- 10/10/24

- 135

- 240

- 43

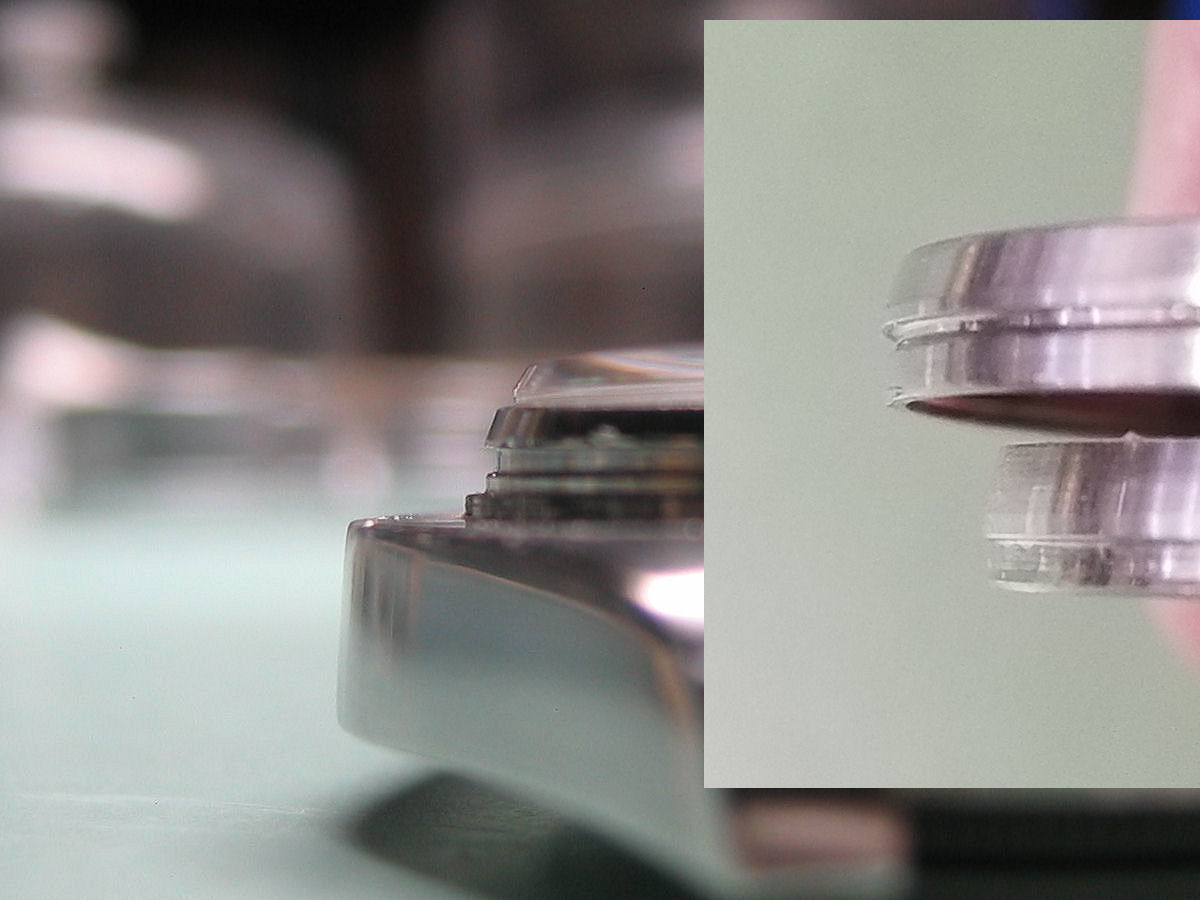

As you can see, the bezel on this watch took some force to remove. & with the damage, I am hesitant to attempt to reassemble using the original bezel parts.

2 questions --

1 Has anyone dealt with this type of bezel & crystal retaining system on a rep before?

2 How to remove the wave crystal retaining ring &/or the retaining ring above it with the angled lip that looks like it locks below the bezel?

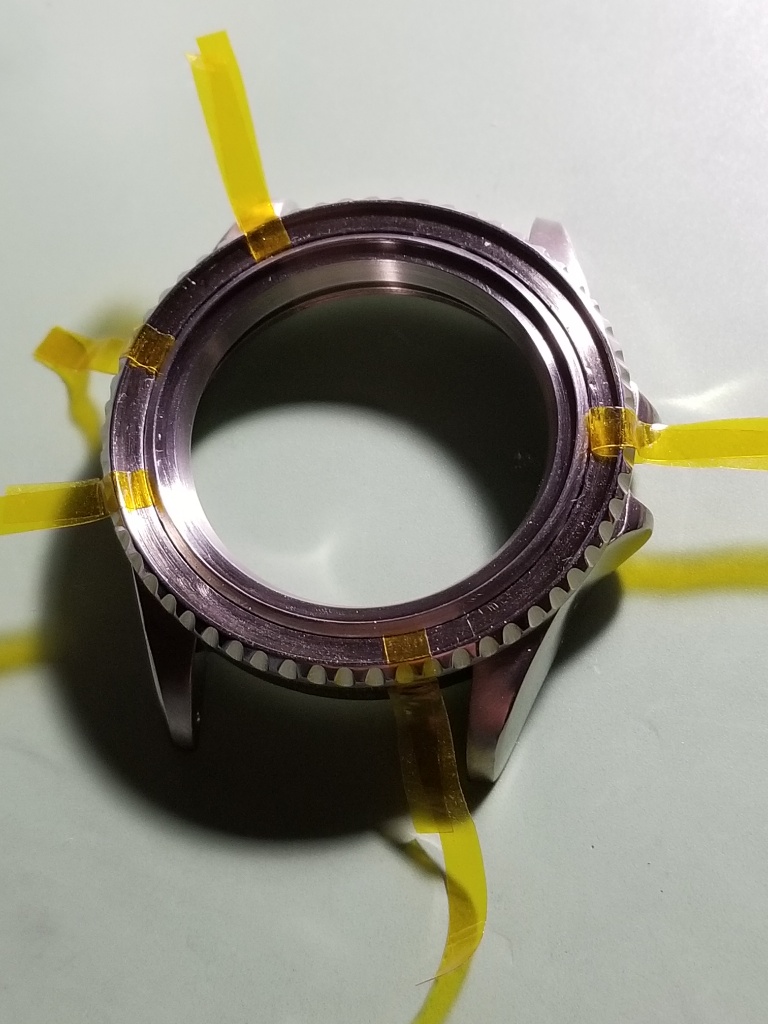

After finally figuring out how to deal with & succeeding in removing the bezel assembly from my 'clone' (separate thread), I agreed to take on a friend's 12 year old GMT rep (he thinks he got it from Andrew) -- the goal was to replace the existing bezel insert (with inaccurate fonts) with a ceramic insert (with accurate fonts). Sounded easy, so I agreed.

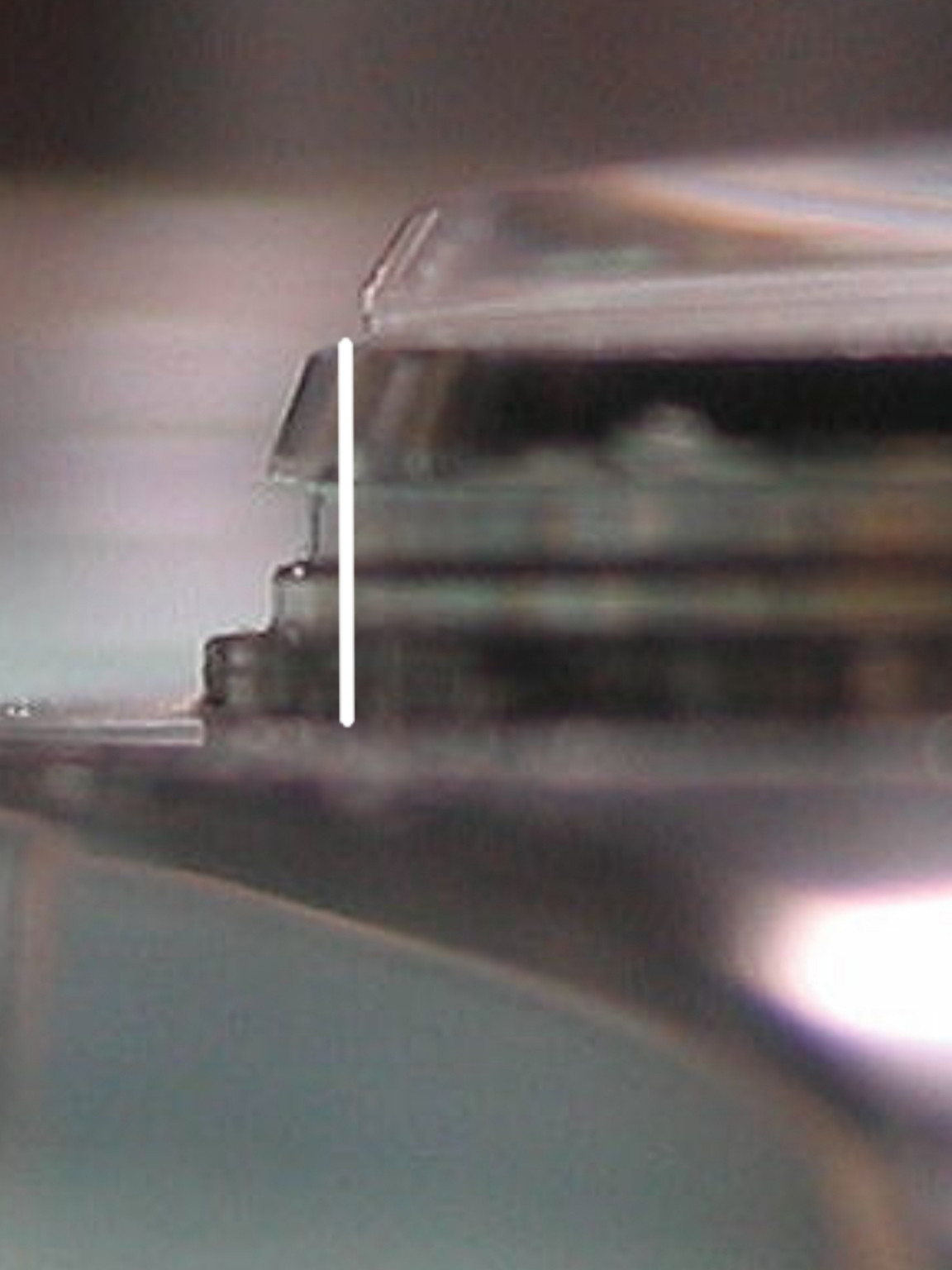

Unfortunately, without going into all the details, the bezel on his watch was far tougher to remove than mine was. Even after a week soaking in multiple types of penetrating oils, heating the case & going through 2 sets of steel bezel remover blades, it had to be literally pried off with 3 screw drivers! & of course with that much force, something was going to get bent -- the bezel, so now we need to replace the 'gold' bezel. Fortunately, I have a new crystal retaining ring, gasket & insert adhesive left over from my project that I can use for this 1. But the layout of his bezel assembly is very different from mine (this 1 has an angled spring in place of the nylon bezel gasket that my bezel had) & it almost looks like the wavy crystal retaining ring is part of the case & not meant to be removed. Plus, there is an additional ring above the wavy retaining ring with an angled lip that is likely where that angled spring locks onto. Anyone know if/how the 2 retaining rings can be removed & whether I can replace them with a wavy retaining ring & nylon gasket (leaving off the angled spring & upper retaining ring)?

2 questions --

1 Has anyone dealt with this type of bezel & crystal retaining system on a rep before?

2 How to remove the wave crystal retaining ring &/or the retaining ring above it with the angled lip that looks like it locks below the bezel?

After finally figuring out how to deal with & succeeding in removing the bezel assembly from my 'clone' (separate thread), I agreed to take on a friend's 12 year old GMT rep (he thinks he got it from Andrew) -- the goal was to replace the existing bezel insert (with inaccurate fonts) with a ceramic insert (with accurate fonts). Sounded easy, so I agreed.

Unfortunately, without going into all the details, the bezel on his watch was far tougher to remove than mine was. Even after a week soaking in multiple types of penetrating oils, heating the case & going through 2 sets of steel bezel remover blades, it had to be literally pried off with 3 screw drivers! & of course with that much force, something was going to get bent -- the bezel, so now we need to replace the 'gold' bezel. Fortunately, I have a new crystal retaining ring, gasket & insert adhesive left over from my project that I can use for this 1. But the layout of his bezel assembly is very different from mine (this 1 has an angled spring in place of the nylon bezel gasket that my bezel had) & it almost looks like the wavy crystal retaining ring is part of the case & not meant to be removed. Plus, there is an additional ring above the wavy retaining ring with an angled lip that is likely where that angled spring locks onto. Anyone know if/how the 2 retaining rings can be removed & whether I can replace them with a wavy retaining ring & nylon gasket (leaving off the angled spring & upper retaining ring)?