kilowattore

Sales Moderator / Section Moderator

Staff member

Moderator Sales

Section Moderator

Certified

Originally posted on Dec.18, 2015

Here's the follow up to my review of the OOB new Davidsen's 036B, found HERE.

This is for sure the most elaborate and challenging project I completed so far.

The amount of work I put on it has been, well, a lot. But it has paid imho. Some details could still be perfected, a few problems arose and I had to work my way around them the best I could. Most of them I solved, for others I had to accept a few compromises. Watch has been assembled and disassembled completely a number of times before I was satisfied with the results.

I beg your pardon in advance if this thread will turn into a long read, those of you who are not that interested in the details of the build's process may skip the text and go directly to the pics

Ok then, but what did I do to this watch?

Davidsen's case set was my choice for this build, mainly because it's the only available case featuring the engravings on the back as per the gen.

The case was completely disassembled and washed with chemicals in order to remove the dullish patina it had when I received it. Afterwards it went through a full spa treatment with a few different grades sandpaper, the area near the lugs was reworked to achieve a cleaner finish where they join the case although some of the machining marks could not be removed completely.

The crystal was re-seated in order to have a little less height above the bezel, crown was cleaned and repolished, I even polished the sides of the lugbars. Not a single part remained untouched

In the works:

Finished:

Old case:

New:

Old:

I ordered an A-F series crownguard from Sead for this build as it is known to be the closest to the gen CG, and it really is. The lever shape is scary close to gen, it has a perfect curve and the tip points nicely towards the watch body.

Unfortunately though when I mounted it on the case I realized the fitment was not good at all, there was a 0.2 mm space in the upper and bottom part, where the CG should touch the case, due to the slightly different shape of DSN and noob cases.

So the choice was between a better overall CG with a perfect lever or a slightly worse CG and lever but with a perfect fitment. I chose the latter. I then disassembled the CG completely, cleaned and refinished a bit the inner shape, retouched the lever tip, shortened a tiny bit the steel CG pin and brushed it to match the titanium of the CG.

Old CG

New CG

I managed to find one of the few dials produced by rolli at the end of last year. I was very lucky indeed as these have been sold out for a long time and no one knows if they will ever be made again.

As I stated in my review DSN's new dial is great, but of course it can't compare to this dial. Here's a GEN vs DSN vs ROLLI comparison

DSN

GEN

ROLLI

As you can see rolli's dial is scary close to the gen one, perfect sausage lume application with a glossy, raised and rounded surface. Perfect numbers shape and inscriptions font. Most of all a perfect match for the tobacco color which rolli claims to be painted using the same Pantone color used for the genuine Panerai dials. The gen dial looks to have a polished slope around numbers and indices that is not visible in rolli's, and that's the only difference I could observe. I talked with rolli about this feature and was told it's due to the coin stamping production process used by Panerai. From what I understood the press that stamps theindices and markers on the brass dial plate leaves a polished rim around the indices that remains visible even after painting the dial surface. Using the same equipment to produce these rep dials would have raised dramatically the production costs, making them too much expensive, so the contours have been machine polished achieving a similar result, close but not the same.

GEN

Rolli

I have to say this dial has a tiny blemish near the 3 marker on the seconds subdial, so tiny though that it can be seen clearly only under specific lights at 10x magnification. Nothing I worry about

The real issue I had to face here was with installing the hands: the FGD hands that came with the dial were not finished very well, there was a lot of lume spilling over the hands' sides and the seconds hand had a tiny blob of lume underneath that prevented the movement from working. It took me quite a bit of time and a mighty migraine to fix these issues, the lume material in excess has been very gently removed with a tootpick from the side and the back of the hands but for the life of me I'm still not completely satisfied with the result, there's a microscopic spot that seems to appear and disappear like it's playing with me :devil:

Anyway I digress, maybe I will just ask rolli to sell a spare hands set to me with his new dial once it's released

Here you can see clearly the lume glowing on the sides of the hands:

Way better now:

GEN

One of the details that were haunting me about this 036 build was the golden outline of the jewels holes in the gen movement. It's one of those things that you just HAVE to do something about it or you will never be satisfied, so here's where I got completely crazy

I found online a special paint with real metal scales in it and bought a micro-brush used in modellism, then I painted the holes by hand.

I cannot even begin to describe how much time and patience I had to put in painting those three little holes without spreading the paint all over the bridges, two movements where sacrificed in order to achieve an acceptable result.

Sacrificed movement

I didn't have the guts to do this on a swiss hi-beat movement worth 250-300 usd so in the end I opted for a hi-beat asian 6497-2 I sourced from Helena Rou. I have to say it is a little more expensive than the usual a6497 you find on the bay but it was by far the cleanest and nicest looking I have seen so far. This means though that there is no Y incabloc installed on this movement and since swapping it is far beyond my skills I will have to live with this flaw. As I said there are always compromises you need to accept

Here's the final result:

NEW

OLD

Now I'm sure I wrote too much as usual, but I tried to describe what goes behid the scenes and unnoticed each time we look at the nice builds that some members are posting. I'd like to thank each ad every one of them for the inspiration and for what I learnt reading and looking at their builds.

On to the rest of the pictorial:

Final wristie!

:cheers:

Luminor Marina Militare PAM 036

A review in two parts

PART 2 - the rolli/FGD 036B build

A review in two parts

PART 2 - the rolli/FGD 036B build

Here's the follow up to my review of the OOB new Davidsen's 036B, found HERE.

This is for sure the most elaborate and challenging project I completed so far.

The amount of work I put on it has been, well, a lot. But it has paid imho. Some details could still be perfected, a few problems arose and I had to work my way around them the best I could. Most of them I solved, for others I had to accept a few compromises. Watch has been assembled and disassembled completely a number of times before I was satisfied with the results.

I beg your pardon in advance if this thread will turn into a long read, those of you who are not that interested in the details of the build's process may skip the text and go directly to the pics

Ok then, but what did I do to this watch?

CASE

Davidsen's case set was my choice for this build, mainly because it's the only available case featuring the engravings on the back as per the gen.

The case was completely disassembled and washed with chemicals in order to remove the dullish patina it had when I received it. Afterwards it went through a full spa treatment with a few different grades sandpaper, the area near the lugs was reworked to achieve a cleaner finish where they join the case although some of the machining marks could not be removed completely.

The crystal was re-seated in order to have a little less height above the bezel, crown was cleaned and repolished, I even polished the sides of the lugbars. Not a single part remained untouched

In the works:

Finished:

Old case:

New:

Old:

CROWNGUARD

I ordered an A-F series crownguard from Sead for this build as it is known to be the closest to the gen CG, and it really is. The lever shape is scary close to gen, it has a perfect curve and the tip points nicely towards the watch body.

Unfortunately though when I mounted it on the case I realized the fitment was not good at all, there was a 0.2 mm space in the upper and bottom part, where the CG should touch the case, due to the slightly different shape of DSN and noob cases.

So the choice was between a better overall CG with a perfect lever or a slightly worse CG and lever but with a perfect fitment. I chose the latter. I then disassembled the CG completely, cleaned and refinished a bit the inner shape, retouched the lever tip, shortened a tiny bit the steel CG pin and brushed it to match the titanium of the CG.

Old CG

New CG

DIAL

I managed to find one of the few dials produced by rolli at the end of last year. I was very lucky indeed as these have been sold out for a long time and no one knows if they will ever be made again.

As I stated in my review DSN's new dial is great, but of course it can't compare to this dial. Here's a GEN vs DSN vs ROLLI comparison

DSN

GEN

ROLLI

As you can see rolli's dial is scary close to the gen one, perfect sausage lume application with a glossy, raised and rounded surface. Perfect numbers shape and inscriptions font. Most of all a perfect match for the tobacco color which rolli claims to be painted using the same Pantone color used for the genuine Panerai dials. The gen dial looks to have a polished slope around numbers and indices that is not visible in rolli's, and that's the only difference I could observe. I talked with rolli about this feature and was told it's due to the coin stamping production process used by Panerai. From what I understood the press that stamps theindices and markers on the brass dial plate leaves a polished rim around the indices that remains visible even after painting the dial surface. Using the same equipment to produce these rep dials would have raised dramatically the production costs, making them too much expensive, so the contours have been machine polished achieving a similar result, close but not the same.

GEN

Rolli

I have to say this dial has a tiny blemish near the 3 marker on the seconds subdial, so tiny though that it can be seen clearly only under specific lights at 10x magnification. Nothing I worry about

The real issue I had to face here was with installing the hands: the FGD hands that came with the dial were not finished very well, there was a lot of lume spilling over the hands' sides and the seconds hand had a tiny blob of lume underneath that prevented the movement from working. It took me quite a bit of time and a mighty migraine to fix these issues, the lume material in excess has been very gently removed with a tootpick from the side and the back of the hands but for the life of me I'm still not completely satisfied with the result, there's a microscopic spot that seems to appear and disappear like it's playing with me :devil:

Anyway I digress, maybe I will just ask rolli to sell a spare hands set to me with his new dial once it's released

Here you can see clearly the lume glowing on the sides of the hands:

Way better now:

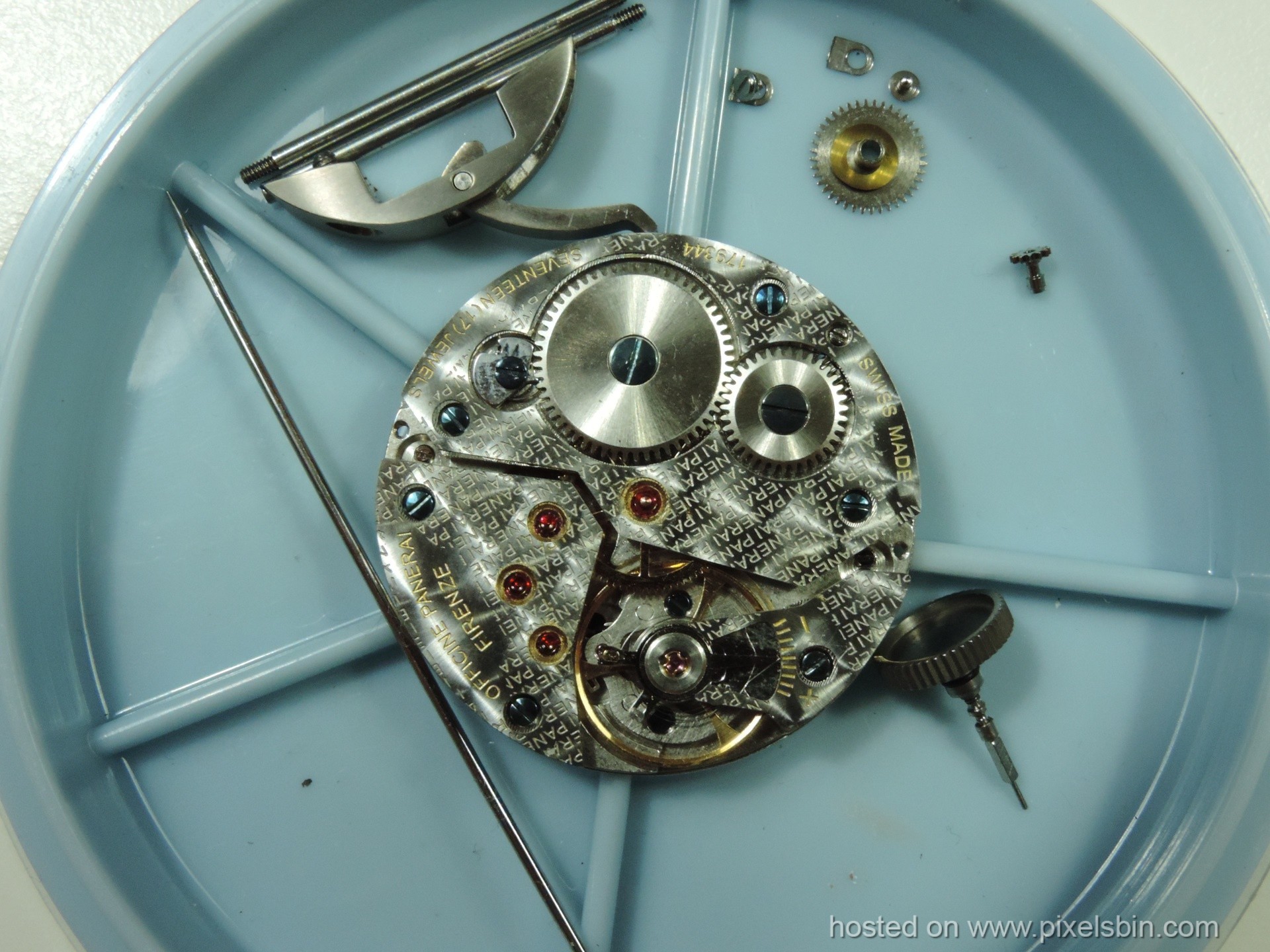

CASEBACK AND MOVEMENT

GEN

One of the details that were haunting me about this 036 build was the golden outline of the jewels holes in the gen movement. It's one of those things that you just HAVE to do something about it or you will never be satisfied, so here's where I got completely crazy

I found online a special paint with real metal scales in it and bought a micro-brush used in modellism, then I painted the holes by hand.

I cannot even begin to describe how much time and patience I had to put in painting those three little holes without spreading the paint all over the bridges, two movements where sacrificed in order to achieve an acceptable result.

Sacrificed movement

I didn't have the guts to do this on a swiss hi-beat movement worth 250-300 usd so in the end I opted for a hi-beat asian 6497-2 I sourced from Helena Rou. I have to say it is a little more expensive than the usual a6497 you find on the bay but it was by far the cleanest and nicest looking I have seen so far. This means though that there is no Y incabloc installed on this movement and since swapping it is far beyond my skills I will have to live with this flaw. As I said there are always compromises you need to accept

Here's the final result:

NEW

OLD

Now I'm sure I wrote too much as usual, but I tried to describe what goes behid the scenes and unnoticed each time we look at the nice builds that some members are posting. I'd like to thank each ad every one of them for the inspiration and for what I learnt reading and looking at their builds.

On to the rest of the pictorial:

Final wristie!

:cheers:

Last edited: