-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

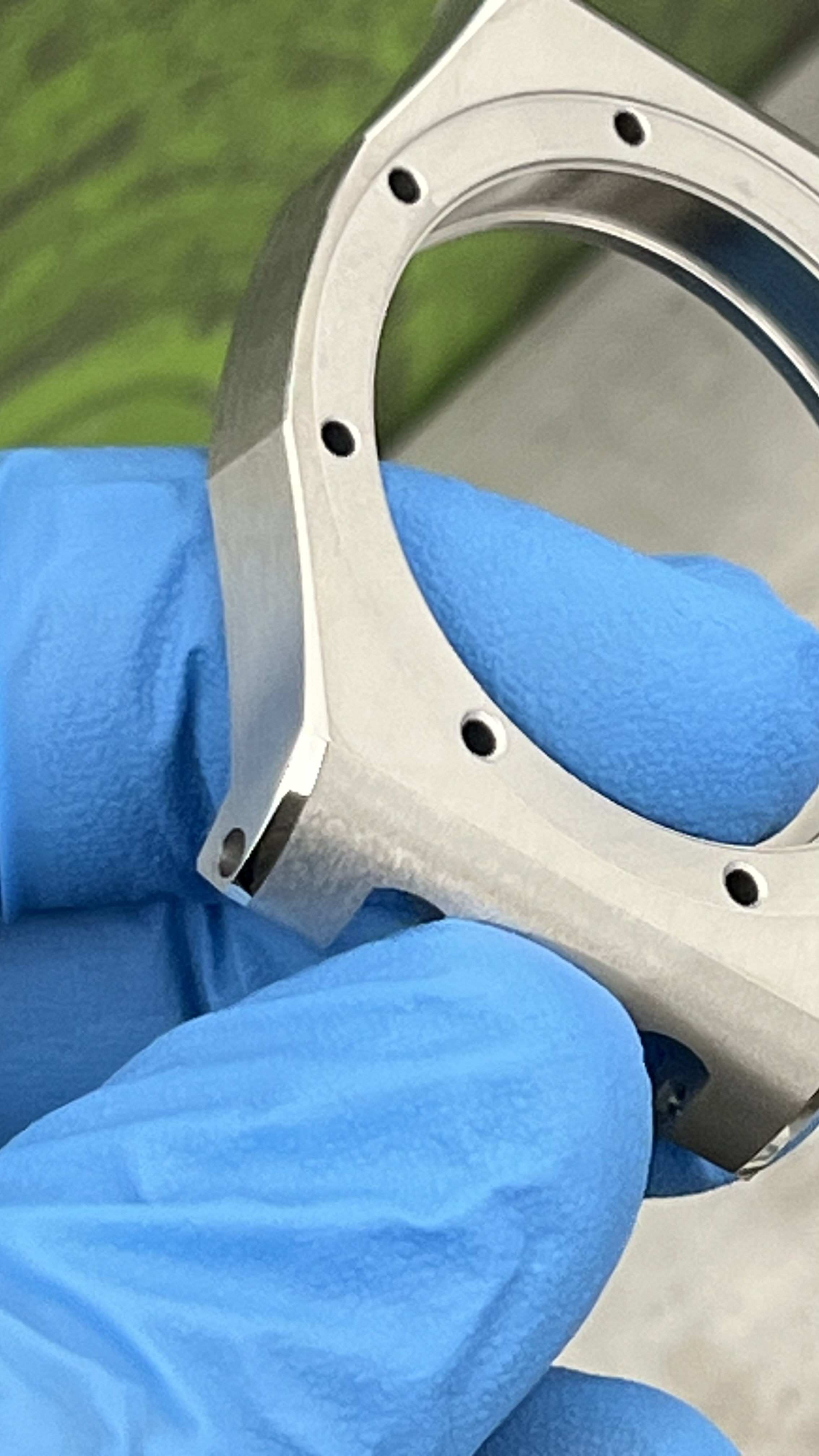

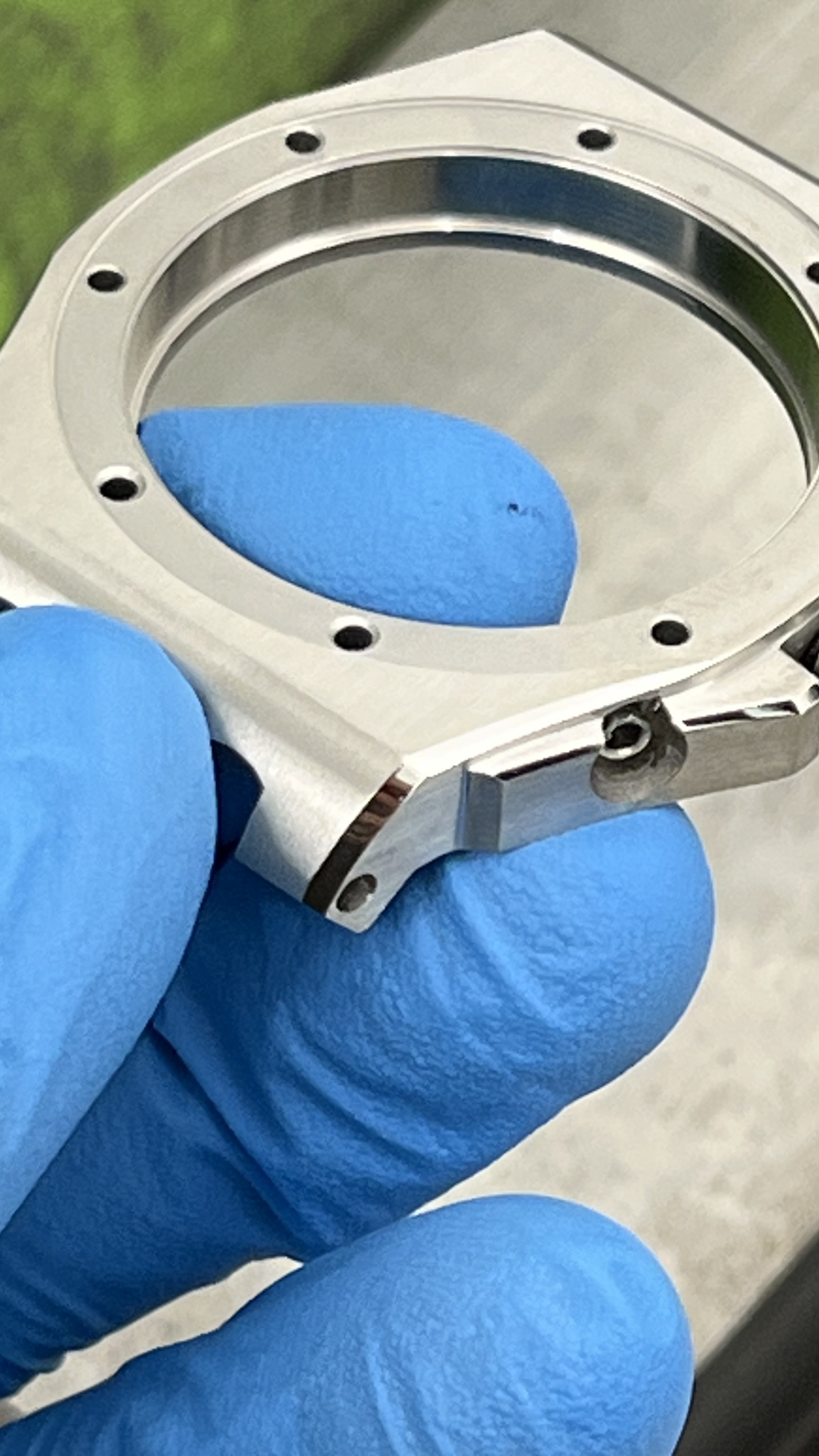

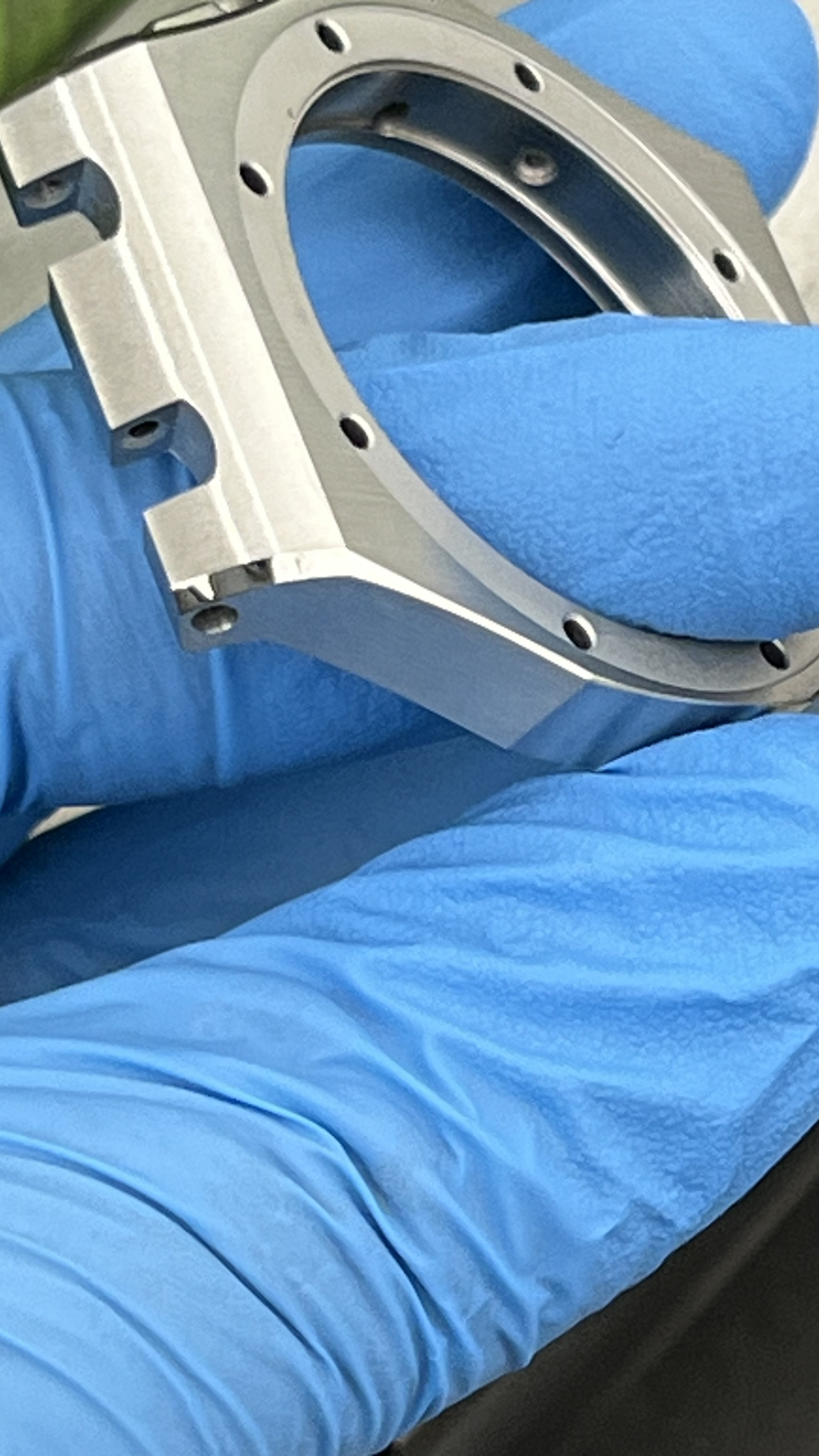

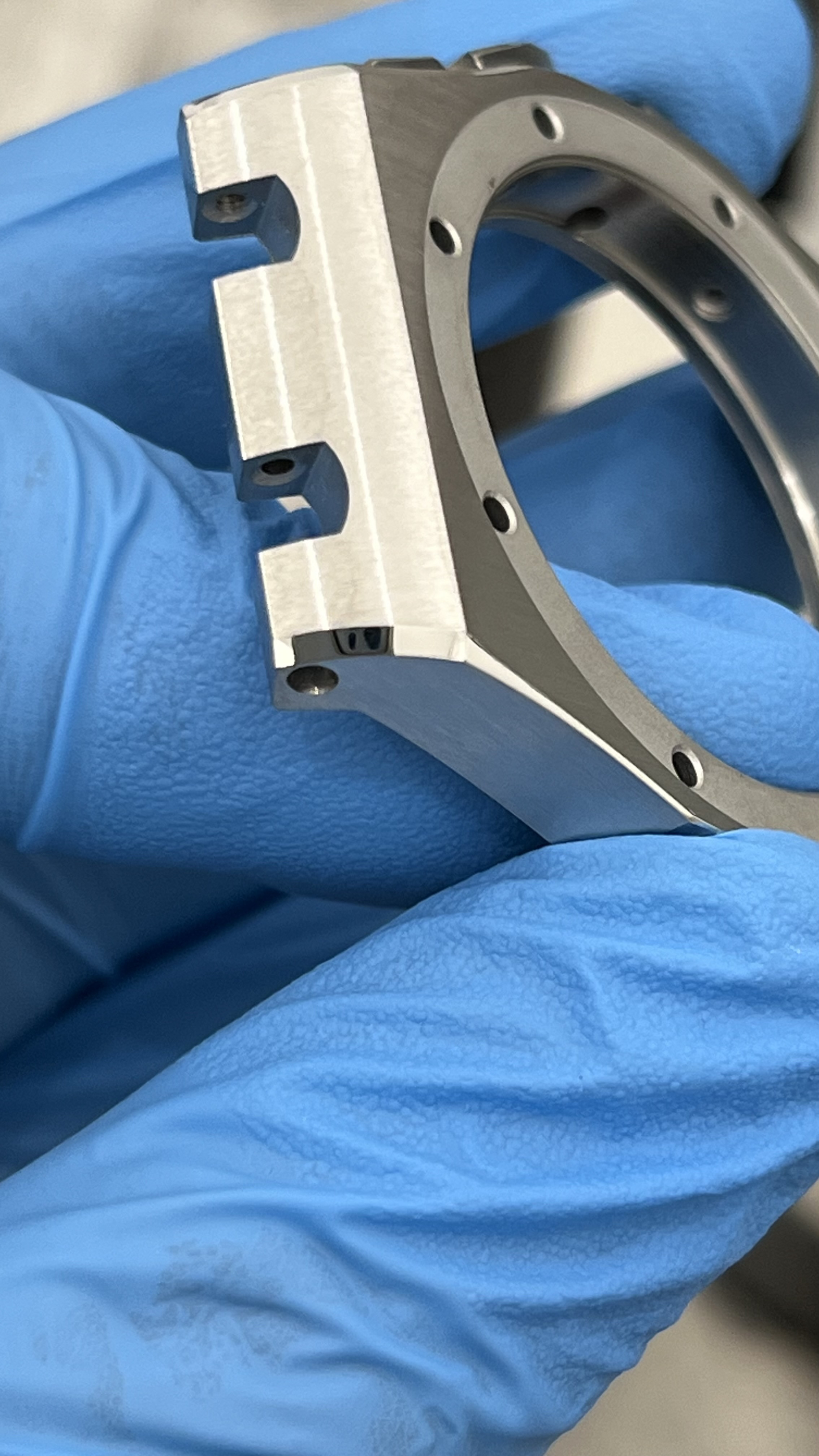

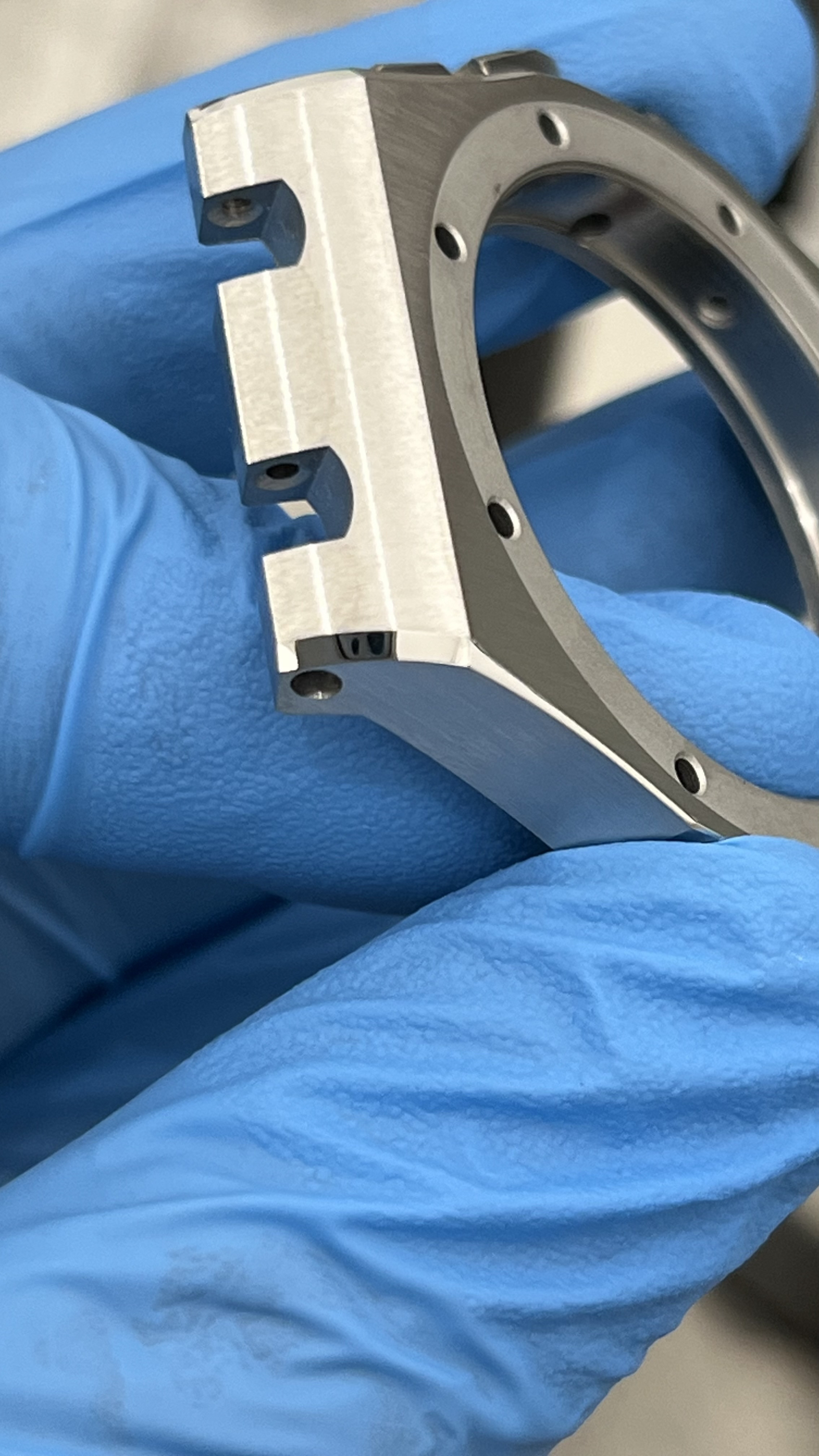

Brushing polishing case AP offshore

- Thread starter Johnny Depp

- Start date

Ludwig79

You're Saying I Can Sell?

Lovely job. Thank you for sharing.

May I ask you which tools, did you use?

I was literally smoothing out some hard edges on a cheap quartz version of a 16202, and I'm quite curious about your approach.

Cheers

L

May I ask you which tools, did you use?

I was literally smoothing out some hard edges on a cheap quartz version of a 16202, and I'm quite curious about your approach.

Cheers

L

I use the lapping machine, sander machine, and by hand with paper in some corners.Lovely job. Thank you for sharing.

May I ask you which tools, did you use?

I was literally smoothing out some hard edges on a cheap quartz version of a 16202, and I'm quite curious about your approach.

Cheers

L

Ludwig79

You're Saying I Can Sell?

Thank you for the quick reply!

For guitar polishing I normally start at 400 grit and I stop at 1500 or 2000 if I want to have a matt finish.

I use polishing compound if I want to achieve a gloss polished final result instead.

Yesterday, while working on my Oak rep I was using 320 to smooth (and re- shape) some details on the links and bracelet, and then using some pads and steel wool to keep the brushing finish similar to how the rep came from the TD.

May I ask you which grit(s) or polishing pads or steel wool you used here?

In a sense, I noticed that the brushing on the Oak seems a bit stronger or coarser than the brushed finish that I see on my nautilus rep made by @legend

Also, I noticed in a few AP and PP videos that watchmakers use thin wooden stick or small batons to support sand paper or polishing pads, and I tried that and indeed it helps to achieve a good regular finish.

Thanks a lot again

L

For guitar polishing I normally start at 400 grit and I stop at 1500 or 2000 if I want to have a matt finish.

I use polishing compound if I want to achieve a gloss polished final result instead.

Yesterday, while working on my Oak rep I was using 320 to smooth (and re- shape) some details on the links and bracelet, and then using some pads and steel wool to keep the brushing finish similar to how the rep came from the TD.

May I ask you which grit(s) or polishing pads or steel wool you used here?

In a sense, I noticed that the brushing on the Oak seems a bit stronger or coarser than the brushed finish that I see on my nautilus rep made by @legend

Also, I noticed in a few AP and PP videos that watchmakers use thin wooden stick or small batons to support sand paper or polishing pads, and I tried that and indeed it helps to achieve a good regular finish.

Thanks a lot again

L

AP and Patek have different surface finishings. The AP brushing is typically coarser and more visual whereas the Patek one is softer and more refined.Thank you for the quick reply!

For guitar polishing I normally start at 400 grit and I stop at 1500 or 2000 if I want to have a matt finish.

I use polishing compound if I want to achieve a gloss polished final result instead.

Yesterday, while working on my Oak rep I was using 320 to smooth (and re- shape) some details on the links and bracelet, and then using some pads and steel wool to keep the brushing finish similar to how the rep came from the TD.

May I ask you which grit(s) or polishing pads or steel wool you used here?

In a sense, I noticed that the brushing on the Oak seems a bit stronger or coarser than the brushed finish that I see on my nautilus rep made by @legend

Also, I noticed in a few AP and PP videos that watchmakers use thin wooden stick or small batons to support sand paper or polishing pads, and I tried that and indeed it helps to achieve a good regular finish.

Thanks a lot again

L

For AP, there are also different types of brushing employed for different models and also watches sent in for service typically come out looking different as the additional brushing is done along the existing finish instead of having them polished off and redone.

ExactlyAP and Patek have different surface finishings. The AP brushing is typically coarser and more visual whereas the Patek one is softer and more refined.

For AP, there are also different types of brushing employed for different models and also watches sent in for service typically come out looking different as the additional brushing is done along the existing finish instead of having them polished off and redone.

- 19/11/16

- 754

- 83

- 28

Hi @Johnny Depp

I like it so much, what a job !

I think my AP collection will soon fly to Italy

Ludwig79

You're Saying I Can Sell?

I had the same feeling.AP and Patek have different surface finishings. The AP brushing is typically coarser and more visual whereas the Patek one is softer and more refined.

For AP, there are also different types of brushing employed for different models and also watches sent in for service typically come out looking different as the additional brushing is done along the existing finish instead of having them polished off and redone.

If I take the 16202 as reference, would you be able to suggest the grit of sand paper or steel wool to use to achieve that effect?

No hard feelings if you prefer not to share this information. I'm not attempting to become a modder overnight, I'm just trying to expand my knowledge and skills.

Cheers

L