Hi everyone, while playing the waiting game on my milk case to arrive and Ruby to message back on a dial, I have a couple questions on the dial mounting.

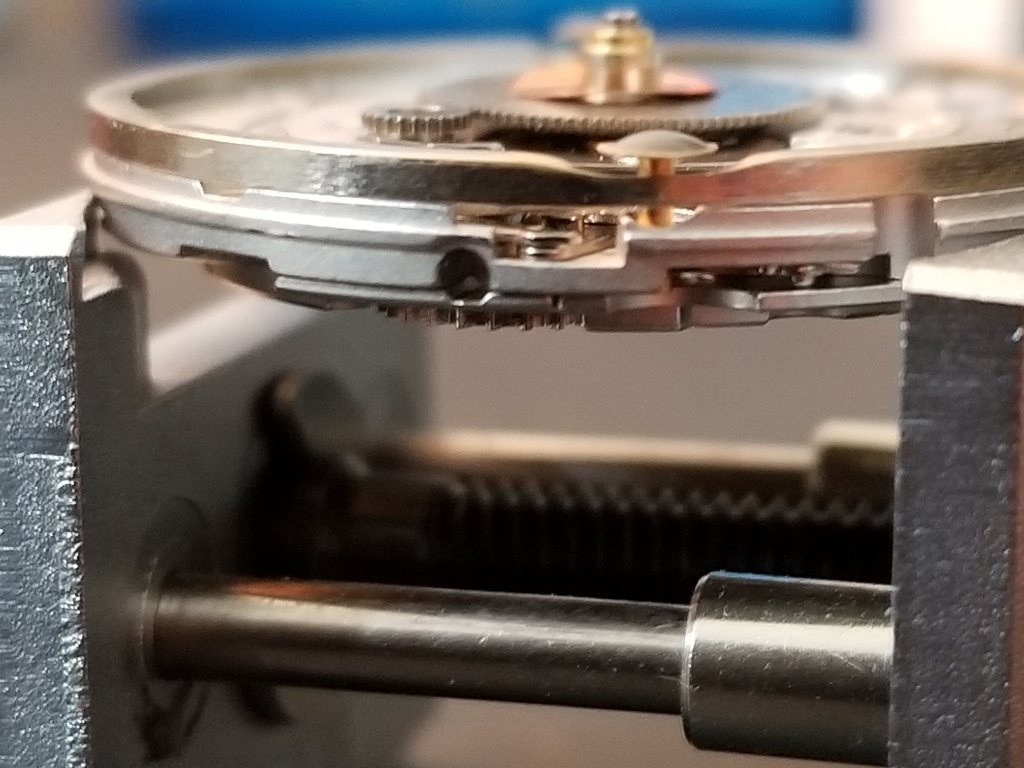

Tripdog had said I'll need to break off the dial mounts and glue the dial to the spacer so that it fits, and of course allows the DWO to rotate. My question on that is: how will I be able to keep the dial+ring secure on the movement? i have never had to do this so I am unaware of this process, so any and all info/advice is welcome! In addition to that question, is anyone familiar with the process of taking an eta2836 and swapping the drive with a swiss 2846? (appears to make it a low beat). I saw a post on rwg someone did it back in 2012, curious if anyone knows how to do that.

Thanks everyone xD

Tripdog had said I'll need to break off the dial mounts and glue the dial to the spacer so that it fits, and of course allows the DWO to rotate. My question on that is: how will I be able to keep the dial+ring secure on the movement? i have never had to do this so I am unaware of this process, so any and all info/advice is welcome! In addition to that question, is anyone familiar with the process of taking an eta2836 and swapping the drive with a swiss 2846? (appears to make it a low beat). I saw a post on rwg someone did it back in 2012, curious if anyone knows how to do that.

Thanks everyone xD

Last edited: