-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:1 Nautilus 3700 Case/Bezel/Rehaut Run Interest List

- Thread starter Davin0011

- Start date

- 25/12/21

- 154

- 129

- 43

I've got a list in the main post about what parts will work best iirc. I think most common is going to be the AP movement though that will need a new date wheel, rep bracelet, and then I would expect to see service hands/dials from those who don't already have vintage stuff.This is a very interesting project - looking forward to see some amazing 3700 frankens.

Which parts (on top of this case set) do you guys plan to use for your builds? K2121 caliber? Which dial, hands, bracelet?

That said, I'll be listing my personal vacheron soon here, which will be the best bang for your buck for movement and date wheel.

- 25/12/21

- 154

- 129

- 43

Hey all,

I'm extending the deposit window another week. Life gets busy, doesn't make sense to rush the deposits. Final payments, though, I feel 2 weeks is fair.

I am also gathering interest in gen case gaskets (the black bit). They come in packs of 5. I have a gen gasket for myself on order to compare with my cheap ebay rep gasket and my PPF gasket. If the gen is noticeably better than the reps, I'll move forward with middle-manning a group gasket buy.

I'm extending the deposit window another week. Life gets busy, doesn't make sense to rush the deposits. Final payments, though, I feel 2 weeks is fair.

I am also gathering interest in gen case gaskets (the black bit). They come in packs of 5. I have a gen gasket for myself on order to compare with my cheap ebay rep gasket and my PPF gasket. If the gen is noticeably better than the reps, I'll move forward with middle-manning a group gasket buy.

- 25/12/21

- 154

- 129

- 43

A little update for everyone, and a couple minor changes to the run.

To my surprise, two people have resigned from the run. While I try to emphasize the importance of following through with your sign-up, there's nothing I can do to force people to follow through. Sometimes I can sort of see it coming, (like with ILOVE3800 signing up for 2 sets and then asking what it comes with), but I digress.

Currently there are two people who have not replied to my message regarding the run starting and the deposit request. One person has replied, but has been travelling and hasn't had time to send payment.

So in light of everything happening, I'm changing my approach a little. To those of you who have already sent deposits, rest assured this should not affect you. Once I receive the deposit from the person mentioned above, the run will be greenlit. That will make 5 sign-ups with payment submitted, marking half the MOQ. After the run is greenlit, I will leave a window open to submit deposits, from those who have already signed up and those who are on the fence, until the parts are machined. After that point, the extra 5 sets will be available for purchase at a higher price.

As it stands, this is looking like the route forward:

1. Greenlight the machine shop by June 2nd.

2. Receive first set of machined parts around start of July

3. Adjustments if needed, then machine the rest of the parts

4. All parts received around start of August

5. Machine and press crown tubes by hand

6. Shipping sets out late August - early September

As for the crystal gaskets, I am still waiting on pricing from switzerland, but the pricing from my cnc shop stands as worst case. I will be proceeding with my gasket design for the bezel, as I have not been able to acquire a gen gasket, so a custom gasket will be required nevertheless.

To my surprise, two people have resigned from the run. While I try to emphasize the importance of following through with your sign-up, there's nothing I can do to force people to follow through. Sometimes I can sort of see it coming, (like with ILOVE3800 signing up for 2 sets and then asking what it comes with), but I digress.

Currently there are two people who have not replied to my message regarding the run starting and the deposit request. One person has replied, but has been travelling and hasn't had time to send payment.

So in light of everything happening, I'm changing my approach a little. To those of you who have already sent deposits, rest assured this should not affect you. Once I receive the deposit from the person mentioned above, the run will be greenlit. That will make 5 sign-ups with payment submitted, marking half the MOQ. After the run is greenlit, I will leave a window open to submit deposits, from those who have already signed up and those who are on the fence, until the parts are machined. After that point, the extra 5 sets will be available for purchase at a higher price.

As it stands, this is looking like the route forward:

1. Greenlight the machine shop by June 2nd.

2. Receive first set of machined parts around start of July

3. Adjustments if needed, then machine the rest of the parts

4. All parts received around start of August

5. Machine and press crown tubes by hand

6. Shipping sets out late August - early September

As for the crystal gaskets, I am still waiting on pricing from switzerland, but the pricing from my cnc shop stands as worst case. I will be proceeding with my gasket design for the bezel, as I have not been able to acquire a gen gasket, so a custom gasket will be required nevertheless.

- 25/12/21

- 154

- 129

- 43

- 25/12/21

- 154

- 129

- 43

The case gasket came in. The results were surprising! First, the gen gasket is discernably nicer than either rep I have. However, it is most comparable to the cheap eBay gasket, as opposed to the PPF. The gen and ebay one both have very rounded protrusions, while the PPF is more flat. The ebay one, however, looks cnc machined? There are clear tool marks on the gasket, though they shouldn't impede the functionality.

Ultimately, I would recommend the gen gasket over the alternatives. So far there are two people who are interested in a gen gasket. If I get 5 people, I'll middle man the eBay blister pack of 5 and include it in the buyers' orders. To cover shipping, duties, etc, the cost per gasket is $230USD. +5% if paying G&S.

Final notes:

1. The vacheron sold outside RWI. Big thanks to the buyer!

2. This is the ebay gasket: https://www.ebay.com/itm/375596869140

Ultimately, I would recommend the gen gasket over the alternatives. So far there are two people who are interested in a gen gasket. If I get 5 people, I'll middle man the eBay blister pack of 5 and include it in the buyers' orders. To cover shipping, duties, etc, the cost per gasket is $230USD. +5% if paying G&S.

Final notes:

1. The vacheron sold outside RWI. Big thanks to the buyer!

2. This is the ebay gasket: https://www.ebay.com/itm/375596869140

- 25/12/21

- 154

- 129

- 43

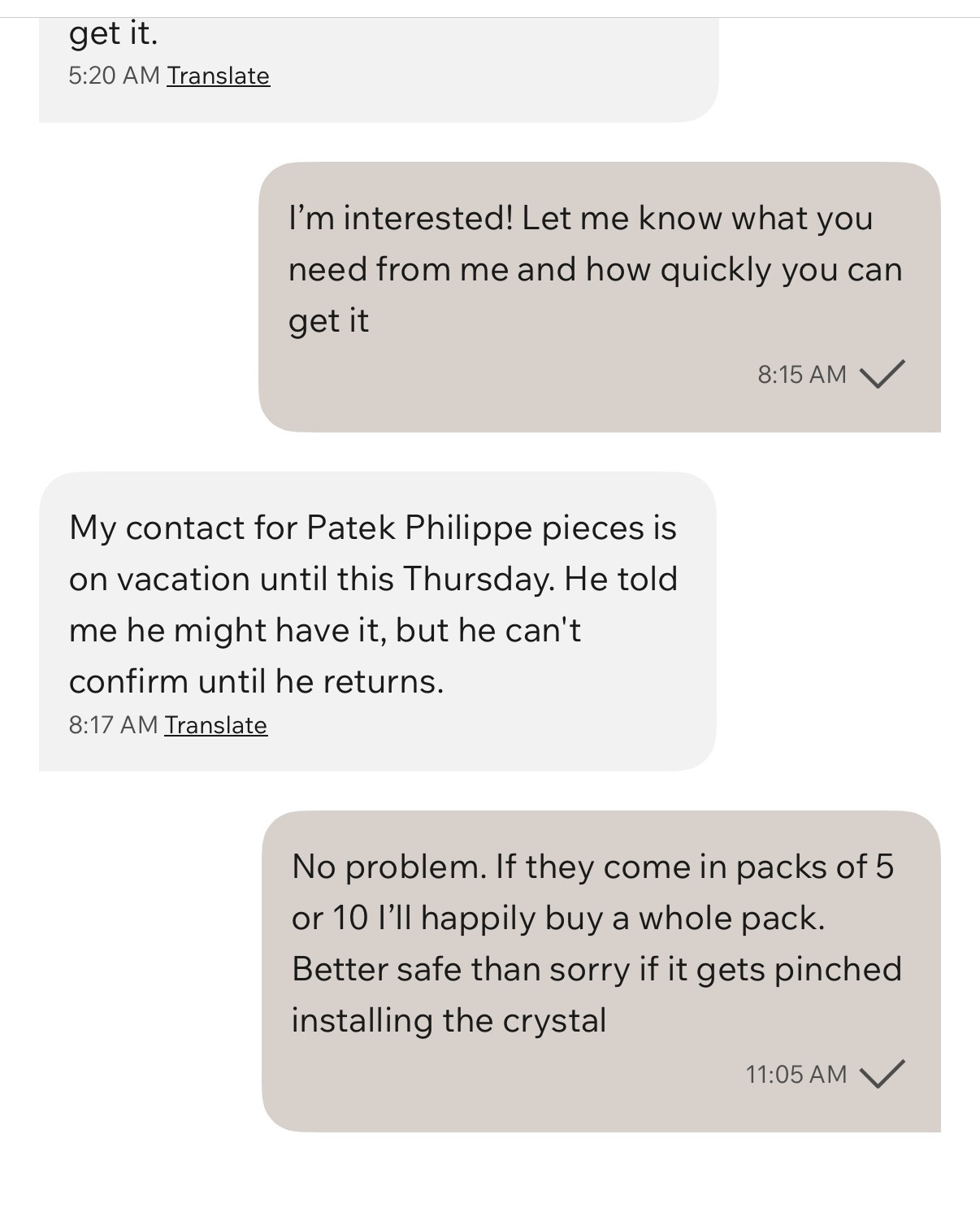

Miniscule update:

1. I'm collecting funds from those who want a case gasket. Ordering them asap

2. The person who sold me my case gasket can supposedly get me a crystal gasket. Not holding my breath, but would be fantastic! If this is the case, I will pause the bezel production until it comes in so I can adjust to gen-spec

1. I'm collecting funds from those who want a case gasket. Ordering them asap

2. The person who sold me my case gasket can supposedly get me a crystal gasket. Not holding my breath, but would be fantastic! If this is the case, I will pause the bezel production until it comes in so I can adjust to gen-spec

- 25/12/21

- 154

- 129

- 43

Just thinking out loud here. I think the reason I haven’t been able to find a 3700 gasket is because they don’t exist. Or, at least, they will never be available to buy. It isn’t a product anymore.

Why? For watches 25+ years old, PP requires you to send it in to Switzerland. They will not provide parts to service centers anymore. Moreover, it’s a part that is replaced out of necessity, not aesthetic, so they don’t pop up used. Why there was ever one for sale (you can find a sold-out listing if you search for it) is beyond me.

The only instance I think I could find one is under perfect circumstances. Being that the case gaskets come in sets of 4 or 5, I presume crystal gaskets could be the same. Or maybe they came with the replacement crystal. But if they came in packs, it’s possible a now-defunct authorized service place has a spare. But from everyone I’ve spoken to who can get gen parts, they couldn’t get the crystal gasket.

So, I’m thinking I’ll put in a firm condition. If the guy I’m waiting to hear back from (should get back to me late next week) doesn’t have one, I will abandon the search so not to delay production, which is scheduled to begin Monday.

That said, if I do somehow acquire a gen gasket after the run is done, I’ll update the bezel design and see if enough people want a replacement to justify manufacturing some.

Why? For watches 25+ years old, PP requires you to send it in to Switzerland. They will not provide parts to service centers anymore. Moreover, it’s a part that is replaced out of necessity, not aesthetic, so they don’t pop up used. Why there was ever one for sale (you can find a sold-out listing if you search for it) is beyond me.

The only instance I think I could find one is under perfect circumstances. Being that the case gaskets come in sets of 4 or 5, I presume crystal gaskets could be the same. Or maybe they came with the replacement crystal. But if they came in packs, it’s possible a now-defunct authorized service place has a spare. But from everyone I’ve spoken to who can get gen parts, they couldn’t get the crystal gasket.

So, I’m thinking I’ll put in a firm condition. If the guy I’m waiting to hear back from (should get back to me late next week) doesn’t have one, I will abandon the search so not to delay production, which is scheduled to begin Monday.

That said, if I do somehow acquire a gen gasket after the run is done, I’ll update the bezel design and see if enough people want a replacement to justify manufacturing some.

Yep, I'm with you on that. I've checked with all of my usual contacts plus many more to no avail. No 3700 crystal gaskets anywhere. So I guess you're right - these are not readily available, least from the usual resellers and independent watchmakers. I can't see much added value in getting an OME gasket if the custom bezel & gasket are measured to work with the gen spec crystal. It's a question of a tolerance of 0.2-0.5mm at most I guess so I can't see how that could affect the project in real life, visually or mechanically. So, yep, I'm OK with you simply producing a custom gasket at whatever specs you find fit. Thanks for pushing this project anyway.Just thinking out loud here. I think the reason I haven’t been able to find a 3700 gasket is because they don’t exist. Or, at least, they will never be available to buy. It isn’t a product anymore.

Why? For watches 25+ years old, PP requires you to send it in to Switzerland. They will not provide parts to service centers anymore. Moreover, it’s a part that is replaced out of necessity, not aesthetic, so they don’t pop up used. Why there was ever one for sale (you can find a sold-out listing if you search for it) is beyond me.

The only instance I think I could find one is under perfect circumstances. Being that the case gaskets come in sets of 4 or 5, I presume crystal gaskets could be the same. Or maybe they came with the replacement crystal. But if they came in packs, it’s possible a now-defunct authorized service place has a spare. But from everyone I’ve spoken to who can get gen parts, they couldn’t get the crystal gasket.

So, I’m thinking I’ll put in a firm condition. If the guy I’m waiting to hear back from (should get back to me late next week) doesn’t have one, I will abandon the search so not to delay production, which is scheduled to begin Monday.

That said, if I do somehow acquire a gen gasket after the run is done, I’ll update the bezel design and see if enough people want a replacement to justify manufacturing some.

- 25/12/21

- 154

- 129

- 43

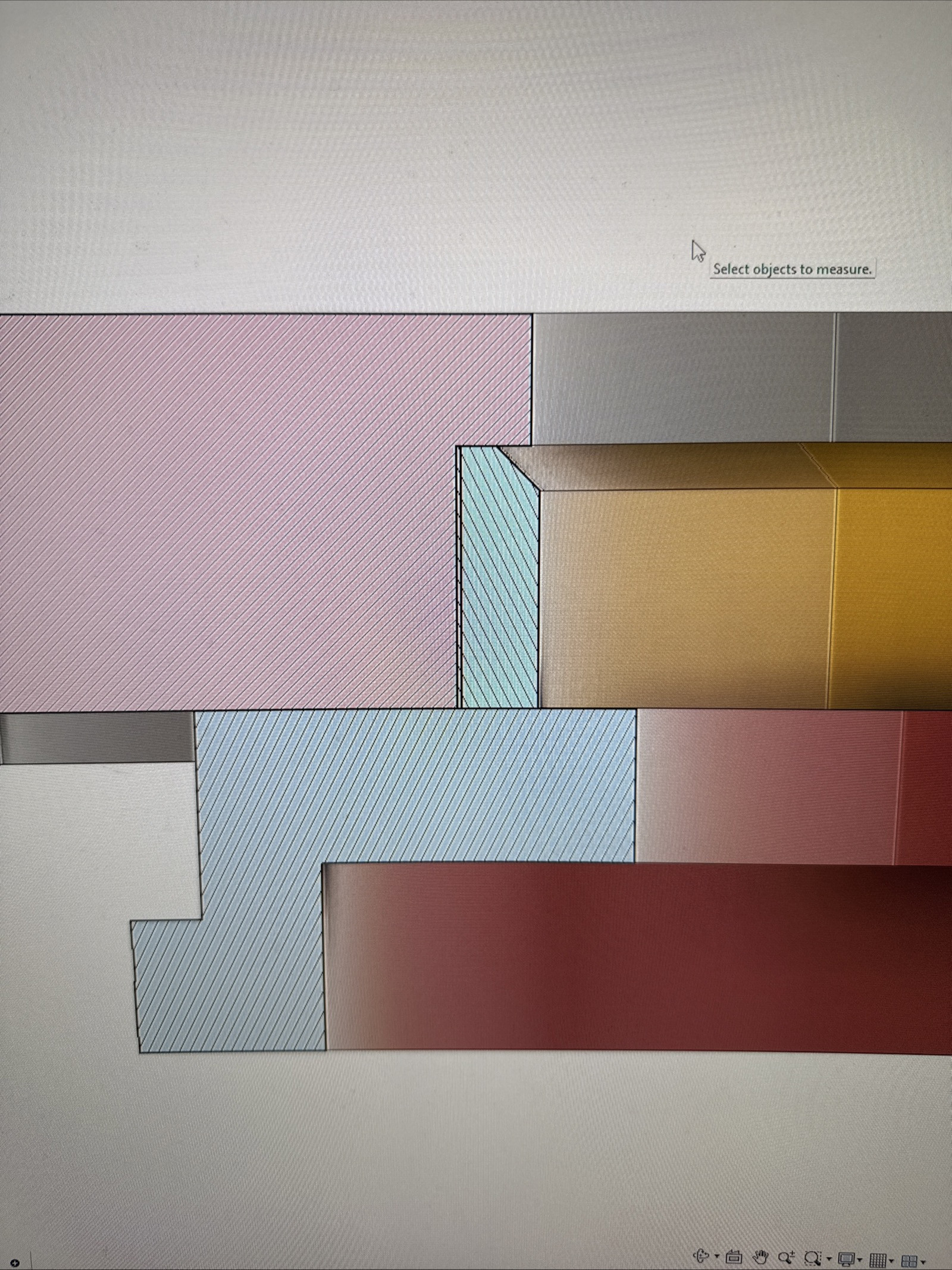

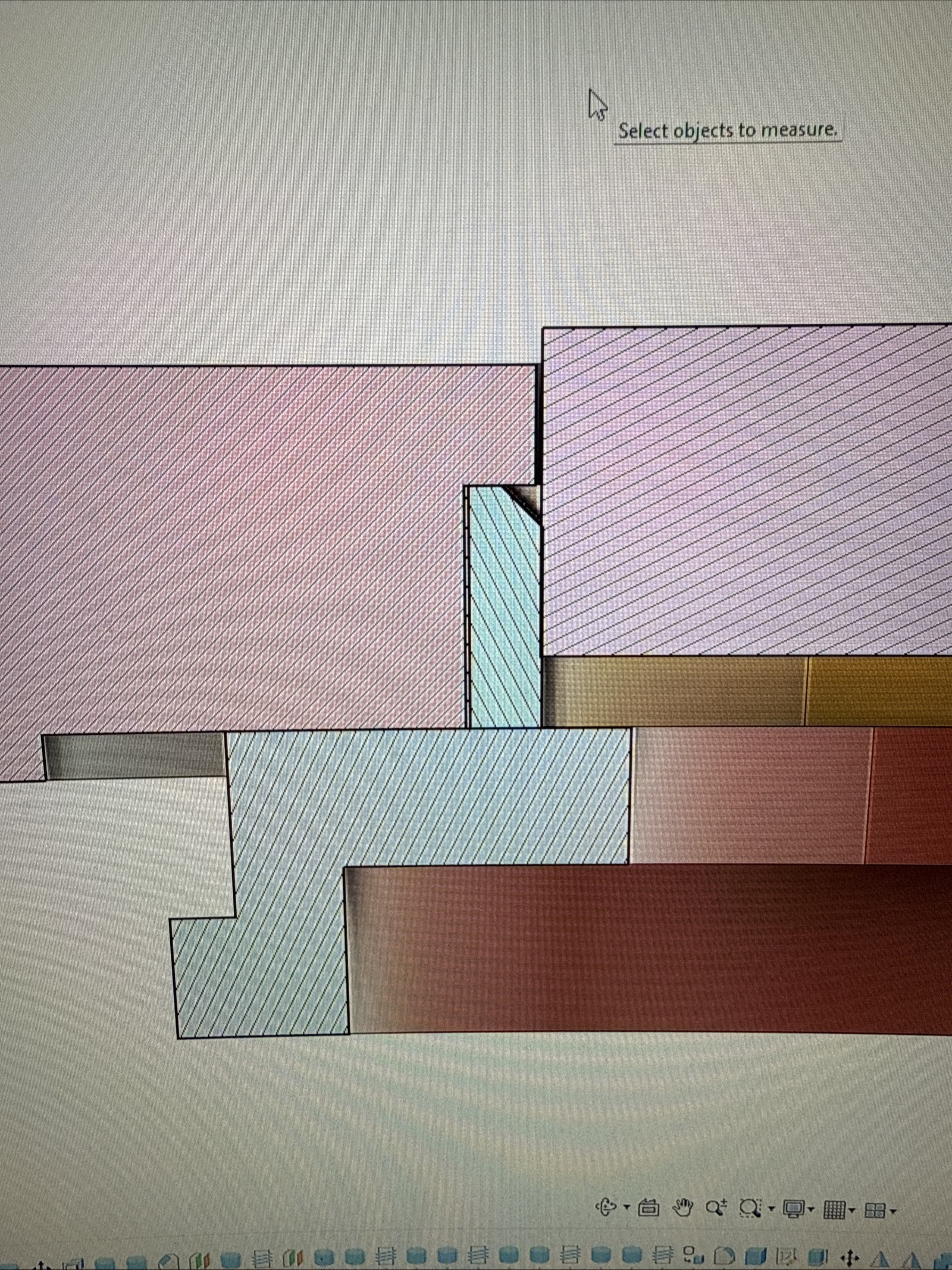

So in terms of tolerances, they do need to be tight for a good waterproof seal. Part of the cost of the CNC work is that I pushed tight tolerances in spots that matter, such as the gasket opening. The gasket should be about 0.05mm oversized to have a good compression fit at this volume. I’m also having a professional watchmaker (not just a guy who serviced stuff, this guy makes watches from scratch himself) go over the files to confirm my tolerances specifically with the crystal gasket.Yep, I'm with you on that. I've checked with all of my usual contacts plus many more to no avail. No 3700 crystal gaskets anywhere. So I guess you're right - these are not readily available, least from the usual resellers and independent watchmakers. I can't see much added value in getting an OME gasket if the custom bezel & gasket are measured to work with the gen spec crystal. It's a question of a tolerance of 0.2-0.5mm at most I guess so I can't see how that could affect the project in real life, visually or mechanically. So, yep, I'm OK with you simply producing a custom gasket at whatever specs you find fit. Thanks for pushing this project anyway.

But yeah, gen or rep gasket won’t make a difference as long as the bezel is made well!

Also, just ordered the case gaskets. Thanks all!

- 25/12/21

- 154

- 129

- 43

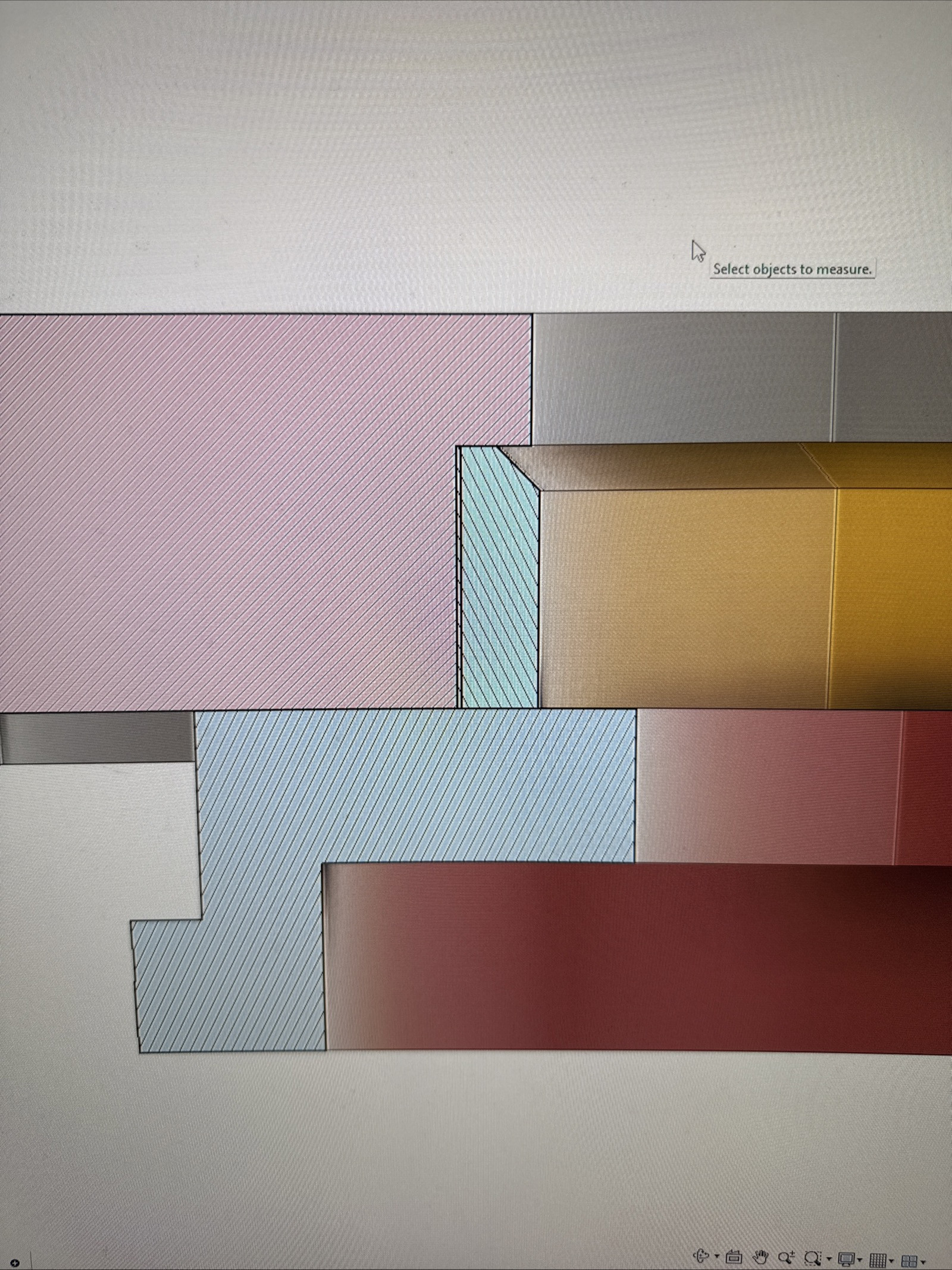

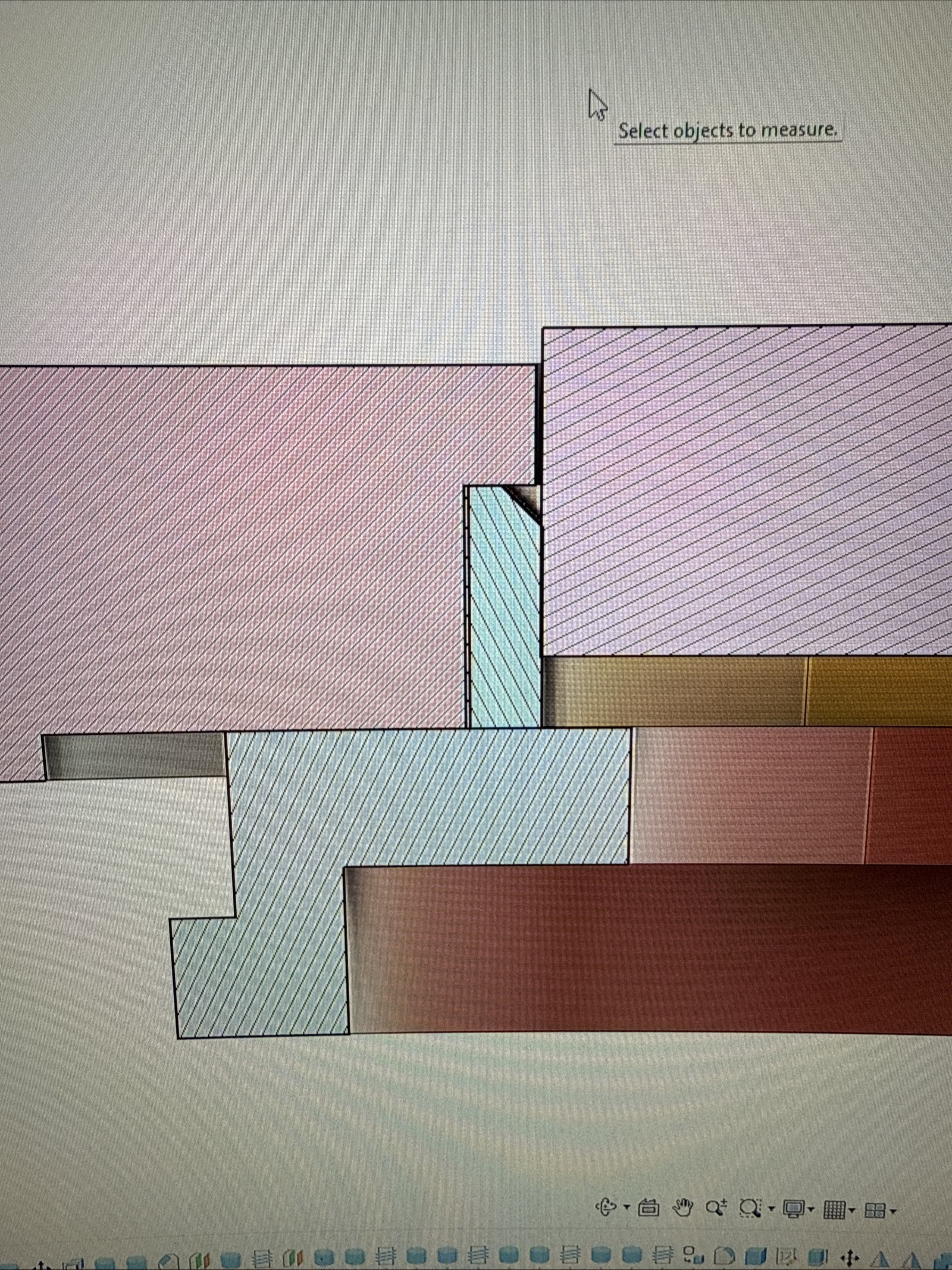

Small update. Comparing the gen gasket with the rep gasket, I updated the bezel model slightly. We're talking a tenth of a millimeter as the largest measurement change, but regardless I felt it necessary. The flat spot of the gasket was 0.6mm including the lip, and 0.5mm at the flats. I adjusted the bezel fit by 0.1mm as originally it was sized for 0.6mm. This was a perfect adjustment, as it changed the inner ring of the gasket cutout from 0.2mm to 0.3mm which matches the case side recess. This had stumped me during modelling, so I'm glad to have figured out that mystery. I doubt it would have made a difference in the end if it was 0.1mm short there due to gasket compression, but nevertheless I am relieved.

Once the crystal gasket tolerances are reviewed by my friend, the bezel model will be finalized for the shop. I am sending payment for the run this week regardless, and just having them do the bezels last.

Once the crystal gasket tolerances are reviewed by my friend, the bezel model will be finalized for the shop. I am sending payment for the run this week regardless, and just having them do the bezels last.

- 25/12/21

- 154

- 129

- 43

Update from the CNC shop. ETA is 18 business days plus shipping. Crazy! Once I’ll post pics as I get them. Very excited

- 25/12/21

- 154

- 129

- 43

Great news. I got bezel measurements from a friend with Gen. My gasket estimates were 100% accurate. Naturally I can’t confirm this without physically testing, but it seems the crystal gaskets I make will be gen spec

- 25/12/21

- 154

- 129

- 43

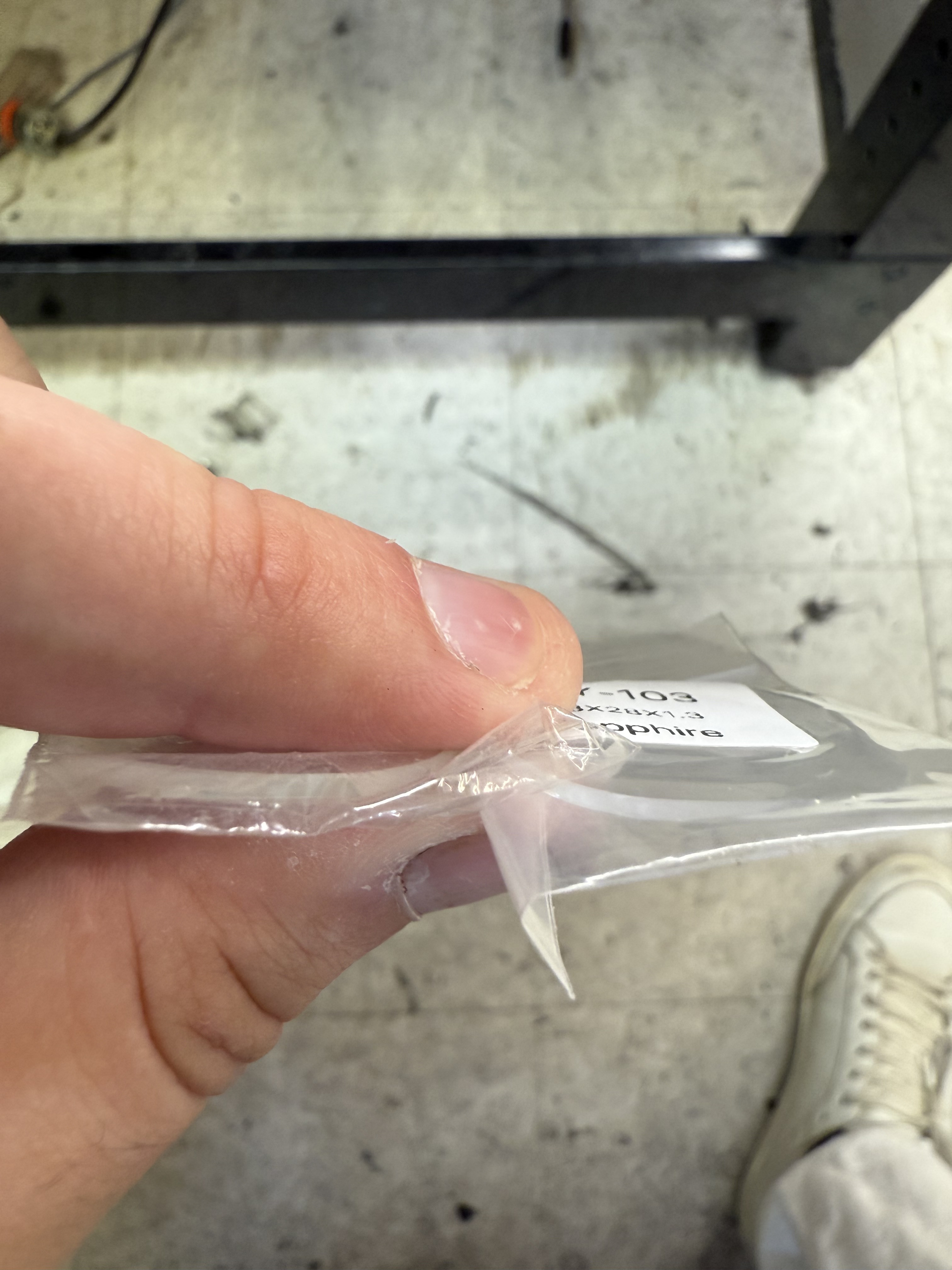

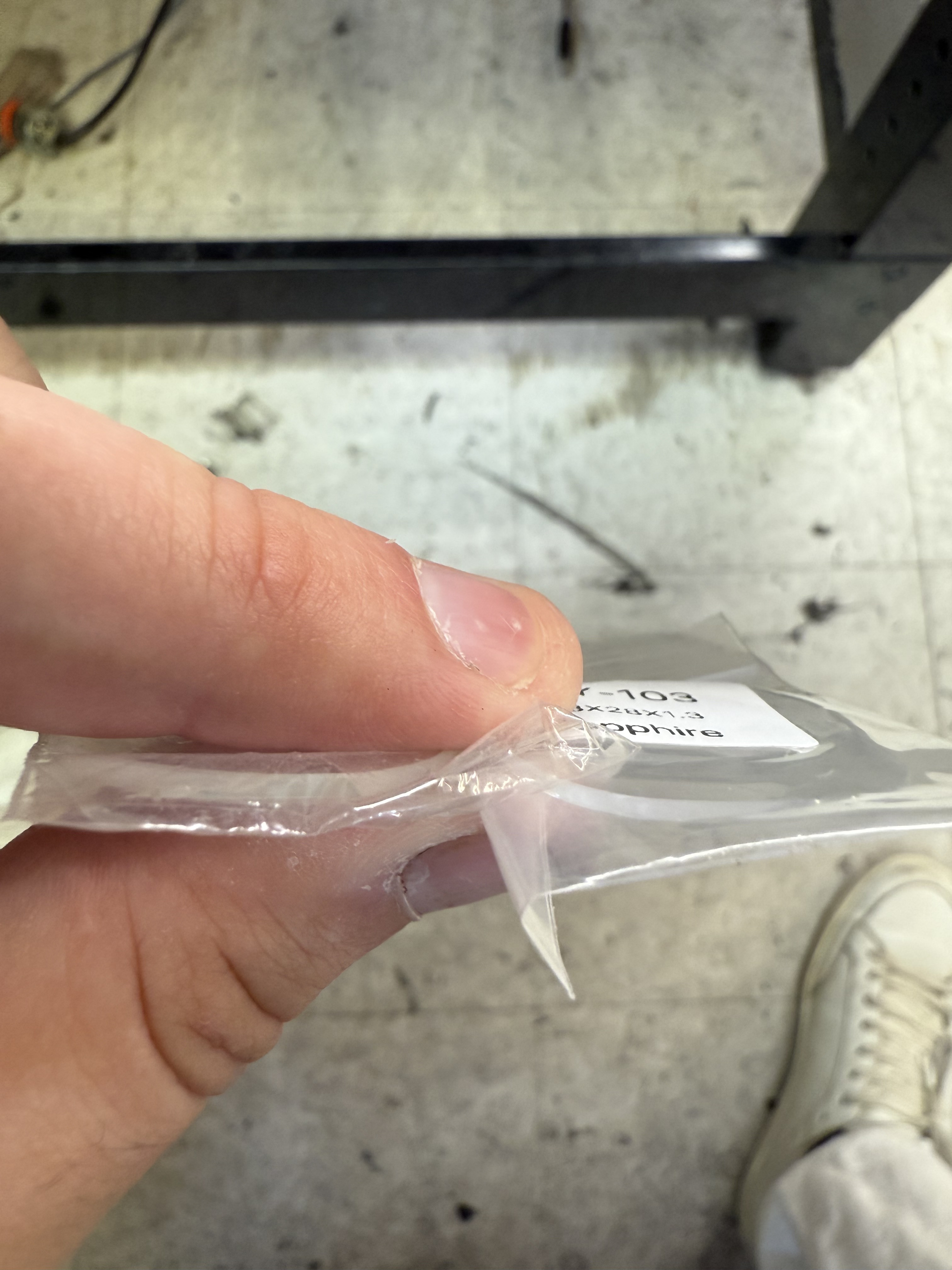

One of the members on the run purchased the eBay crystal for me to check out. It does not appear to be usable. As I feared, it is 1.3mm thick.

Photos are with the crystals measured in their bags, so the caliper reading is oversized.

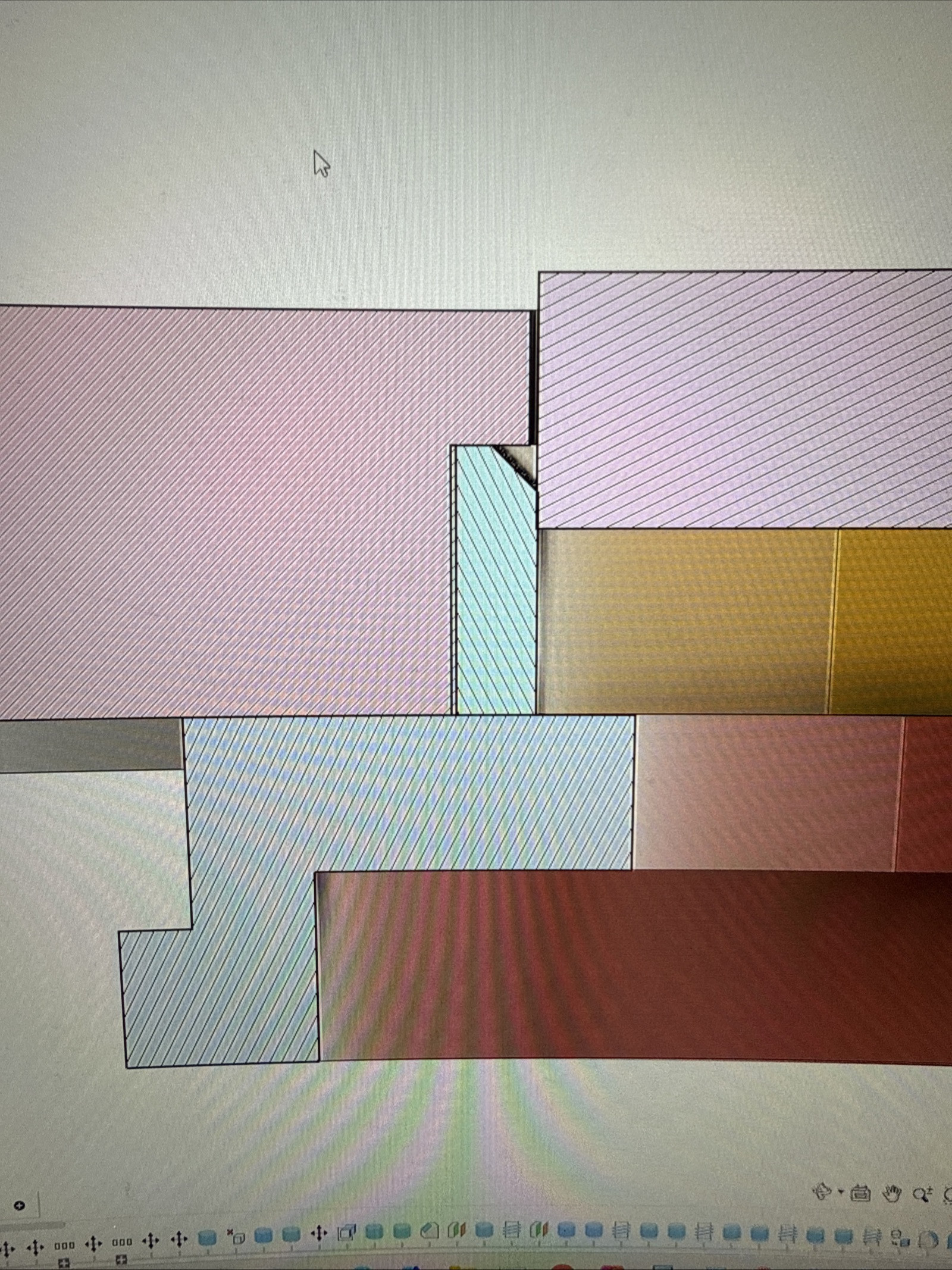

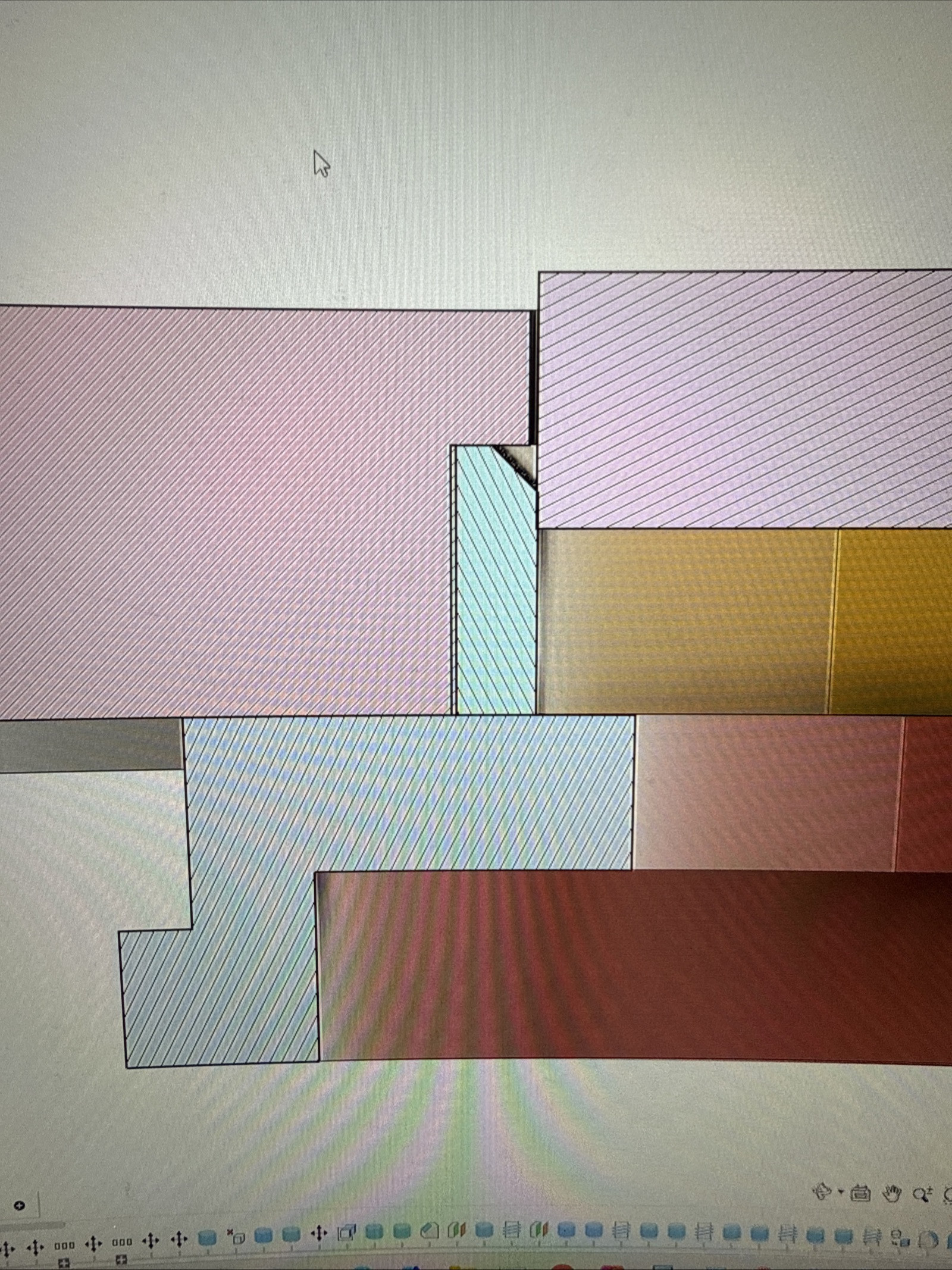

I’ve attached a section analysis of the watch to show why the thickness is an issue. The 3700 has a lip on the bezel, and the gasket sits below. Notice how little of the crystal is actually secured by the gasket if it is 1.3mm thick.

The seller assures me they have used it in a 3700, but I am waiting on photos/videos from them to confirm this.

For now, assume ONLY GEN CRYSTAL will work properly, BUT you could probably get away with the eBay one if you aren’t worried about waterproofing

Photos are with the crystals measured in their bags, so the caliper reading is oversized.

I’ve attached a section analysis of the watch to show why the thickness is an issue. The 3700 has a lip on the bezel, and the gasket sits below. Notice how little of the crystal is actually secured by the gasket if it is 1.3mm thick.

The seller assures me they have used it in a 3700, but I am waiting on photos/videos from them to confirm this.

For now, assume ONLY GEN CRYSTAL will work properly, BUT you could probably get away with the eBay one if you aren’t worried about waterproofing

- 25/12/21

- 154

- 129

- 43

GASKET / CRYSTAL BIG UPDATE!

I am speaking with a shop to manufacture crystals. The ebay one is NOT gen spec. But I have the files, may as well get some made! MOQ will be high, but I have a friend who is willing to take on inventory to mitigate that. eBay crystal is about $160USD, so my target price is $140USD. At the moment there are no gen crystals for sale, so this will be the best bet for most people on the run.

Now for the gaskets. The swiss place declined the project. Here is what the plan is now. As mentioned, my cnc shop can injection mold 100 for $4k. The same guy stocking crystals is up for stocking this too, so really MOQ is 50. There are 6 people on the run who need gaskets, so cost per person is around $330.

However, as this is a huge cost, I am going to buy some Hytrel filament to 3D print test gaskets. If they work perfectly that way then we can use them. I have my doubts, though. The hardness is 60 compared to the proper 72. Perhaps the added volume of this gasket compared to conventional ones will help mitigate. But at the least, testing with a printed one will help confirm the fit prior to manufacturing.

I am speaking with a shop to manufacture crystals. The ebay one is NOT gen spec. But I have the files, may as well get some made! MOQ will be high, but I have a friend who is willing to take on inventory to mitigate that. eBay crystal is about $160USD, so my target price is $140USD. At the moment there are no gen crystals for sale, so this will be the best bet for most people on the run.

Now for the gaskets. The swiss place declined the project. Here is what the plan is now. As mentioned, my cnc shop can injection mold 100 for $4k. The same guy stocking crystals is up for stocking this too, so really MOQ is 50. There are 6 people on the run who need gaskets, so cost per person is around $330.

However, as this is a huge cost, I am going to buy some Hytrel filament to 3D print test gaskets. If they work perfectly that way then we can use them. I have my doubts, though. The hardness is 60 compared to the proper 72. Perhaps the added volume of this gasket compared to conventional ones will help mitigate. But at the least, testing with a printed one will help confirm the fit prior to manufacturing.

Hey man, many thanks for the update. Not only are gen gasket impossible to source but gen crystal are equally hard to find. So hats off for your exploring alternative avenues. Please keep us posted, txs.GASKET / CRYSTAL BIG UPDATE!

I am speaking with a shop to manufacture crystals. The ebay one is NOT gen spec. But I have the files, may as well get some made! MOQ will be high, but I have a friend who is willing to take on inventory to mitigate that. eBay crystal is about $160USD, so my target price is $140USD. At the moment there are no gen crystals for sale, so this will be the best bet for most people on the run.

Now for the gaskets. The swiss place declined the project. Here is what the plan is now. As mentioned, my cnc shop can injection mold 100 for $4k. The same guy stocking crystals is up for stocking this too, so really MOQ is 50. There are 6 people on the run who need gaskets, so cost per person is around $330.

However, as this is a huge cost, I am going to buy some Hytrel filament to 3D print test gaskets. If they work perfectly that way then we can use them. I have my doubts, though. The hardness is 60 compared to the proper 72. Perhaps the added volume of this gasket compared to conventional ones will help mitigate. But at the least, testing with a printed one will help confirm the fit prior to manufacturing.