The D6x50L one?I just found this on AliExpress: 4,17€ | Tooleye Carbide Chamfer Milling Cutter 60 90 120° Tungsten Steel Cnc Cutter 2and3 Flutes Chamfering Mill Metal Cutter End Mills

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

5513 rebuild with old-crowns custom case

- Thread starter tribal

- Start date

That’s the one I have used.The D6x50L one?

but i have only done this thing once

For people in the US this set includes a 5/32 90 degree end mill and can be ordered via Amazon Prime.

5/32 is equal to 3.9688 mm which should be close enough.

5/32 is equal to 3.9688 mm which should be close enough.

automatico

Known Member

- 5/10/11

- 117

- 237

- 43

I said:

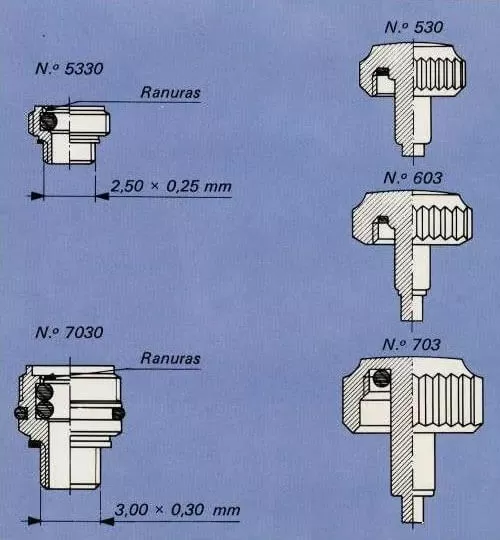

Genuine Rlx 6.0mm and 7.0mm case tubes use the same tap size...3.0mm X .35mm (3.0mm diameter with .35mm thread pitch).

Later sapphire DJ etc. have 6.0mm crowns with 5.3mm case tubes and use a different case tube tap...2.0mm X .25mm (2.0mm diameter with .25mm thread pitch).

I made a typo mistake on the 5.3mm case tube tap size. It should have been be 2.5mm X .25mm (2.5mm diameter with .25mm thread pitch).

I looked at my case tube taps for older 6.0 and 7.0 tubes and they all are 3.0 X .35mm and they came from different USA supply houses.

I looked at the Esslinger website today and they are offering 3.0mm X .35mm taps for Rlx 6.0 case tubes and I have also seen 3.0mm X .30mm taps mentioned on forums.

I have been getting by with the 3.0mm X .35mm taps but have read a LOT of posts concerning case tube thread sizes on different forums.

So...I am officially backing out on case tube sizes. Looking back, I should have kept out of it...typos and all.

Genuine Rlx 6.0mm and 7.0mm case tubes use the same tap size...3.0mm X .35mm (3.0mm diameter with .35mm thread pitch).

Later sapphire DJ etc. have 6.0mm crowns with 5.3mm case tubes and use a different case tube tap...2.0mm X .25mm (2.0mm diameter with .25mm thread pitch).

I made a typo mistake on the 5.3mm case tube tap size. It should have been be 2.5mm X .25mm (2.5mm diameter with .25mm thread pitch).

I looked at my case tube taps for older 6.0 and 7.0 tubes and they all are 3.0 X .35mm and they came from different USA supply houses.

I looked at the Esslinger website today and they are offering 3.0mm X .35mm taps for Rlx 6.0 case tubes and I have also seen 3.0mm X .30mm taps mentioned on forums.

I have been getting by with the 3.0mm X .35mm taps but have read a LOT of posts concerning case tube thread sizes on different forums.

So...I am officially backing out on case tube sizes. Looking back, I should have kept out of it...typos and all.

rainyknight

World’s okayest watch fan

I’m hoping to compile all this information into a big post. I’m gonna grab both an 0.30 and 0.35 tap and see how each of them fares. I measured the shoulder of the case tube, it’s 3.78mm so I would think a 4mm counterbore would do. The OG 5513 tutorial by @Megahz1 used a 6mm 90deg counterbore I believe, and just titrated to effect.Right chaps, now we have the tap (or back and forth method) sorted for our 7030 tubes... what countersink tool are we using?

Any recommendations? @Karbon74 - Do you have a link, Pika buddy?

rainyknight

World’s okayest watch fan

This guy and this photo are the only two sources that conflict with the prevailing M3x0.35 wisdom. I’m gonna try to tap both into a block of steel and give it a try. I can tell you now that I had far more trouble getting a gen 7030 tube into the Old Crowns case than every other Rolex servicing video I’ve seen. I’m gonna order both the 0.30 and 0.35 taps that @HulkyGalore found on eBay (I also found this on Amazon and see how an Esslinger tube compares. Will post my results once everything arrives.I said:

Genuine Rlx 6.0mm and 7.0mm case tubes use the same tap size...3.0mm X .35mm (3.0mm diameter with .35mm thread pitch).

Later sapphire DJ etc. have 6.0mm crowns with 5.3mm case tubes and use a different case tube tap...2.0mm X .25mm (2.0mm diameter with .25mm thread pitch).

I made a typo mistake on the 5.3mm case tube tap size. It should have been be 2.5mm X .25mm (2.5mm diameter with .25mm thread pitch).

I looked at my case tube taps for older 6.0 and 7.0 tubes and they all are 3.0 X .35mm and they came from different USA supply houses.

I looked at the Esslinger website today and they are offering 3.0mm X .35mm taps for Rlx 6.0 case tubes and I have also seen 3.0mm X .30mm taps mentioned on forums.

I have been getting by with the 3.0mm X .35mm taps but have read a LOT of posts concerning case tube thread sizes on different forums.

So...I am officially backing out on case tube sizes. Looking back, I should have kept out of it...typos and all.

Holidays are over and family has left for home so I can now get back into buiding. Looking to buy 2 drvintage 5513 cases. Can anyone verify if the crown tube is correctly threaded and not glued? I see the above pic which looks like glue where purple Locktite 222 is normally called for on the threads. Also, I'm seeing crown tube needs countersunk like the gen and the lugs need to be drilled to 1.2mm? Is this still the case with his latest batch?

Tube threaded M3x0.35 and glue/thread lock applied.

An Athaya 702 tube should go straight in without further work.

GEN/GEN-spec 7030 tube would need countersinking and installing carefully if threads are 0.30. All answered in this thread.

Think there is only a single batch, so lug holes will need drilling out to 1.3mm for fat spring bars.

An Athaya 702 tube should go straight in without further work.

GEN/GEN-spec 7030 tube would need countersinking and installing carefully if threads are 0.30. All answered in this thread.

Think there is only a single batch, so lug holes will need drilling out to 1.3mm for fat spring bars.

Last edited:

I fitted a Gen 702 crown and a Athaya 7020 Crown Tube (for a gen crown) to my old crowns case. I did have to counterbore it using the 5/32 90 degree end mill in the set I posted above. Without it the tube stuck to far our and the rubber gasket at the base of the tube was visible.

I also found a Tudor 7016/7021 style caseback in my parts box that fit it! A standard Vietnam caseback is too small however this one fit perfectly. I am going to polish it up to match the case but I was glad I did not have to find someone to mod the caseback.

Next I am going to get it engraved and when its back from that swap the insert and install the movement.

I also found a Tudor 7016/7021 style caseback in my parts box that fit it! A standard Vietnam caseback is too small however this one fit perfectly. I am going to polish it up to match the case but I was glad I did not have to find someone to mod the caseback.

Next I am going to get it engraved and when its back from that swap the insert and install the movement.

No, you can use a 703 Tube without retapping. Also you can retap the existing threads. But not really necessary.In order to re-tap, its my understanding the M3 hole will need to be filled in with weld and then re-drilled and tapped, is this correct?

rainyknight

World’s okayest watch fan

A brief update: sent my old crowns midcase to @369mafia for some casework and… lost in the post. Luckily I had bivintage make me a case with just an M2 pilot hole, I have a case and M3x0.3 tap in the mail I’ll post results when they come in

Way easier to buy 703 gen Spec Tubes without the small edge on the back. Look here. No need to countersink the tube hole.Tube threaded M3x0.35 and glue/thread lock applied.

An Athaya 702 tube should go straight in without further work.

GEN/GEN-spec 7030 tube would need countersinking and installing carefully if threads are 0.30. All answered in this thread.

Think there is only a single batch, so lug holes will need drilling out to 1.3mm for fat spring bars.

Any link please?Way easier to buy 703 gen Spec Tubes without the small edge on the back. Look here. No need to countersink the tube hole.

I just found this on AliExpress: 5,68€ | Case Screw Crown Tube With Gasket O-Ring For RLX Day Tona, GMT SUB Submariner Watch Replacement 3135 Movement Watch Case Tube

Do we think/know if they are GEN-spec 0.30 or REP-spec 0.35?I just found this on AliExpress: 5,68€ | Case Screw Crown Tube With Gasket O-Ring For RLX Day Tona, GMT SUB Submariner Watch Replacement 3135 Movement Watch Case Tube

Have you used one in your case, DrV?

I use exactly this tubes for my cases. Perfect fit without any work + gen 703-704 crowns fits on this tube.Do we think/know if they are GEN-spec 0.30 or REP-spec 0.35?

Have you used one in your case, DrV?