-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Black Dial Stainless Steel Tag Heuer Carrera Chronograph 43mm

- Thread starter SSTEEL

- Start date

Actually the bracelet is very nice gen-like. I have a gen owned by a friend to compare. Only the SEL that is really not correct. The shiny part on SEL shouldbe the same as on the links i.e. like an individual piece. On the rep shiny part on SEL is round/tubular instead of flat.

I will be carrying a side by side photo comparison between the rep, and gen Tag Heuer Carrera bracelets, as like you say, the rep is pretty close, but want to highlight more likes/tells etc.

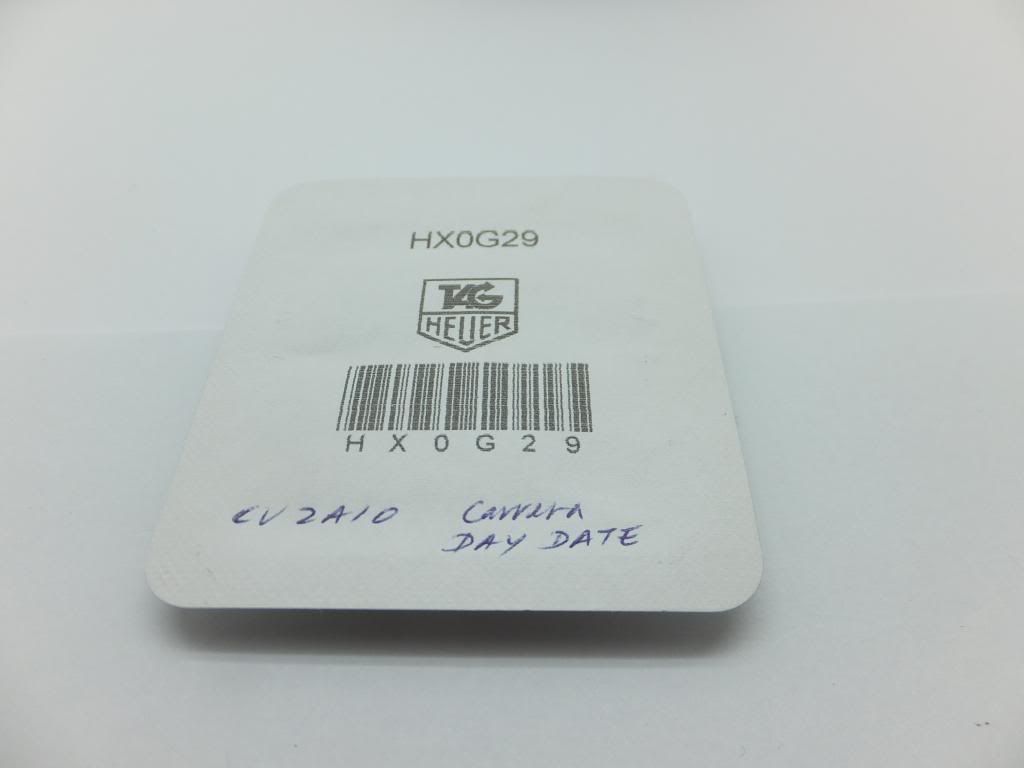

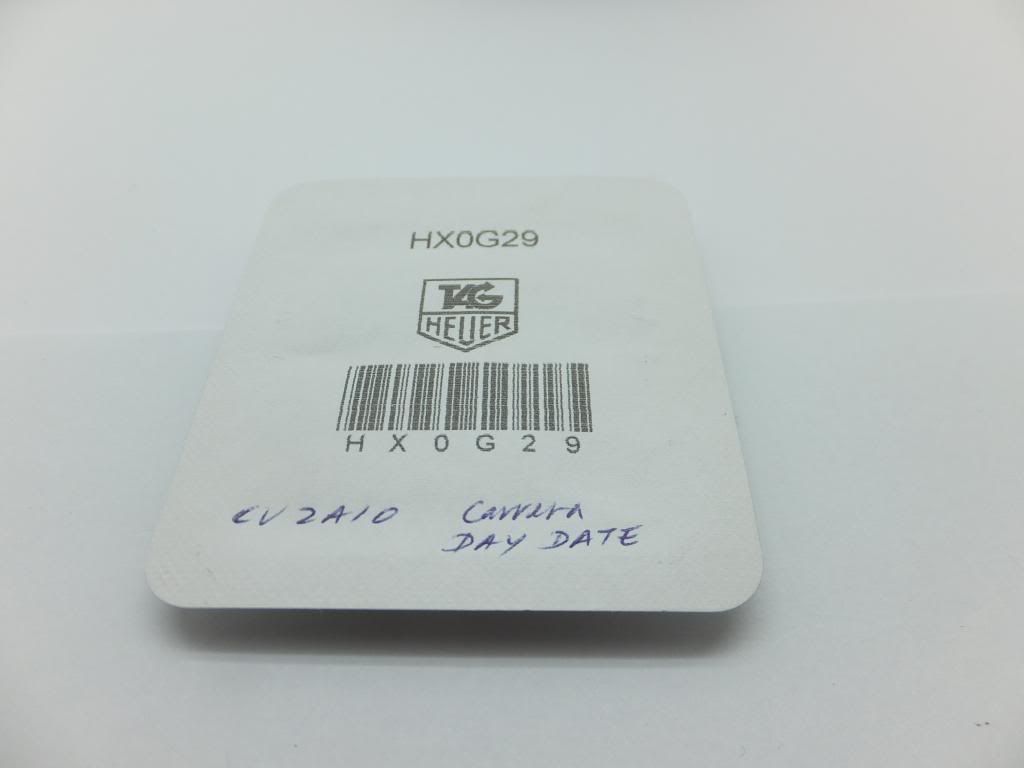

Well no turning back now. Just dropped this lot on my gen parts which are being shipped out to me tomorrow.

Well, not quite the full amount above on gen parts, some of it has gone for my TC Sub LV Type II with DWO V3, and Canon Pinion 4

Regarding the franken build, I will keep all progress updates within this thread, however, for the up and coming side by side comparisons I plan to do (Gen Vs Rep) parts, I will start new threads within the Tag Heuer sub forum to serve reference to RWI members just like I did with the Gen vs Rep carrera bracelets.

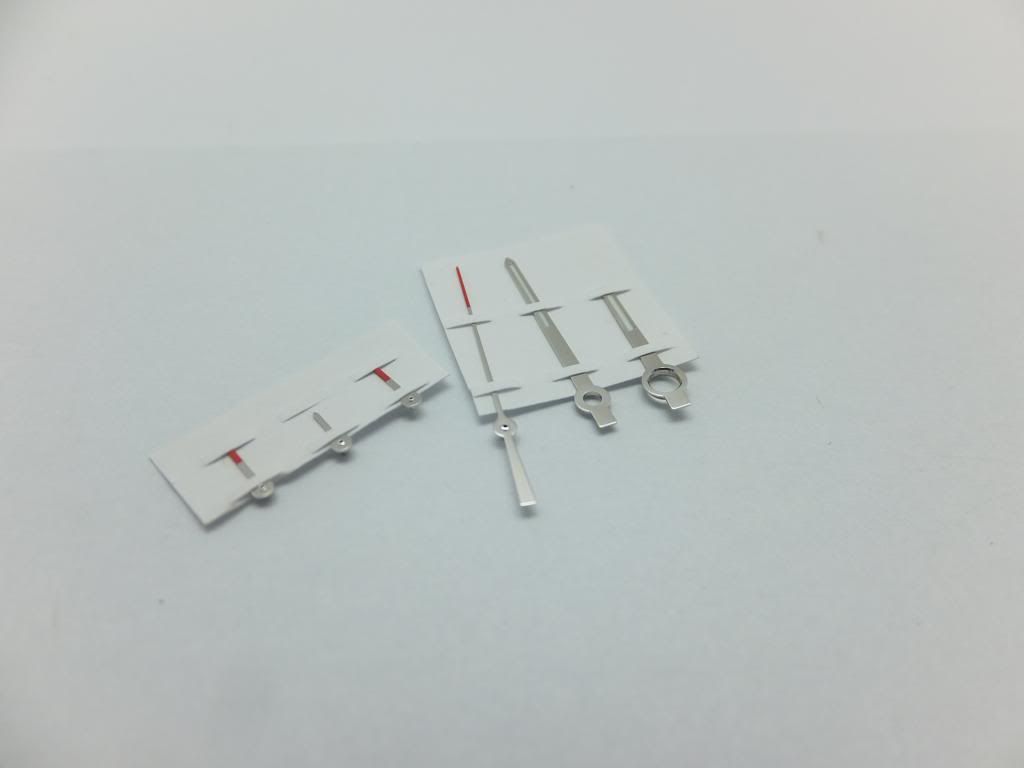

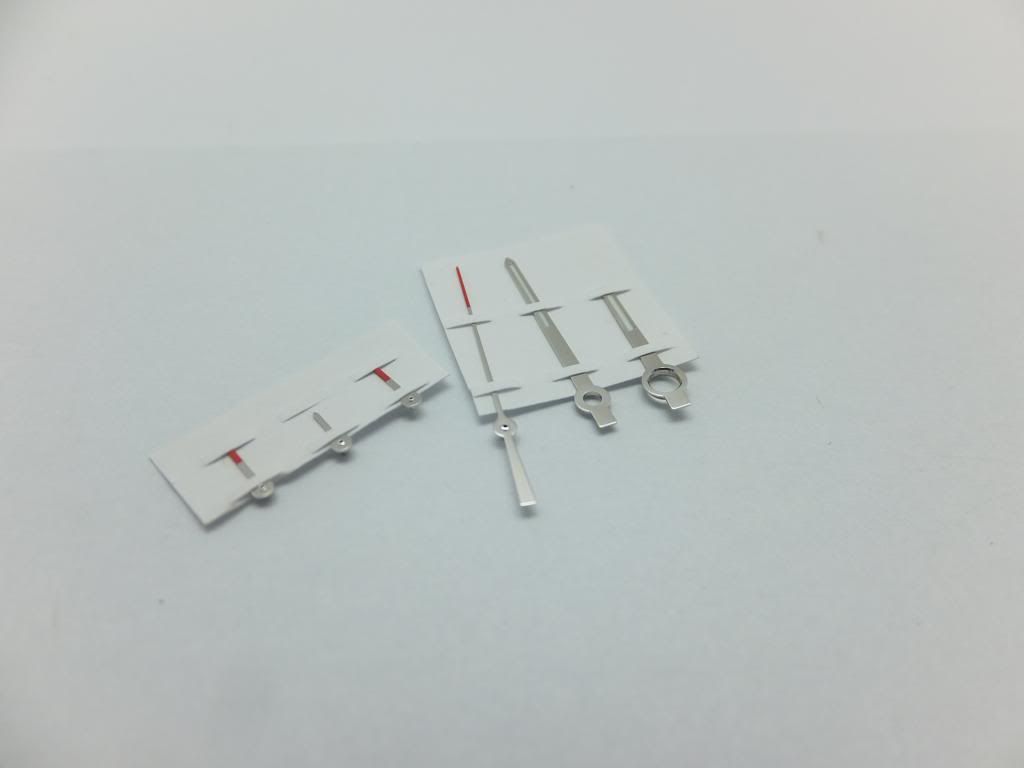

Some Gen parts eye candy heading my way tomorrow

Well, not quite the full amount above on gen parts, some of it has gone for my TC Sub LV Type II with DWO V3, and Canon Pinion 4

Regarding the franken build, I will keep all progress updates within this thread, however, for the up and coming side by side comparisons I plan to do (Gen Vs Rep) parts, I will start new threads within the Tag Heuer sub forum to serve reference to RWI members just like I did with the Gen vs Rep carrera bracelets.

Some Gen parts eye candy heading my way tomorrow

Wow indeed.

I'm still thinking about replacing the dial in mine. I did a small picture comparison today and I must say that it's a real damn good rep dial in this TAG rep. Not flawless of course but really close to gen. Look:

SSTEEL, do you think that it's the easy swap with the dials? I mean will the gen dial fit perfectly to a rep case and movement?

I'm still thinking about replacing the dial in mine. I did a small picture comparison today and I must say that it's a real damn good rep dial in this TAG rep. Not flawless of course but really close to gen. Look:

SSTEEL, do you think that it's the easy swap with the dials? I mean will the gen dial fit perfectly to a rep case and movement?

Wow indeed.

I'm still thinking about replacing the dial in mine.

SSTEEL, do you think that it's the easy swap with the dials? I mean will the gen dial fit perfectly to a rep case and movement?

From chatting to a couple of other modders of this model, the gen movement/dial/hands should all fit into the rep case. The only things that are unknown at this point is the gen crown and pushers, but I will find out soon enough

razorblade

I'm Pretty Popular

- 18/8/12

- 1,156

- 1

- 0

Good luck mate! I'll be waiting to see the end results. :cheers:From chatting to a couple of other modders of this model, the gen movement/dial/hands should all fit into the rep case. The only things that are unknown at this point is the gen crown and pushers, but I will find out soon enoughIf they do fit, then this puppy could well be water proof too! But of course I will be testing for this before I fit the ETA movement.

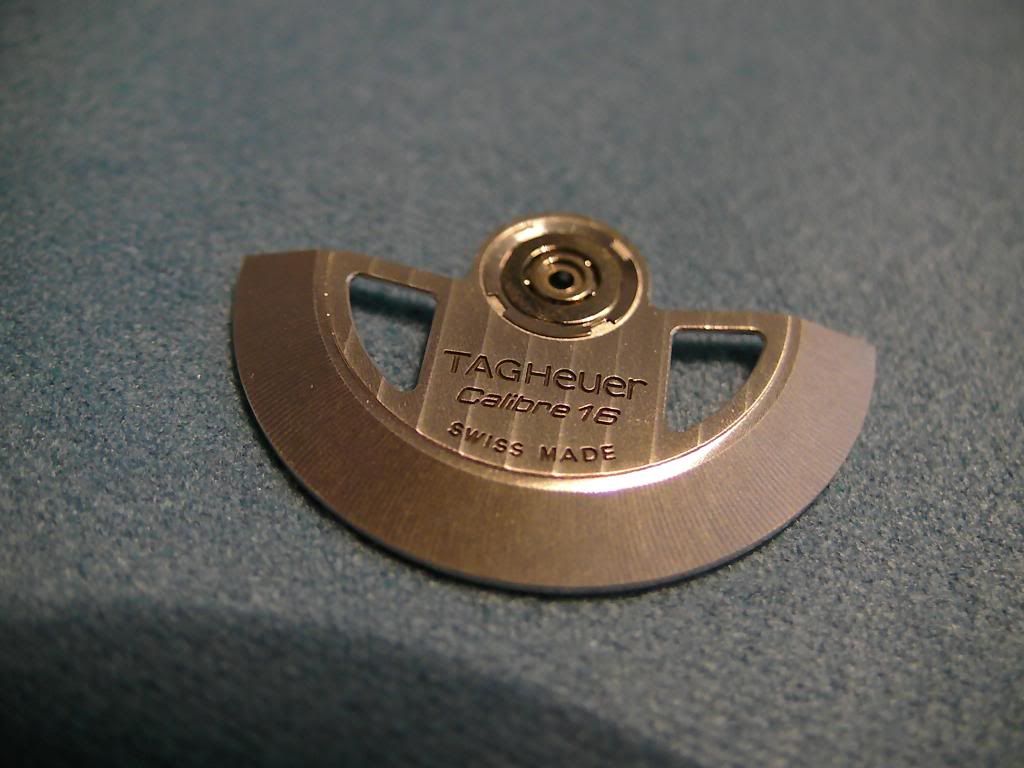

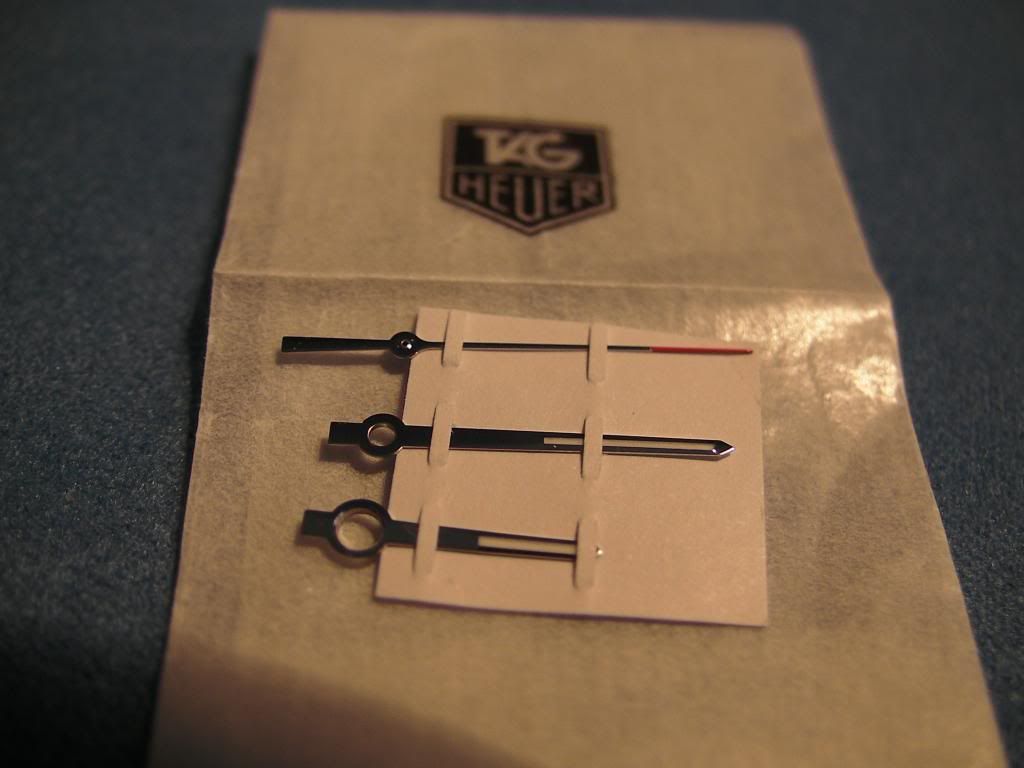

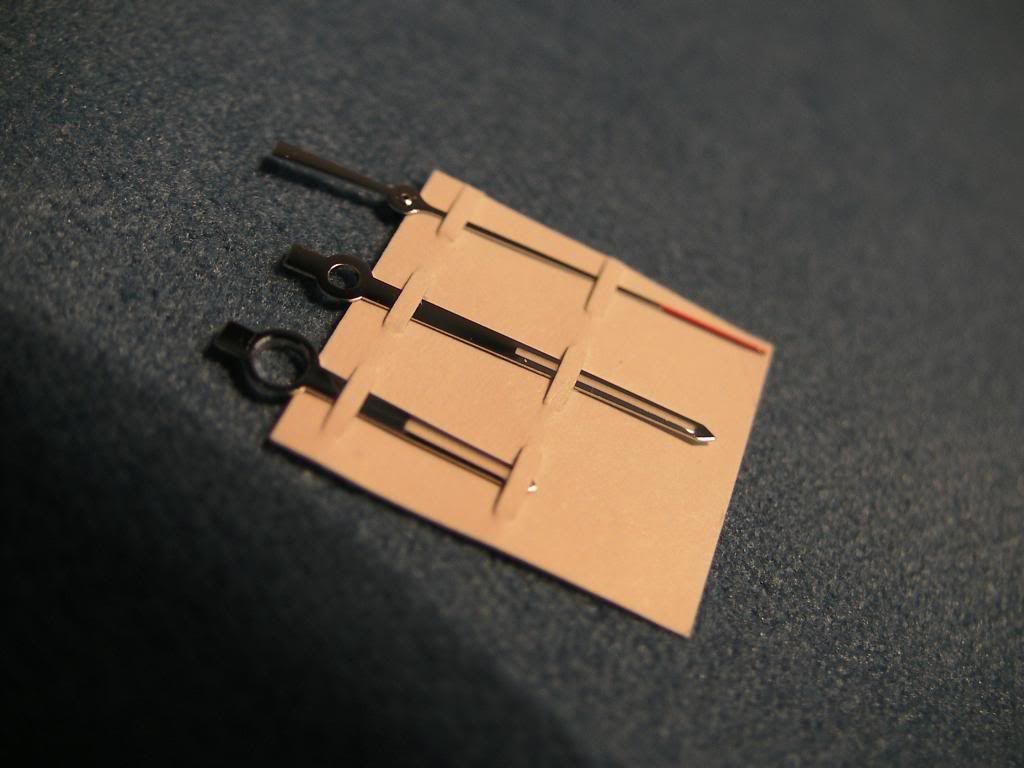

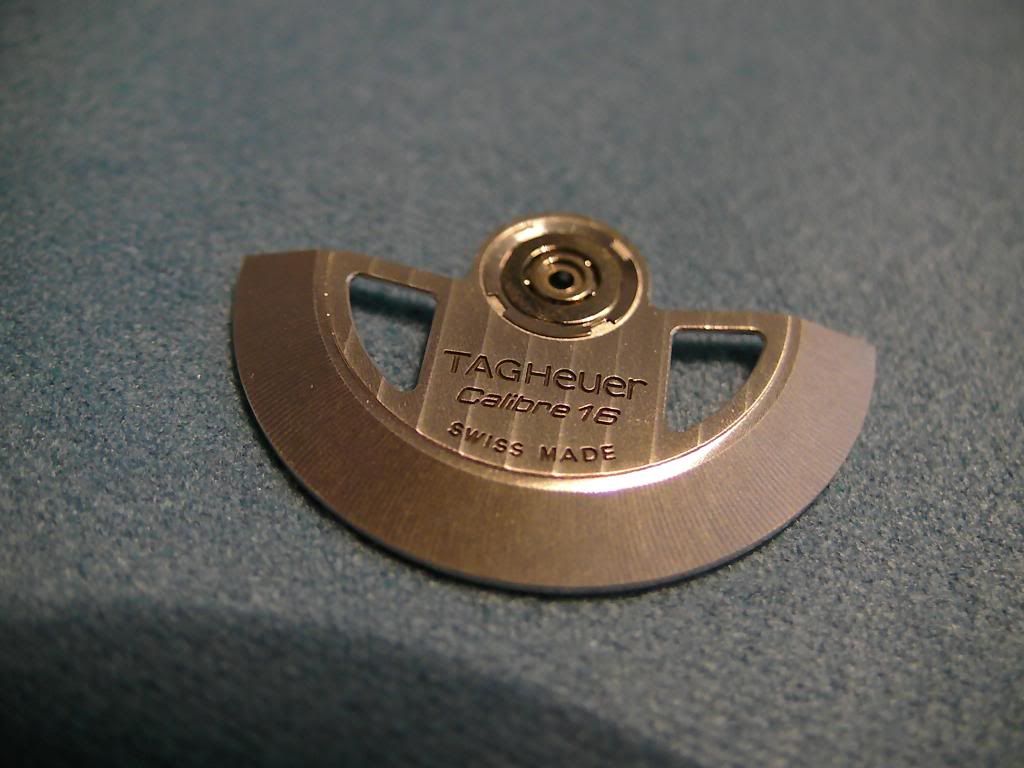

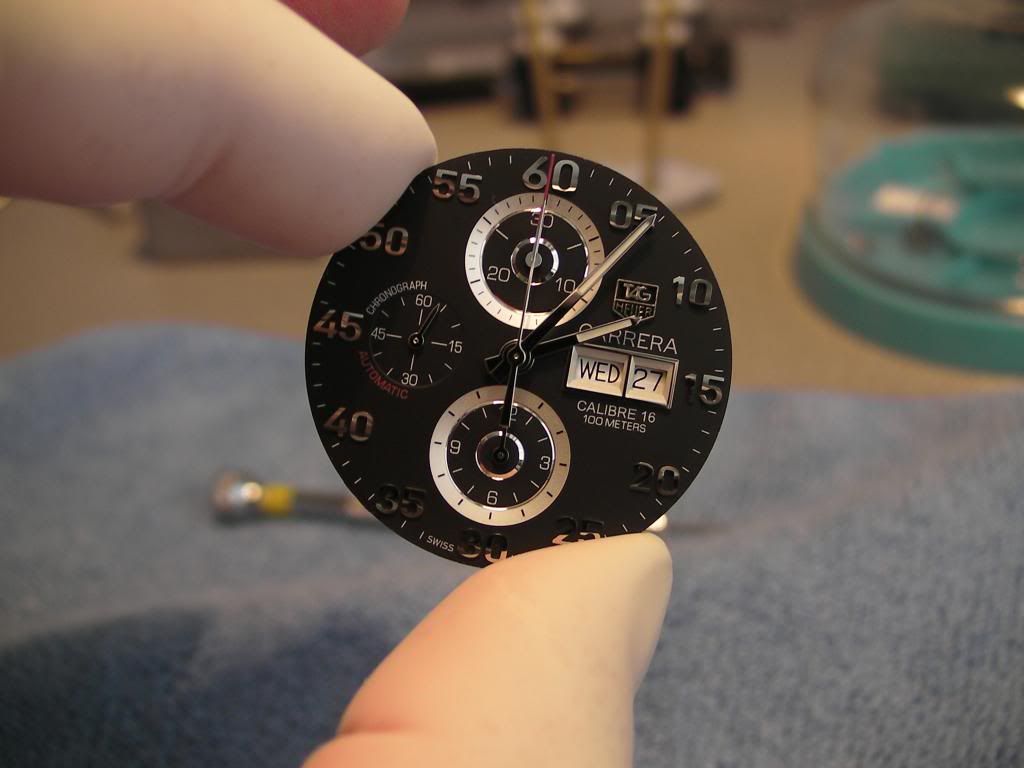

Ok, grabbed just a few photos/eye candy for you all of the gen parts. Put the kettle on

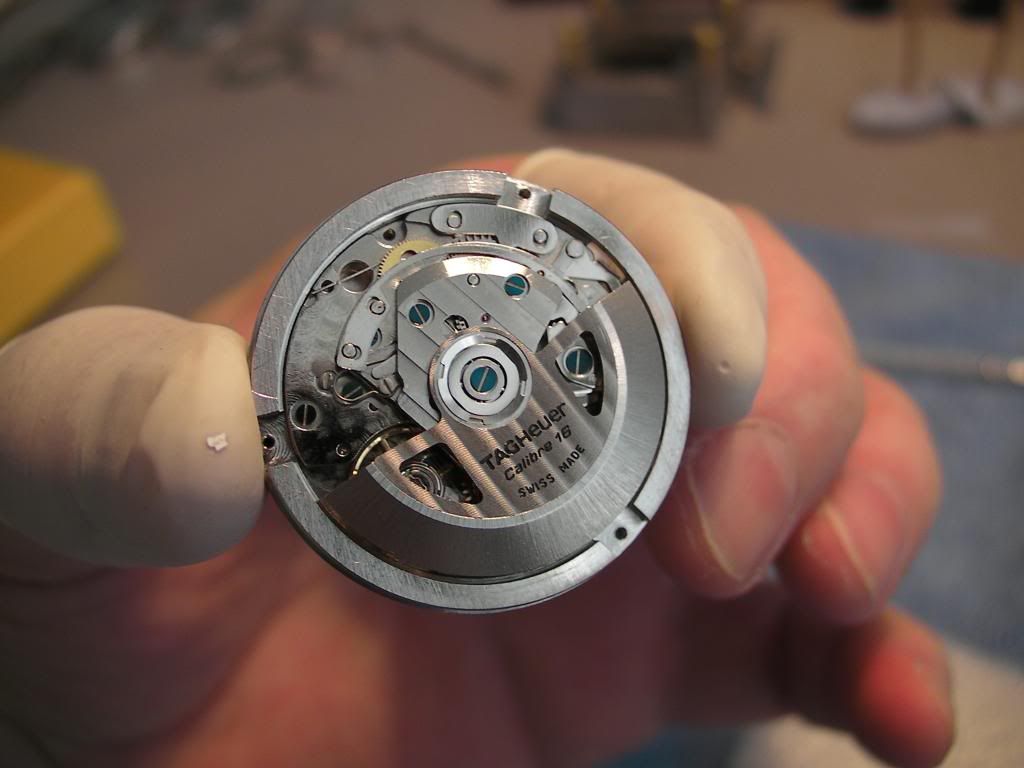

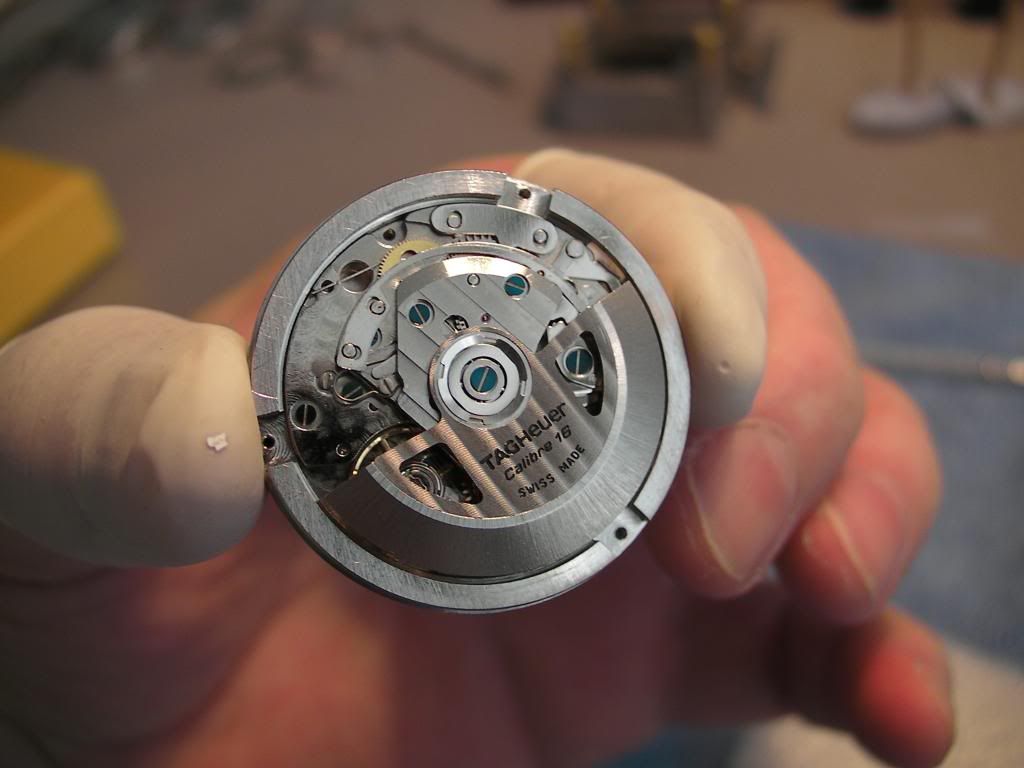

And now onto the heart. a genuine Swiss ETA 7750 movement..

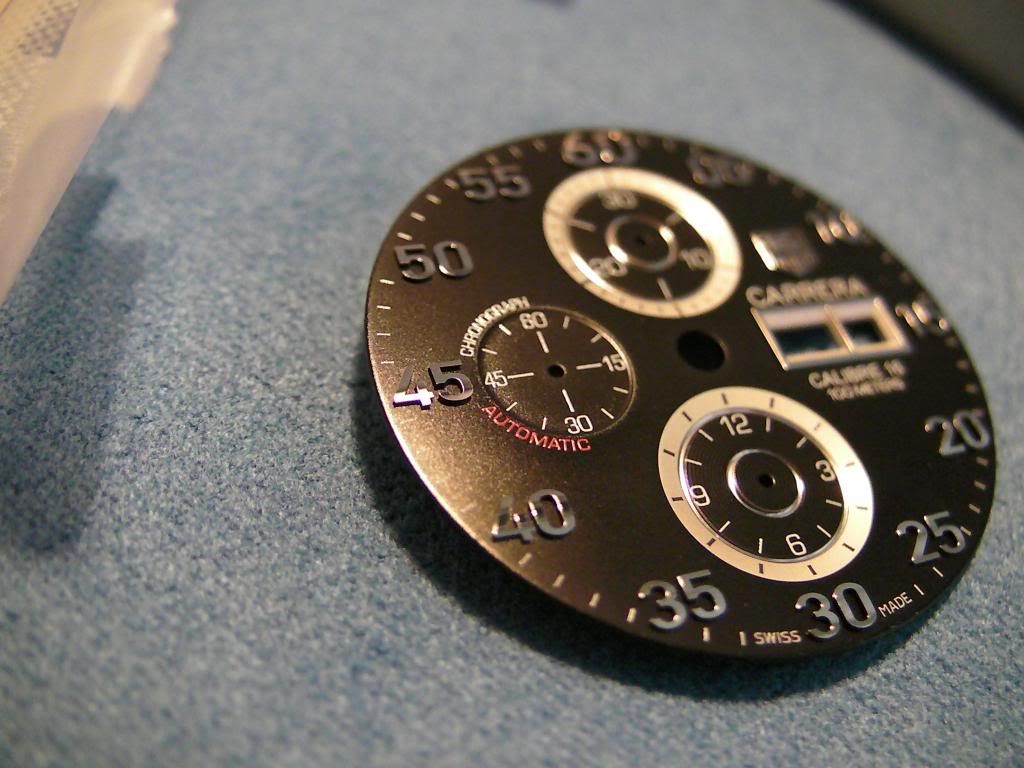

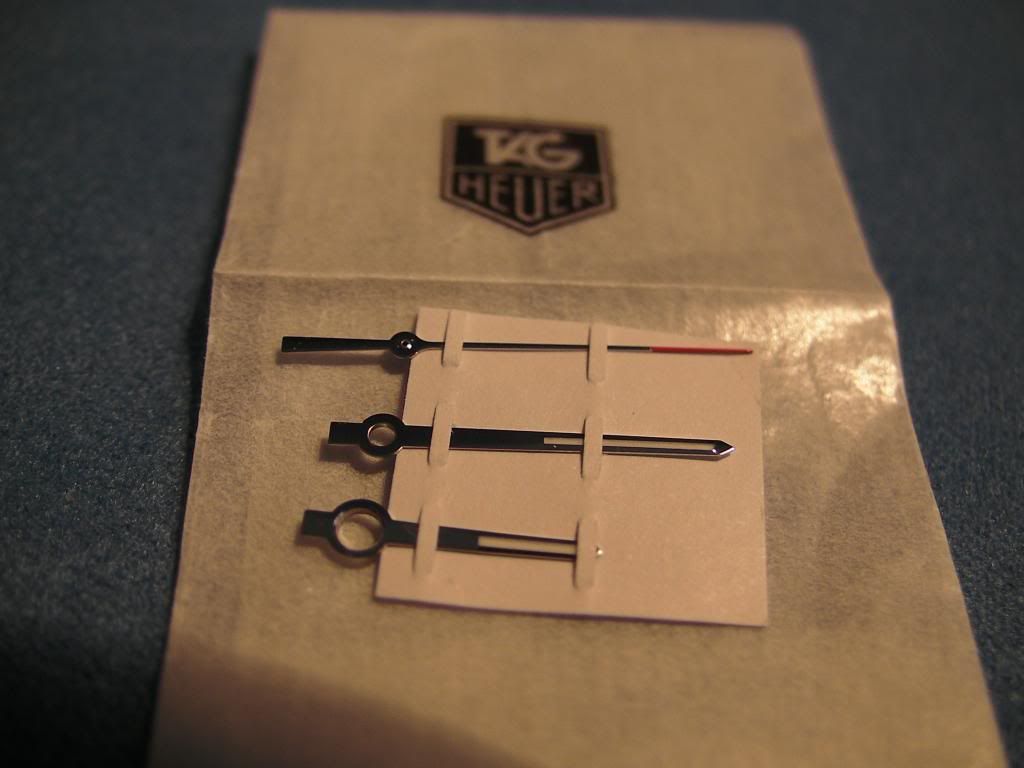

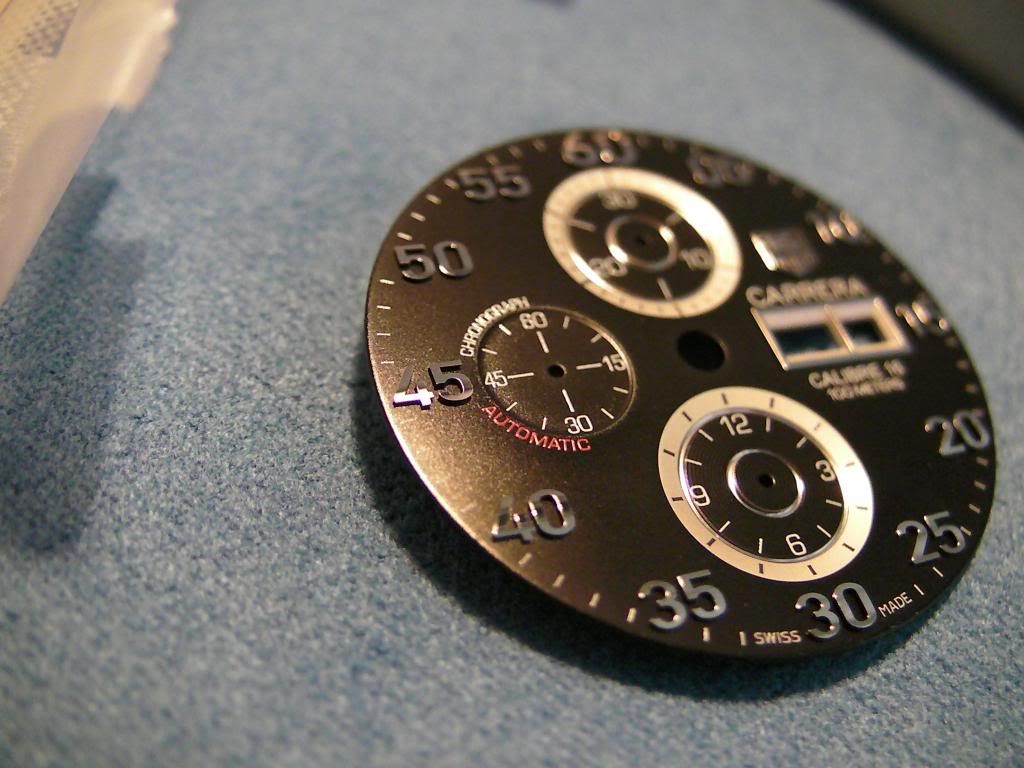

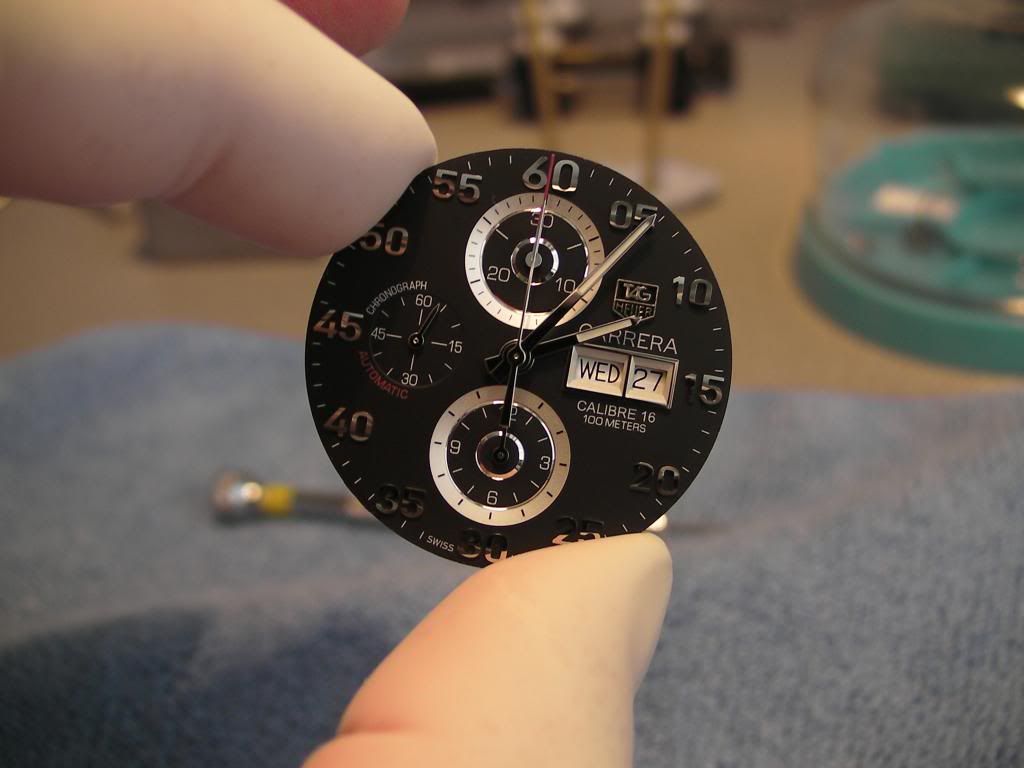

Now onto the gen dial..

Quick photo of the rep dial, and TAG badge

Reset rep pusher

Start rep pusher

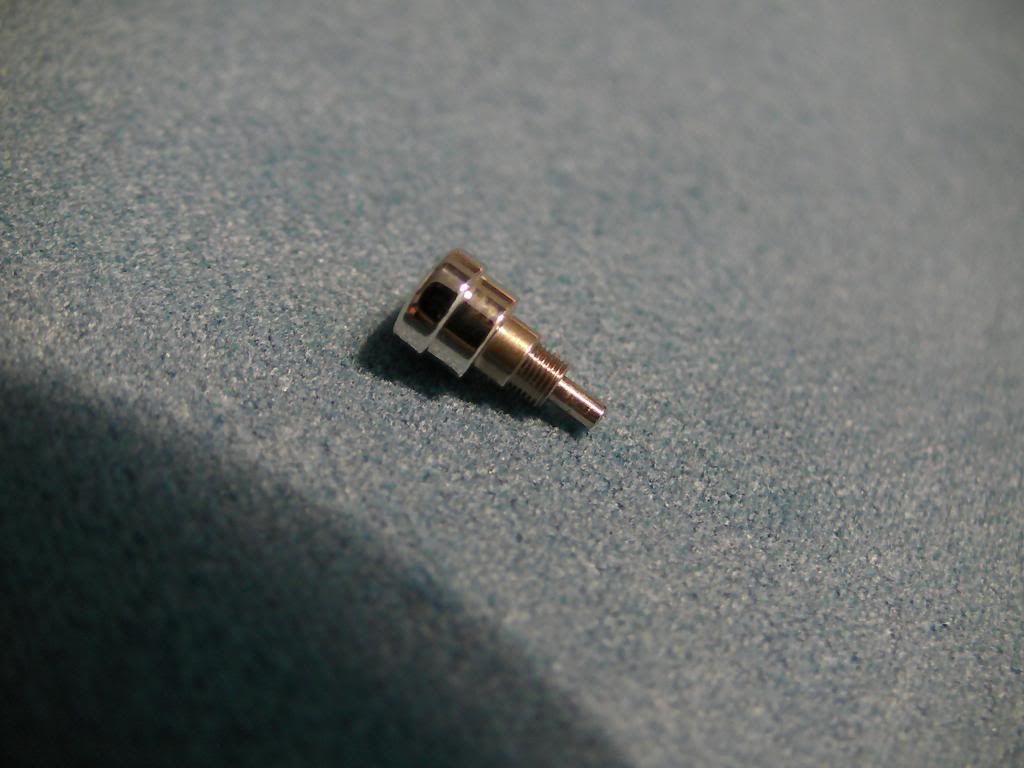

Rep crown

Asian 7750

I will get side by side comparison photos which will have their own threads in the Tag Heuer section as and when I carry out the transplant.

And now onto the heart. a genuine Swiss ETA 7750 movement..

Now onto the gen dial..

Quick photo of the rep dial, and TAG badge

Reset rep pusher

Start rep pusher

Rep crown

Asian 7750

I will get side by side comparison photos which will have their own threads in the Tag Heuer section as and when I carry out the transplant.

Ssteel, and what are you going to do with the crystal? Leave it as it is?

I think that although there is a colourless AR in the latest batch instead of blueish it's still far from a gen effect. It's difficult to catch but something's wrong with it. What do you think?

I think that although there is a colourless AR in the latest batch instead of blueish it's still far from a gen effect. It's difficult to catch but something's wrong with it. What do you think?

Leaving it as it is for now as its pretty much spot on, so too is the rep chapter ring.

I will still keep my eyes open for gen crystal, and chapter ring though, and if I can get a good deal, including gaskets, I may as well get these too.

Found these aftermarket crystals on eBay..

http://www.ebay.co.uk/sch/i.html?_t...=Tag+Heuer+Carrera+crystal&_sacat=0&_from=R40

I will contact my supplier out of curiosity on price for gen.

My supplier sells the gen crystal for $250

I will still keep my eyes open for gen crystal, and chapter ring though, and if I can get a good deal, including gaskets, I may as well get these too.

Found these aftermarket crystals on eBay..

http://www.ebay.co.uk/sch/i.html?_t...=Tag+Heuer+Carrera+crystal&_sacat=0&_from=R40

I will contact my supplier out of curiosity on price for gen.

My supplier sells the gen crystal for $250

Leaving it as it is for now as its pretty much spot on, so too is the rep chapter ring.

I will still keep my eyes open for gen crystal, and chapter ring though, and if I can get a good deal, including gaskets, I may as well get these too.

Found these aftermarket crystals on eBay..

http://www.ebay.co.uk/sch/i.html?_t...=Tag+Heuer+Carrera+crystal&_sacat=0&_from=R40

I will contact my supplier out of curiosity on price for gen.

My supplier sells the gen crystal for $250

Steel, that ebay thing is not sapphire, its mineral and no AR. I bought that once and got them AR coated to FineDD, when he's still around. His colorless AR give a purple (not blue) tinge on mineral, its on my day date carrera ATM. Quite nice but set me almost in shipping + coating $100-ish.

Gen is the way to go I suppose, but not sure it fits rep case correctly. If that timebymail is gen spec, then gen would fit, although not very tight. Still no AR, mind you.

Had a bit of spare time today, so started on the Carrera frankening work, but today I only wanted to remove movement to inspect the pushers construction to see if they were gen like, but sadly they are not, so I will not be able to use my gen pushers in this project, but no problem. I will buy a cheap quartz model to experiment on further with the pushers, so alls not lost yet.

Onto the photos..

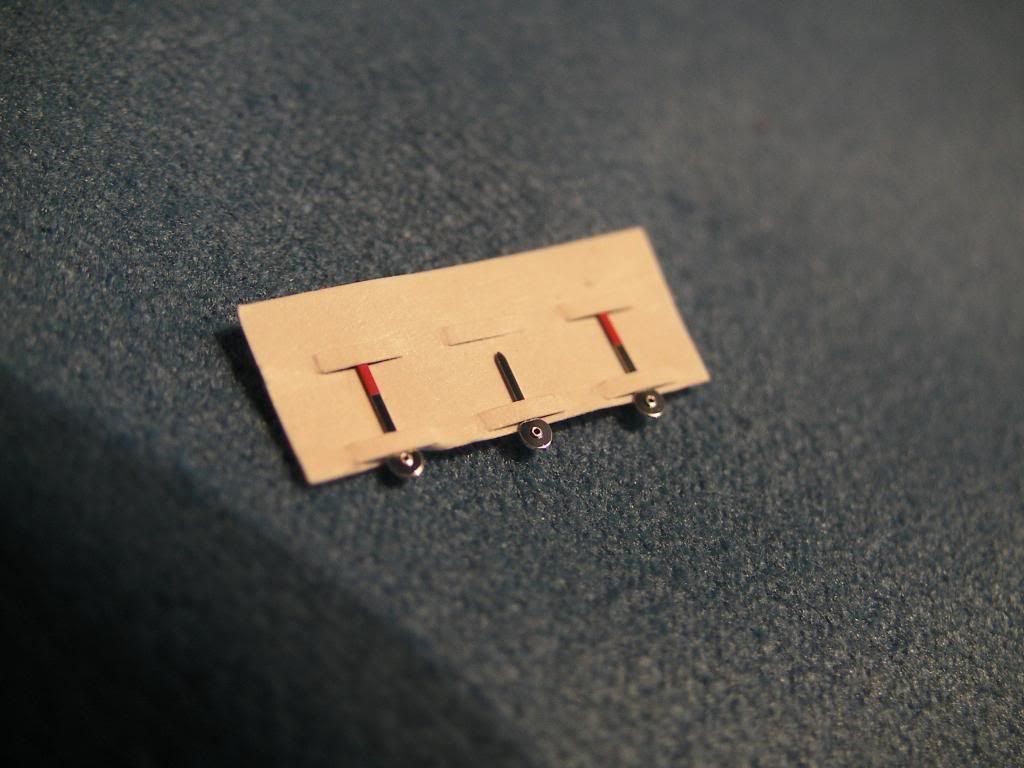

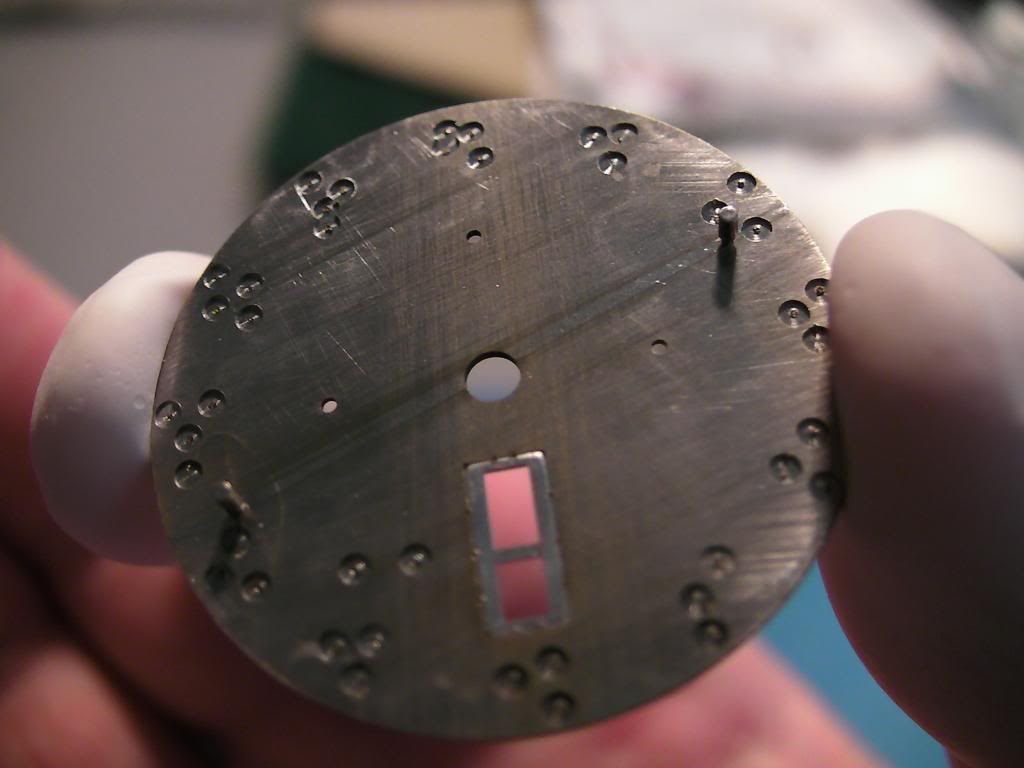

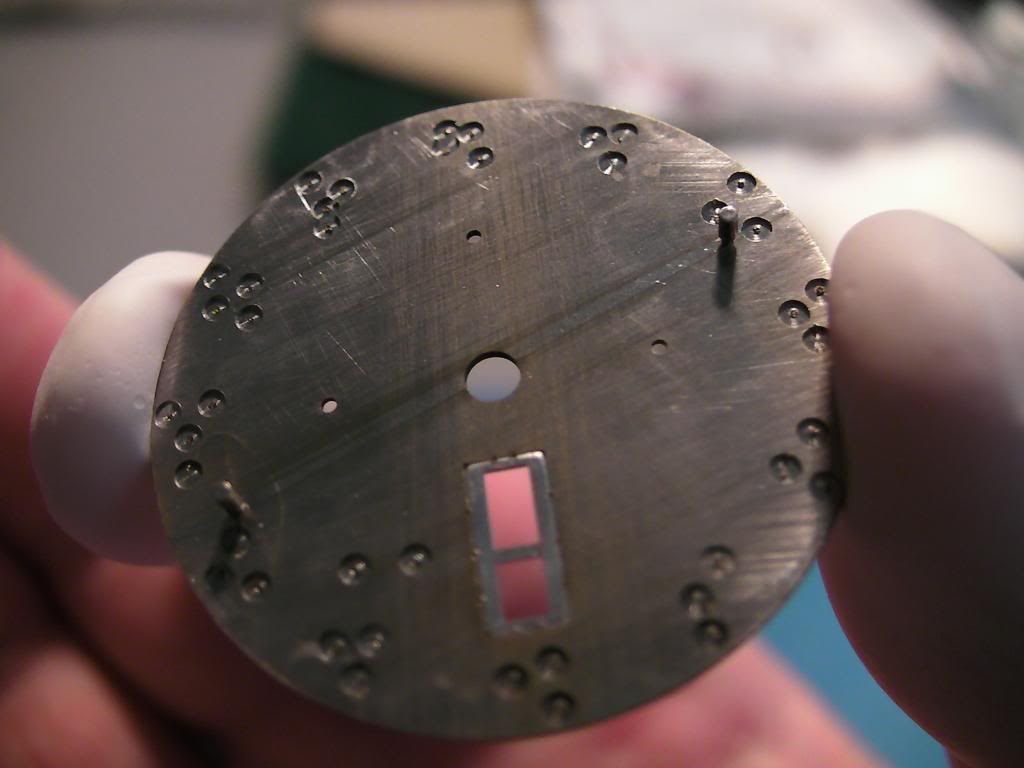

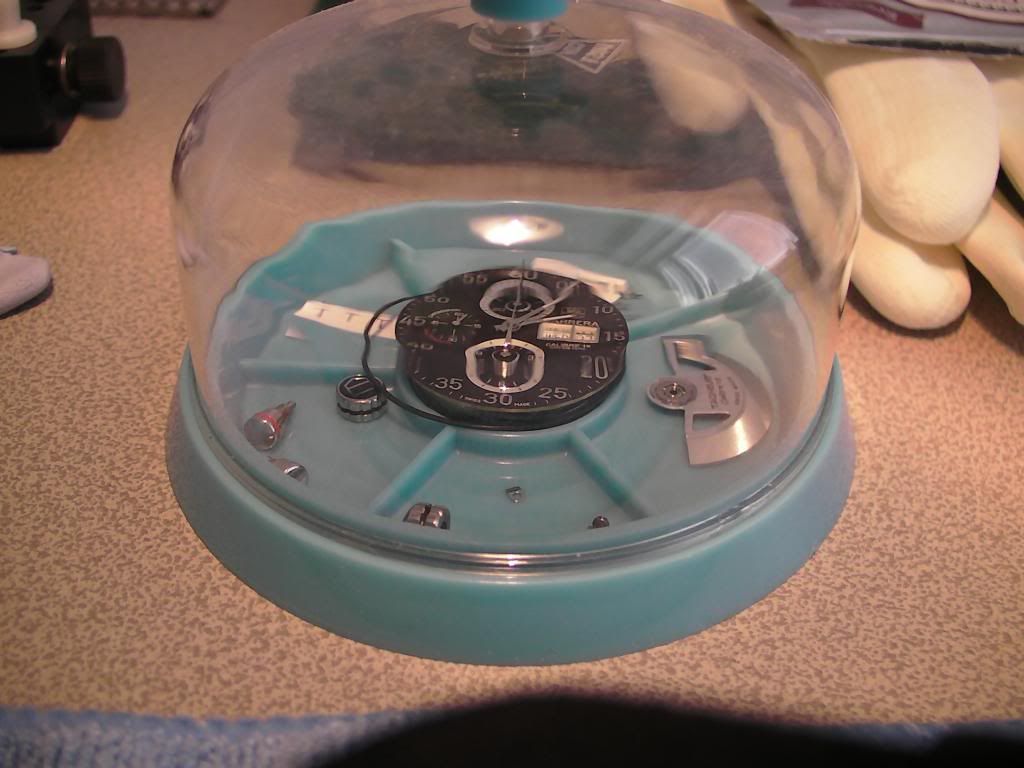

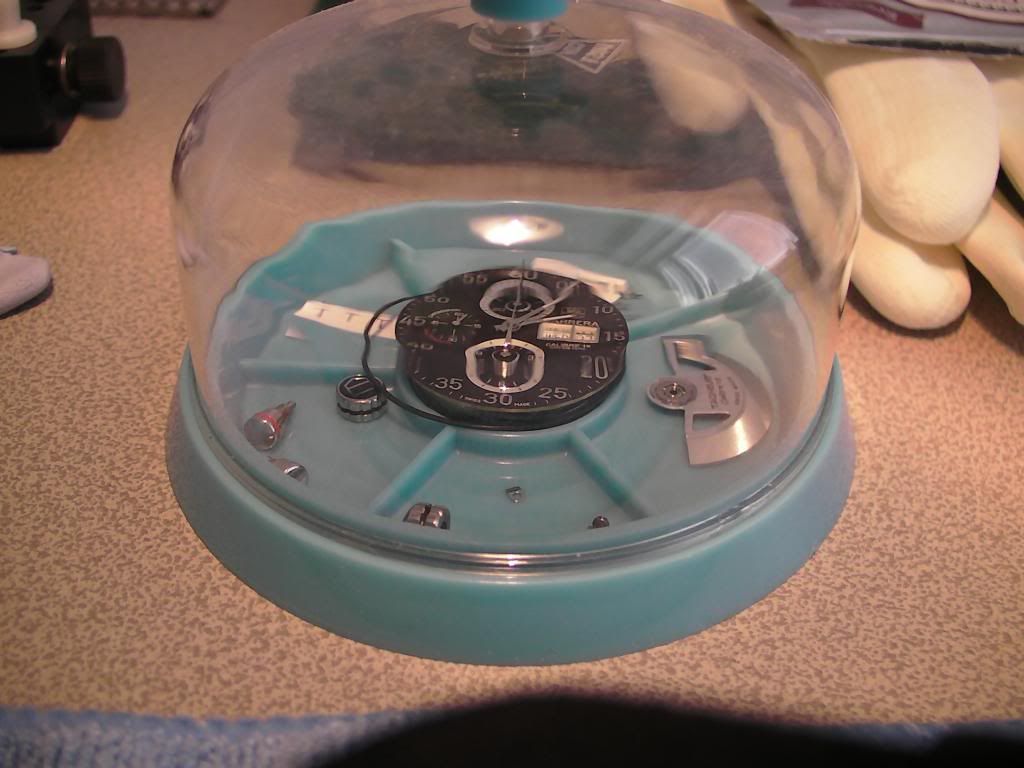

Movement complete with dial, and movement holder. Photos for reference in case I need to refit the movement holder to the same position on the gen Calibre 16 movement.

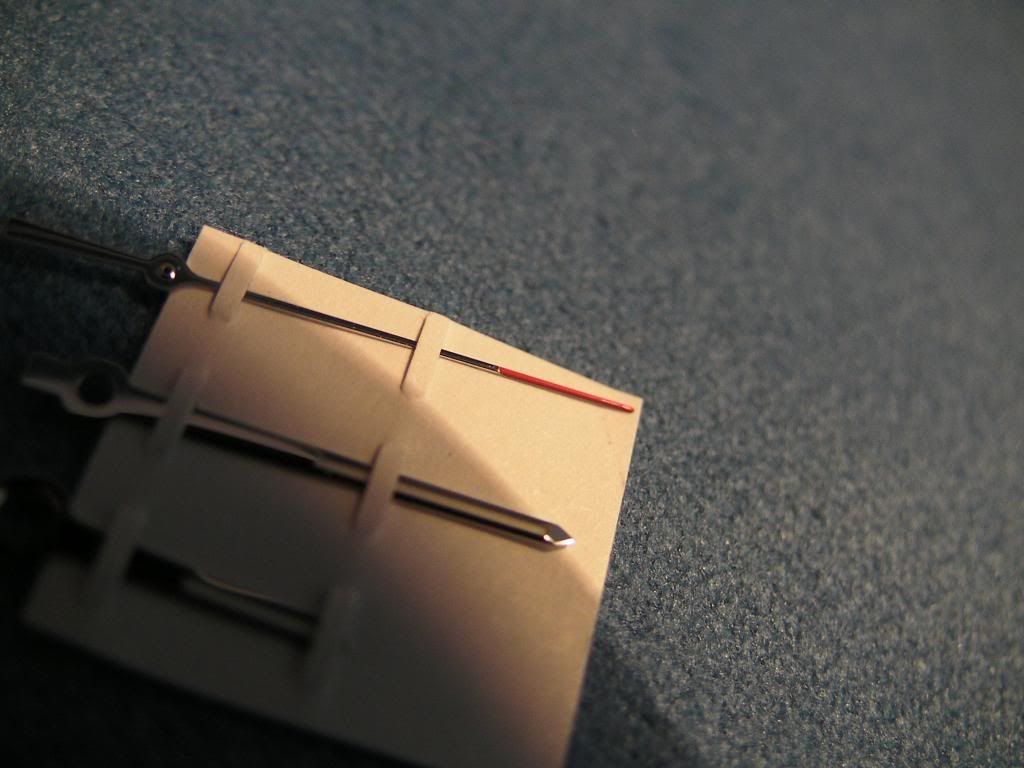

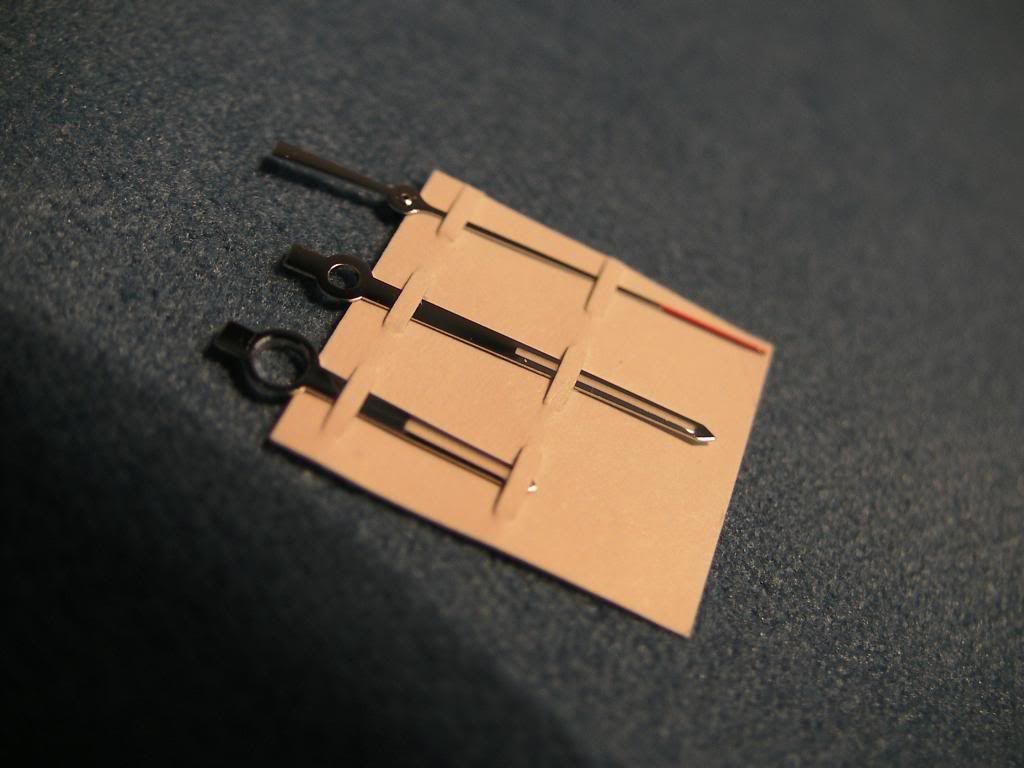

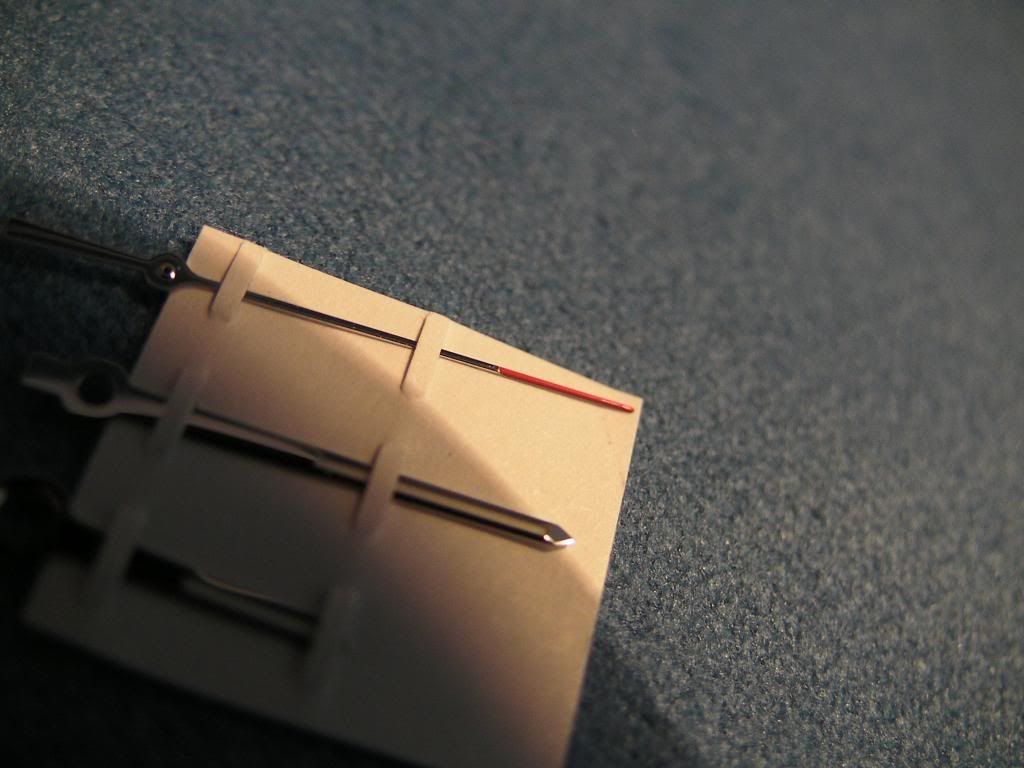

Photos of fitted rep pushers, notice the lack of small flat screwdriver slot..

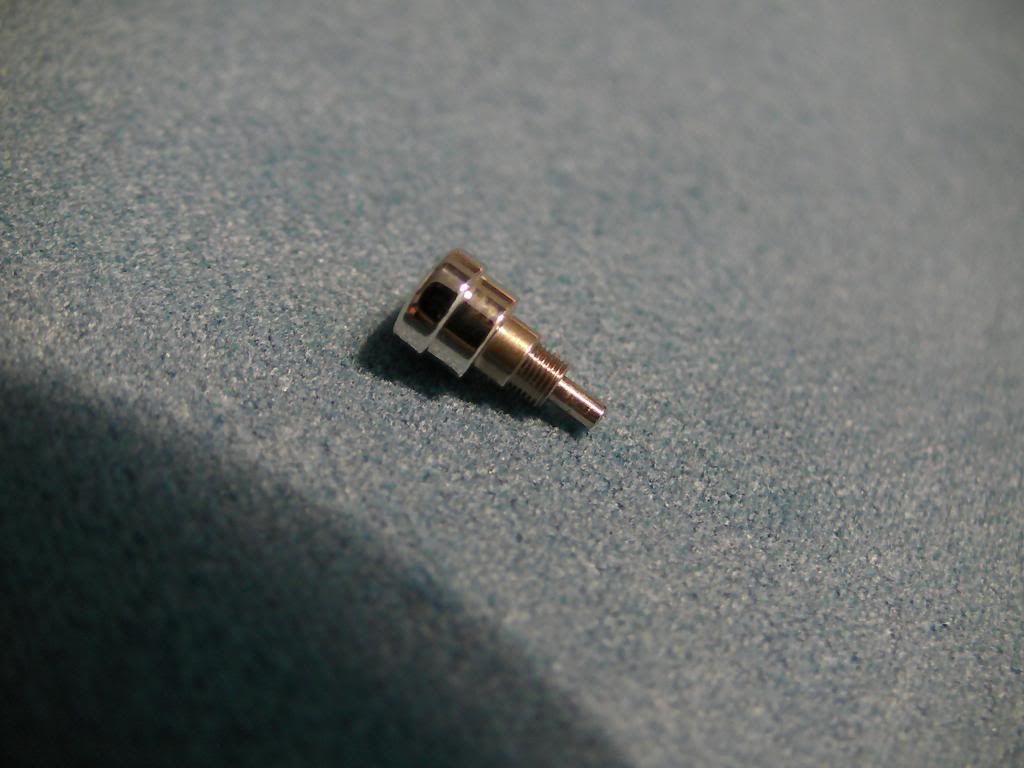

Gen pusher, showing the screw end..

Another, better (I hope) photo of the rep internal end with no screw slot..

The rep pushers are held in place with what looks like tiny cir-clips, and on closer inspection, they do have rubber o-rings for water resistance, which is a bonus.

I have decided at this point that I will only complete this project once I have received my water resistance tester, and hand press, so I apologise to those who have been following this project, and looking forward to the finished project, but alas it won't be completed now until August time due to family vacation, and parts/tools arriving.

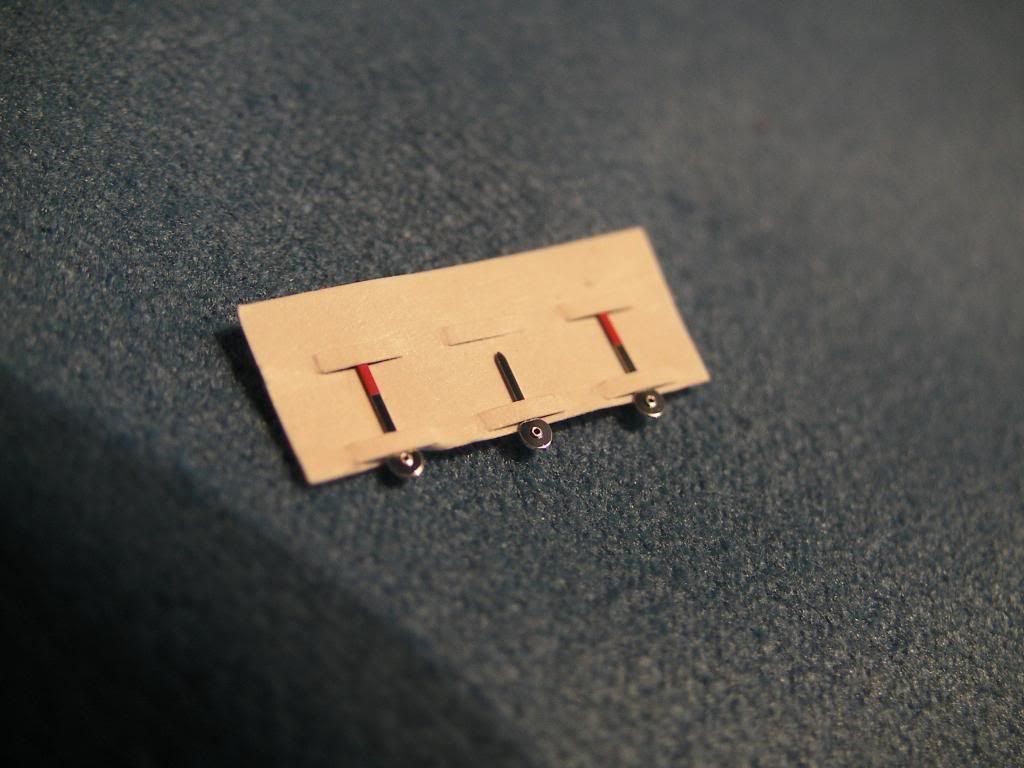

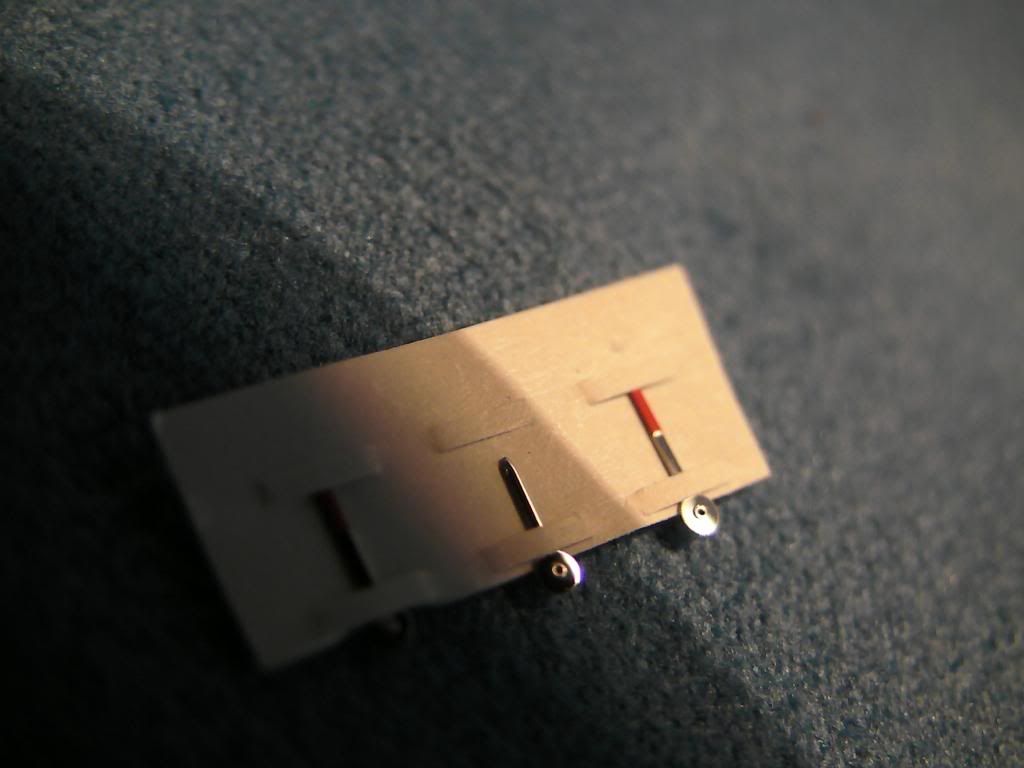

Photos below after movement holder ring removed from the movement. The holder is machined to exact tolerances to simply push fit onto the movement, and it was not screwed in place as I first thought. Lets hope I don't need to rework this holder for the Calibre 16. We shall see.

Rep movement holder..

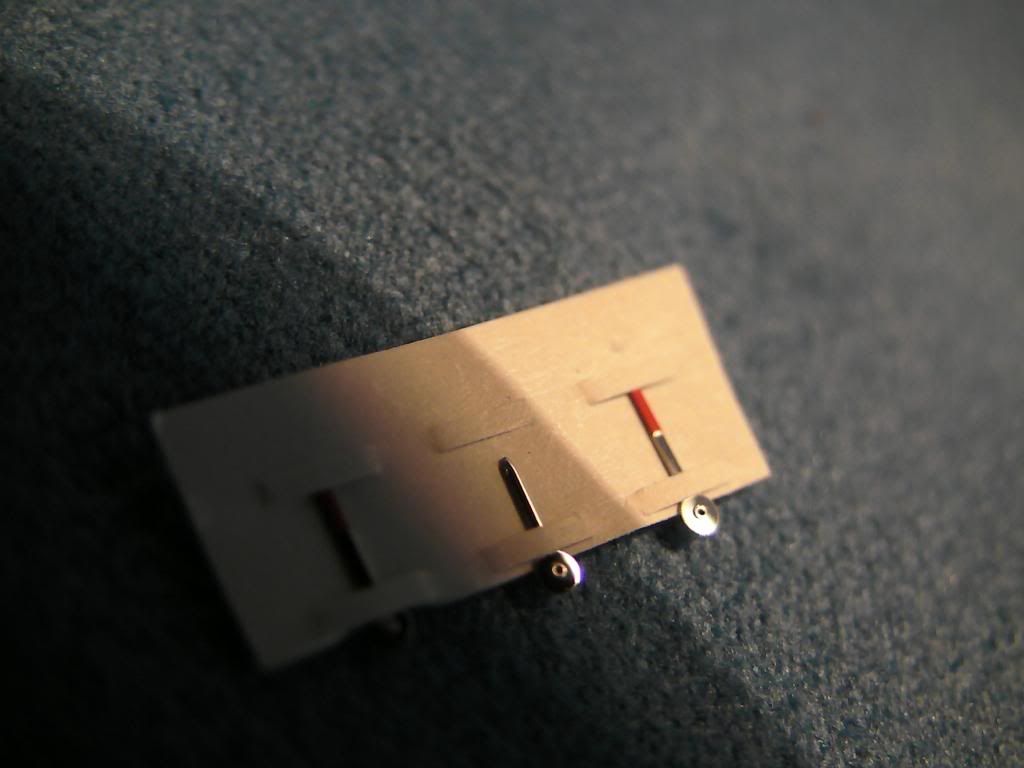

And to close, a photo of where the rep movement will reside until I get that cheap quartz Carrera to play with

There is a case back gasket, and crown inner gasket I discovered, the latter seals on the non-screw-down tube, so whilst not a tight water resistance seal, it is sealed nevertheless. As mentioned above, I will be carrying out a water resistance test when I get my tool, and obviously post results in this thread.

Thanks for following

Onto the photos..

Movement complete with dial, and movement holder. Photos for reference in case I need to refit the movement holder to the same position on the gen Calibre 16 movement.

Photos of fitted rep pushers, notice the lack of small flat screwdriver slot..

Gen pusher, showing the screw end..

Another, better (I hope) photo of the rep internal end with no screw slot..

The rep pushers are held in place with what looks like tiny cir-clips, and on closer inspection, they do have rubber o-rings for water resistance, which is a bonus.

I have decided at this point that I will only complete this project once I have received my water resistance tester, and hand press, so I apologise to those who have been following this project, and looking forward to the finished project, but alas it won't be completed now until August time due to family vacation, and parts/tools arriving.

Photos below after movement holder ring removed from the movement. The holder is machined to exact tolerances to simply push fit onto the movement, and it was not screwed in place as I first thought. Lets hope I don't need to rework this holder for the Calibre 16. We shall see.

Rep movement holder..

And to close, a photo of where the rep movement will reside until I get that cheap quartz Carrera to play with

There is a case back gasket, and crown inner gasket I discovered, the latter seals on the non-screw-down tube, so whilst not a tight water resistance seal, it is sealed nevertheless. As mentioned above, I will be carrying out a water resistance test when I get my tool, and obviously post results in this thread.

Thanks for following

Cheers, I take it you tried with the gen crystal then? I got my gen parts from a great guy from Malaysia who is also on eBay.

Curiosity got the better of me, I wanted to check if the Calibre 16 gen movement would fit the rep 7750 movement holder, and it looks very very tight, and unsure if it will actually fit at all, I didn't want to push too hard in fitting it just yet, as I will need to get to the dial feet holders on the sides of the movement.

Once dial is fitted, I will try again.

Curiosity got the better of me, I wanted to check if the Calibre 16 gen movement would fit the rep 7750 movement holder, and it looks very very tight, and unsure if it will actually fit at all, I didn't want to push too hard in fitting it just yet, as I will need to get to the dial feet holders on the sides of the movement.

Once dial is fitted, I will try again.