- 12/3/18

- 37,531

- 80,164

- 113

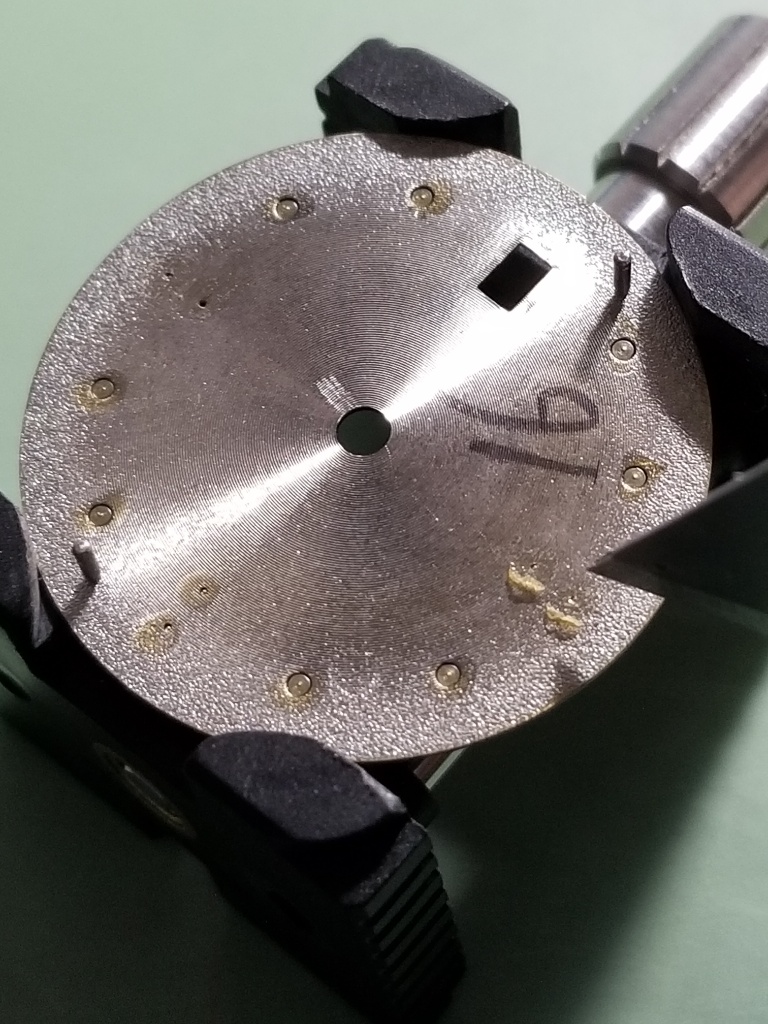

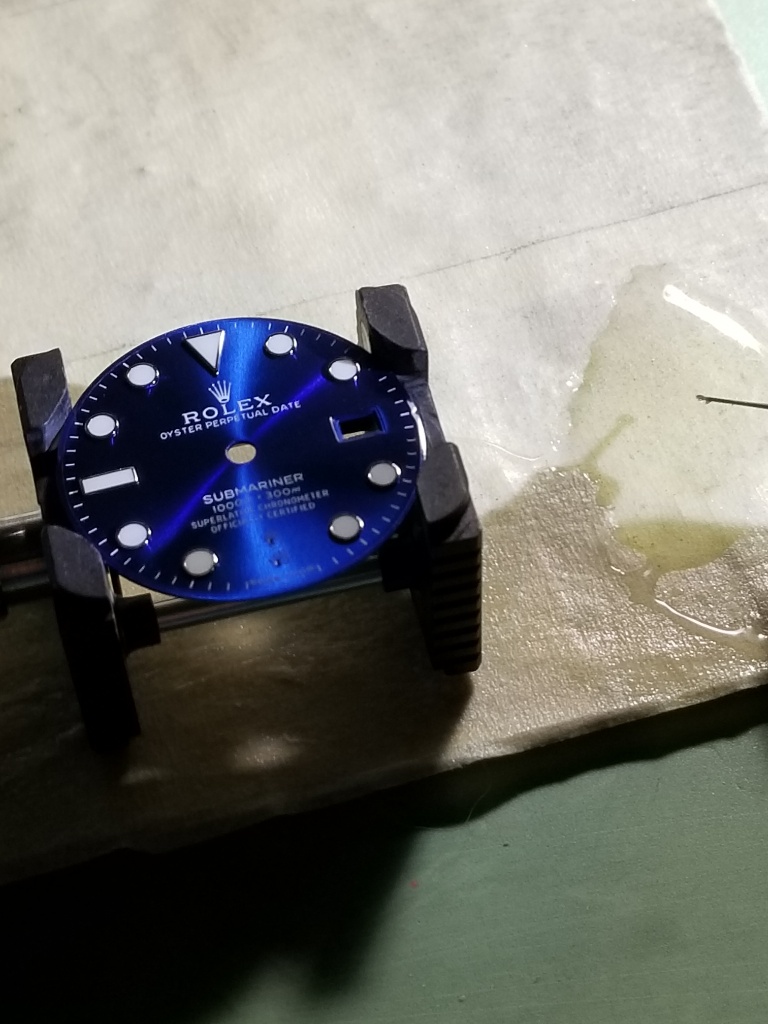

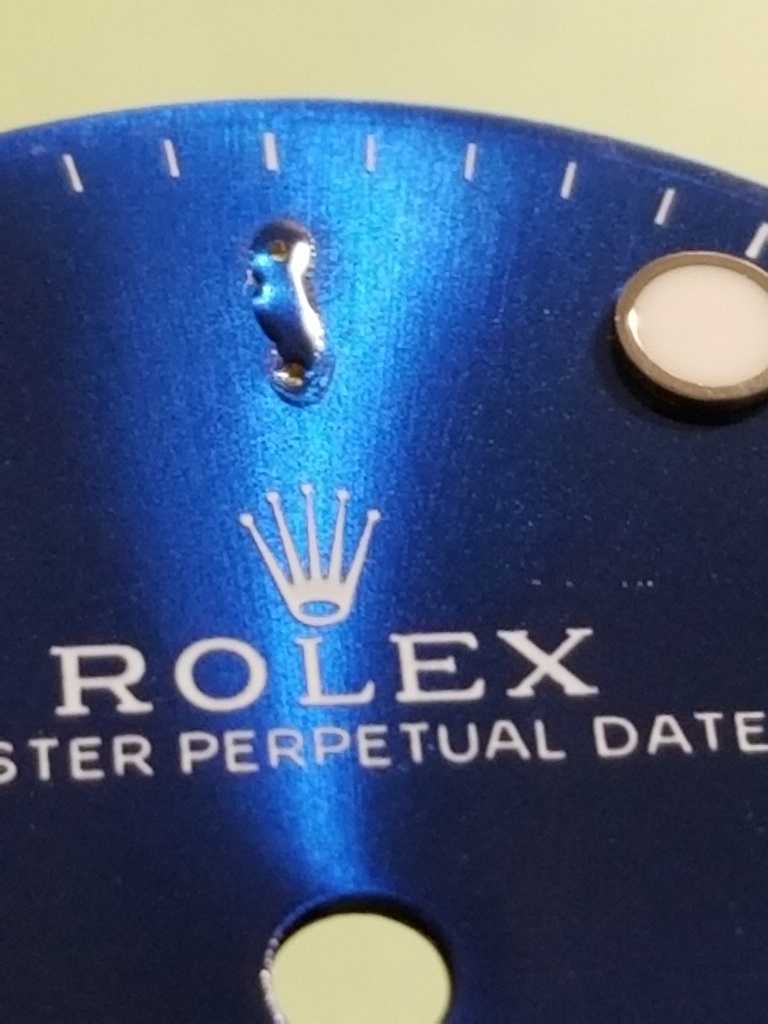

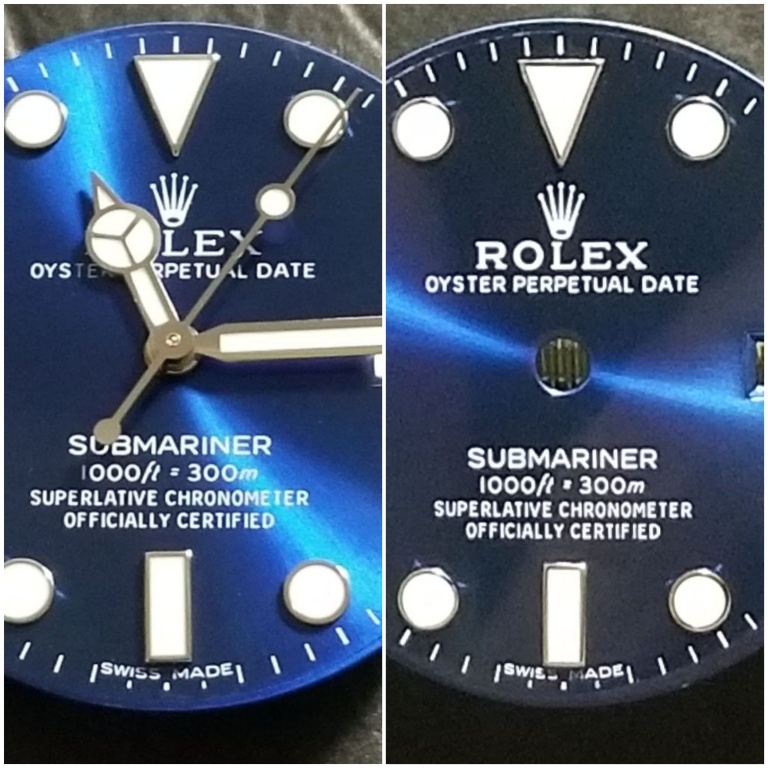

I've never tried it on anything but a smooth glossy dial. It is a polish, so it will make satin or matte finishes shinier. You said a "tiny" bit. If it's all on a plateau of the dial, this could work. If the glue also spans a valley it's probably not the best approach.Thank you for your response. Do you think it would be ok on an AP 15202 dial?

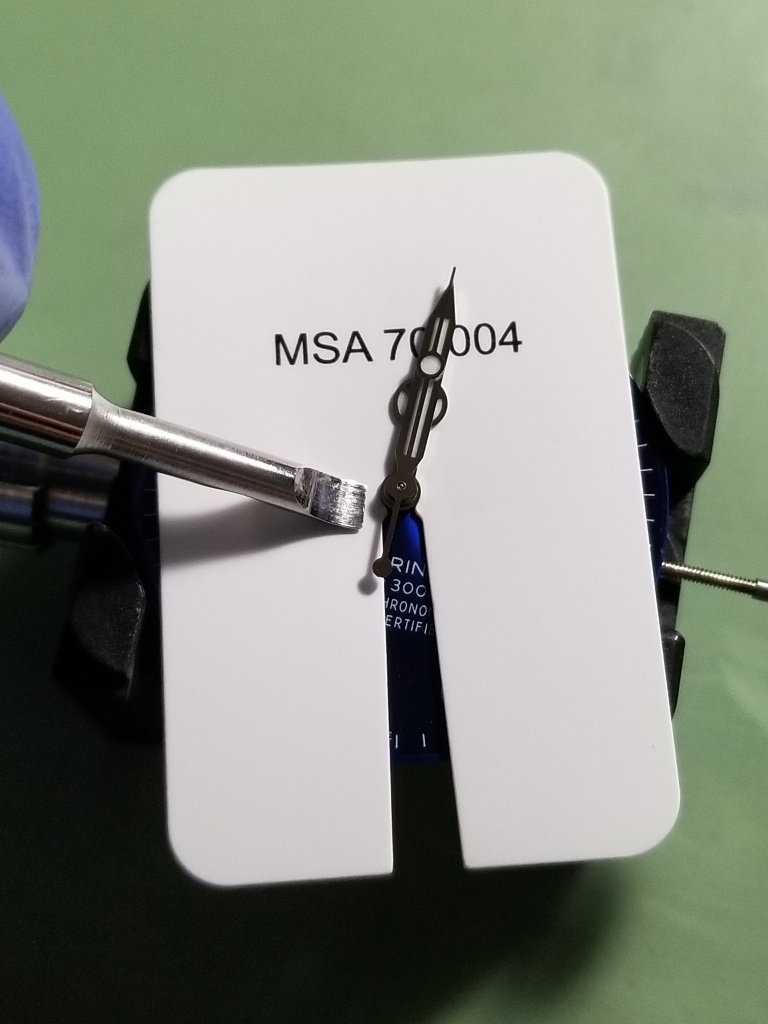

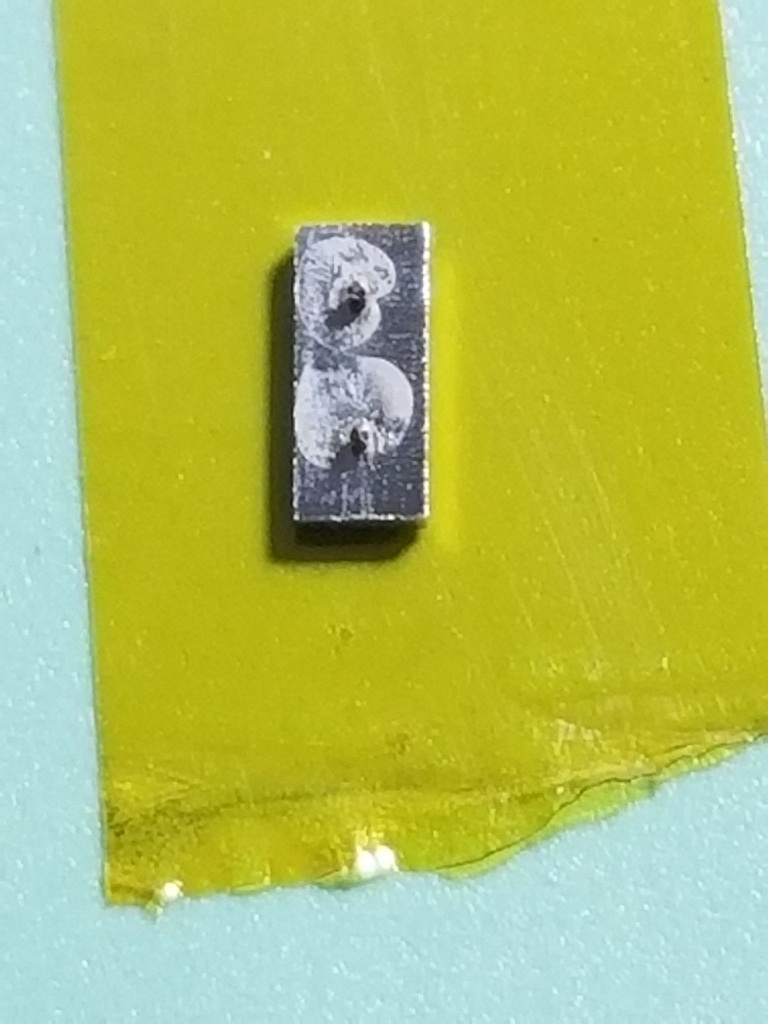

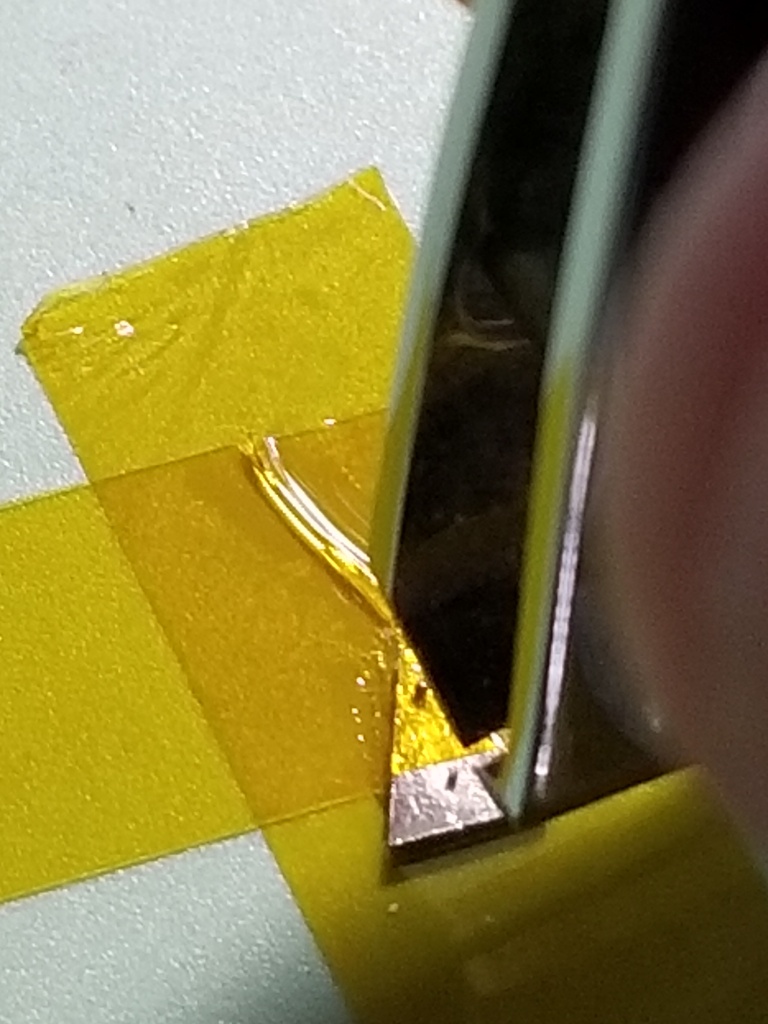

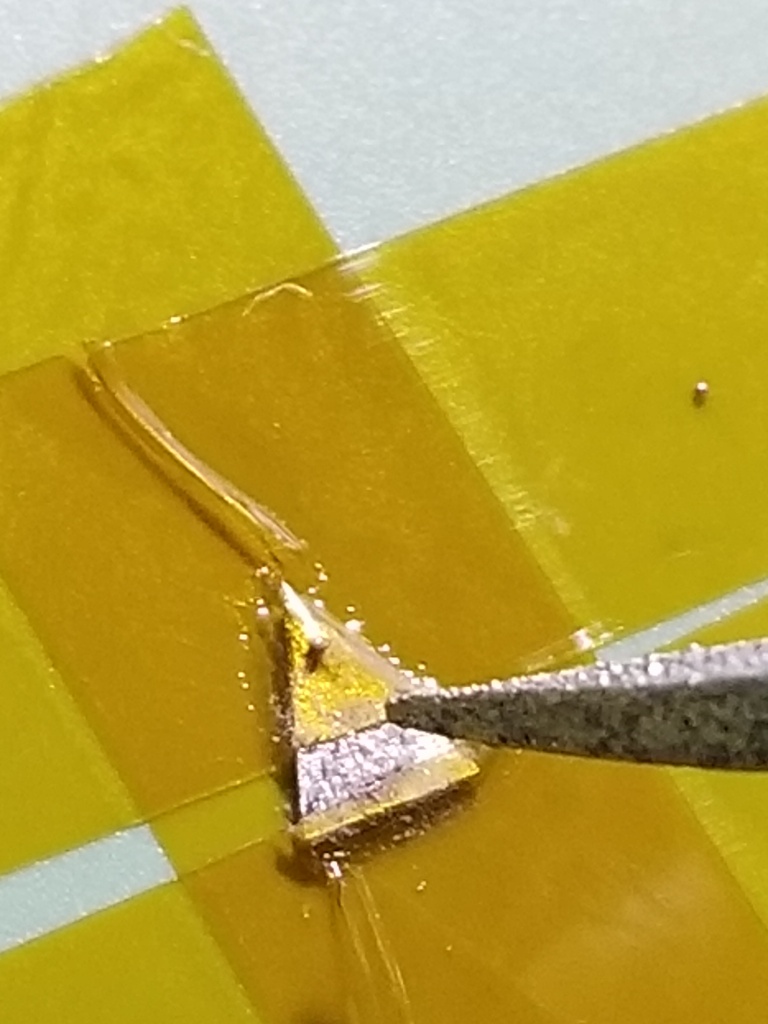

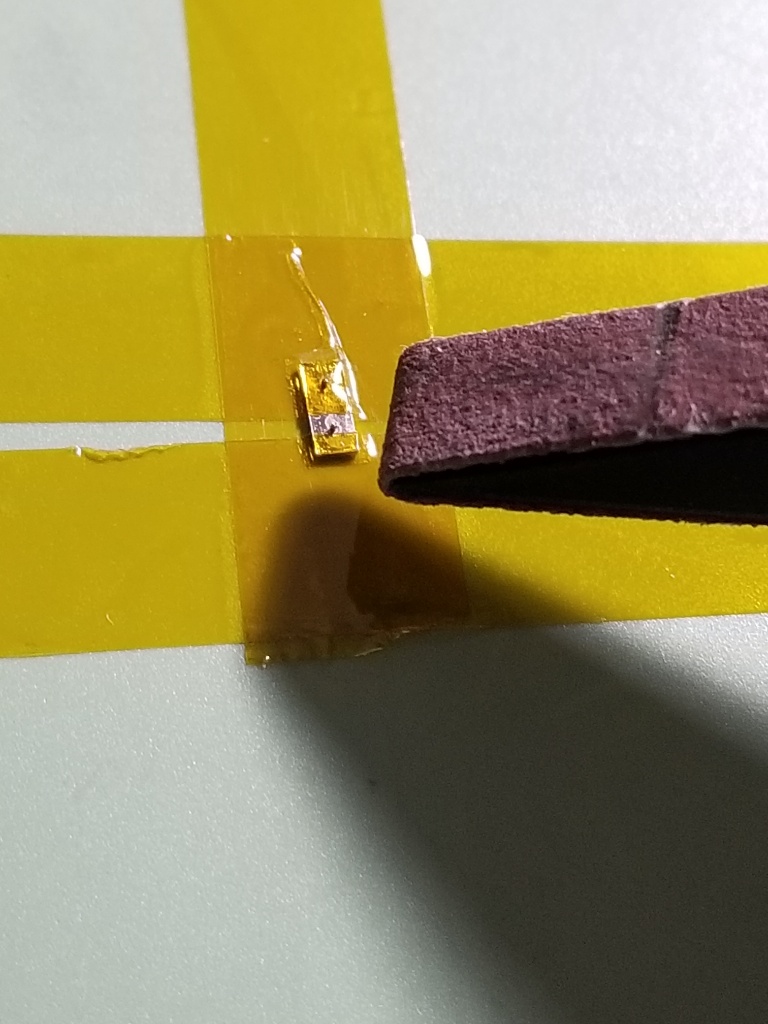

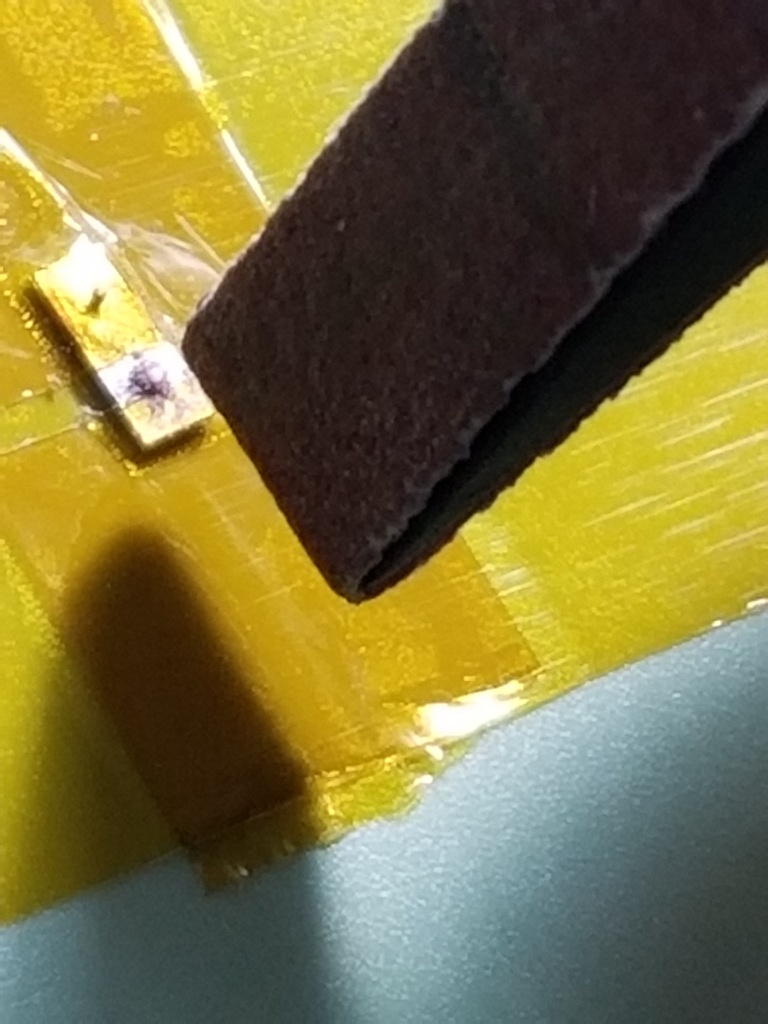

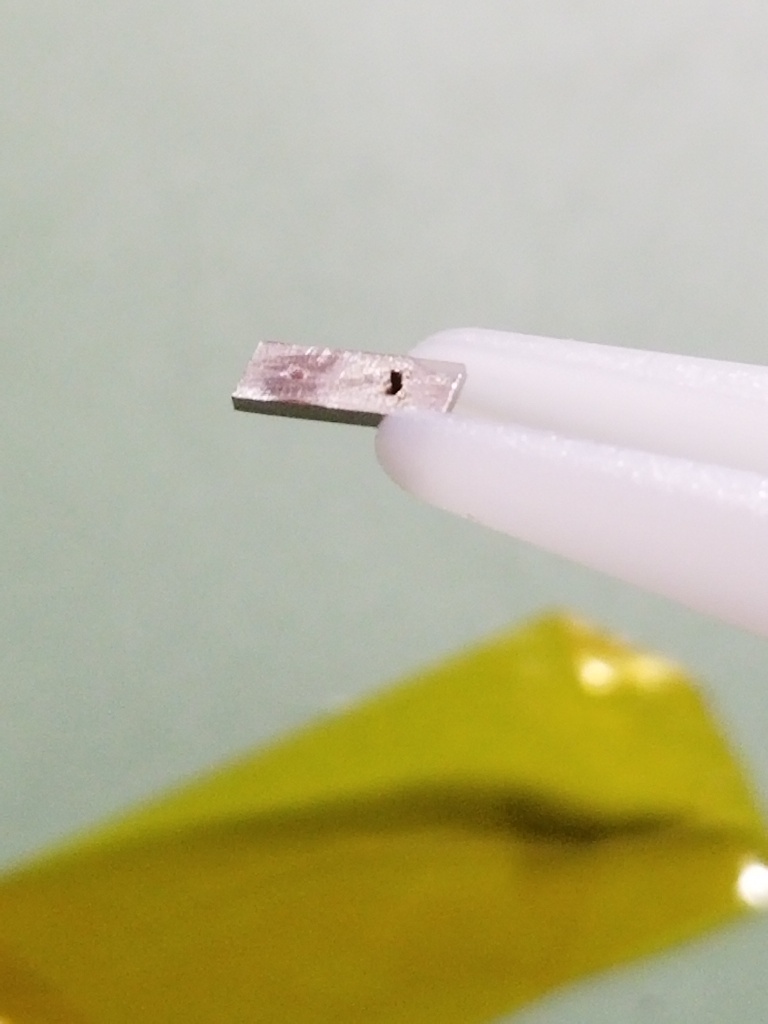

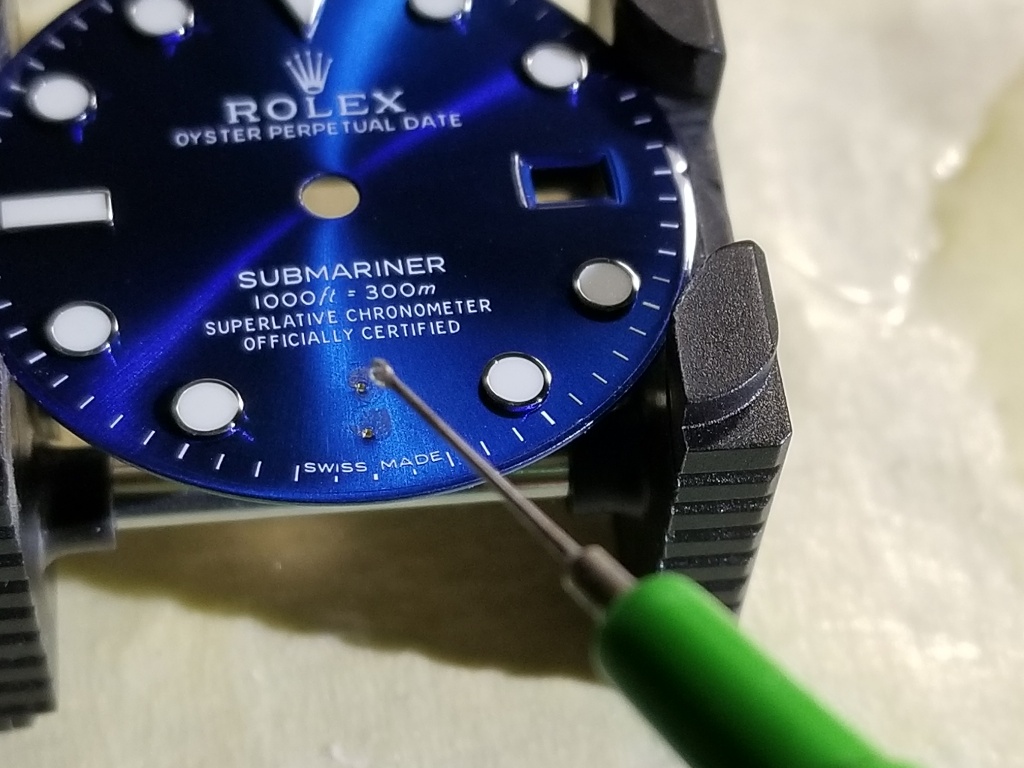

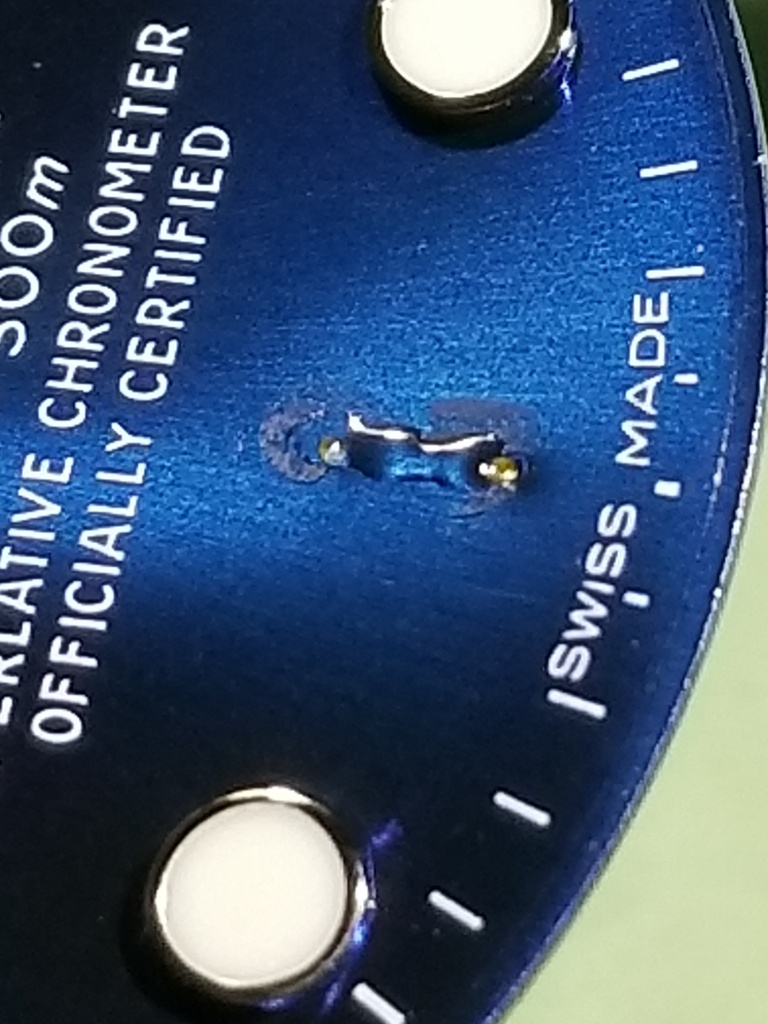

If attempting it, I would rub the glue blob with a tiny backing tool through a wax laden lens cloth. A good candidate for a tool is a post shaped spring bar tool whose diameter is reduced by sanding it down. I made one of these for pressing stem release buttons. The cloth needs to be thick enough so the tool doesn't poke through but thin enough not to rub against surrounding surfaces.

I have removed cured epoxy from a hand (long story how it got there) by gently brushing the blob with a tiny brush slightly damp with Acetone. After the blob softened I was able to pop it loose with a sewing needle point. No damage to the hand from either the Acetone or the needle point.

This kind of approach takes great patience, steady hands and some luck. Acetone is not normally damaging to hands - it's used to remove lume prior to re-luming. But if used on a dial it would have to be used so minimally (on top of the glue blob only) that chances for a removal without detection are pretty low. If I had a junk AP dial I'd love to put a glue blob on a plateau and see what I could do with it but I don't. I think the same technique of rubbing the glue blob with a tiny backing tool through a slightly damp Acetone laden lens cloth could work. Once the blob is sufficiently softened, it can be scraped away with a bevel tip toothpick or pegwood, optimistically without scratching the dial.

Last edited: