I also wanted to find a way to make dials cheap. I found dial blanks on Ali for a few cents each, but they need to be polished, have holes for the center pinion drilled exactly in the center, and have dial feet soldiered on.

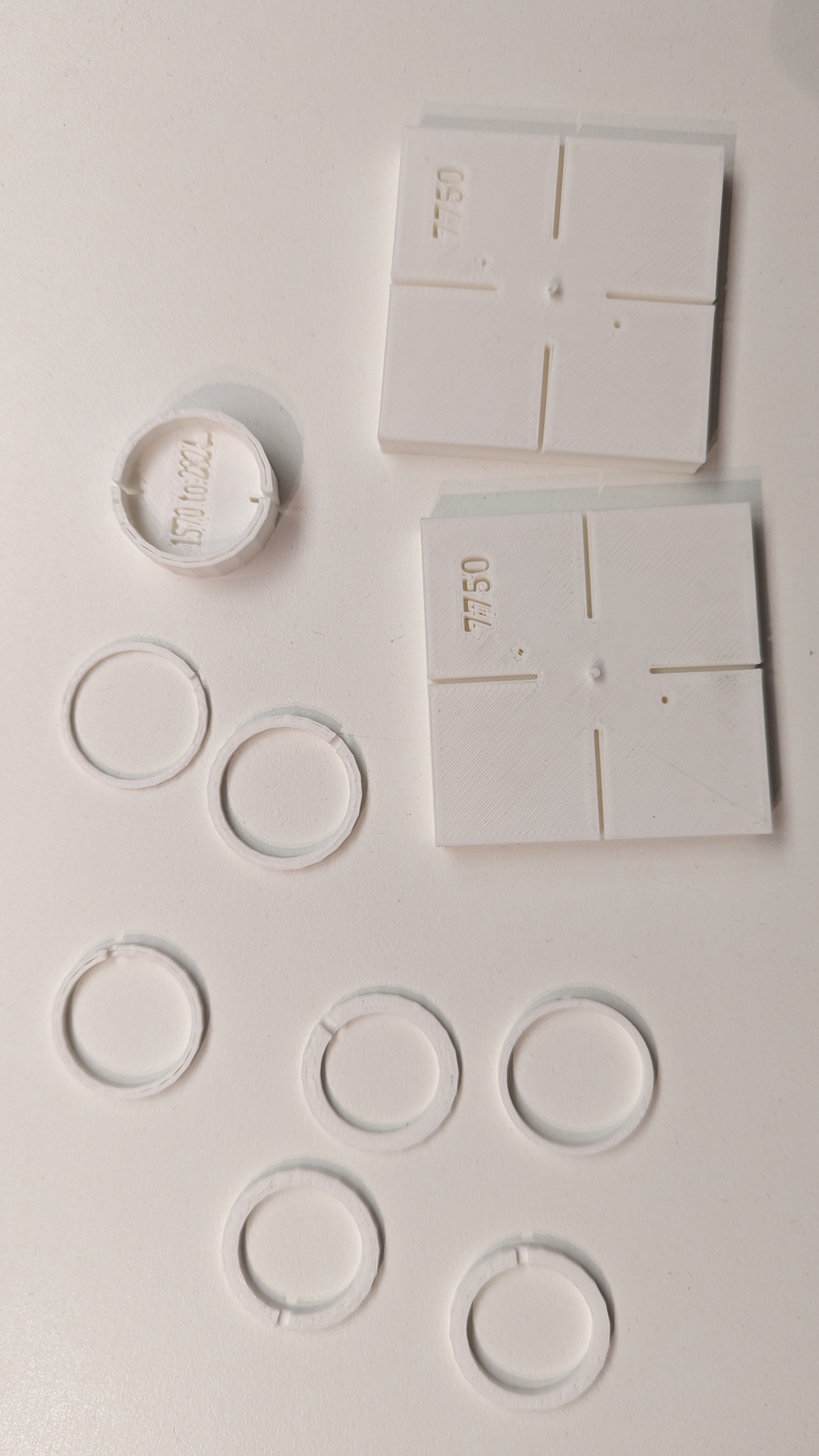

Buy the ones that are .5mm thick, in the diameter you need (27mm for Rolex, 28 or 29mm for Raffles, 38-39mm for Panerai, etc)

Polishing is just elbow grease and abrasive...not much time to be saved here.

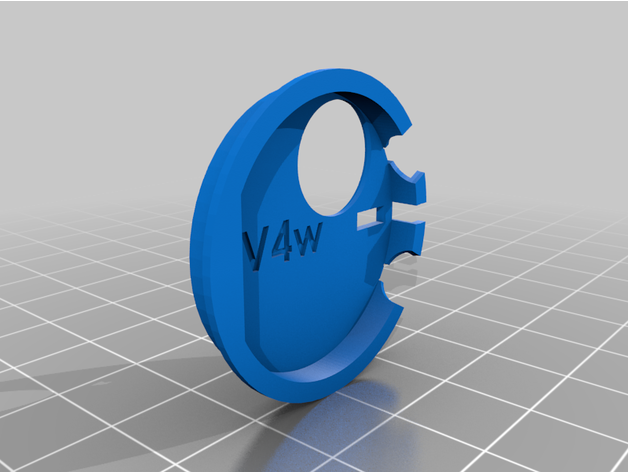

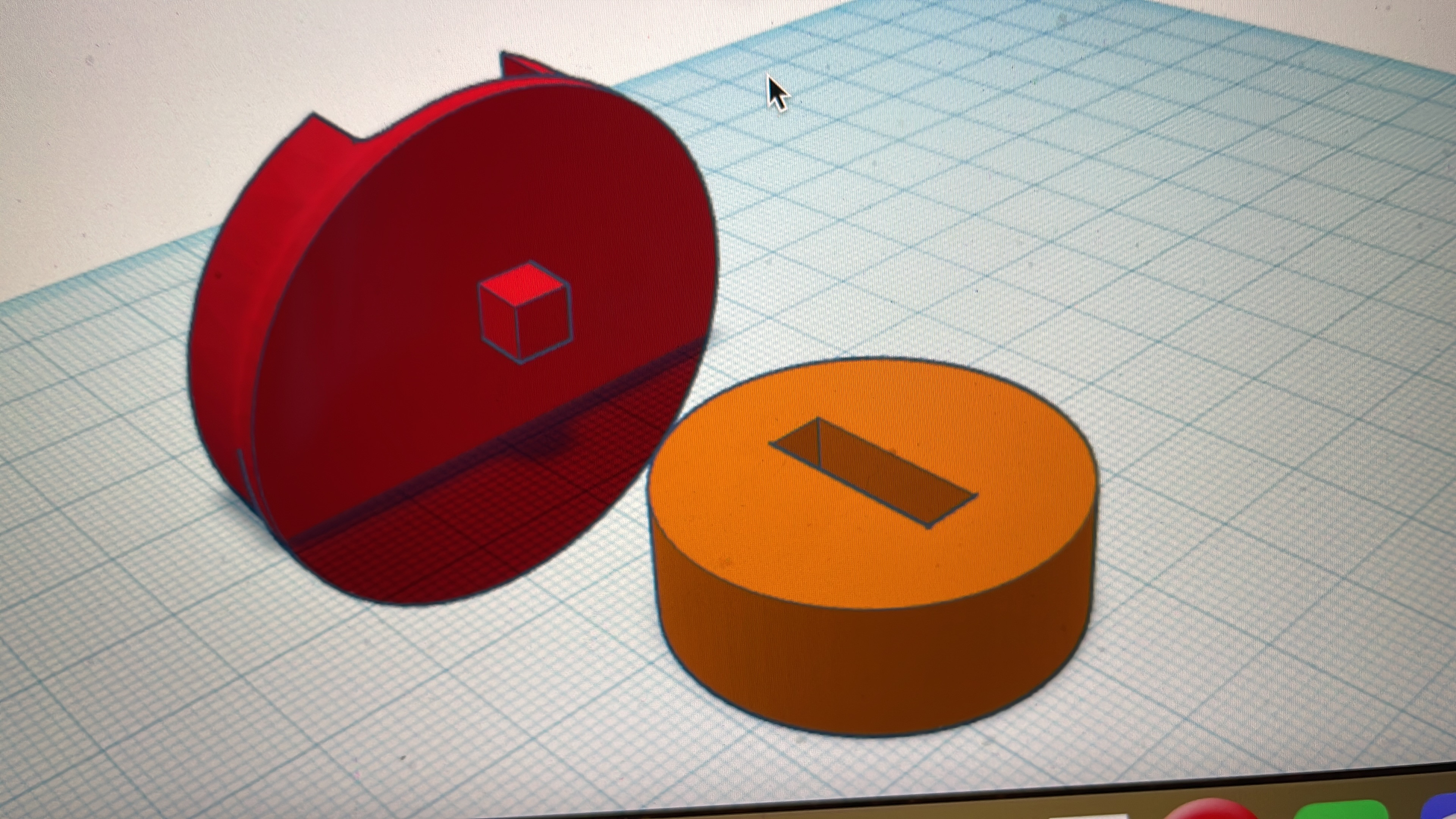

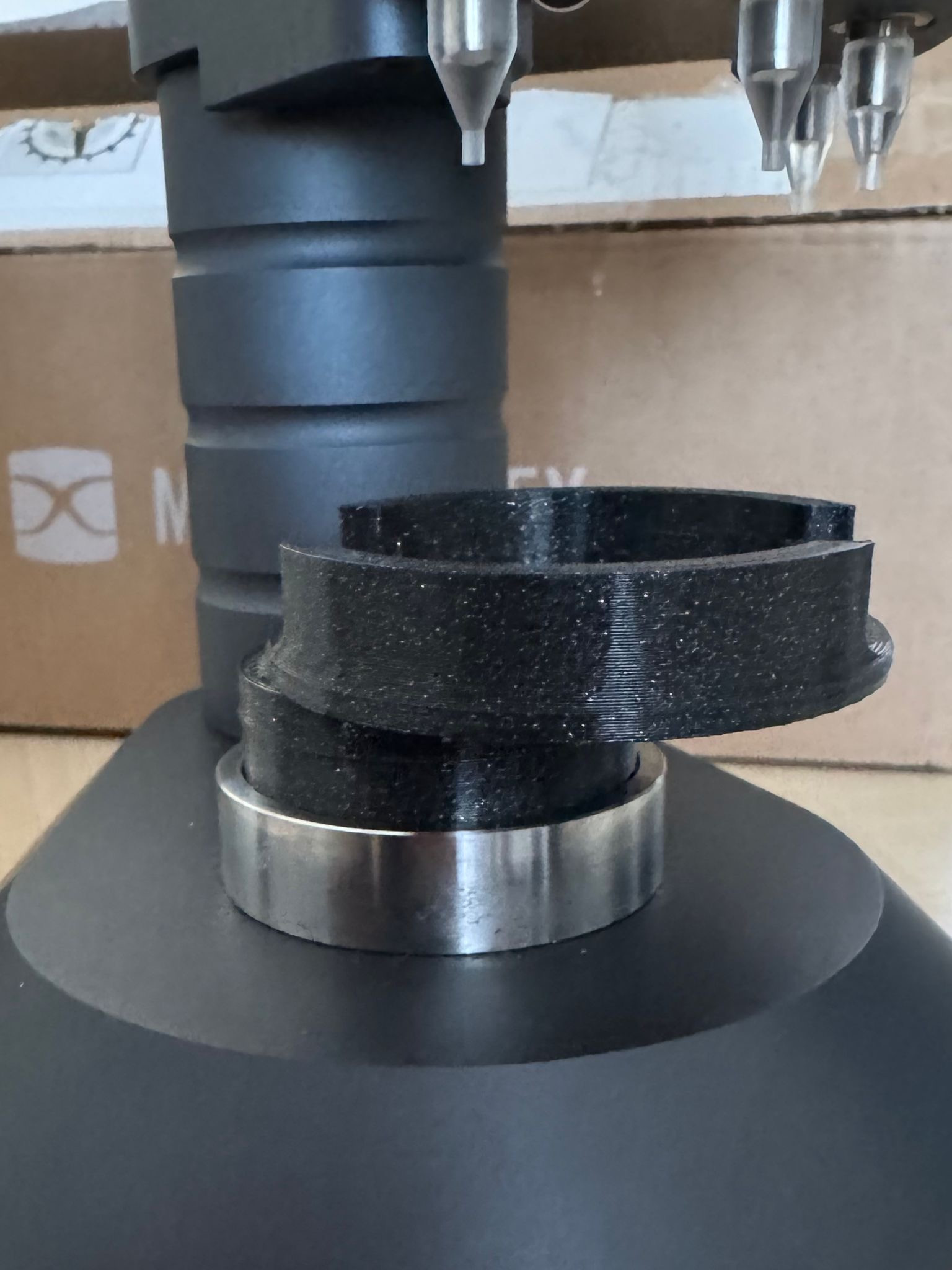

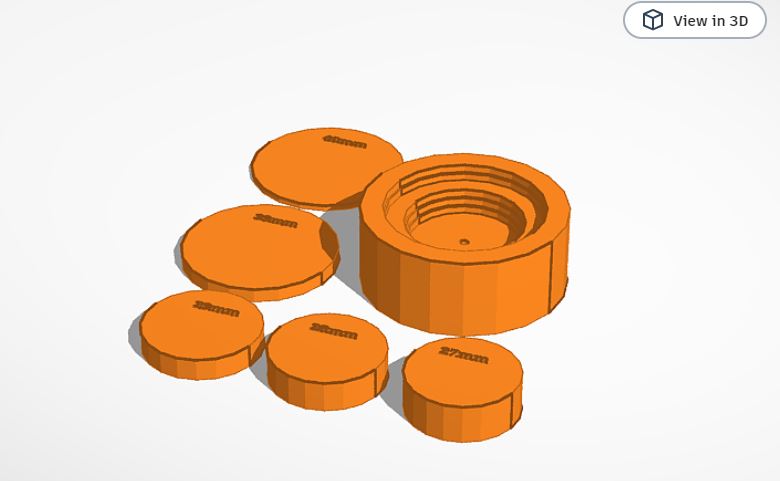

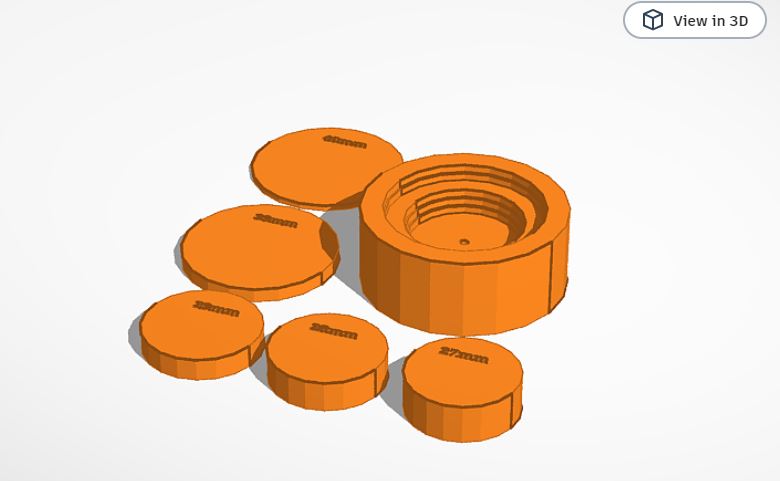

For drilling the center hole, I made this jig:

3D design Watch Dial Drill Jig created by David Patterson with Tinkercad

www.tinkercad.com

Put the dial blank in the correct size opening (27mm, 28mm, 29mm for Rolex, 38mm and 39mm for Panerai) and then the correct "plug" to support it. Flip it over and drill through the 2mm center hole, which should keep the bit straight and parallel. It works better on a drill press than a hand drill, as any variation from perpendicular is prone to snapping bits.