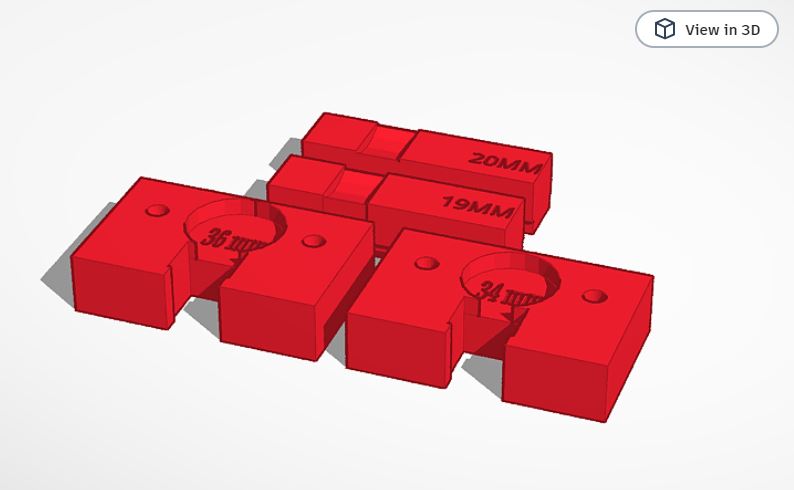

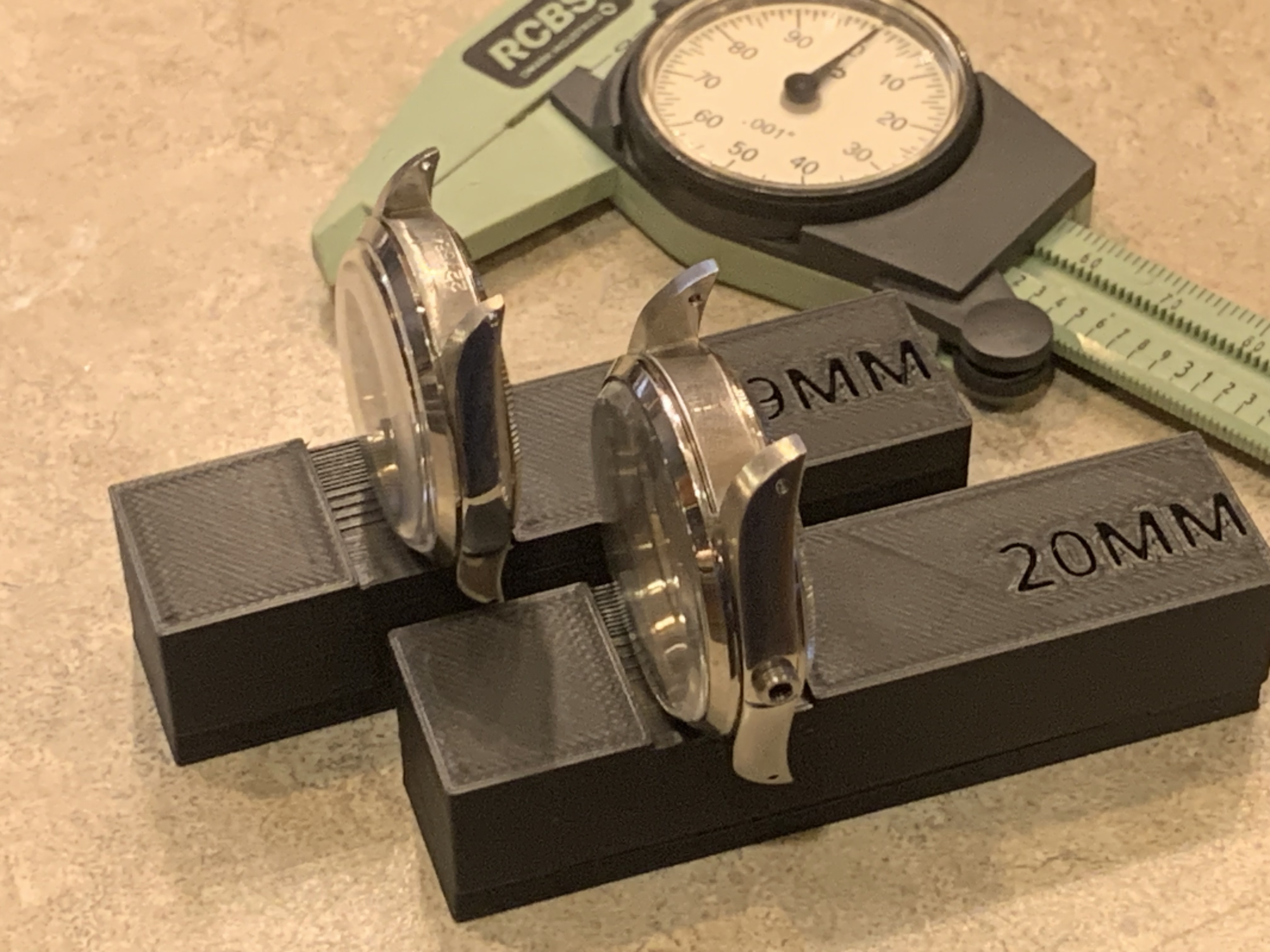

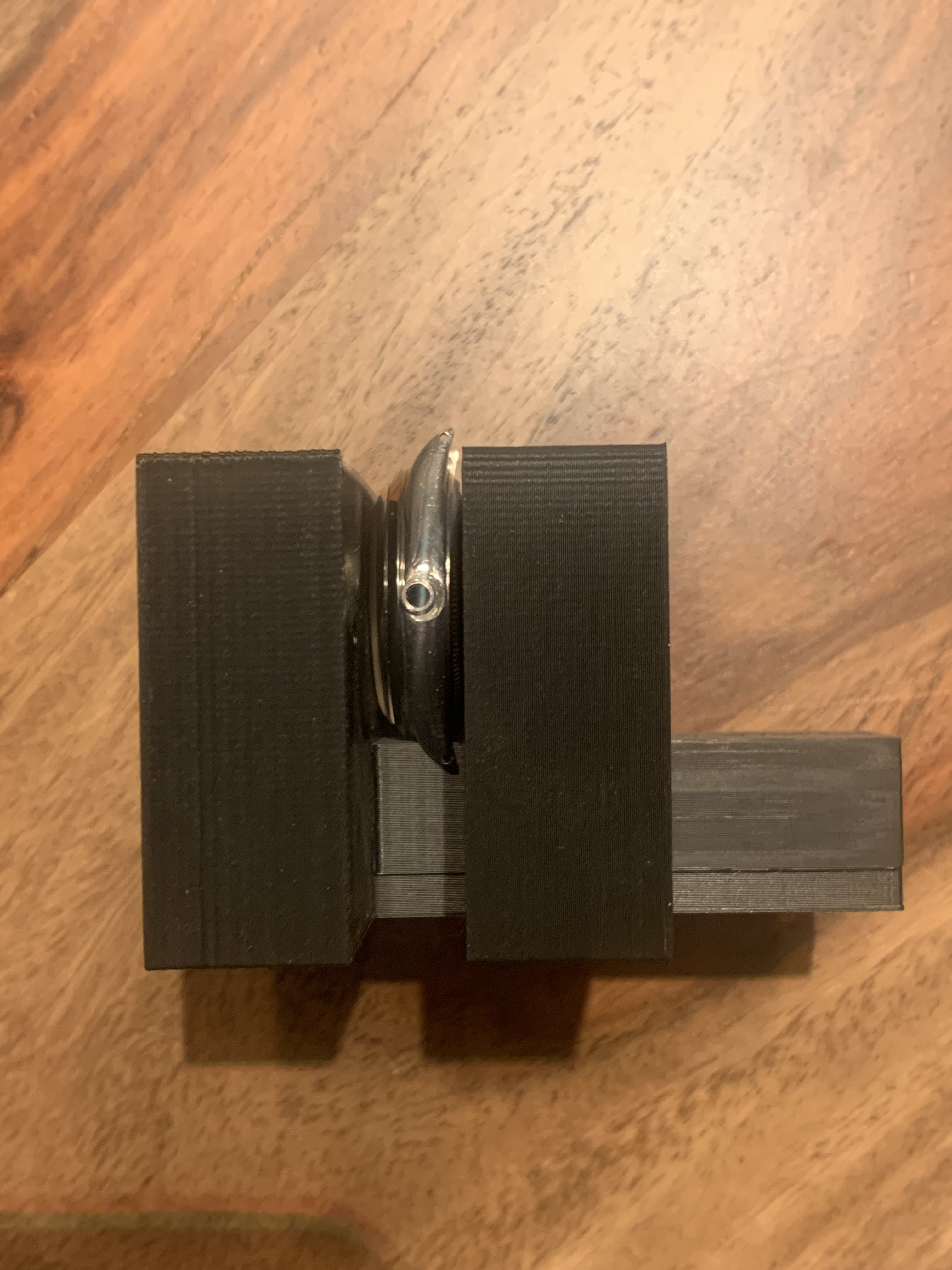

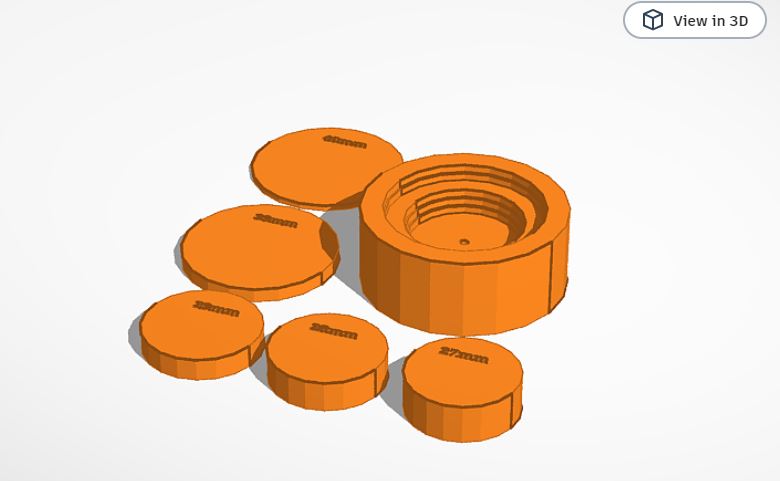

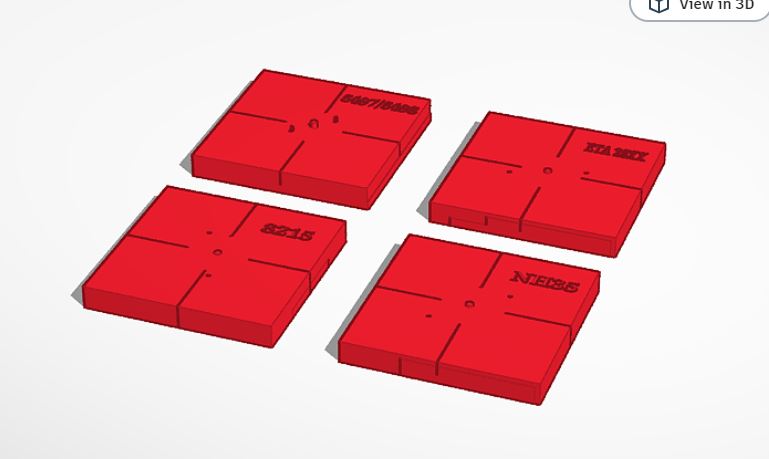

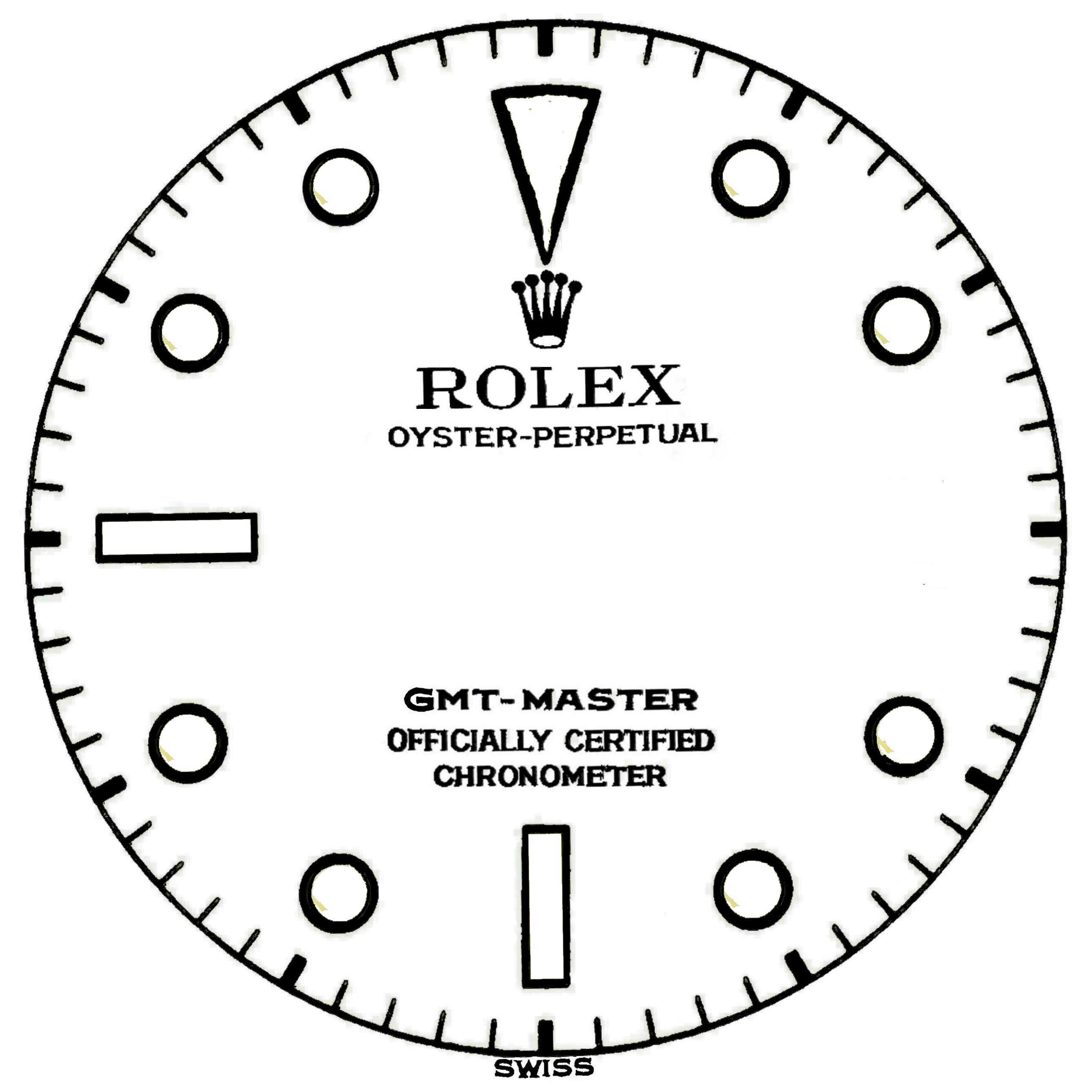

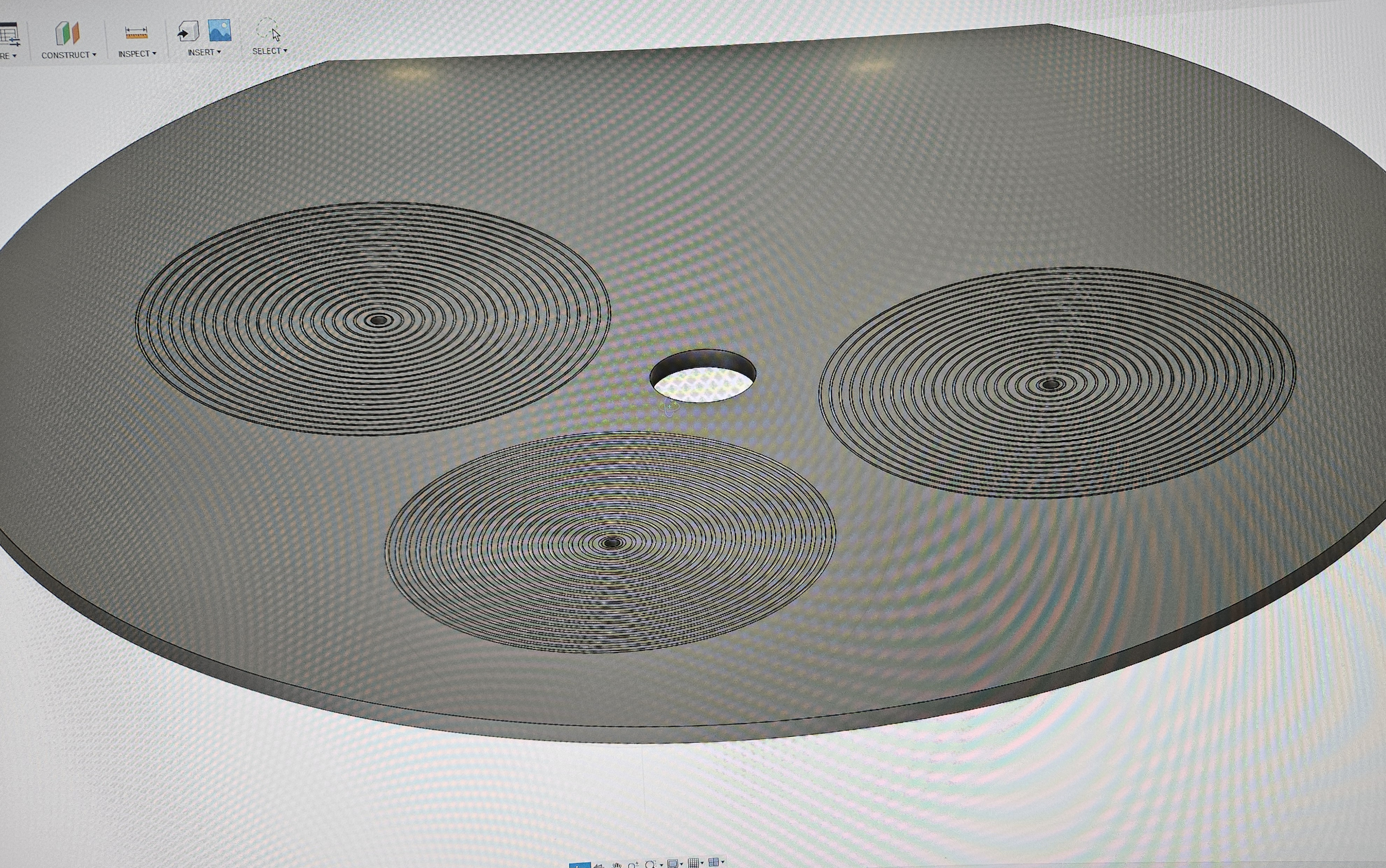

I got myself a 3D printer for Christmas and have been toying around with it. I'm far from an expert in either 3D printing, CAD design, or watchmaking, but I came up with a few things that are working well for me and thought I'd pass them along for anyone to use, improve, or adapt. Some are finished products, some are still being tweaked, and some might not work at all, but it's a starting point, and I continue to try to improve them as I go.

Please add yours if you have anything to share!

NOTE: 3D printers are not precise to fractions of a millimeter, so anything you print will likely require a little bit of clean up...surfaces sanded, especially mating surfaces, holes chased with a drill, etc. They're the equivalent of castings, and need a small amount of final "machining" to be ready to use. Unless you get lucky and it's perfect right out of the machine, lol.

Please add yours if you have anything to share!

NOTE: 3D printers are not precise to fractions of a millimeter, so anything you print will likely require a little bit of clean up...surfaces sanded, especially mating surfaces, holes chased with a drill, etc. They're the equivalent of castings, and need a small amount of final "machining" to be ready to use. Unless you get lucky and it's perfect right out of the machine, lol.

Last edited: