-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TUDOR Black Bay 54 - 7924 Big Crown Build

- Thread starter nbeezy

- Start date

- 5/6/22

- 98

- 65

- 18

my first instinc was drillpress, do you think a handdrill has advantages?Have a look on cousins UK, they have the hand drills and taps. The thing to remember is light and slow, take your time and don't rush it. I haven't looked but I would imagine there are loads of tutorials on here how to do it.

It's what he is using in the video plus easy access and cheaper than a drillpress.my first instinc was drillpress, do you think a handdrill has advantages?

- 5/6/22

- 98

- 65

- 18

From what i can tell hes using a reamer. Could be the cleanest option to incrementally open the hole using reamers.It's what he is using in the video plus easy access and cheaper than a drillpress.

That's what I was thinking. I spoke to the guy in the video and he told me that he uses 7mm crowns and not the 8mm because they're a bit to big for the mid case, maybe something to keep in mind.From what i can tell hes using a reamer. Could be the cleanest option to incrementally open the hole using reamers.

Here are the sub hands in rose gold

Green/Blue/ Cyan luminous NH35 NH36 Miyota 8215 821A ETA2824 2836 watch hands | eBay

Green/Blue/ Cyan luminous NH35 NH36 Miyota 8215 821A ETA2824 2836 watch hands.

www.ebay.de

- 5/6/22

- 98

- 65

- 18

Boys, all parts arrived safe and sound

Its time to risk the life of a perfectly good bb54 in the pursuit of greatness

Its time to risk the life of a perfectly good bb54 in the pursuit of greatness

- 27/7/15

- 1,970

- 1,072

- 113

- 5/6/22

- 98

- 65

- 18

unfortunately i suffered some setbacks by the hands of an incompetent watchmaker. but some work should be done this coming weekendAny updates here? I bought an gen bb58 case for the same project haha

Oh sad to hear that… I wish you luck with the next oneunfortunately i suffered some setbacks by the hands of an incompetent watchmaker. but some work should be done this coming weekend

- 5/6/22

- 98

- 65

- 18

only thing that got permanantly damaged is the original zf dial so i got a raffles 29mm vintage dial. i did some cad work to make sure the print fits within the rehaut opening but ill have to find out on the weekendOh sad to hear that… I wish you luck with the next one

- 5/6/22

- 98

- 65

- 18

By now im getting used to spontaneous setbacks and today is no different.

Nevertheless there were some interesting revelations:

1: watertest

The case seems to leak from bezel region (something to keep in mind for every zf bb54 buyer)

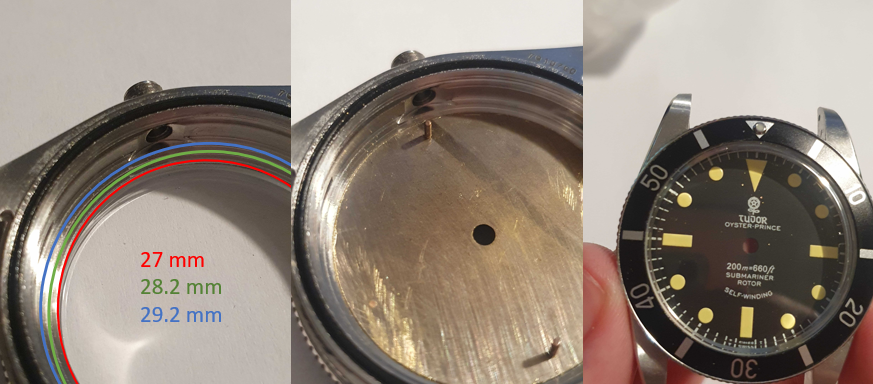

2: inner case dimensions

Plan: swap in 29 mm raffles dial

The rehaut opening is 27 mm across and the entire dial print fits comfortably inside. I thought it would be pretty close with the "T swiss T" at 6 o'clock but i got pleasantly surprised by the spacing. This means railroad dials (wich i avoided because of spacial concerns) should work fine aswell.

Everything was going smooth until it was time to reistall the crown stem. The movement sits too high.

This is caused by staggered inner diameters leading up to the rehaut opening in the case. The 29mm dial sits (neatly) inside a 29.2 mm inner diameter.

This is followed by the actual rehaut position with an inner diameter of 28.2 mm.

3: fitting the dial

The dial needs to be 28.2 mm max, this meant that i had to shave off approx. 0.4 mm radius.

I set my calipers to 0.4 mm and fixed the sled with the lock scew. I then draged the calipers around the outer circumference of the dial, engraving the smaller diameter onto the backside of the dial.

Now its time to grind the dial to size. This was a stright forward (although scary) process using a metal file. After a few adjustments i got the dial to roughly 28 mm all around.

The edge obviously wont be pretty but thats where the 27 mm rehaut diameter comes into play. As far as i can tell everything looks clean when installed.

I would not reccomend trying this with a gloss dial. You will have a generous amount of shavings flying around and they will get on the face of the dial. There is no visible damage to my matte dial, but a gloss dial will need some protection.

So the final verdict is that you can make a 29mm dial fit the ZF bb54 with one hour worth of grinding. Sadly there doesnt seem to be a 28 mm plug and play dial available online (let me know if you find something interesting).

Next up is modifying the case to accept the anthaya brevet crowntube...

Nevertheless there were some interesting revelations:

1: watertest

The case seems to leak from bezel region (something to keep in mind for every zf bb54 buyer)

2: inner case dimensions

Plan: swap in 29 mm raffles dial

The rehaut opening is 27 mm across and the entire dial print fits comfortably inside. I thought it would be pretty close with the "T swiss T" at 6 o'clock but i got pleasantly surprised by the spacing. This means railroad dials (wich i avoided because of spacial concerns) should work fine aswell.

Everything was going smooth until it was time to reistall the crown stem. The movement sits too high.

This is caused by staggered inner diameters leading up to the rehaut opening in the case. The 29mm dial sits (neatly) inside a 29.2 mm inner diameter.

This is followed by the actual rehaut position with an inner diameter of 28.2 mm.

3: fitting the dial

The dial needs to be 28.2 mm max, this meant that i had to shave off approx. 0.4 mm radius.

I set my calipers to 0.4 mm and fixed the sled with the lock scew. I then draged the calipers around the outer circumference of the dial, engraving the smaller diameter onto the backside of the dial.

Now its time to grind the dial to size. This was a stright forward (although scary) process using a metal file. After a few adjustments i got the dial to roughly 28 mm all around.

The edge obviously wont be pretty but thats where the 27 mm rehaut diameter comes into play. As far as i can tell everything looks clean when installed.

I would not reccomend trying this with a gloss dial. You will have a generous amount of shavings flying around and they will get on the face of the dial. There is no visible damage to my matte dial, but a gloss dial will need some protection.

So the final verdict is that you can make a 29mm dial fit the ZF bb54 with one hour worth of grinding. Sadly there doesnt seem to be a 28 mm plug and play dial available online (let me know if you find something interesting).

Next up is modifying the case to accept the anthaya brevet crowntube...

- 5/6/22

- 98

- 65

- 18

I had the idea to swap the sapphire with a superdome plexi. measuring the crystal from the outside gives me 30.05 mm and it appears the crystal is simply pressed into the case.

Does anyone have any imput on what to look out for in the new plexi? My first instinkt was "Sternkreuz überhoch gewölt 305".

i assume that will give me the most pronounced dome effect?

Does anyone have any imput on what to look out for in the new plexi? My first instinkt was "Sternkreuz überhoch gewölt 305".

Uhrenglas Sternkreuz HH Überhoch gewölbt Punaise für Armbanduhren 254 - 343,7 | eBay

Sternkreuz HH: Punaise Überhoch gewölbt, rund. Kunststoff / Acryl Uhrenglas. Sternkreuz - Kunststoff-Uhrengläser für Armbanduhren. Sternkreuz Hw: hochgewölbt, rund. Sternkreuz N: Lentille normalgewölbt, rund.

www.ebay.de

i assume that will give me the most pronounced dome effect?

- 9/8/10

- 964

- 855

- 93