chubbychaser911

Active Member

- 31/10/19

- 405

- 112

- 43

Hey all,

I was extremely fortunate to win a beautiful gen spec 1675 case, plus bezel and crystal, in the RWI 2019 raffle. So I thought it would be nice to catalogue the progress from its arrival today to completion - and along the way to get advice and recommendations from you, the vastly more experienced RWI crowd. My huge thanks go to milk051506 for these cases, yodog for the scalloped edge bezel, and tripdog for his reworking of the case prior to it being sent to me.

Trip's photo review of the case is here.

I also went ahead and bought two of milk's bezel inserts. One fuchsia and one BLRO. This chap is a goldmine of lovely GMT parts for us!

I've only just received the case today, so I've just had the briefest of ganders this evening and taken a couple of snaps.

This weekend, I'll start to give more thought to the other parts I'll need to source to get on with the project.

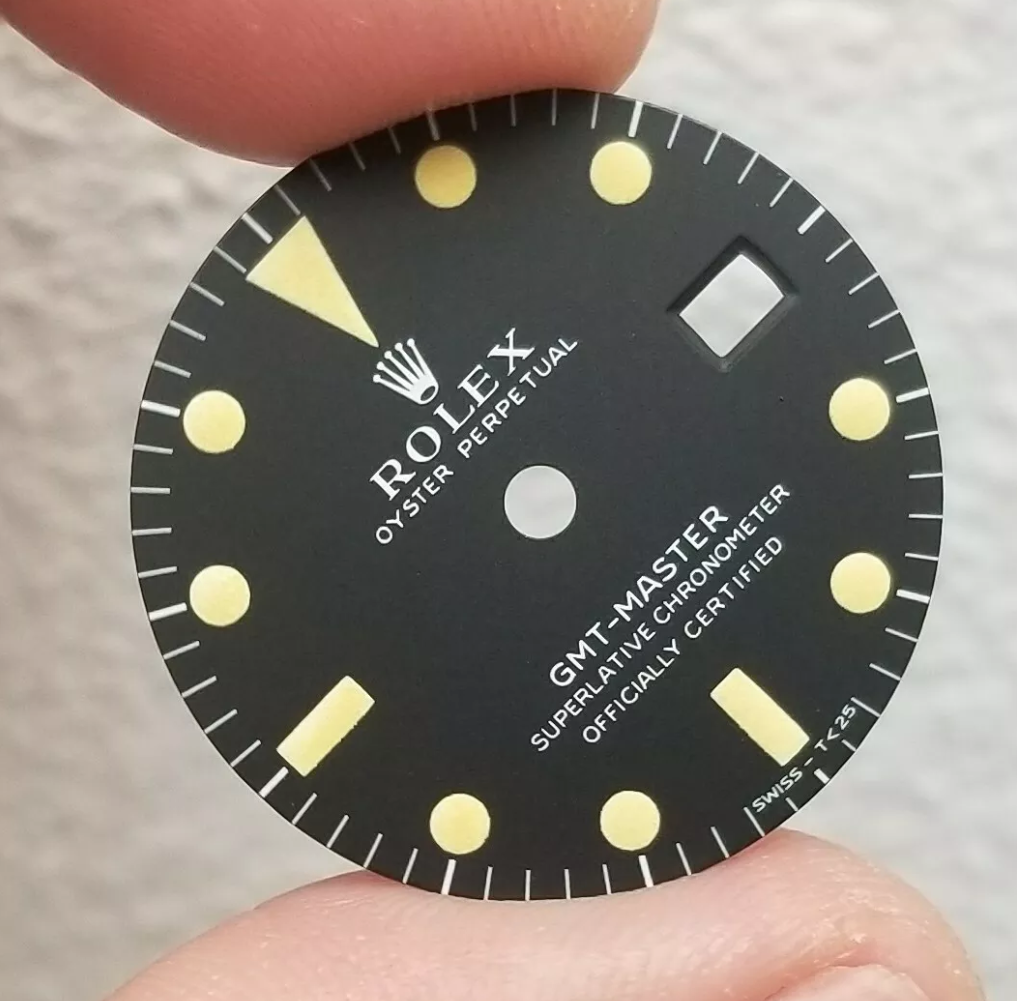

I've already had some advice from tripdog: "I would look at early versions of the 1675 GMT if I were you, the case and lugs are quite slim, so an early gilt dialed 1675 would be the obvious choice for me as the cases from these watches would have been polished and brushed many times since the late 50's/early 60's. A gloss gilt dial, dwarf GMT hand, 7206 rivet bracelet - would make a great looking watch." He recommended Ruby's for a dial - so I'm currently looking at those. Any other thoughts and advice would be welcome.

I'll post progress pics as the project advances.

Thanks again to RWI for the great raffle prizes!

Is there any problem with using the milk case as 16750.

Good evening everyone too I am waiting for the case milk051506 , I took inspiration from this 1675 which was sold on H.Q.milton https://www.hqmilton.com/timepieces...-1675-with-mark-1-dial-and-fuchsia-bezel-4790, these are the pieces that I have bought so far, waiting for their arrival, then it is sent to kilowattore

Love that dial, where from? Insert too? Might have a go myself, with help from a respected modder

You will not get a response. He has been banned from the forum

Oh ok. What did he do? May I ask?

He questioned a mod, lol.

I need your help. In the past few weeks, i cracked 5 crystals for my milk case build. I bought from different fabric and machined them, but still the same.

I always bought a 25-116 crystal and have these sizes:

Case diameter: 28.90mm

Crystal outer diameter (original): 30.30mm

Crystal outer diameter (turned down): 30.00mm

After putting the crystal to the case diameter: 30.20mm

crystal retaining ring inner diameter: 30.15mm

I can put the crystal on the case. It sits tight on the case. When I tried to press the retaining ring over the crystal, it cracks along the cyclop.

I used my lathe and shaved the outer diameter of the plexy from: 30.30mm to 30.00mm. Once I shaved it to 29.90mm - still cracked :-(What do you mean you 'machined' them?

Do you know the size? How many mm should the plexi be bigger than the retaining ring ?You need to shave the outer diameter of the plexy a little bit.

I used my lathe and shaved the outer diameter of the plexy from: 30.30mm to 30.00mm. Once I shaved it to 29.90mm - still cracked :-(

Do you know the size? How many mm should the plexi be bigger than the retaining ring ?

To use the official expression, when seeing a sexy pic... "Phwoooar!"

Solution6 removing 0.3mm from the diameter with a nail file sounds like a lengthy process for a view hour. If you have a trick, I'd love to see the video on it. I am currently really desperate.

My both favorite dealer in Germany are currently out of order. I have to wait till I get a new one for a view weeks.