- 14/12/20

- 650

- 688

- 93

A little background:

I recently picked up a VSF 126610LV Starbucks (M2M) whose bezel had roughly 0.5mm of vertical play (absolutely stunning and near perfect watch otherwise!). ~0.5mm of vertical play is not that terrible, but still fairly noticeable. The bezel rotation actually felt pretty good, but the vertical play was a little too much for me to leave it be….so the tinkering began!

When I pulled off the bezel to investigate, the bezel gasket (aka the hytrel ring) was actually black in color (not sure it was the stock gasket as I’ve only seen the white hytrel version with my other reps) and a bit deformed and split apart. I had read a few posts here recommending wrapping dental floss around the bezel gasket a few times to tighten things up, so that’s what I did. And with a little trial and error (ie wrapped ~10mm section, then 15mm section, then 20mm section, etc), I got the bezel back on and feeling pretty good and with virtually no vertical play. However, the bezel rotation was a little inconsistent…going from a little tight to a little loose as I turned the bezel. Also, in the process of removing and reseating the bezel several times, I managed to mangle the bezel gasket even more. So eventually I had to cut out the really damaged areas which left it in 2 shortened pieces. And even with all that damage and in 2 pieces, this little bugger still worked surprisingly well! Moral of the story here is these little bezel gaskets can take a lot of abuse and still work pretty well!

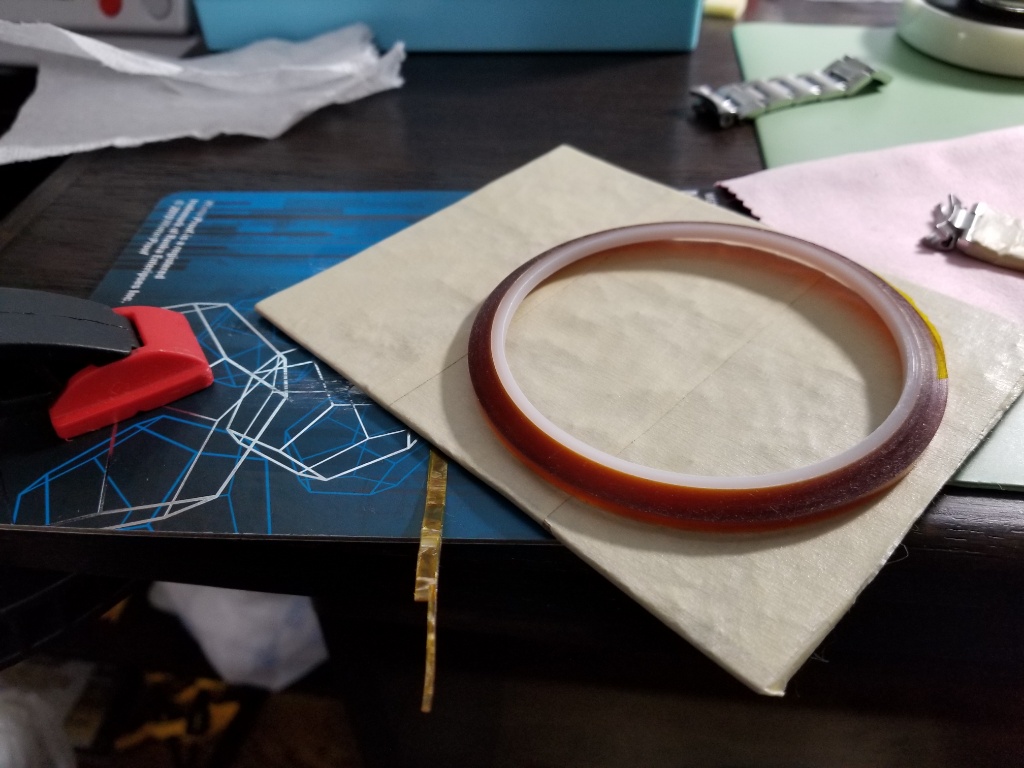

Short term solution:

Given the poor state of the original bezel gasket, I thought it best to pick up some new ones…which I did from 2 sellers on ebay (here: https://www.ebay.com/itm/161620824457 and here: https://www.ebay.com/itm/293590263482). Unfortunately both were a little undersized for the job. As a result, when trying to reseat (ie press down) the bezel, the slightly undersized gaskets would invariably get caught on the crystal retaining ring…thus not allowing the bezel to rotate properly (the bezel rotation becomes super tight once the bezel gasket is deformed and only partially seated around the crystal retaining ring). So I stretched one ring out by hand (just a tiny bit and very gently) and then went back to the dental floss technique. I didn’t have much luck this time until I literally wrapped the entire ring with dental floss....which actually got it feeling pretty good. However, as I pulled the bezel on and off to make adjustments, the dental floss was beginning to slightly fray. So I think using dental floss may be a good short-term solution, but it will eventually fray and loosen/fail if you’re like me and enjoy endlessly fiddling with the bezel!

Long-term solution:

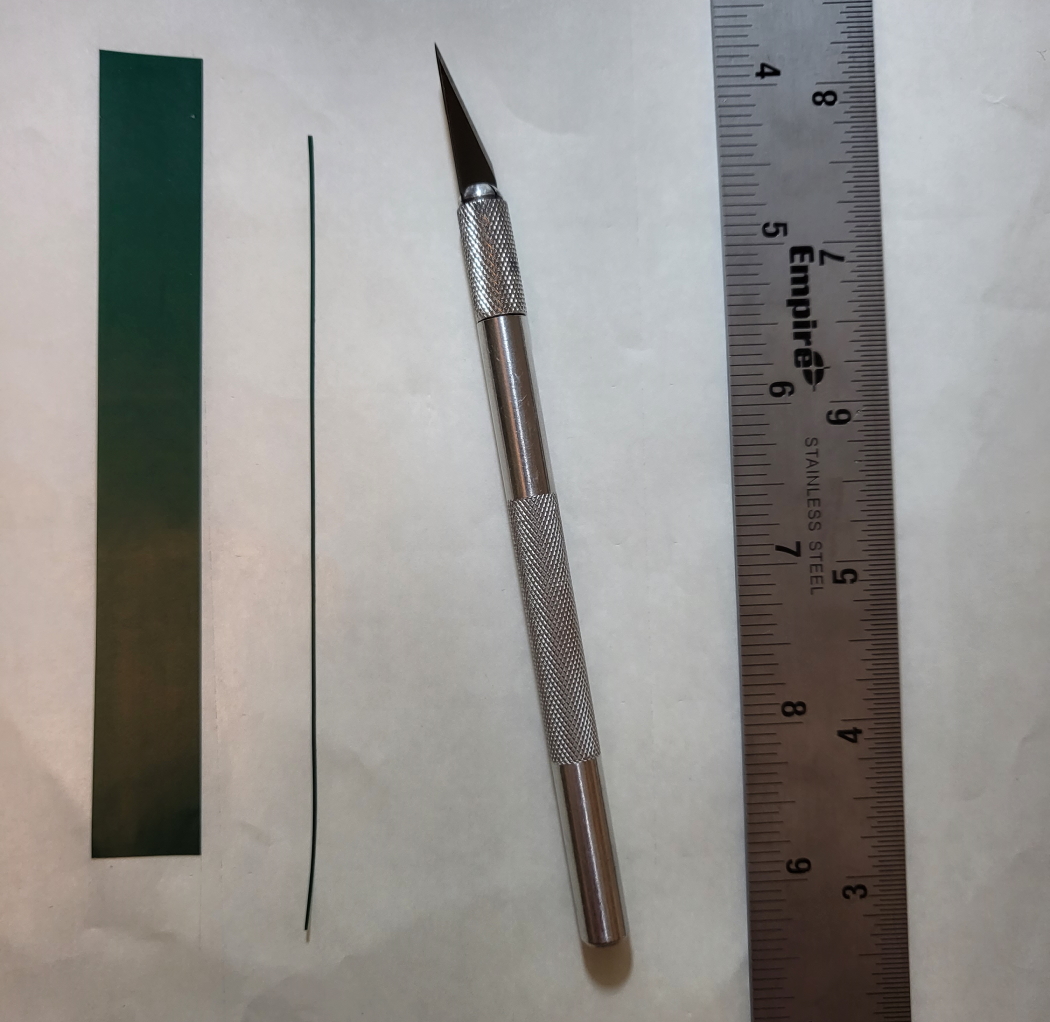

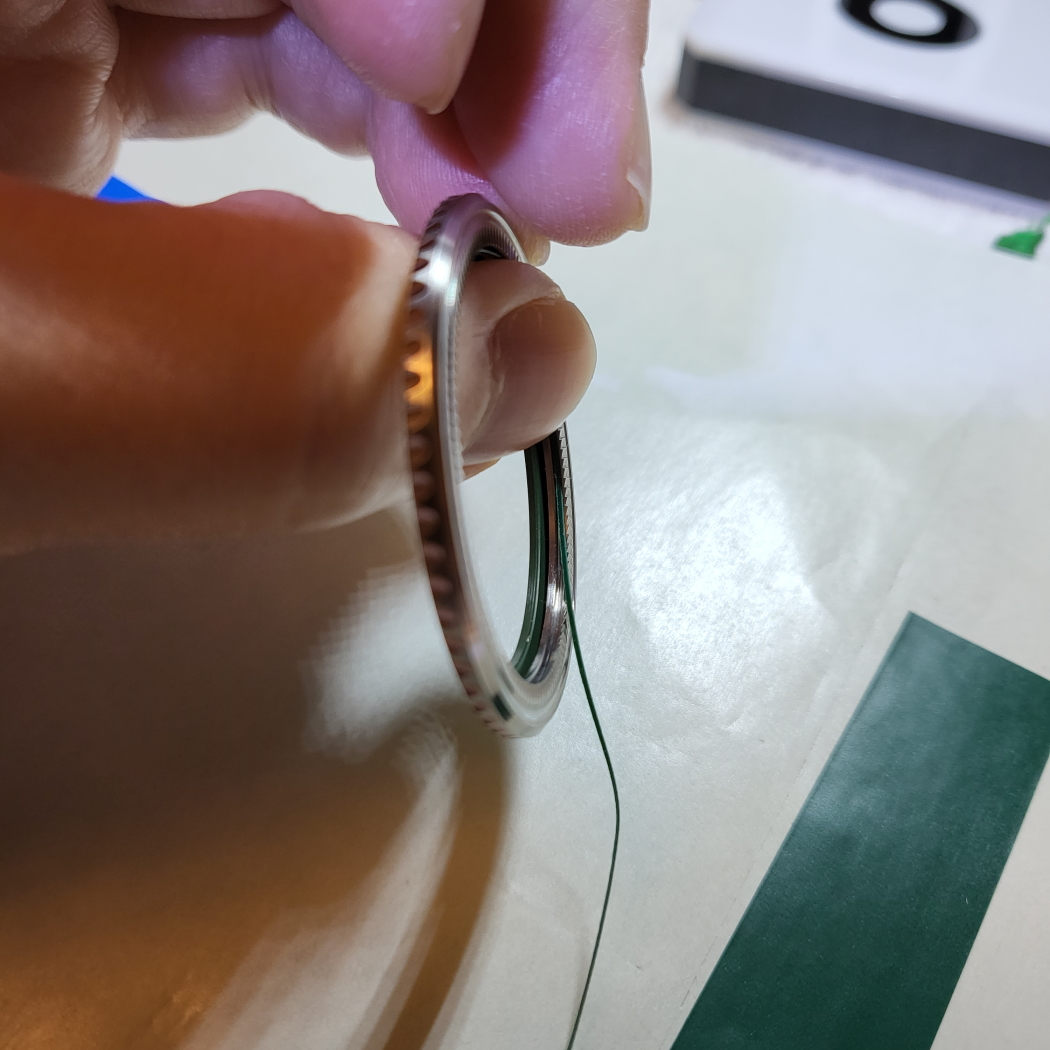

In light of the above, I thought lining the “bezel channel” that the hytrel ring sits in may accomplish the same thing as the dental floss and be a better long-term option (more on why below). To do so, the first thing that came to mind was using a thin strip of tape…so I grabbed some standard electrical tape because it’s fairly thick at ~0.15mm (compared scotch tape at only ~0.03mm). The channel is roughly 0.6mm wide and ~4.5 inches in circumference, so I cut a roughly 0.5mm wide strip of electrical tape about 4.5 inches in length (using an x-acto knife and a ruler). I then carefully lined the bezel channel with this thin strip of tape. And I’ll be damned…it worked beautifully! After a little trial and error, I ended up overlapping the tape strip about 1.5 inches (ie I used a ~6 inch strip to cover roughly 4.5 inches of circumference...thus 1.5 inches of overlap). The end result was fantastic. The bezel action feels extremely close to my gen 126610LN and there is ZERO vertical play! And the best part is the only thing touching the bezel retaining ring is the bezel gasket. So this fix should last a long time (ie no fragile dental floss rubbing against the crystal retaining ring that will eventually fray and ultimately fail).

Final thoughts:

I think what’s going on here is the inner diameter of the ebay hytrel ring is actually very close to the correct size needed. However, the outer diameter of this ring is too small for the bezel channel that it sits in. As a result, the hytrel ring can not maintain the perfectly circular shape needed to properly and fully slide over the crystal retaining ring (ie it too easily becomes oval in shape as you press down)…thus resulting in it getting caught (and deformed) on the crystal retaining ring (and therefore not allowing the bezel to turn correctly). The tape lining effectively applies pressure uniformly to the entire circumference of the hytrel ring, allowing it to maintain the perfectly circular shape needed for it to be properly pressed onto the crystal retaining ring. That’s my theory anyway….and I’m sticking with it!

Hope the above helps others experiencing the same (and I think very common) issue.

Pictures to follow:

I recently picked up a VSF 126610LV Starbucks (M2M) whose bezel had roughly 0.5mm of vertical play (absolutely stunning and near perfect watch otherwise!). ~0.5mm of vertical play is not that terrible, but still fairly noticeable. The bezel rotation actually felt pretty good, but the vertical play was a little too much for me to leave it be….so the tinkering began!

When I pulled off the bezel to investigate, the bezel gasket (aka the hytrel ring) was actually black in color (not sure it was the stock gasket as I’ve only seen the white hytrel version with my other reps) and a bit deformed and split apart. I had read a few posts here recommending wrapping dental floss around the bezel gasket a few times to tighten things up, so that’s what I did. And with a little trial and error (ie wrapped ~10mm section, then 15mm section, then 20mm section, etc), I got the bezel back on and feeling pretty good and with virtually no vertical play. However, the bezel rotation was a little inconsistent…going from a little tight to a little loose as I turned the bezel. Also, in the process of removing and reseating the bezel several times, I managed to mangle the bezel gasket even more. So eventually I had to cut out the really damaged areas which left it in 2 shortened pieces. And even with all that damage and in 2 pieces, this little bugger still worked surprisingly well! Moral of the story here is these little bezel gaskets can take a lot of abuse and still work pretty well!

Short term solution:

Given the poor state of the original bezel gasket, I thought it best to pick up some new ones…which I did from 2 sellers on ebay (here: https://www.ebay.com/itm/161620824457 and here: https://www.ebay.com/itm/293590263482). Unfortunately both were a little undersized for the job. As a result, when trying to reseat (ie press down) the bezel, the slightly undersized gaskets would invariably get caught on the crystal retaining ring…thus not allowing the bezel to rotate properly (the bezel rotation becomes super tight once the bezel gasket is deformed and only partially seated around the crystal retaining ring). So I stretched one ring out by hand (just a tiny bit and very gently) and then went back to the dental floss technique. I didn’t have much luck this time until I literally wrapped the entire ring with dental floss....which actually got it feeling pretty good. However, as I pulled the bezel on and off to make adjustments, the dental floss was beginning to slightly fray. So I think using dental floss may be a good short-term solution, but it will eventually fray and loosen/fail if you’re like me and enjoy endlessly fiddling with the bezel!

Long-term solution:

In light of the above, I thought lining the “bezel channel” that the hytrel ring sits in may accomplish the same thing as the dental floss and be a better long-term option (more on why below). To do so, the first thing that came to mind was using a thin strip of tape…so I grabbed some standard electrical tape because it’s fairly thick at ~0.15mm (compared scotch tape at only ~0.03mm). The channel is roughly 0.6mm wide and ~4.5 inches in circumference, so I cut a roughly 0.5mm wide strip of electrical tape about 4.5 inches in length (using an x-acto knife and a ruler). I then carefully lined the bezel channel with this thin strip of tape. And I’ll be damned…it worked beautifully! After a little trial and error, I ended up overlapping the tape strip about 1.5 inches (ie I used a ~6 inch strip to cover roughly 4.5 inches of circumference...thus 1.5 inches of overlap). The end result was fantastic. The bezel action feels extremely close to my gen 126610LN and there is ZERO vertical play! And the best part is the only thing touching the bezel retaining ring is the bezel gasket. So this fix should last a long time (ie no fragile dental floss rubbing against the crystal retaining ring that will eventually fray and ultimately fail).

Final thoughts:

I think what’s going on here is the inner diameter of the ebay hytrel ring is actually very close to the correct size needed. However, the outer diameter of this ring is too small for the bezel channel that it sits in. As a result, the hytrel ring can not maintain the perfectly circular shape needed to properly and fully slide over the crystal retaining ring (ie it too easily becomes oval in shape as you press down)…thus resulting in it getting caught (and deformed) on the crystal retaining ring (and therefore not allowing the bezel to turn correctly). The tape lining effectively applies pressure uniformly to the entire circumference of the hytrel ring, allowing it to maintain the perfectly circular shape needed for it to be properly pressed onto the crystal retaining ring. That’s my theory anyway….and I’m sticking with it!

Hope the above helps others experiencing the same (and I think very common) issue.

Pictures to follow: