I’m not a material specialist by any means, but I’ve recently ordered two VSF subs 126610LN from Ryan. They’re advertised as 904L, Ryan confirmed 904L and it happens that I had a neodymium magnet laying around. I’ve checked both bracelets and they show no signs of attraction whatsoever. The color is spot on like gen. I have some points to think that 904L might have been used there, but I would like to get 100% confirmation.I just came across this great write-up and have to say: I learned a lot!

But to BoulderJ's point: when the factories today claim that they are using "Rolex-grade" 904L steel - is this true? Prices increased accordingly

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SS 316L vs. 316F vs. 904L- The final VERDICT- A technical study

- Thread starter ALE7575

- Start date

I’m not a material specialist by any means, but I’ve recently ordered two VSF subs 126610LN from Ryan. They’re advertised as 904L, Ryan confirmed 904L and it happens that I had a neodymium magnet laying around. I’ve checked both bracelets and they show no signs of attraction whatsoever. The color is spot on like gen. I have some points to think that 904L might have been used there, but I would like to get 100% confirmation.

Thanks for your thoughts! This is indeed interesting. I am just wondering whether 316L or 316F stainless steel alloys are magnetic at all? My understanding was that all of these high great steel variants were supposed to be rather non-magnetic...

Bonjour, je viens de voir une usine ( QF ) qui propose des daytona en or avec cette description : Boîtier en acier inoxydable massif 904L plaqué ou jaune 18 carats, réplique 1:1, métal Cu-W pour augmenter le poids de la montre pour correspondent au poids de la montre en ou véritable, presque le même poids que la montre authentique.

Connaissez vous ce métal : Cu-W ?

Merci d'avance.

Connaissez vous ce métal : Cu-W ?

Merci d'avance.

Tungsten CopperBonjour, je viens de voir une usine ( QF ) qui propose des daytona en or avec cette description : Boîtier en acier inoxydable massif 904L plaqué ou jaune 18 carats, réplique 1:1, métal Cu-W pour augmenter le poids de la montre pour correspondent au poids de la montre en ou véritable, presque le même poids que la montre authentique.

Connaissez vous ce métal : Cu-W ?

Merci d'avance.

I can't add much, but I can say with comfort that cheap stainless steel is magnetic. Haven't you walked in a new-ish public bathroom and noticed the "stainless" railings are already rusting?

The old school trick for building materials was to make 100% sure that the "rust free" steel you purchased was non-magnetic. There could be a few exceptions, but I doubt those apply to watches.

The old school trick for building materials was to make 100% sure that the "rust free" steel you purchased was non-magnetic. There could be a few exceptions, but I doubt those apply to watches.

From my little experience in metals sorting business, 316 and 904l have no magnetic properties. Lower grades of stainless steel like 4xx series are magnetic. A common stainless in the daily applications is 304 and is in general non-magnetic, but it could become partially magnetic under cold processing/ forging. I also purchased recently a VSF sub 126610LN that is supposed to have 904l alloy. I have at the yard equipment that could read the type of alloy the watch is made of, but this would lead to slightly damaging the surface of the watch on the contact spot, so I don’t think I’ll make an attempt

Very cool fun facts!From my little experience in metals sorting business, 316 and 904l have no magnetic properties. Lower grades of stainless steel like 4xx series are magnetic. A common stainless in the daily applications is 304 and is in general non-magnetic, but it could become partially magnetic under cold processing/ forging. I also purchased recently a VSF sub 126610LN that is supposed to have 904l alloy. I have at the yard equipment that could read the type of alloy the watch is made of, but this would lead to slightly damaging the surface of the watch on the contact spot, so I don’t think I’ll make an attempt

UptonDowntown

A Turk, Left Quirk, I Lurk

- 4/11/23

- 9

- 12

- 3

Interesting. I’m actually a little surprised to learn that nobody actually knows if the Rolex reps are using 904 now or not. I would have thought this to have been sorted years ago.

- 15/1/07

- 43

- 25

- 18

Good to know, thanks for the infoFrom my little experience in metals sorting business, 316 and 904l have no magnetic properties. Lower grades of stainless steel like 4xx series are magnetic. A common stainless in the daily applications is 304 and is in general non-magnetic, but it could become partially magnetic under cold processing/ forging. I also purchased recently a VSF sub 126610LN that is supposed to have 904l alloy. I have at the yard equipment that could read the type of alloy the watch is made of, but this would lead to slightly damaging the surface of the watch on the contact spot, so I don’t think I’ll make an attempt

article of extreme importance and could be useful to other people in my case was wondering about the different materials used on our rep

rossco17111

Getting To Know The Place

- 13/12/23

- 19

- 18

- 3

Agree, as I’m reading a lot of reps now advertised as 904, so would be keen to understand if that is indeed true or if all factories and TDs have become a bit more brazen on their advertising practices…Interesting. I’m actually a little surprised to learn that nobody actually knows if the Rolex reps are using 904 now or not. I would have thought this to have been sorted years ago.

For the weightet watches nowadays its not 904L. 904L is in Rolex SS Models.

But who knows. would be cool if PT would test again

But who knows. would be cool if PT would test again

- 28/4/24

- 622

- 784

- 93

It’s fascinating how much is trotted out as fact, that we tend to believe is the source appears knowledgeable. Your scratch test is a case in point, all I have read about 904L states it is softer than 316L, yet your real world test showed the opposite, so are the Rep manufacturers actually using even true 316L steel? I’d have to question that from your results. Also I have to accept my 126610 is not 904L.

The info may be dated. I have recently read that 904 is only 1.3x the cost of 316, not 3x. This may make things more palatable for factories. Maybe therefore the listings are truthful, the TDs are truthful. Maybe. A $500 watch goes to $650. Possible.

mrjwatches

Do not accept unsolicited offers

- 13/6/24

- 3

- 0

- 1

Super informative, I was wondering what the actual/visible differences between 316L and 904L were.

- 29/3/22

- 74

- 25

- 18

As an mechanical engineer i will translate for Europeans:

The material 1.4539 or AISI 904L has excellent resistance to many organic and inorganic acids. Thanks to its high molybdenum content, this grade also offers good resistance to stress corrosion cracking and pitting. The material 1.4539 is seawater resistant.

But it is not a real special steel which rolex tries to think us.

The material 1.4404 or AISI 316L is one of the most commonly used corrosion-resistant stainless steels. Due to the 2 - 2.5% molybdenum addition, this material offers significantly improved corrosion resistance than 1.4301/1.4307. Due to its lower carbon content compared to 1.4401, the material 1.4404 is also characterized by good processing properties.

1.4404 is also nothing special its just A4 material which you can buy for stainless steel screws etc.

Problem 1.4404 is not full resistant against chlorides but butter resistant than A2 1.4301 or AISI 304.

By the way who knows if its A2 or A4 material, cause optical you cannot see it good.

What would be the real deal:

1.4529 which is marekt as HCR (high corrosiv resistant) also called 926.

Due to its high number of alloying elements, the material 1.4529 or AISI 926 has excellent resistance to numerous organic and inorganic acids. Thanks to its high molybdenum content, this grade also offers good resistance to stress corrosion cracking and pitting.

1.4529 or 926 will be used in tunnels or swimming pool area if done correctly and you are not living in a shitty country.

Stainless steel A8 1.4529 (also known as super austenitic stainless steel) is an enhanced version of the material 1.4539 and is characterised by its particularly high resistance (CRC V) to localised types of corrosion, such as chlorine-induced crevice, stress or pitting corrosion. Furthermore, it has good polishing and mechanical properties and can be used in a wide range of temperatures. For this reason, the use of this material to fasten load-bearing components is mandatory in certain sectors.

| EN | 1.4539 |

|---|---|

| DIN | X1NiCrMoCu25-20-5 |

| AISI | 904L |

| UNS | N08904 |

But it is not a real special steel which rolex tries to think us.

| EN | 1.4404 |

|---|---|

| DIN | X2CrNiMo17-12-2 |

| AISI | 316L |

| UNS | S31603 |

1.4404 is also nothing special its just A4 material which you can buy for stainless steel screws etc.

Problem 1.4404 is not full resistant against chlorides but butter resistant than A2 1.4301 or AISI 304.

By the way who knows if its A2 or A4 material, cause optical you cannot see it good.

What would be the real deal:

1.4529 which is marekt as HCR (high corrosiv resistant) also called 926.

| EN | 1.4529 |

|---|---|

| DIN | X1NiCrMoCuN25-20-7 |

| AISI | 926 |

| UNS | N08926 |

1.4529 or 926 will be used in tunnels or swimming pool area if done correctly and you are not living in a shitty country.

Stainless steel A8 1.4529 (also known as super austenitic stainless steel) is an enhanced version of the material 1.4539 and is characterised by its particularly high resistance (CRC V) to localised types of corrosion, such as chlorine-induced crevice, stress or pitting corrosion. Furthermore, it has good polishing and mechanical properties and can be used in a wide range of temperatures. For this reason, the use of this material to fasten load-bearing components is mandatory in certain sectors.

This has been discussed and debated adnuseam on this forum. Opinions vary.Super informative, I was wondering what the actual/visible differences between 316L and 904L were.

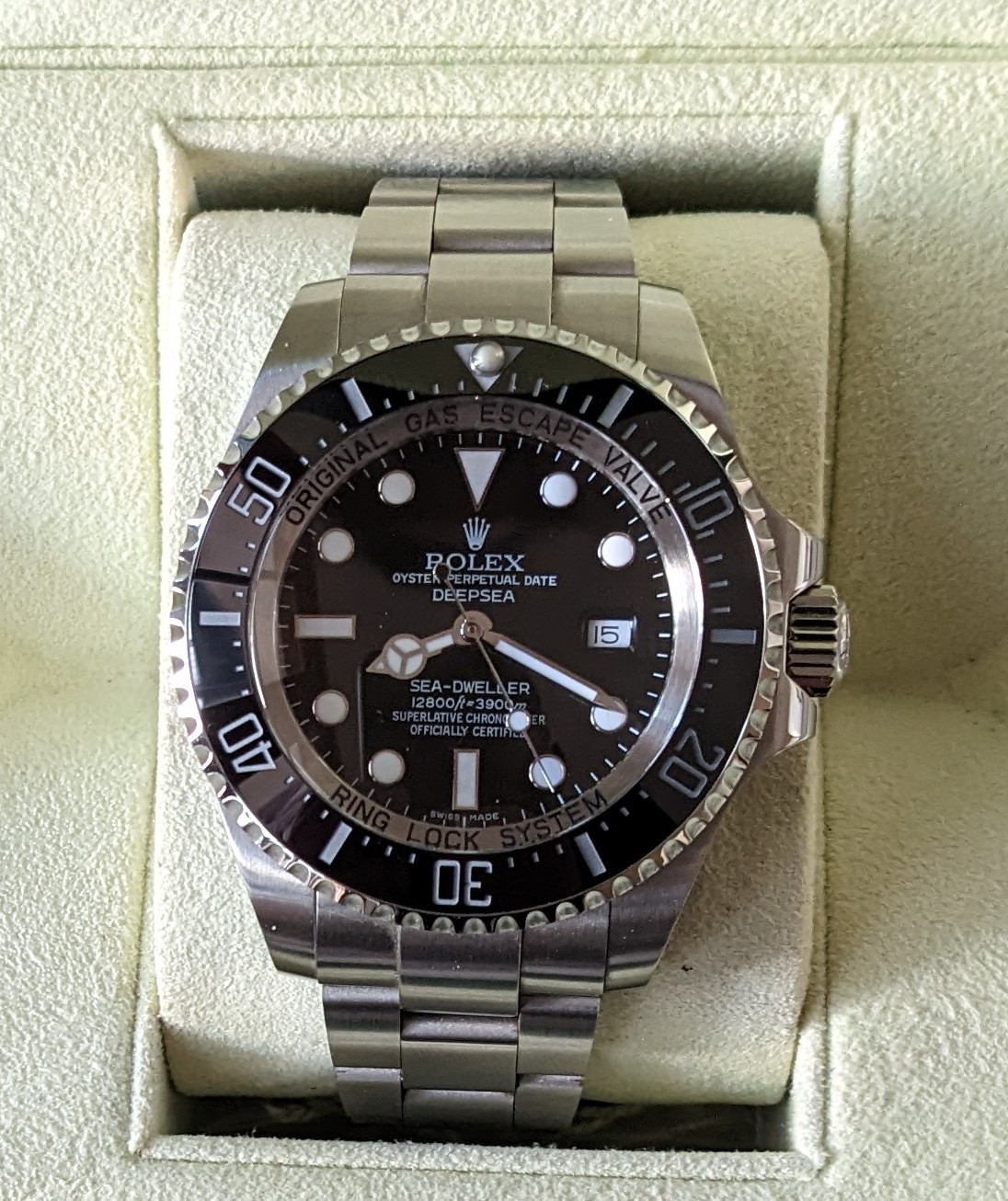

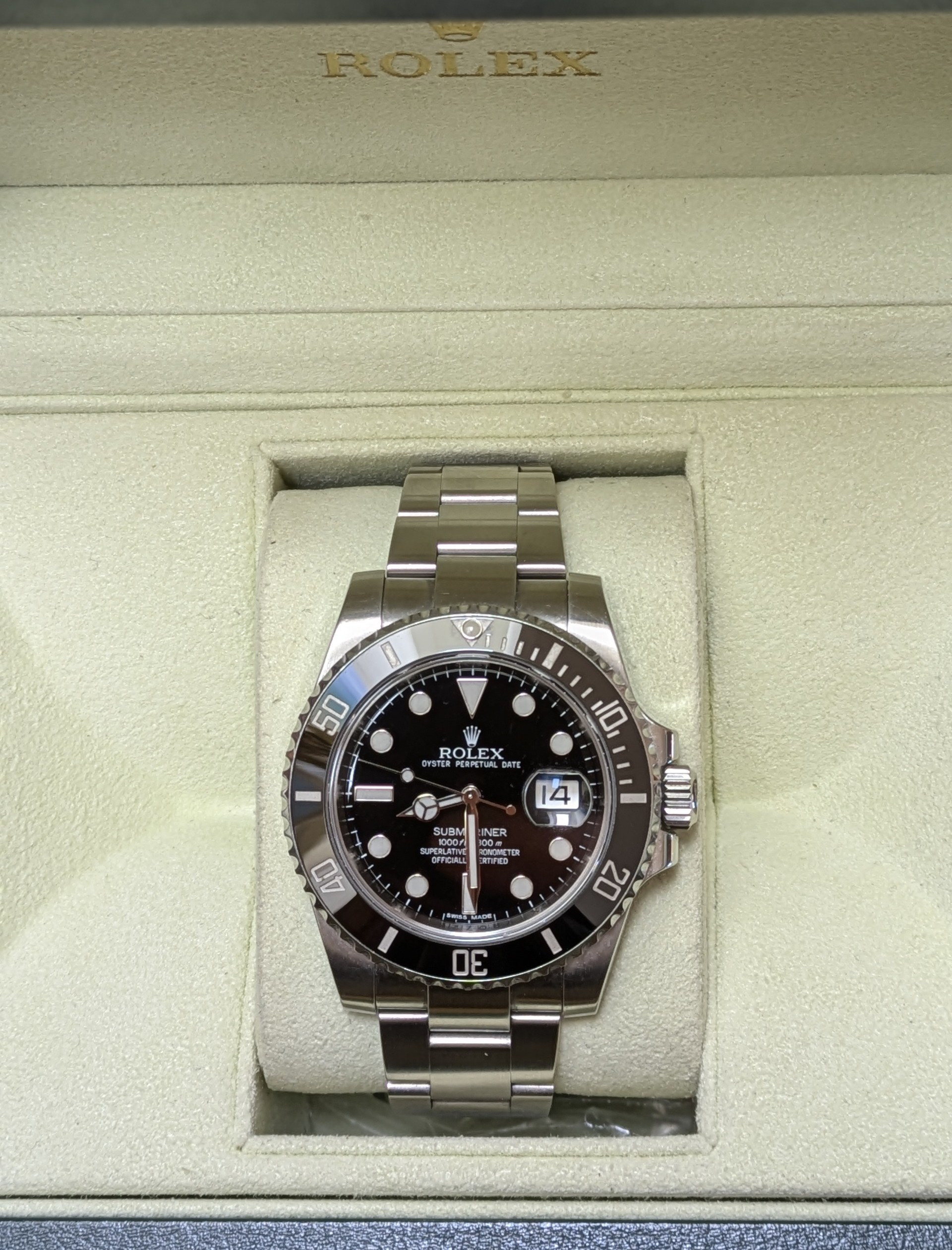

Here's a gen and then two reps, all 904L, taken at the same time under the same light.

And then a 316, again under the same conditions.