Hi all vintage Rolex lovers!

I bought the 268$ cheap version of the 6542 from Intime a while back and the “coin edge” if the bezel is terrible. So I decided to make a new one.

I was using 316L stainless steel and a lathe with milling attachment and a dividing-plate to mill the slots (76) which give an angle of about 4,73 degrees between each slot and that’s a number I calculated from pictures of the gen I’ve looked at on Chrono24 and more.

The setup was simple turn the inner dimensions, exact copy of the rep bezel to fit the case.

Then turn the geometry of the outside by hand (manual lathe) to desired design.

Make a custom holder for the bezel to hold it for milling if the “coin edge”

Then just milling the 76 slots and deburr any sharp edges and finally give it a polish.

It’s my first attempt so there is still room for improvements but I’m still happy with the results.

On to the pictures:

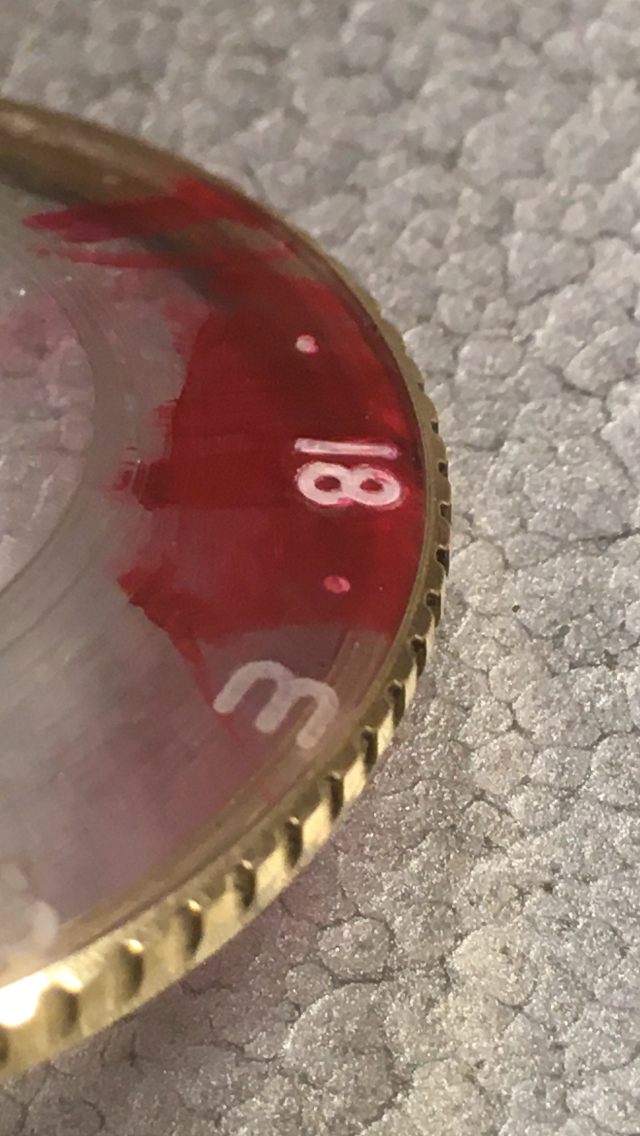

rep bezel

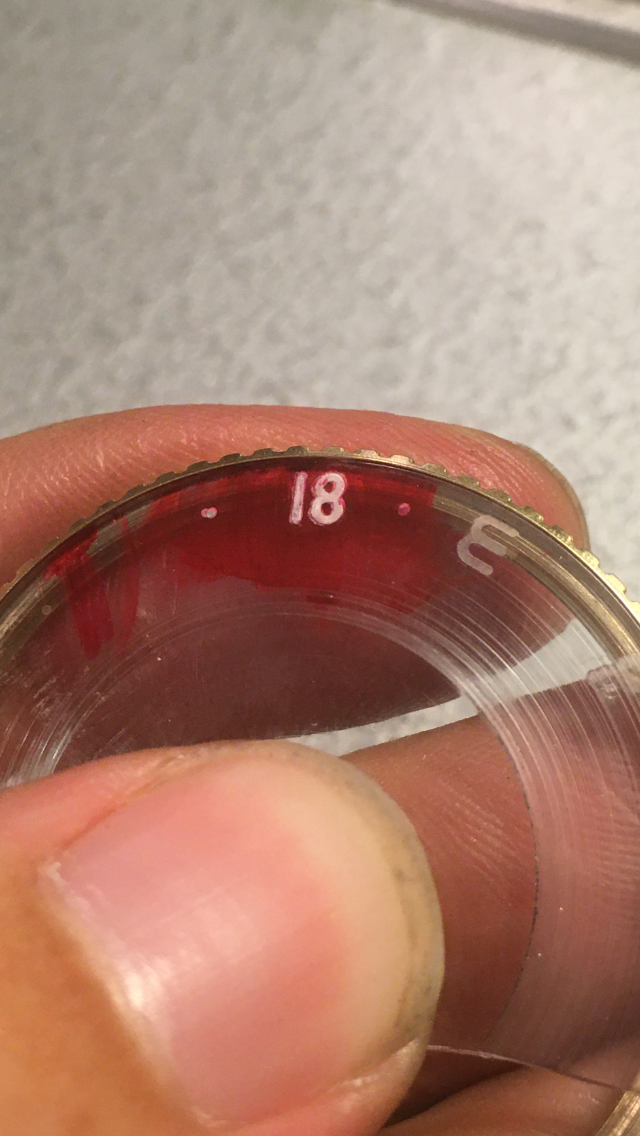

custom bezel

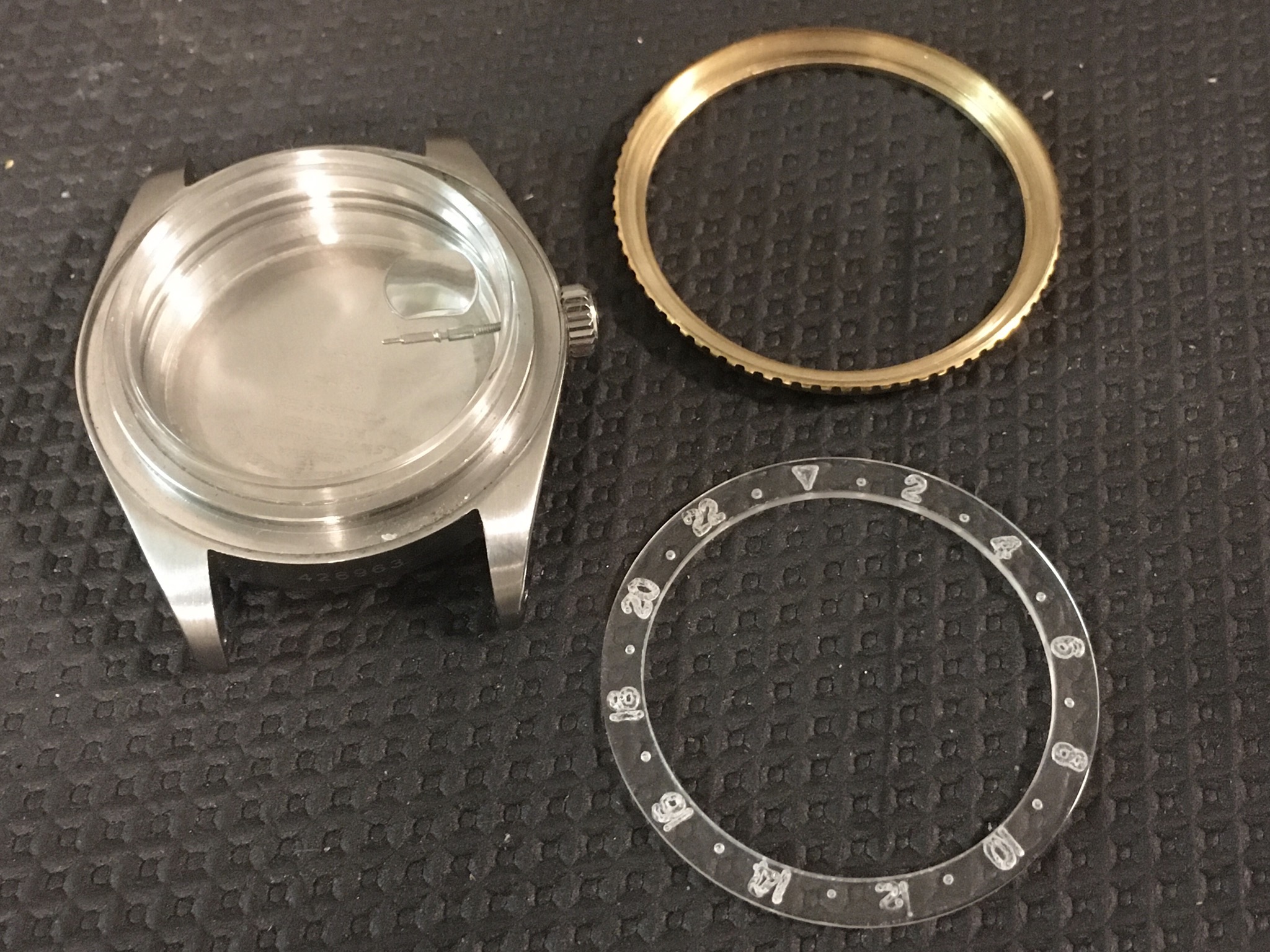

setup in lathe with milling-attachment

I bought the 268$ cheap version of the 6542 from Intime a while back and the “coin edge” if the bezel is terrible. So I decided to make a new one.

I was using 316L stainless steel and a lathe with milling attachment and a dividing-plate to mill the slots (76) which give an angle of about 4,73 degrees between each slot and that’s a number I calculated from pictures of the gen I’ve looked at on Chrono24 and more.

The setup was simple turn the inner dimensions, exact copy of the rep bezel to fit the case.

Then turn the geometry of the outside by hand (manual lathe) to desired design.

Make a custom holder for the bezel to hold it for milling if the “coin edge”

Then just milling the 76 slots and deburr any sharp edges and finally give it a polish.

It’s my first attempt so there is still room for improvements but I’m still happy with the results.

On to the pictures:

rep bezel

custom bezel

setup in lathe with milling-attachment