[mention]Toofsy [/mention] that looks great. Is that a 3D or 2d file?

I had contacted stph_dxtr on IG about making a bezel insert. He quoted me $180 including shipping back to the UK, but that was only for one. He makes them by hand carving from blocks of plexi.

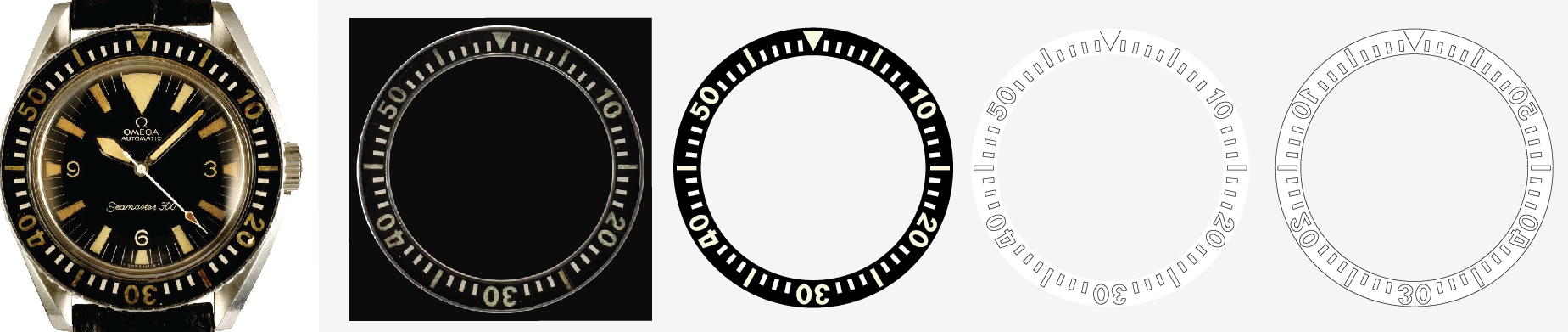

I’m contemplating it, but it is a bit steep. I had been thinking about trying to make my own 3D insert, has anyone got any recommendations for a good beginners 3D rendering program for Mac?

My daughter has decided to join me in modding watches; unfortunately she’s only 3 and she thought she could improve the seamaster dial with a sharpie. I got most of it off, but it has removed some of the “Seamaster” writing. Hopefully I can hide it with some judicious vintagising.

I scanned the dial when I first got it, so if anyone wants a copy of that I can DM it. I’m going to make a decal dial - I’ve done one for my 6538 using the water slide method, but will try the film free for this one. I just have to hope the printers at work are up to the job.

I finally received my bezel removal tool

£90 down and 10 minutes later.

I think I may have flicked out one of the ball bearings - they seem to be 1.5mm - so I imagine not too difficult to replace.

I should have all the parts I need by next week (apart from the insert).

Time allowing I can now start work on the case shaping.

Sent from my iPhone using Tapatalk