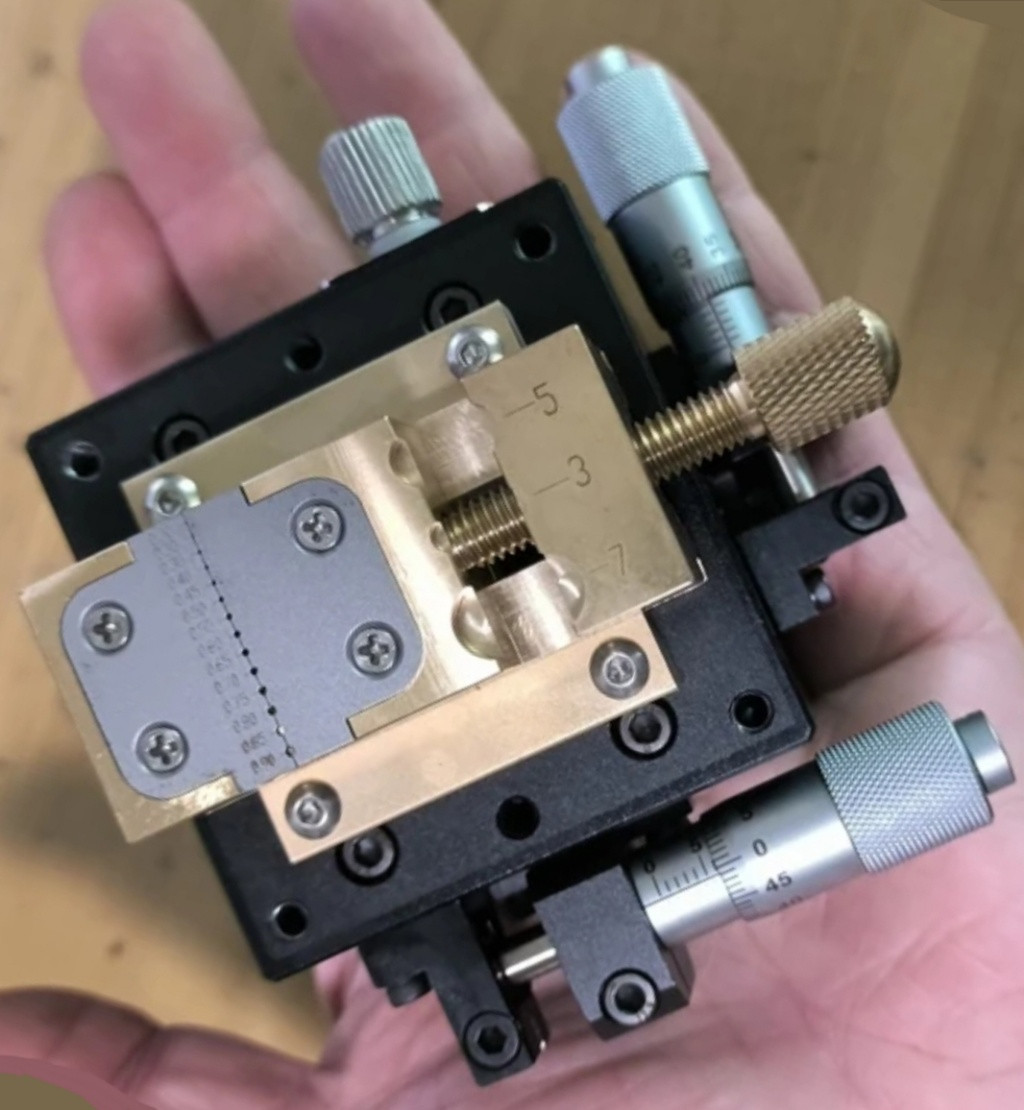

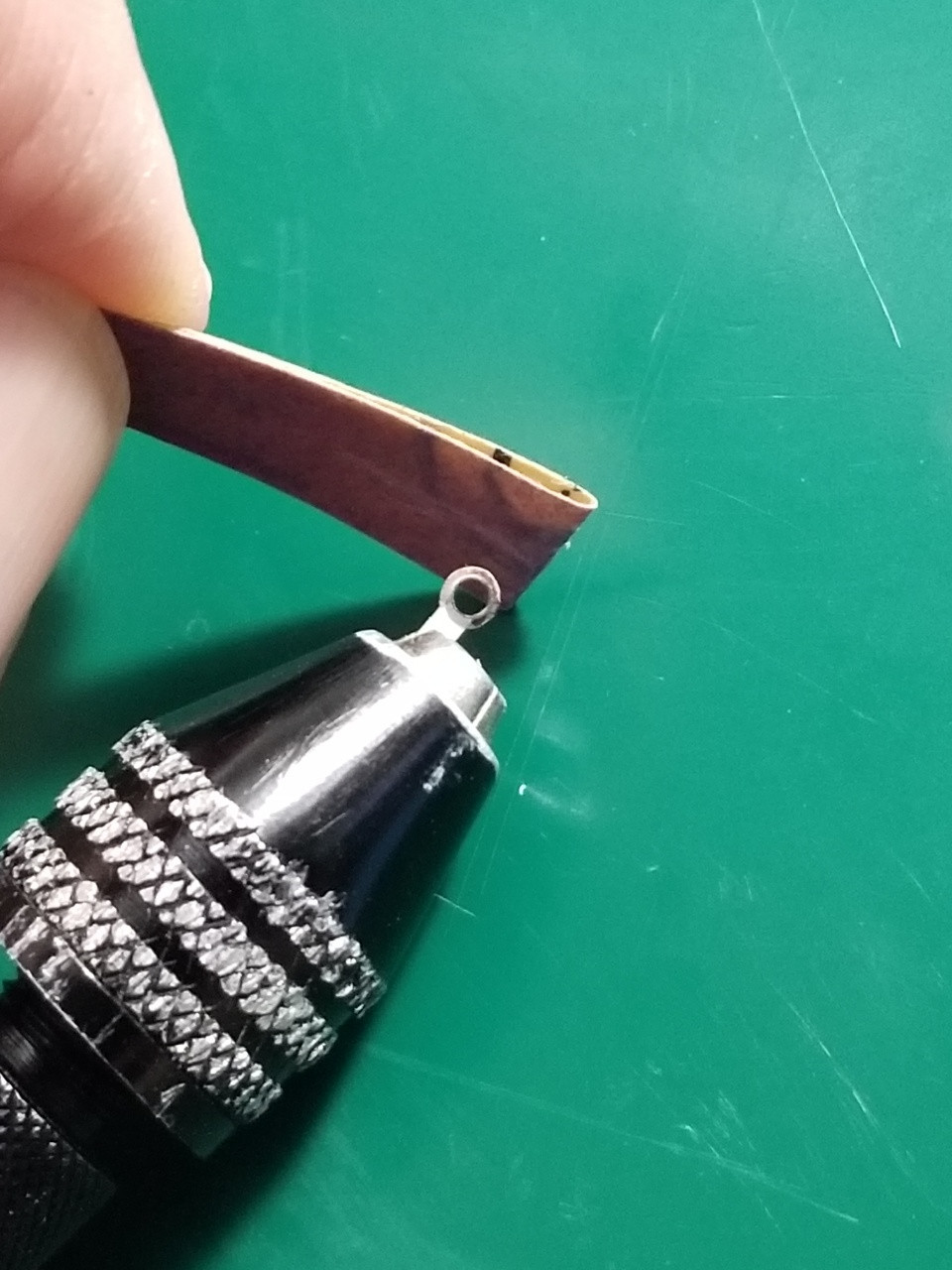

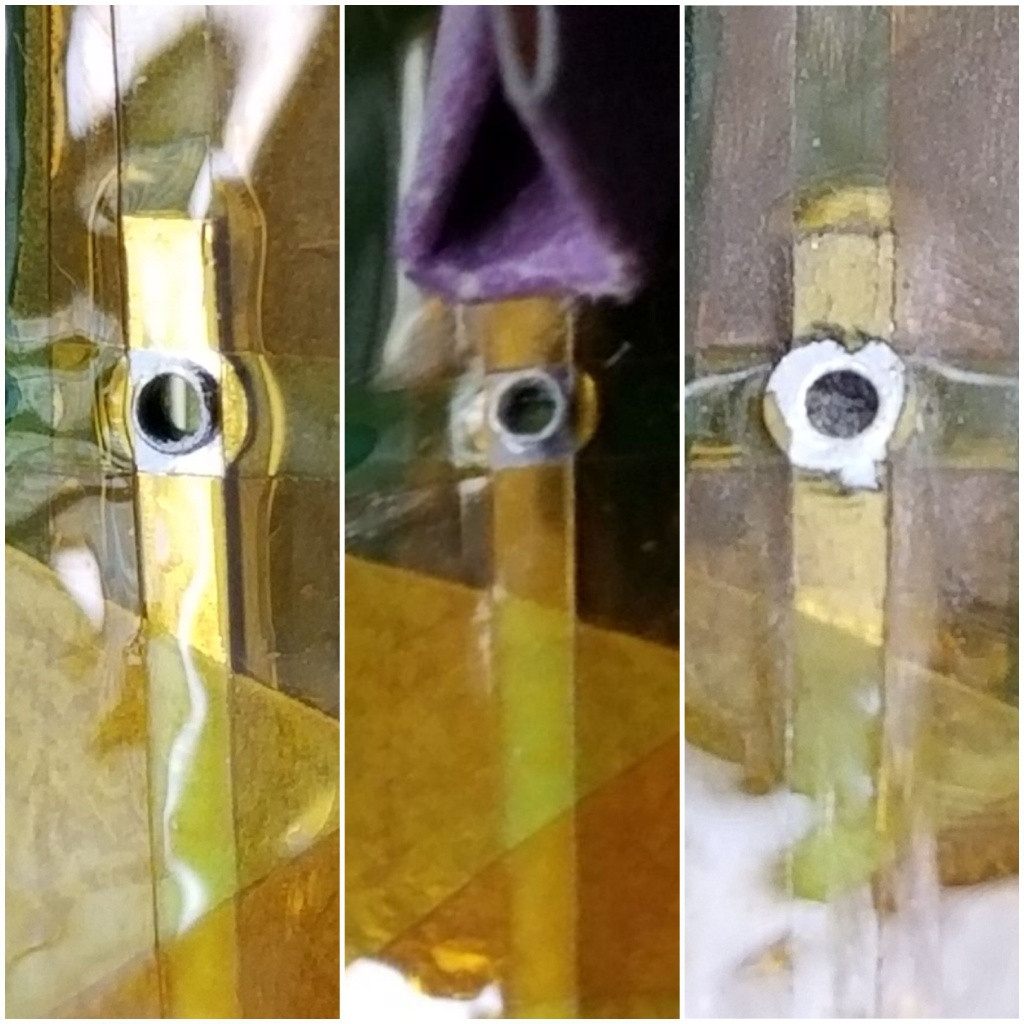

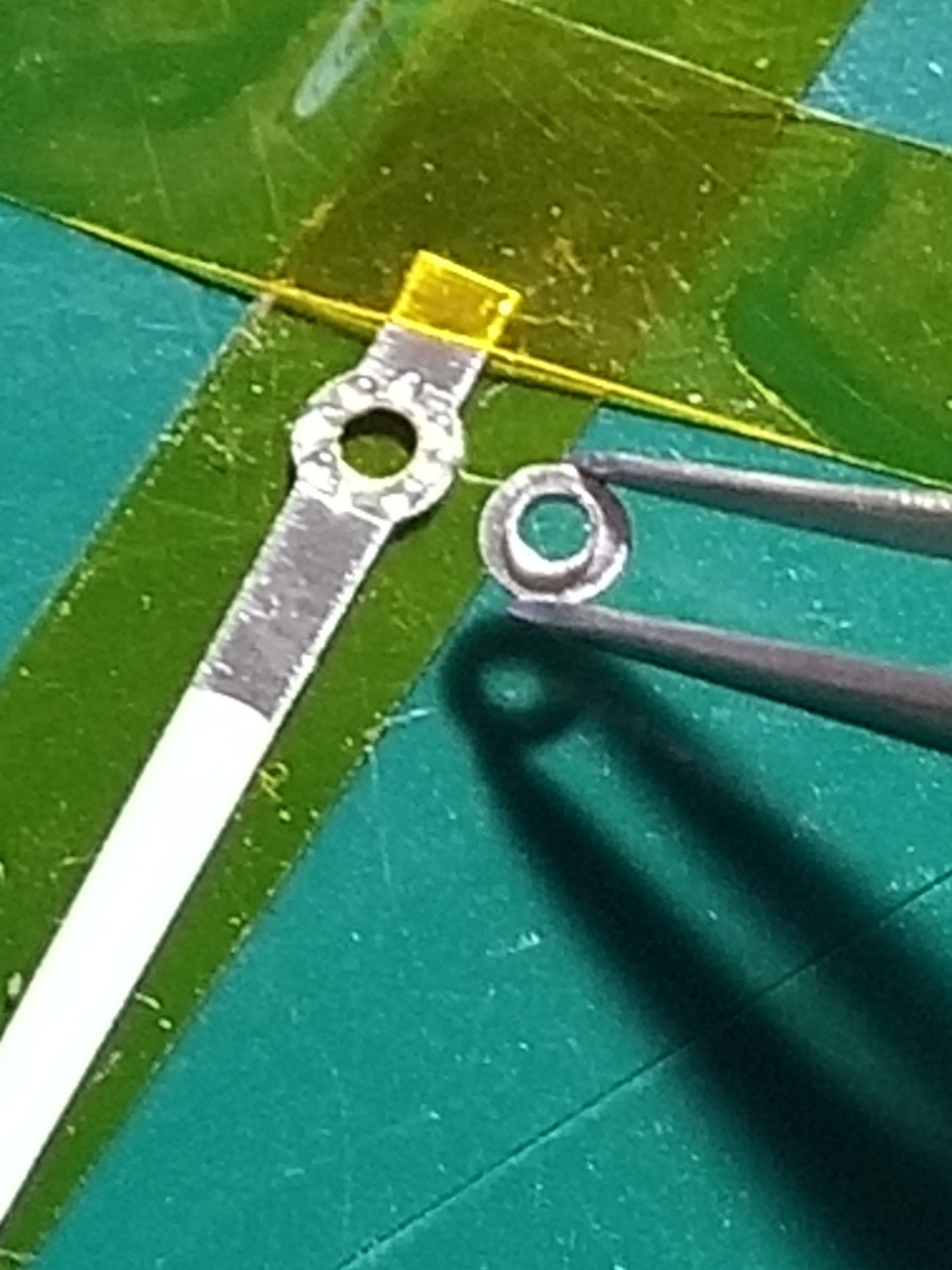

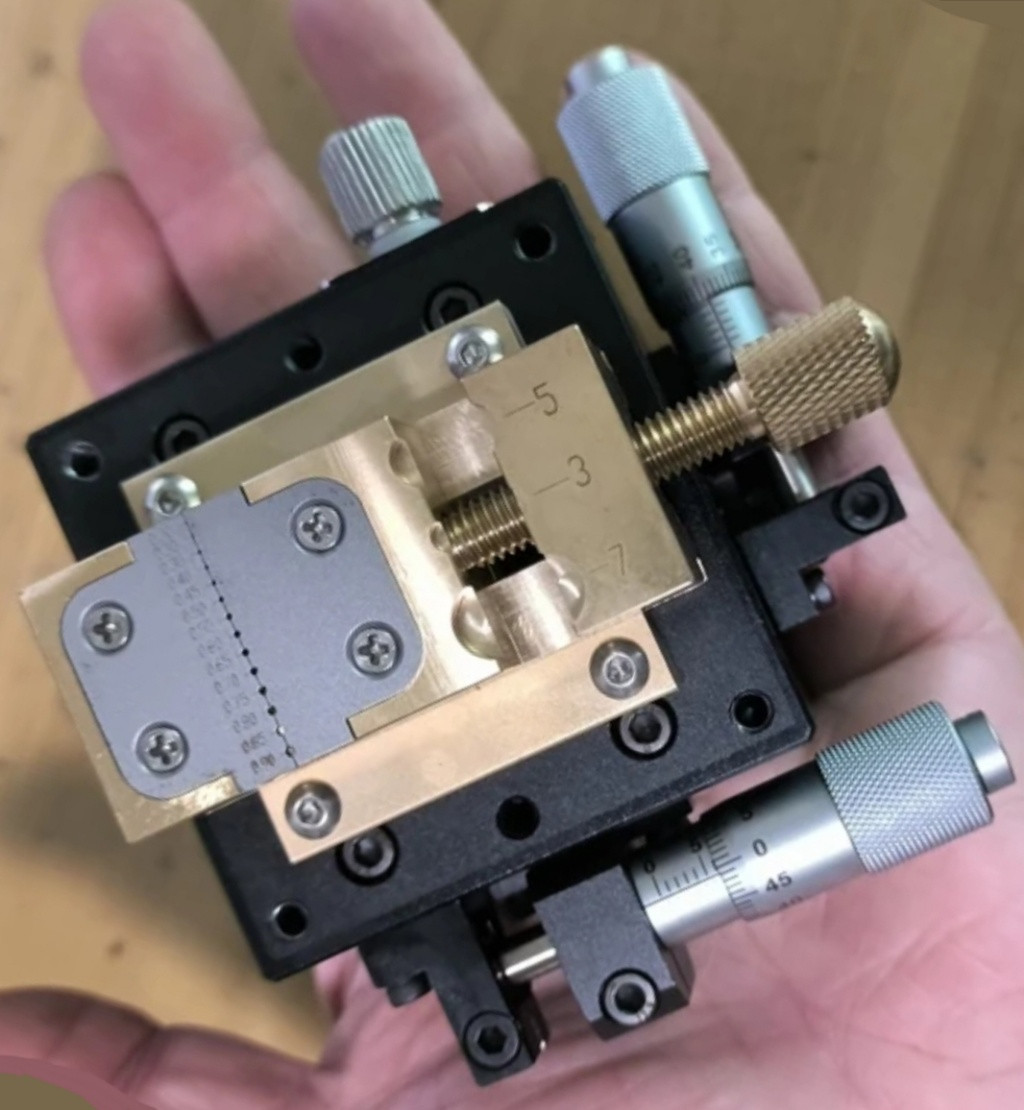

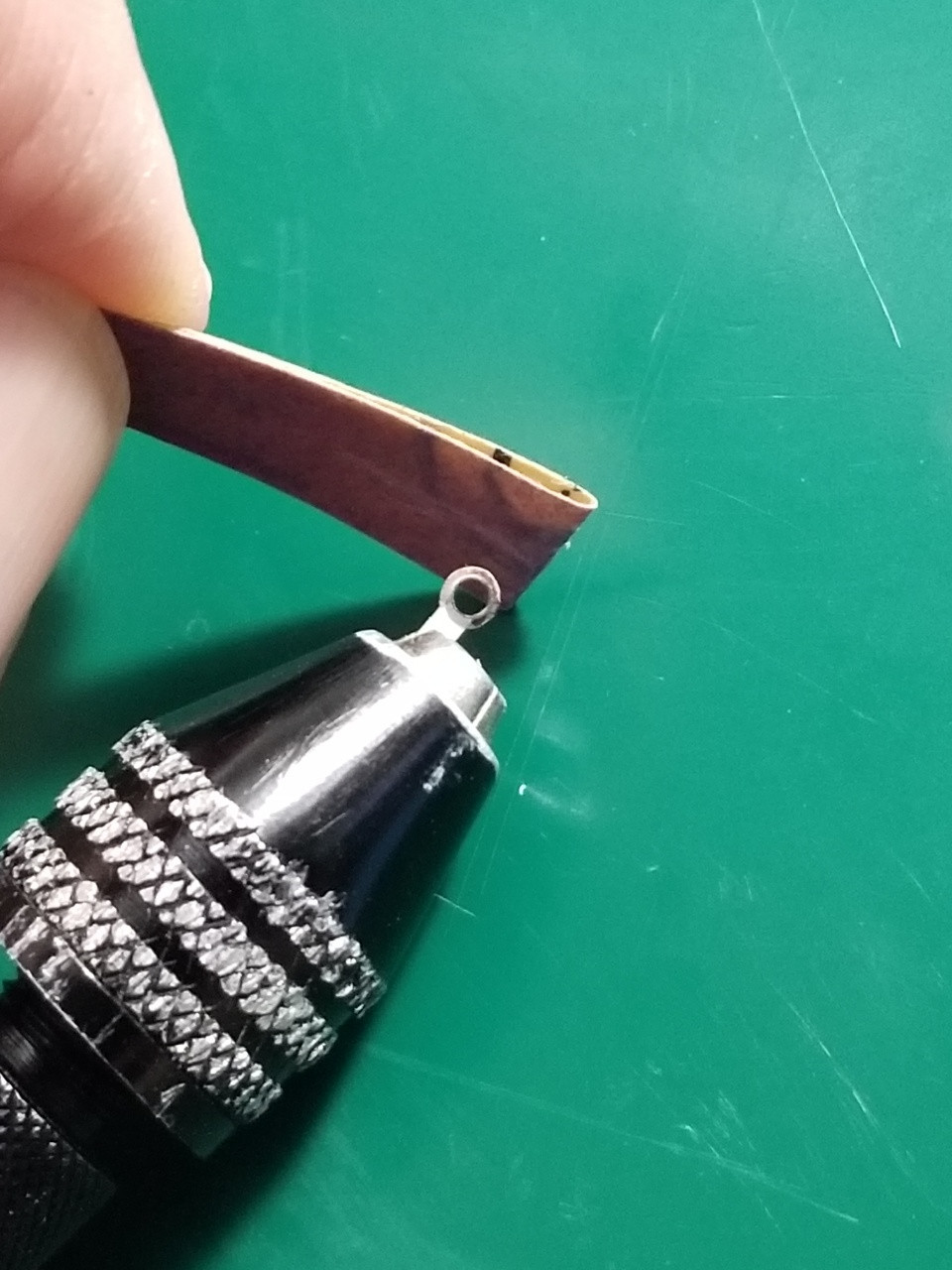

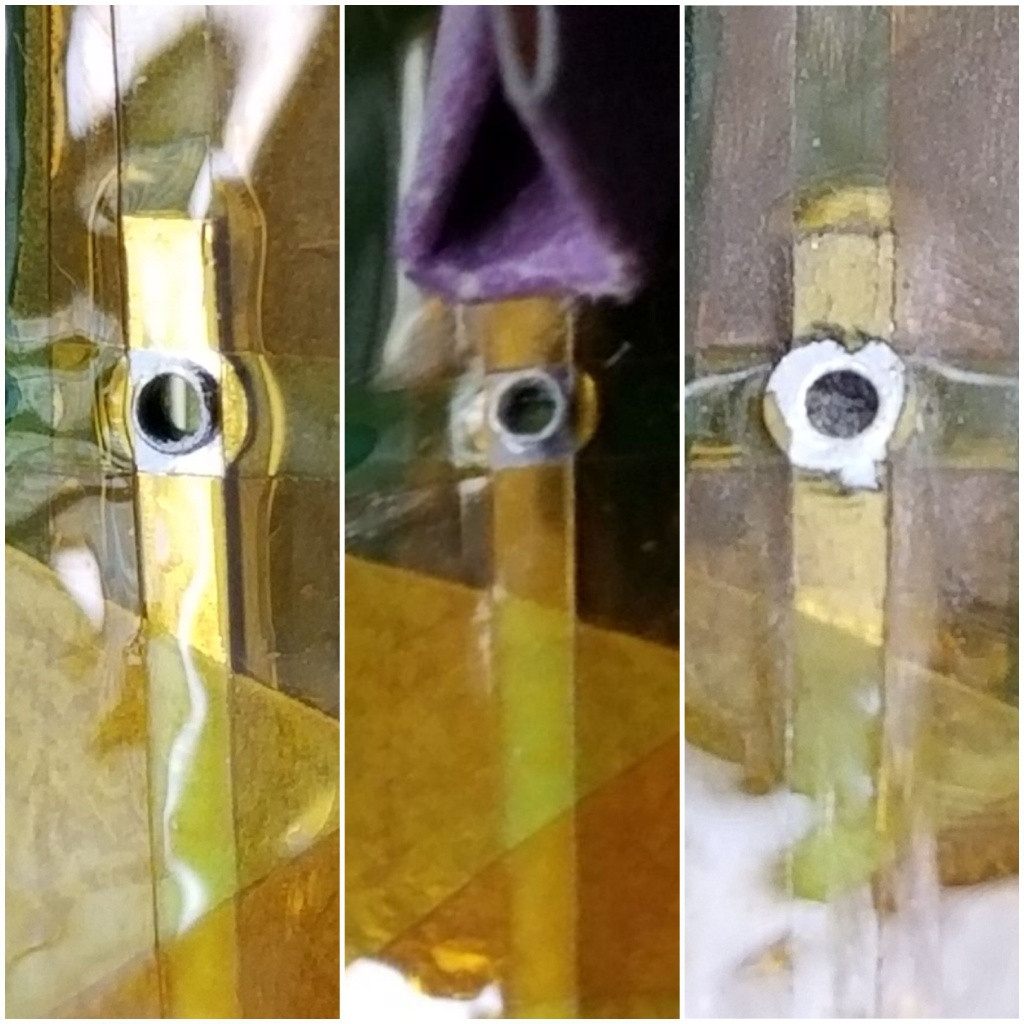

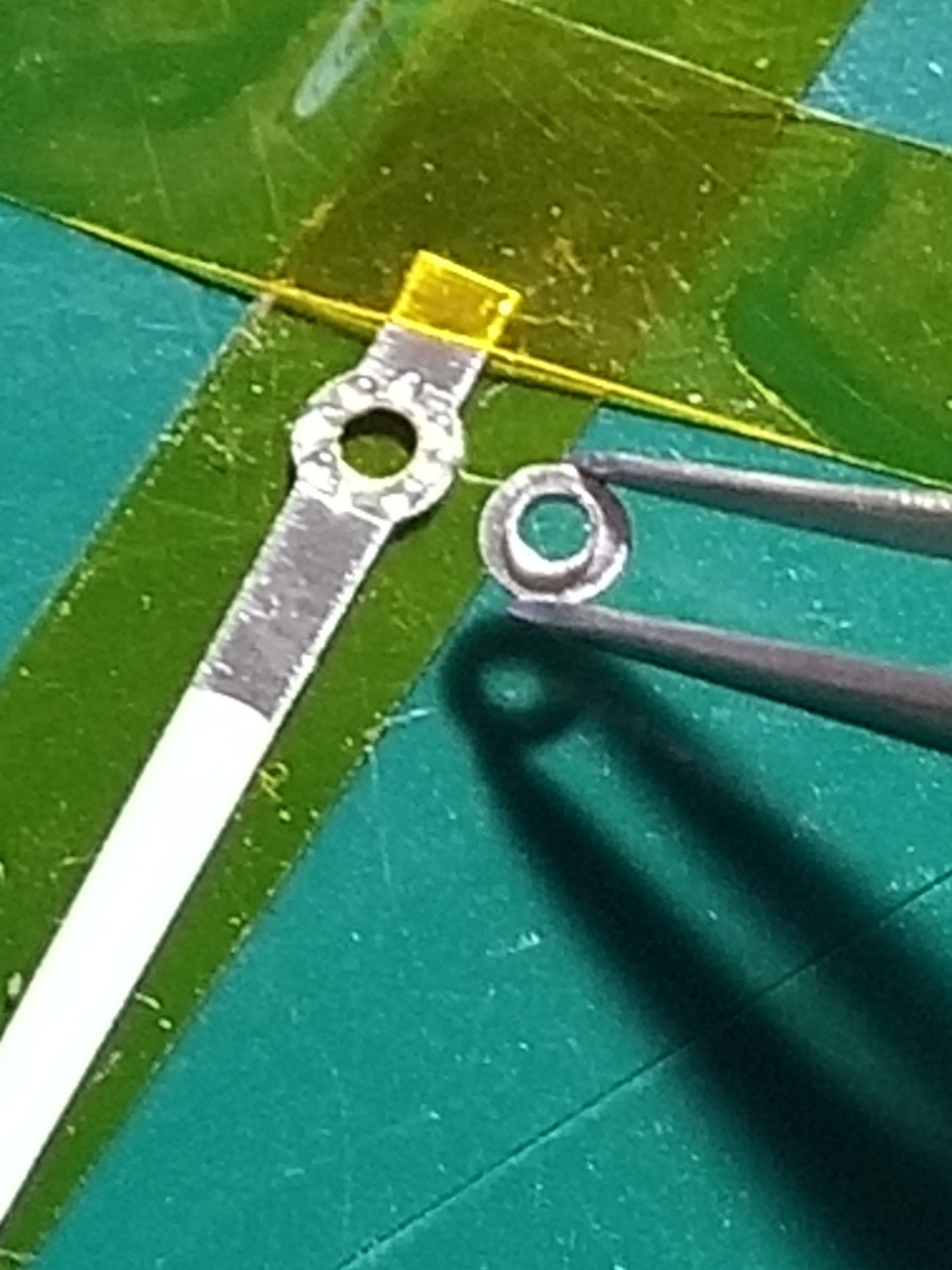

I’ve done this a bunch of times by simply crimping (closing) or broaching (opening) the hands holes. There are tools that can crimp pretty well, some way nicer than this one.

But broaching an hour hand from 140 to 150 just wasn’t going to happen so I used a different approach. Note you can also do some creative things with the hands posts (thinning or widening), but not this time.

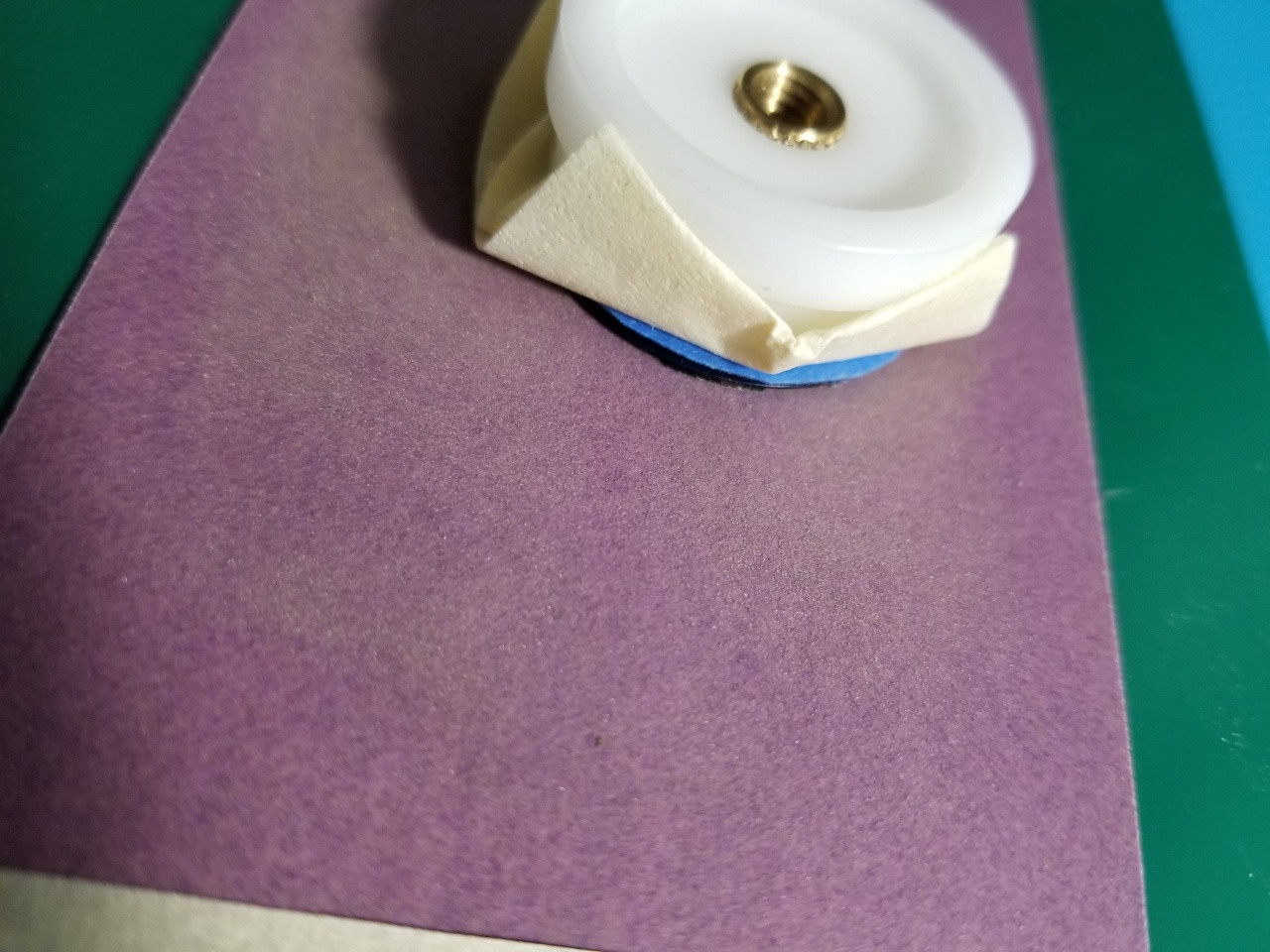

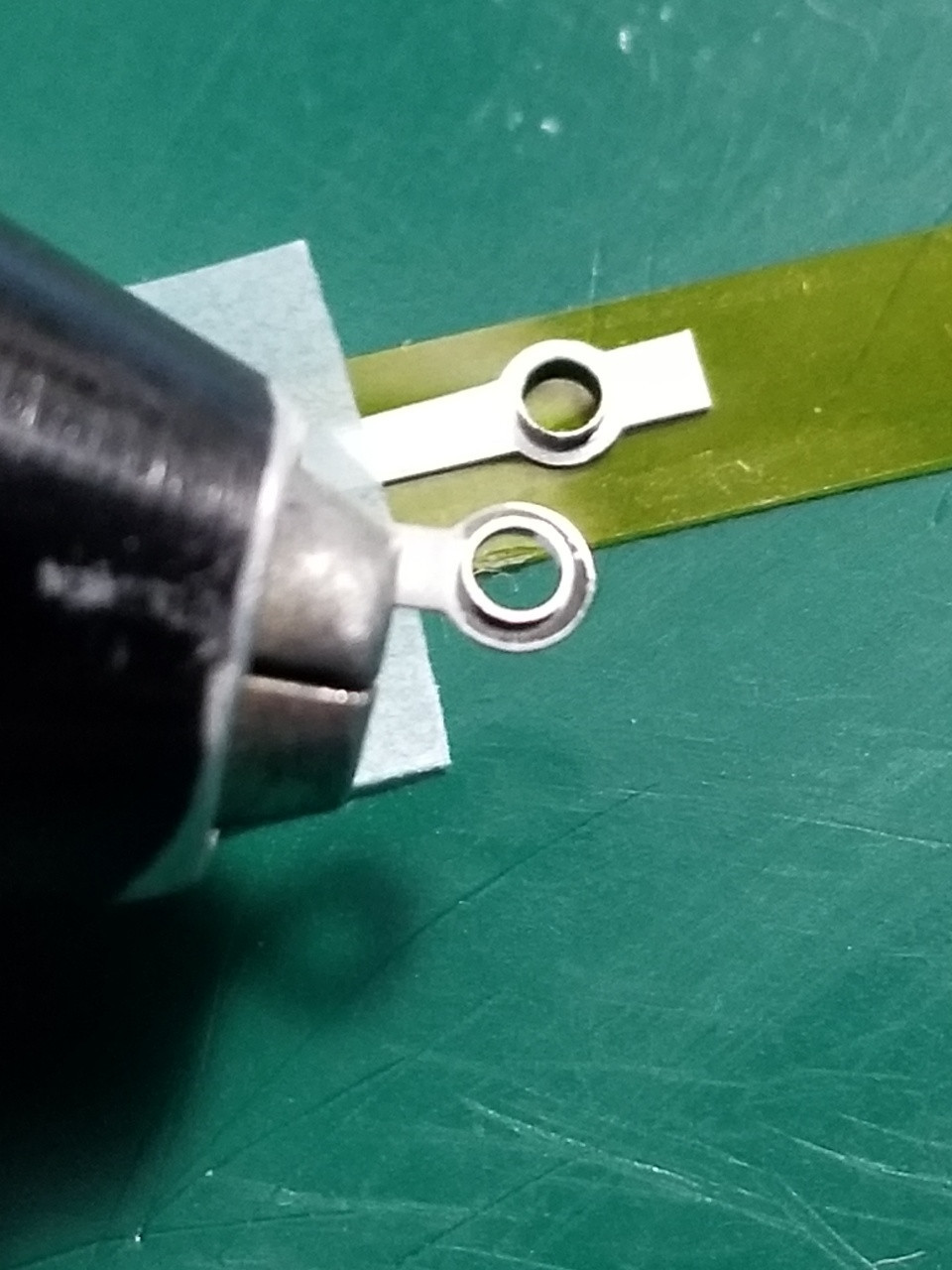

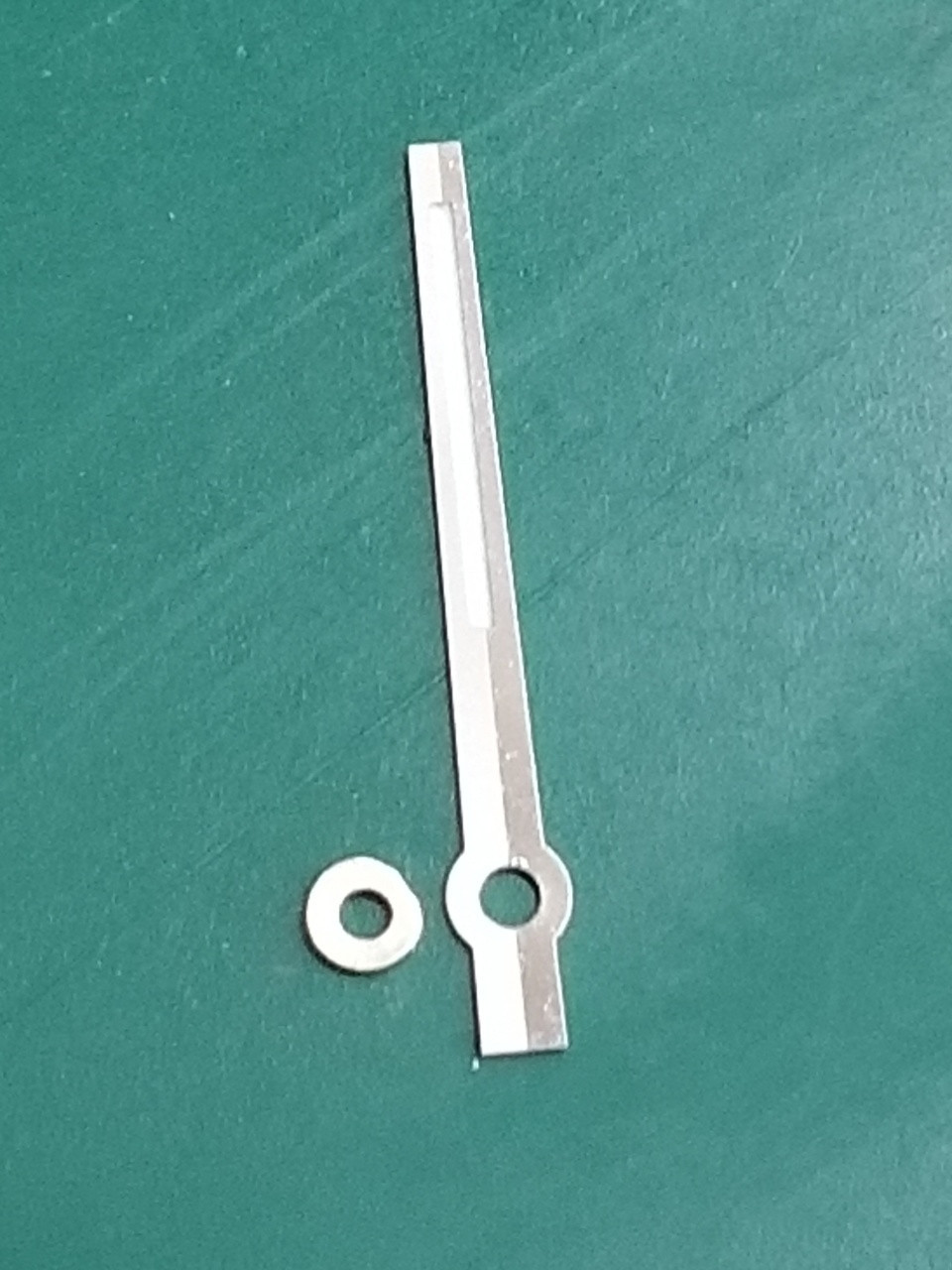

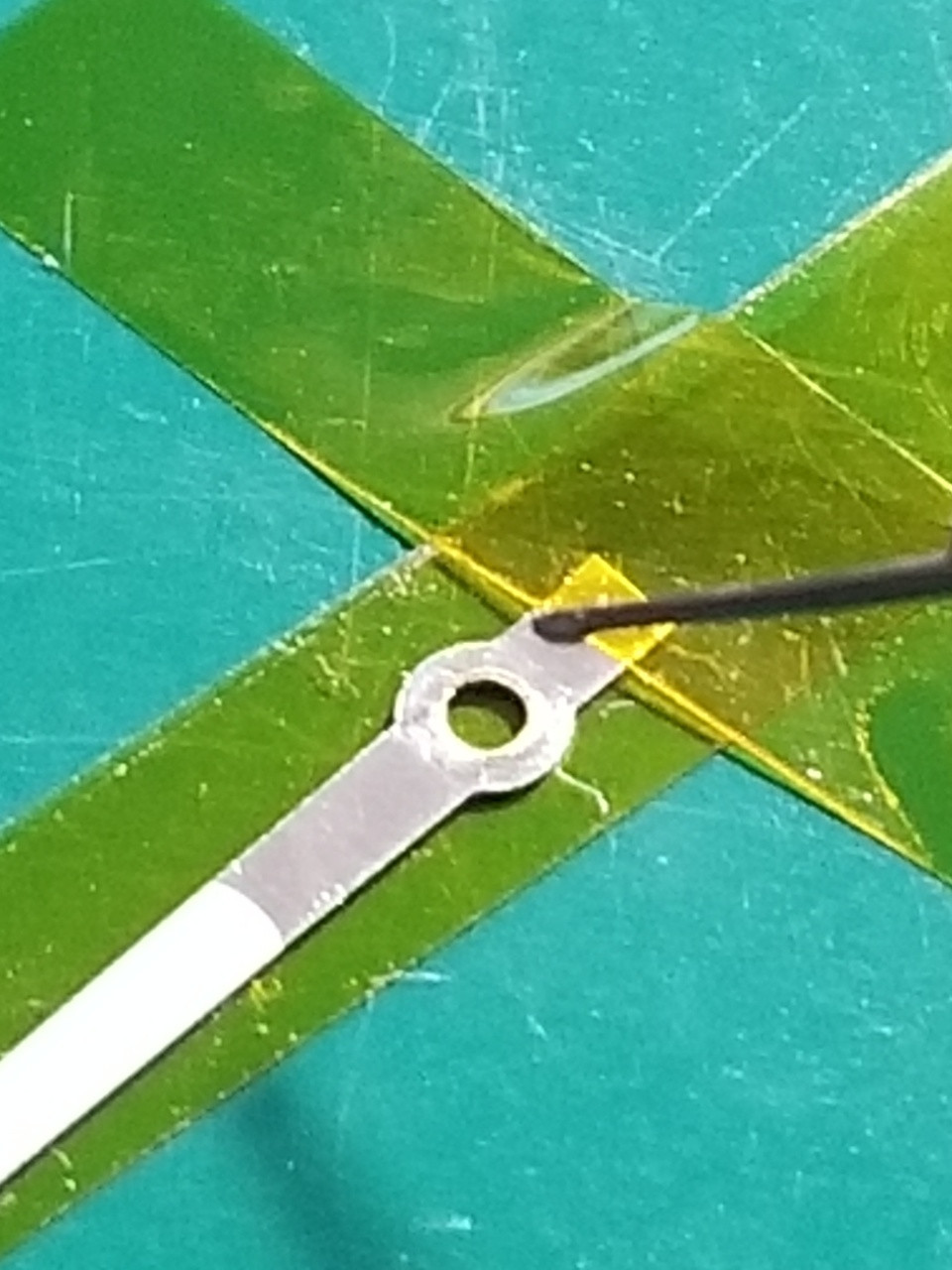

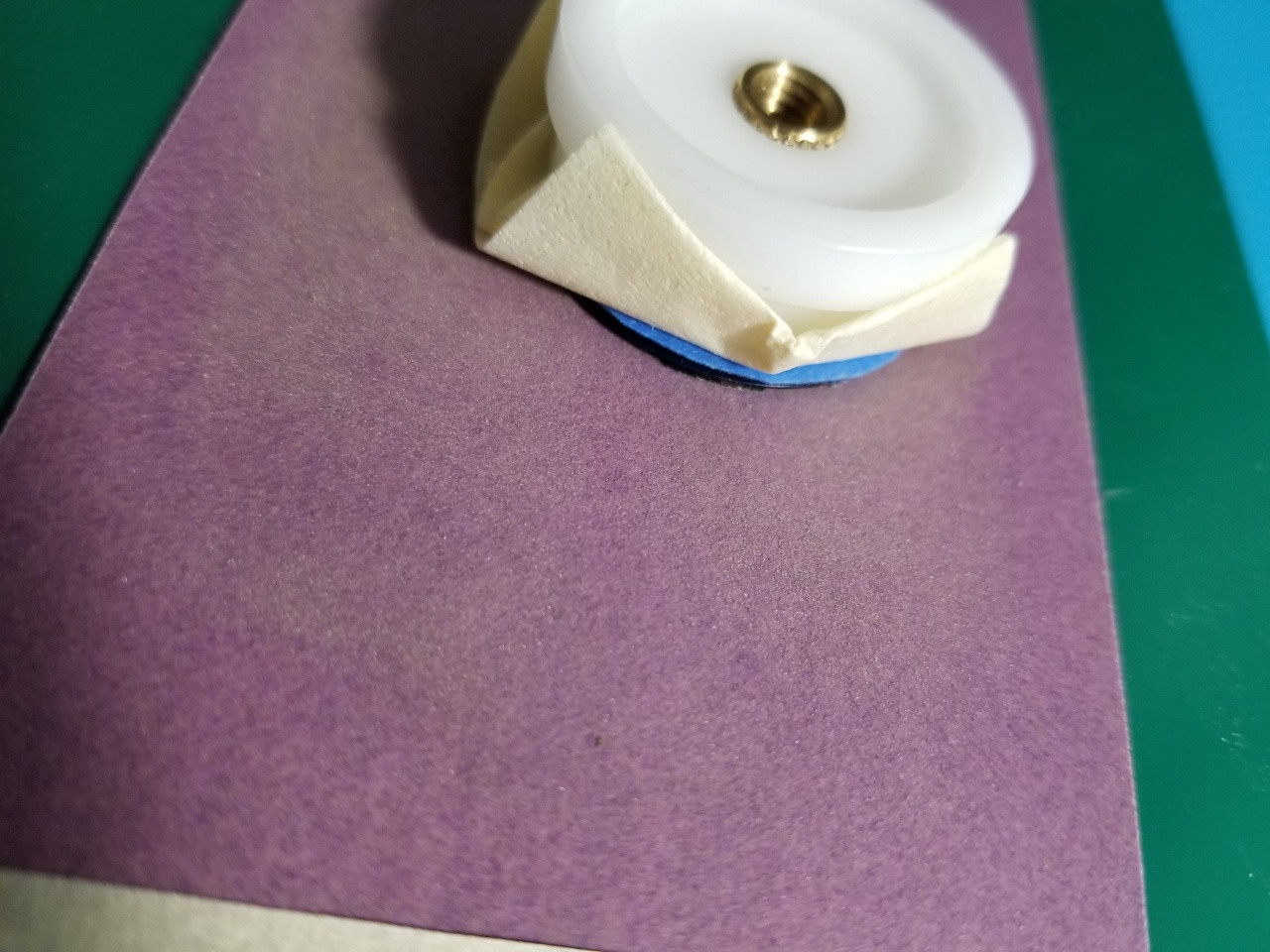

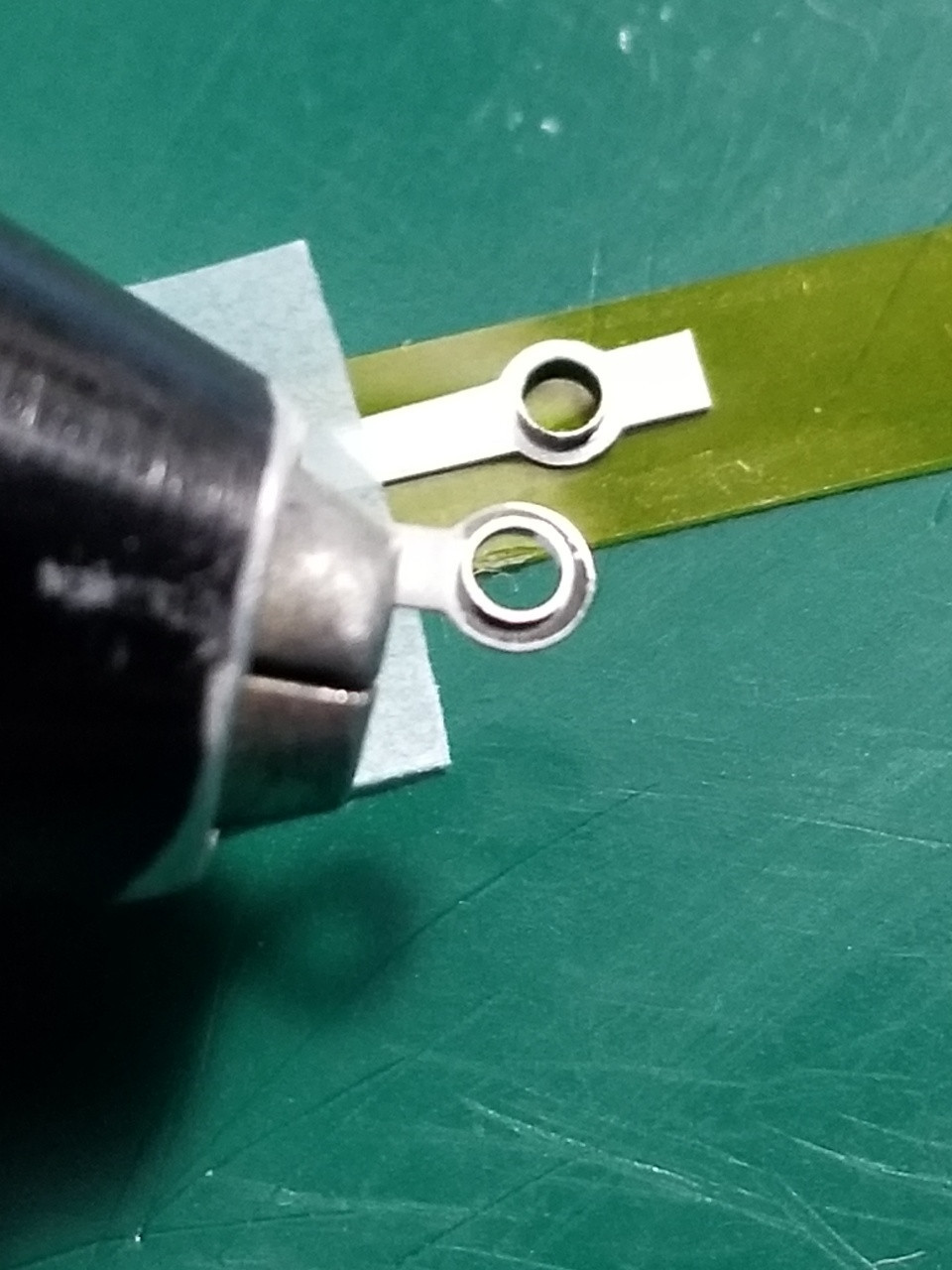

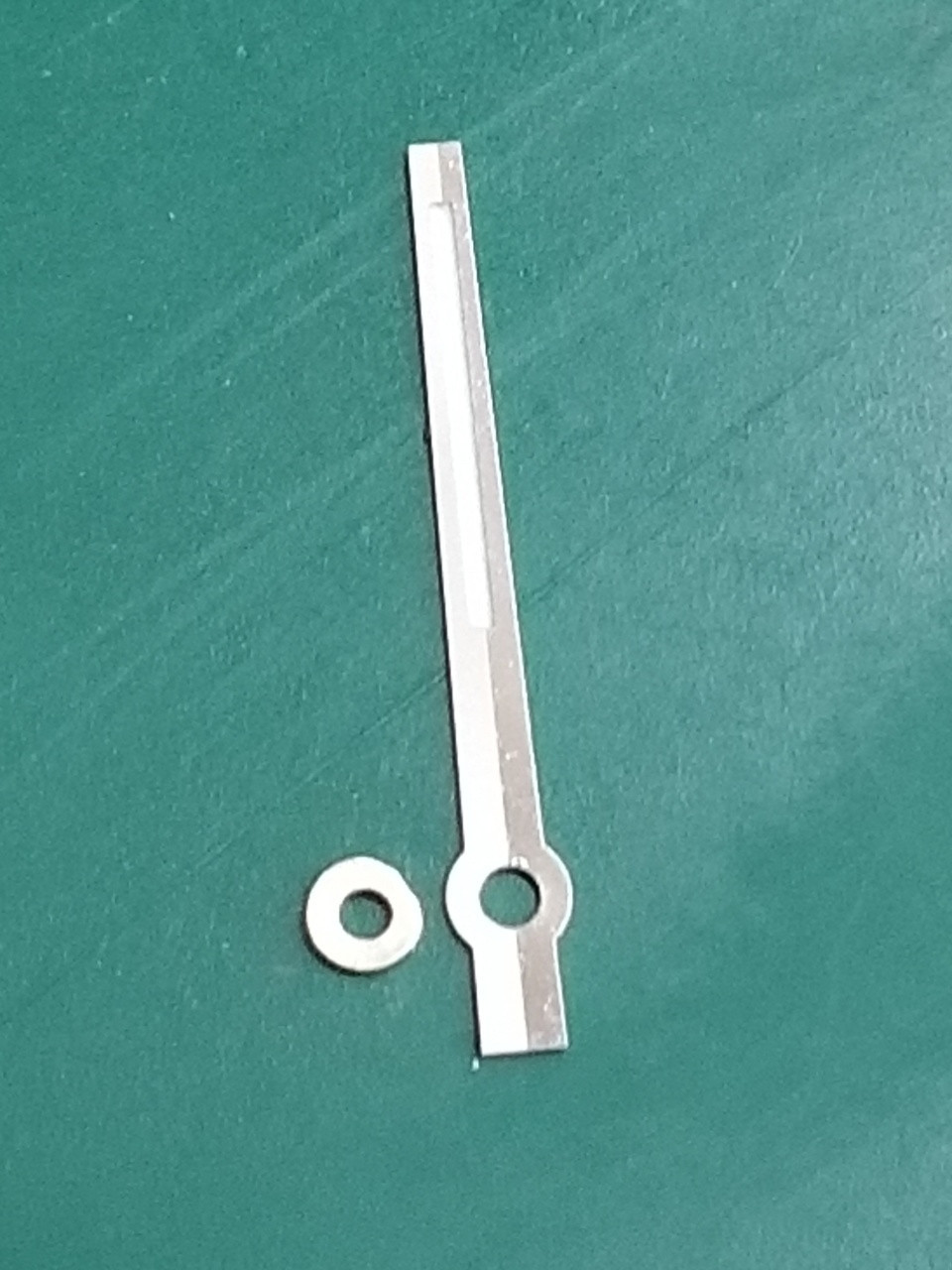

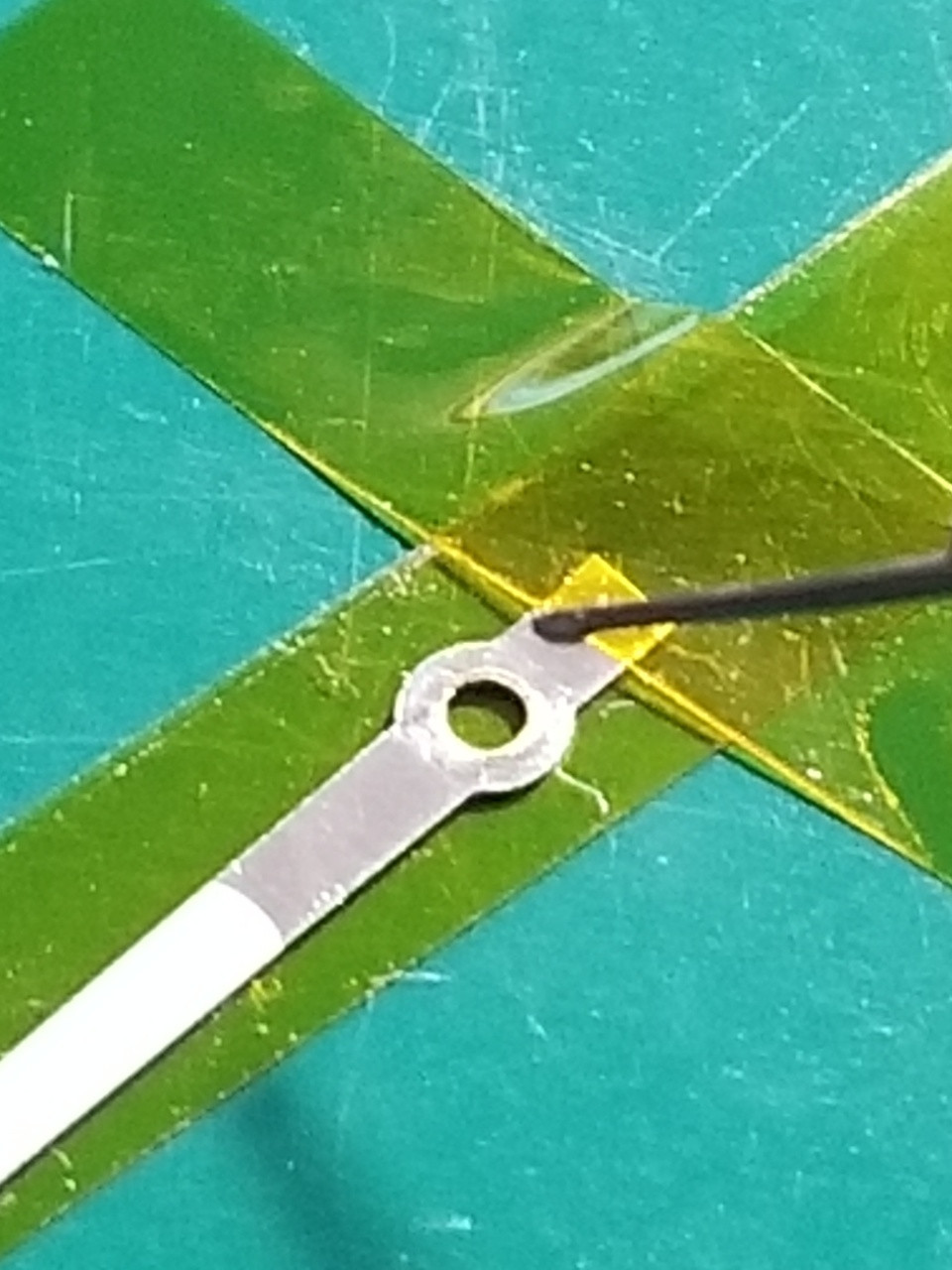

I decided to use some donor ETA hands and mate the ETA hole collars to the 3235 hands after sanding their hole collars off. This was not as hard to do as it might sound, you just need to tape the hands up well so they don’t wiggle around in the dust the sanding creates. The hole collars abrade away pretty quickly with some worn 400 grit sandpaper.

The donor hour hand hole surround was too big around so its outer circle had to be sanded down.

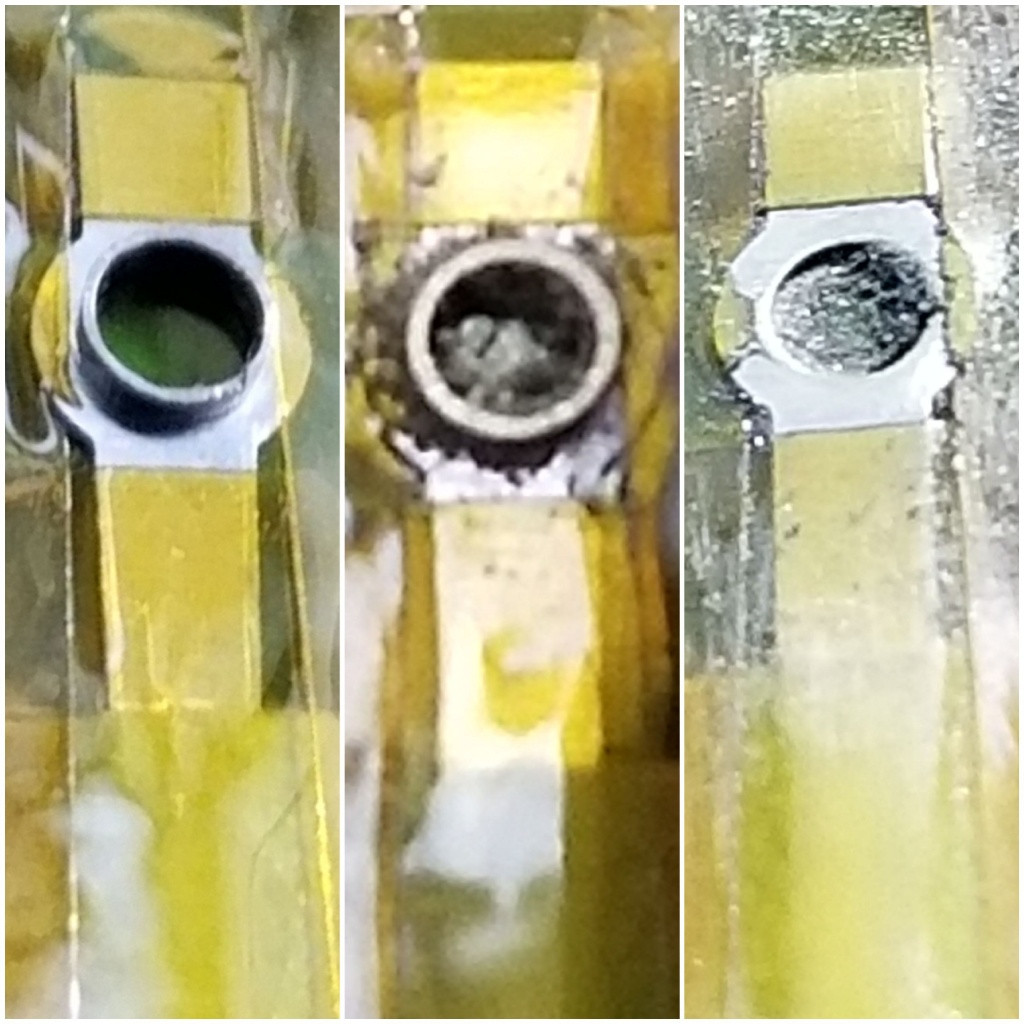

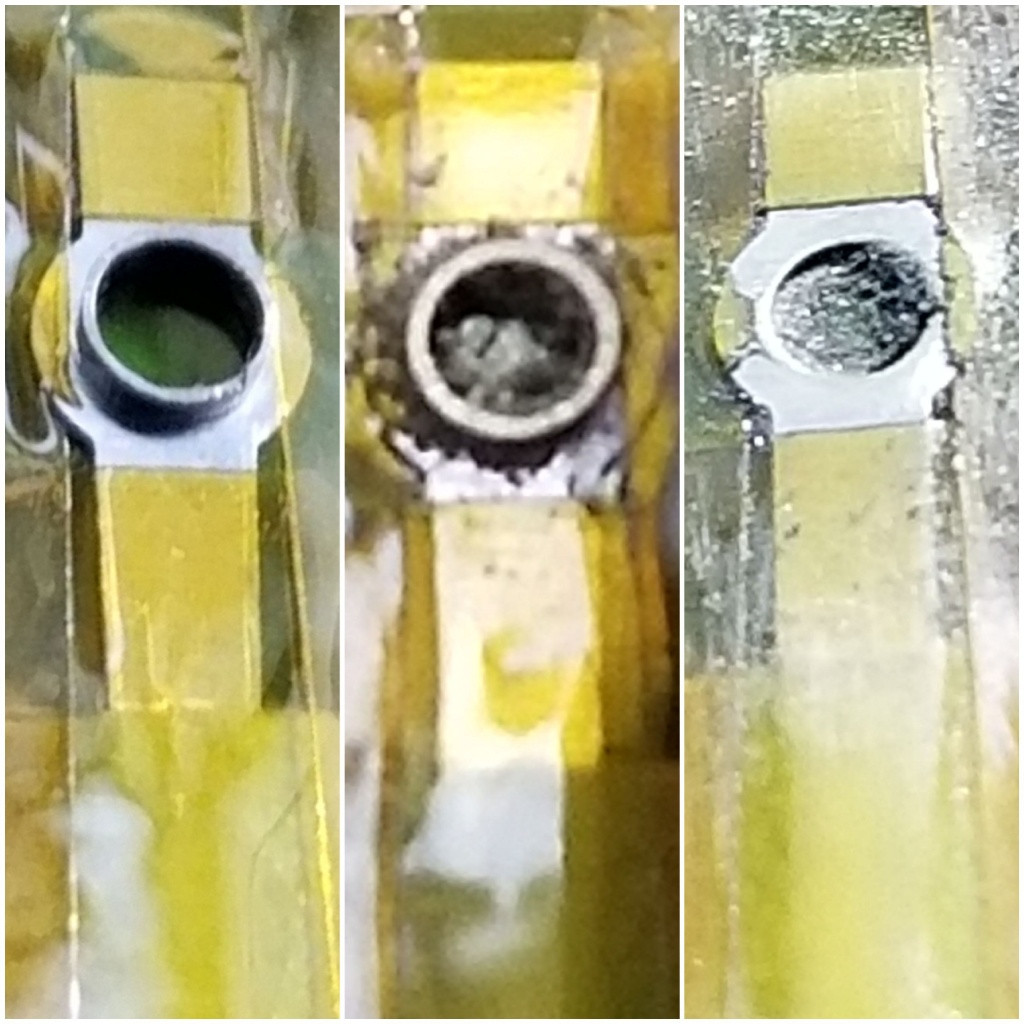

Sanding down the 3235 hour hand hole collar

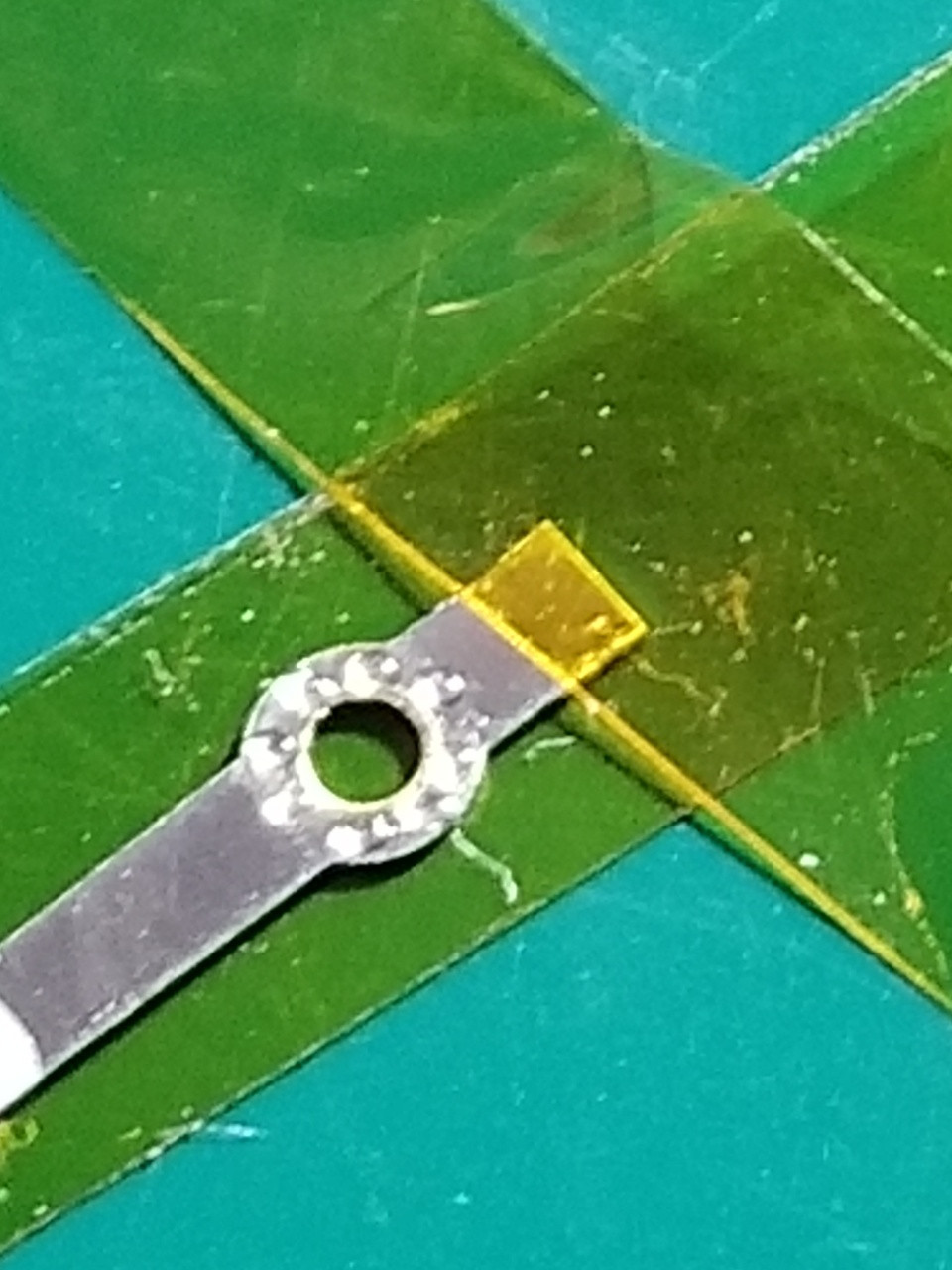

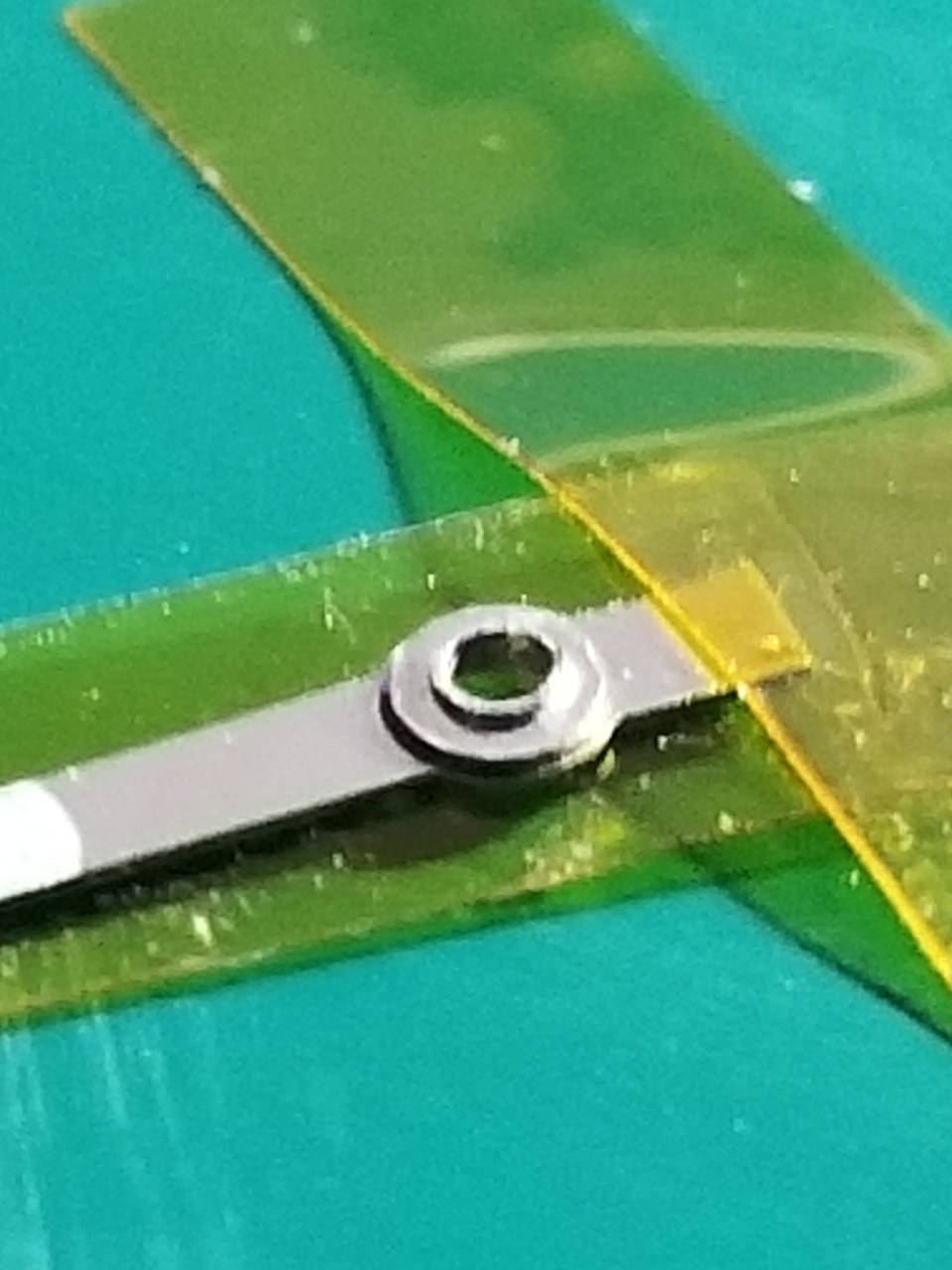

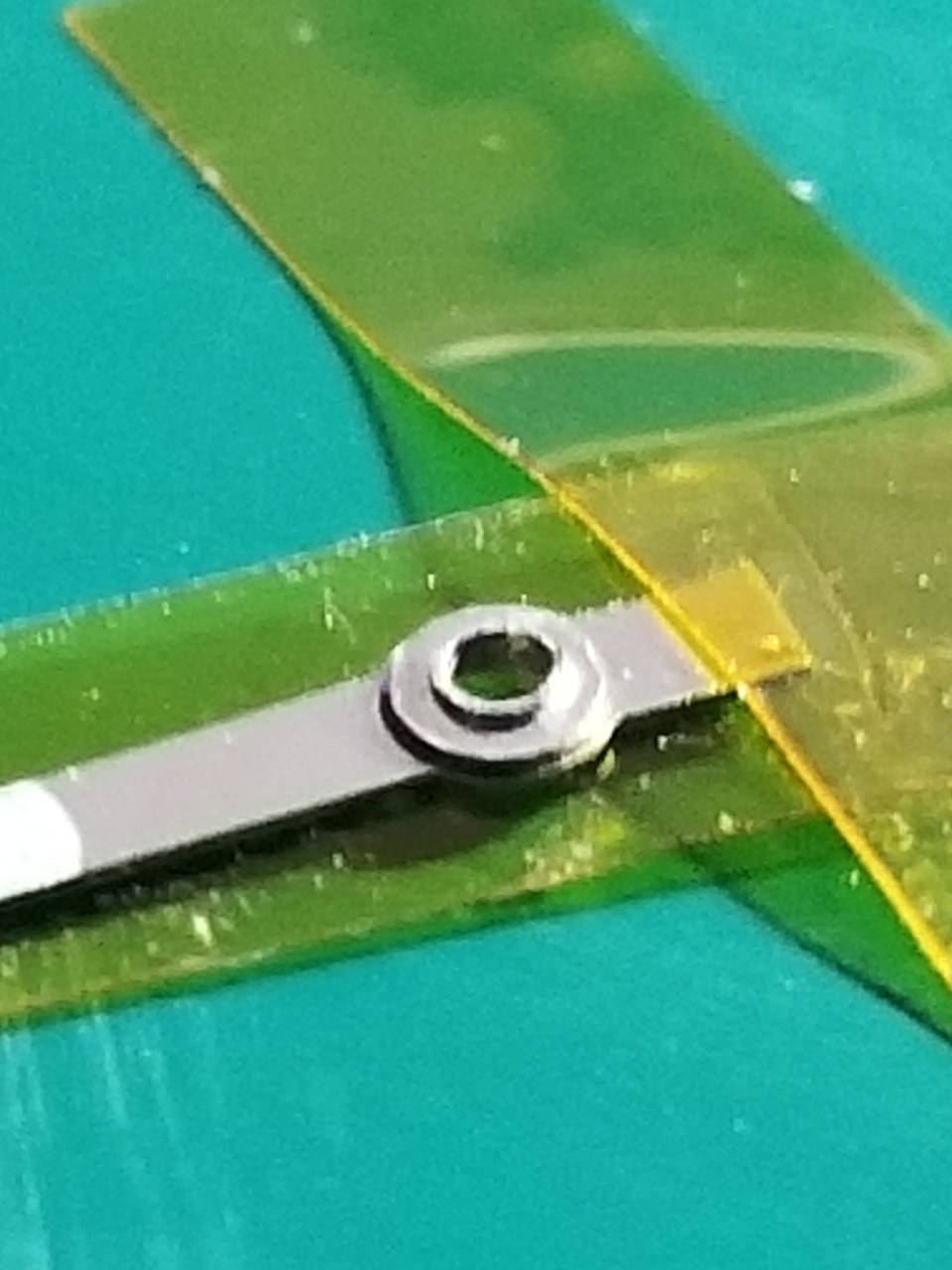

I used my go-to BSI 30 min slow cure epoxy to mate the parts. I let it harden for about 5 minutes so it wouldn’t run over the edges.

I actually tried crimping the minute hand manually with some strong tweezers but the 3235 hole collar was so short it didn’t crimp easily. Not wanting to damage the hand, I used the same replacement technique for it.

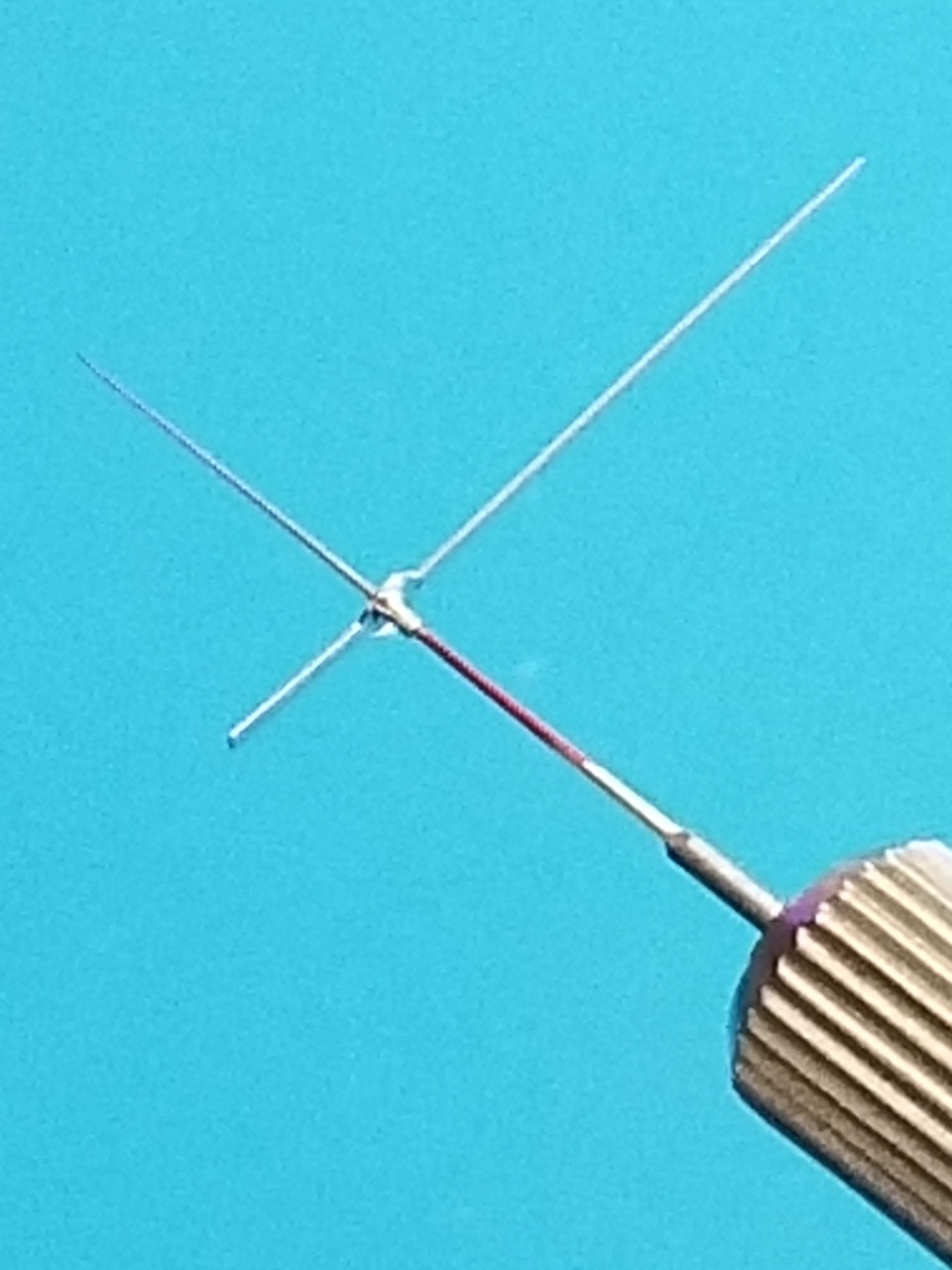

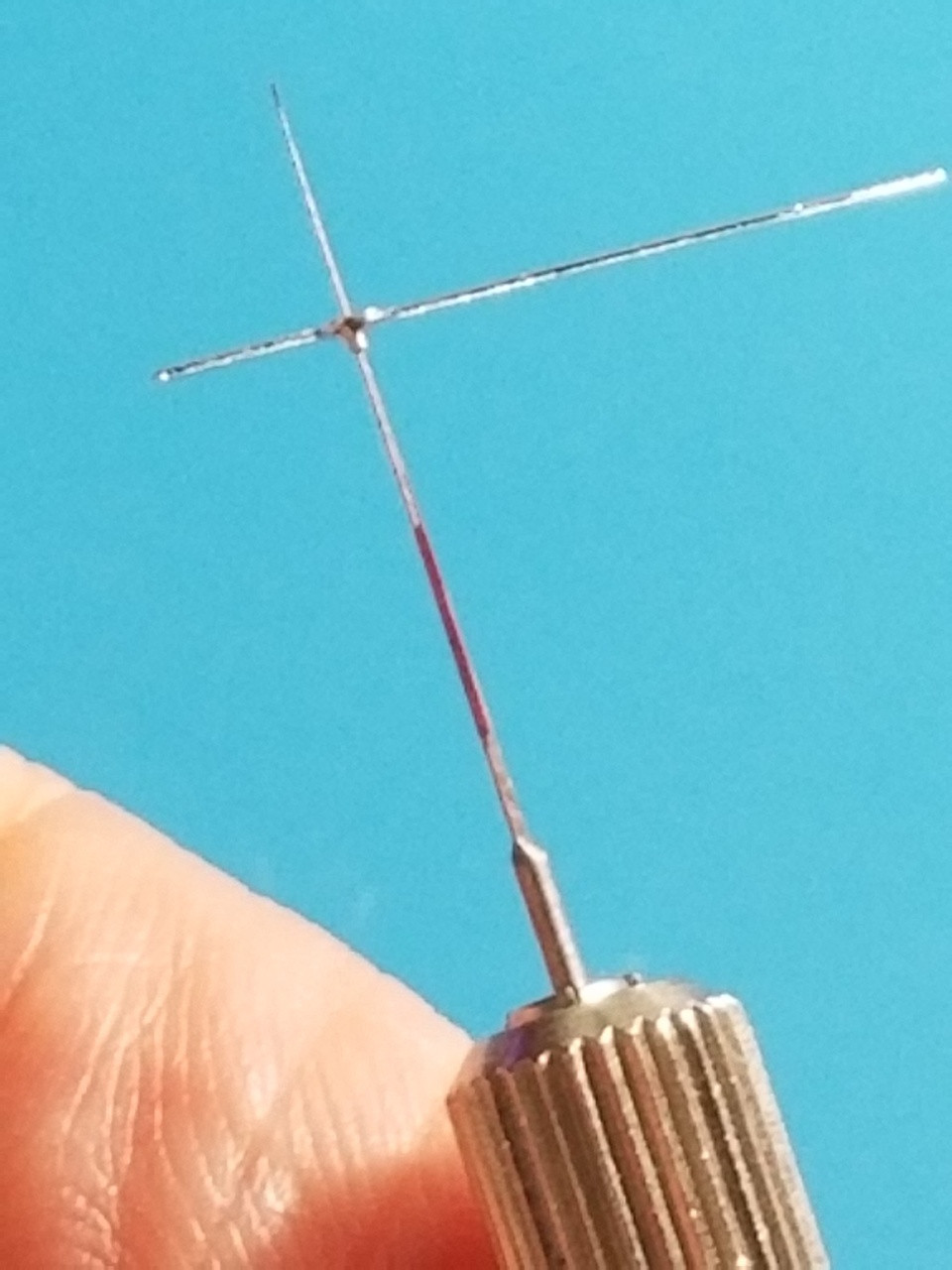

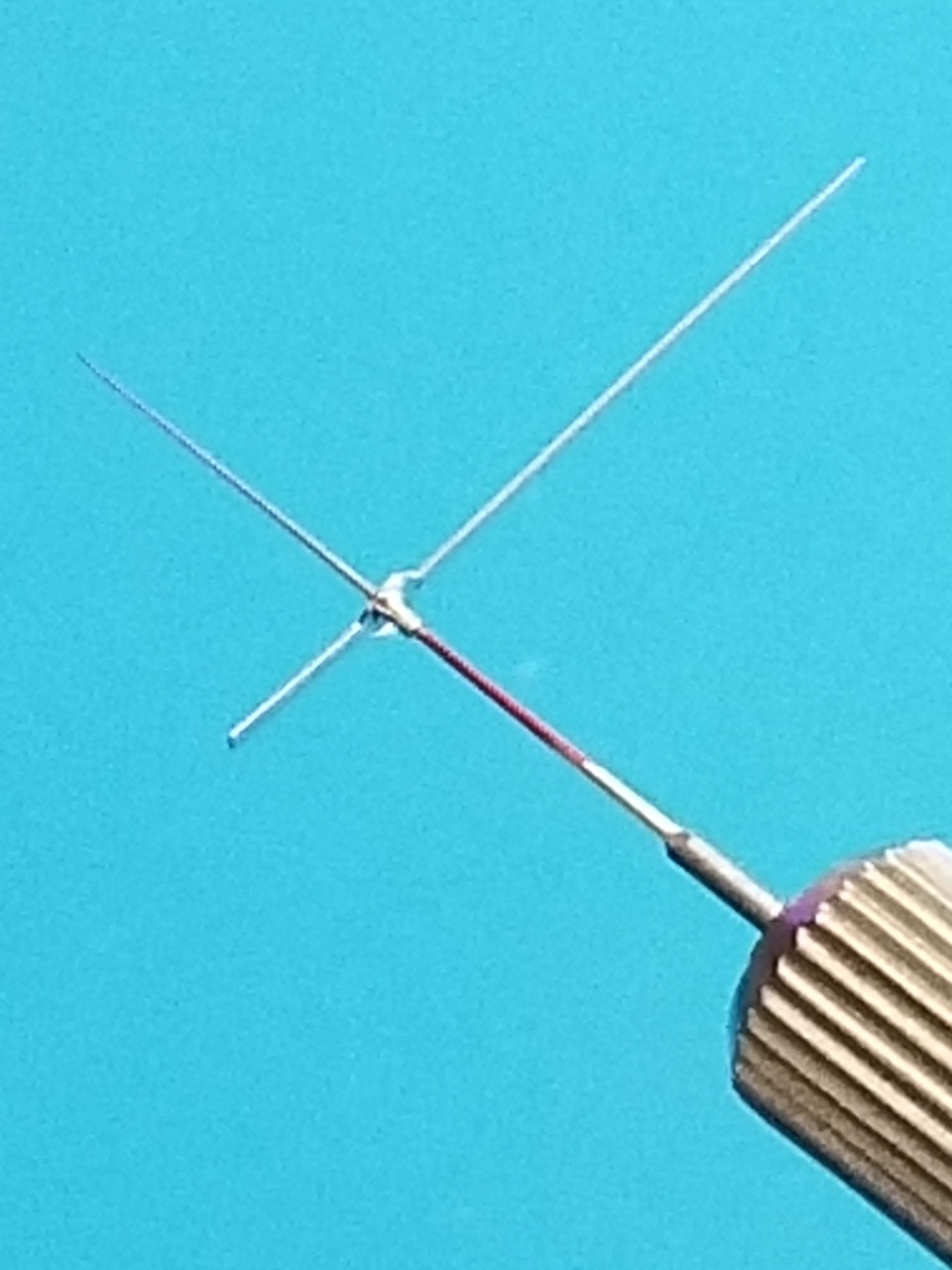

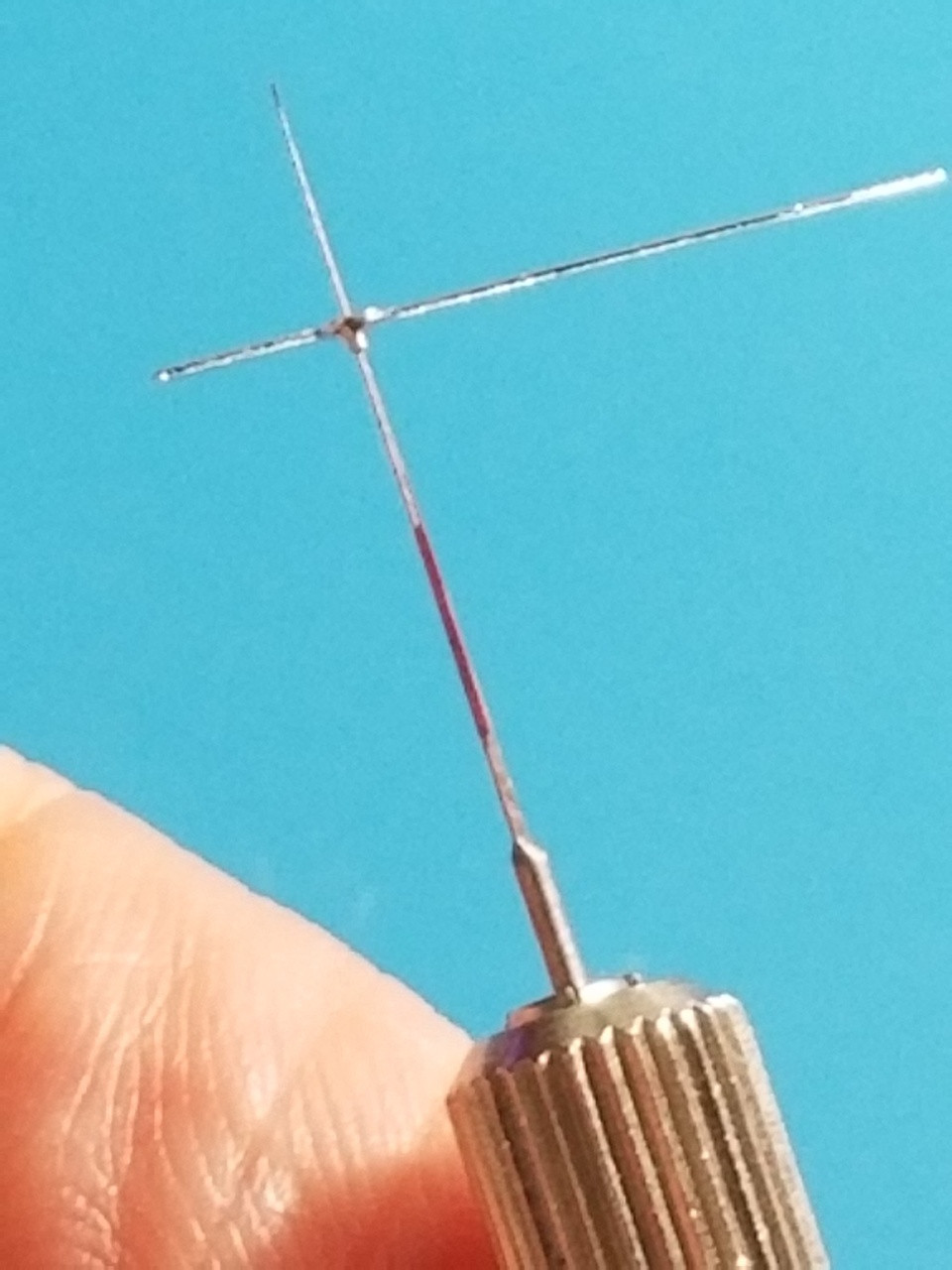

The second hand was able to be broached. I used the 2836 hand to mark the broaching file where it fell to then filed the 3235 hand to that point.

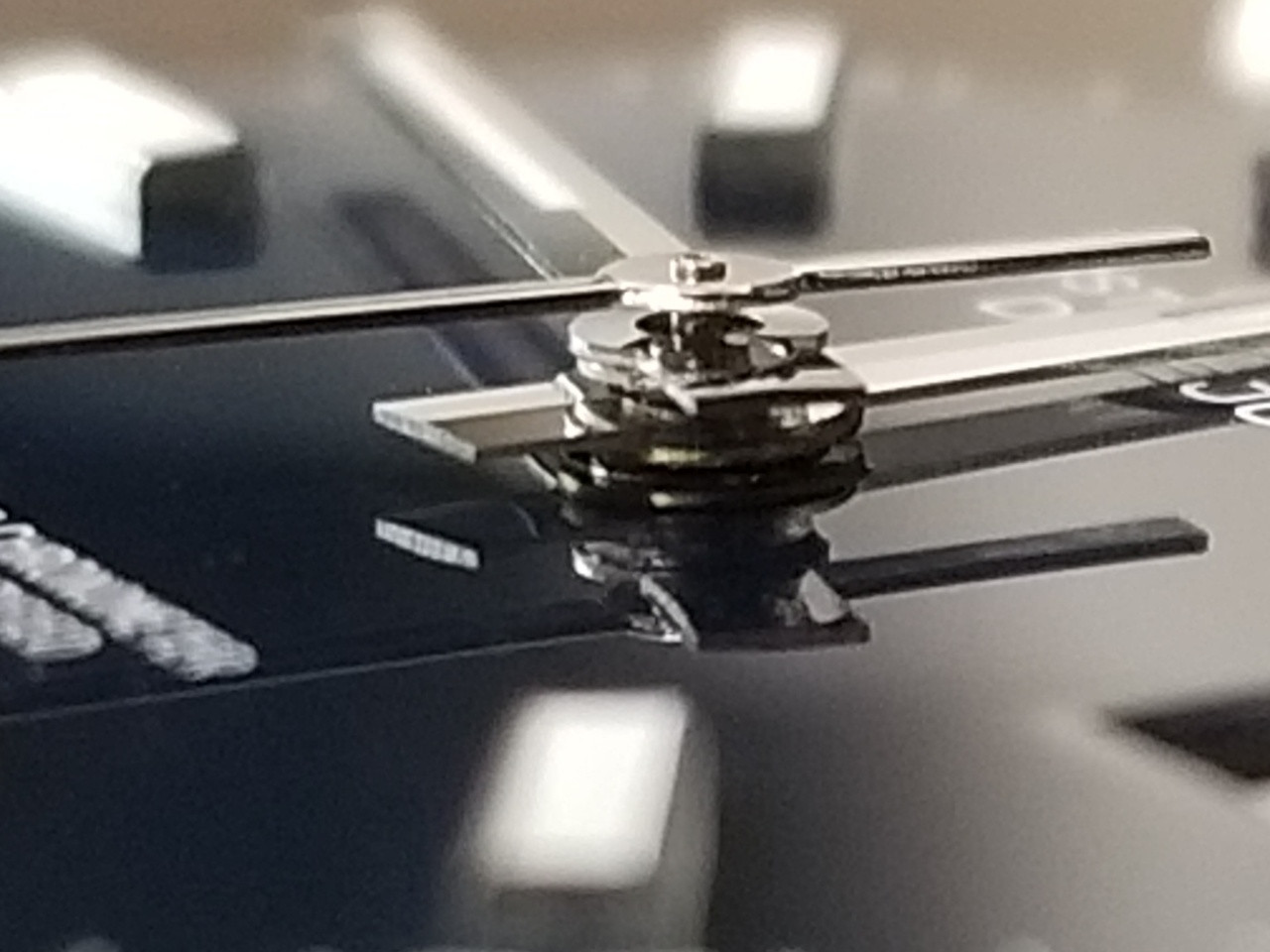

So all that’s left is to mount the hands.

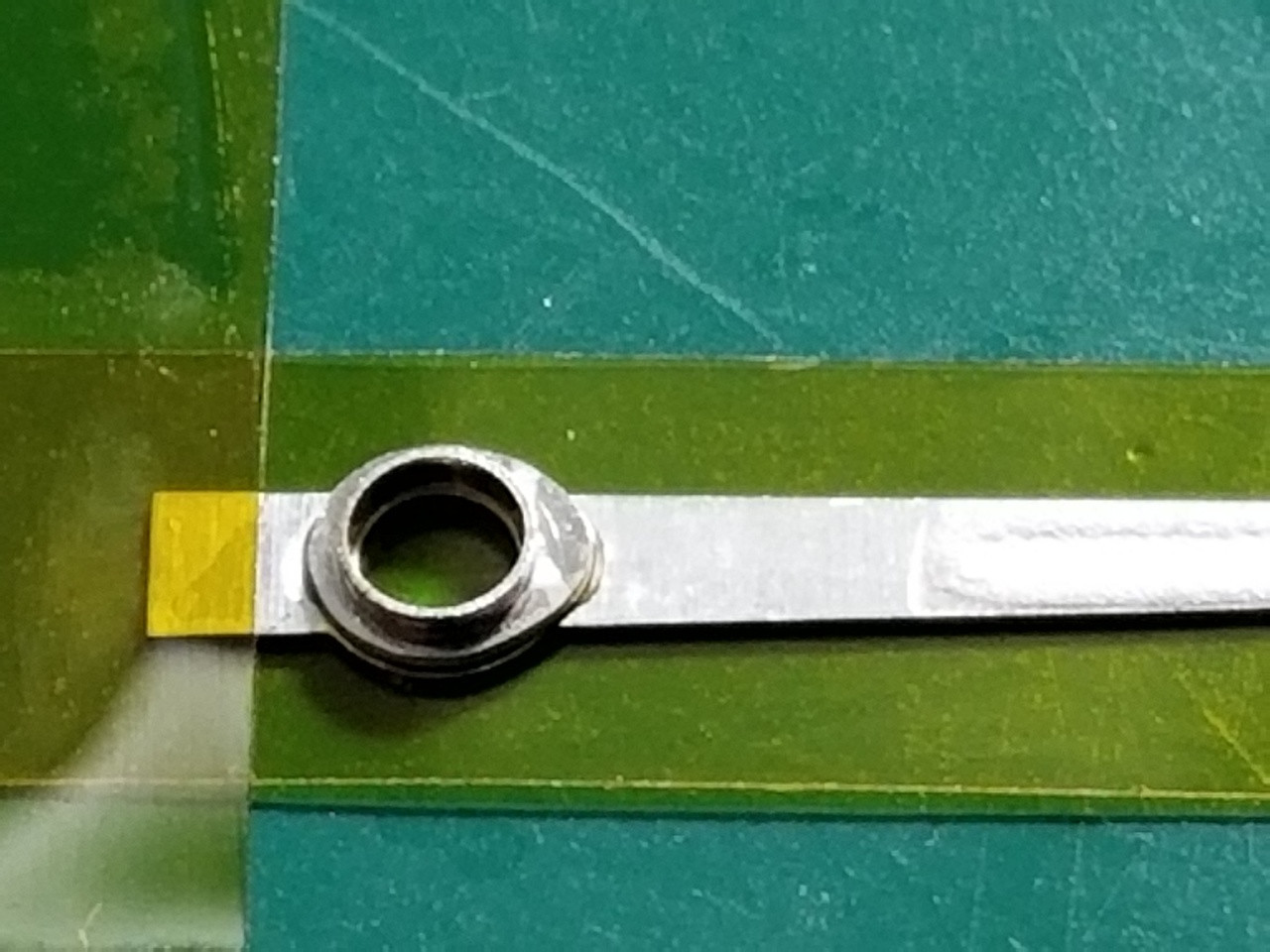

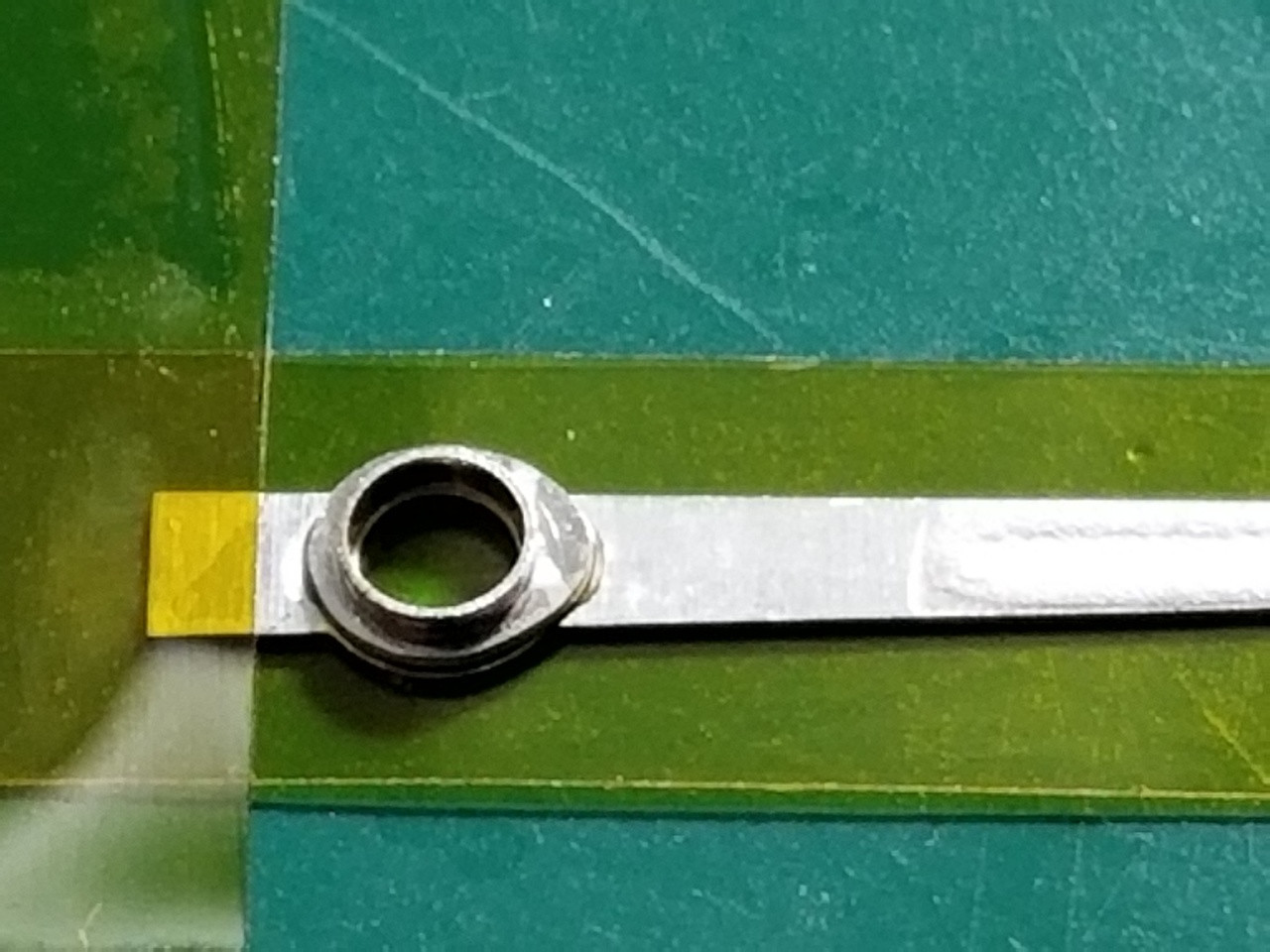

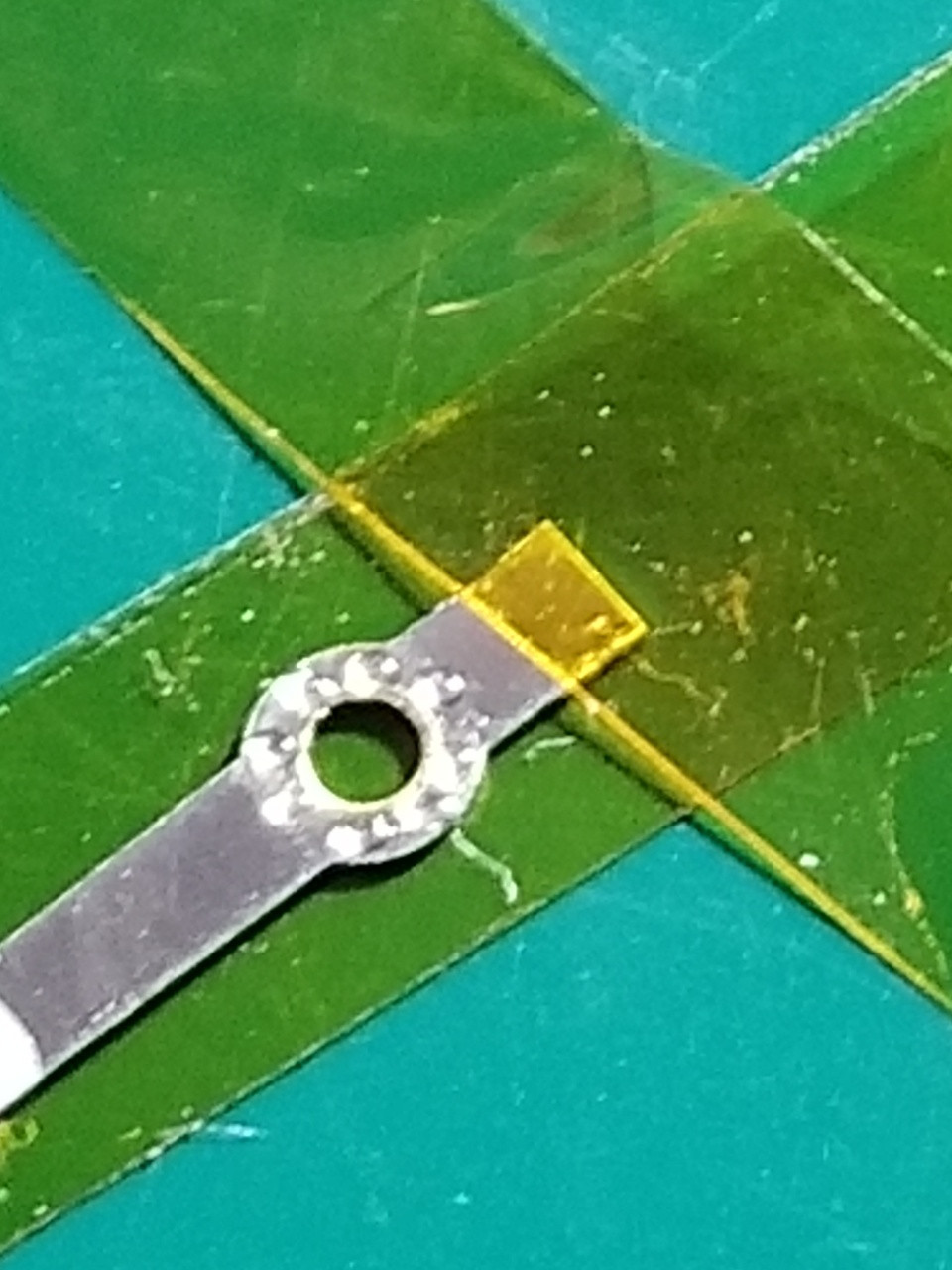

Here you can see the epoxied hand collars.

Then I also used the 3235 crystal, which is a nice improvement. The old one had no cyclops AR at all.

Before

After

I really liked the old Noob dial as it is quite pretty so I swapped some gold markers and coronet onto it and re-purposed it in this TT case set. Yay!

Thanks for looking!

I had some parts lying around doing nothing so I decided to mod a couple of DJ41s. This is the watch to be modded, an old Noob DJ41 with 2836 that was probably about $268 back in the day. It’s a decent case and while the dial is beautiful in its own right, it really isn’t very gen-like.

So the 3235 parts I had were: datewheel, dial, hands, crystal and crown.

Datewheel

This was the easiest mod since the 2836 has plenty of room beneath the dial. This can also be done with a 2824 but is more challenging and often requires grinding the teeth off the 3235 DW to use it as a DWO. Just add some epoxy ribbons to the existing DW and set it in place.

Dial

Here is the CF 3235 dial. Since it has no feet and some underside rims, those will have to be sanded or grinded down. I opted to sand the rims down, though a grinding bit on a dremel could also work.

I covered the dial front with some plastic and then painter’s tape. Then taped it to a die. After that it’s just a few minutes of rubbing. Rotate often to keep it even.

Next the dial gets a bath and blow dry.

The ETA DJ41s have a very wide movement holder that has feet holes but since the dial has no feet and gluing new ones on would mean notching the holder to account for the foot bases, I just epoxied the dial onto the holder. This is a little less convenient to remove if you have to but easy enough. I did have to completely undo it and redo it once because for some still unknown reason to me the dates ended up sitting high so I had to fix that. The cured epoxy slices off from both pieces cleanly, then just wipe with alcohol.

Hands

This was the most challenging part. All the 3235 hands holes had to be modded.

3235 HMS 140/100/20 mm

2836 HMS 150/90/25 mm

I’ve done this a bunch of times by simply crimping (closing) or broaching (opening) the hands holes. There are tools that can crimp pretty well, some way nicer than this one.

But broaching an hour hand from 140 to 150 just wasn’t going to happen so I used a different approach. Note you can also do some creative things with the hands posts (thinning or widening), but not this time.

I decided to use some donor ETA hands and mate the ETA hole collars to the 3235 hands after sanding their hole collars off. This was not as hard to do as it might sound, you just need to tape the hands up well so they don’t wiggle around in the dust the sanding creates. The hole collars abrade away pretty quickly with some worn 400 grit sandpaper.

The donor hour hand hole surround was too big around so its outer circle had to be sanded down.

Sanding down the 3235 hour hand hole collar

I used my go-to BSI 30 min slow cure epoxy to mate the parts. I let it harden for about 5 minutes so it wouldn’t run over the edges.

I actually tried crimping the minute hand manually with some strong tweezers but the 3235 hole collar was so short it didn’t crimp easily. Not wanting to damage the hand, I used the same replacement technique for it.

The second hand was able to be broached. I used the 2836 hand to mark the broaching file where it fell to then filed the 3235 hand to that point.

So all that’s left is to mount the hands.

Here you can see the epoxied hand collars.

Then I also used the 3235 crystal, which is a nice improvement. The old one had no cyclops AR at all.

Before

After

I really liked the old Noob dial as it is quite pretty so I swapped some gold markers and coronet onto it and re-purposed it in this TT case set. Yay!

Thanks for looking!

Last edited: