Oh DearI have buyed this http://puretime.pro/goods.php?id=5512 last week. He ship and I'm waiting to recieve.....

Sent from my SM-G988B using Tapatalk

Oh DearI have buyed this http://puretime.pro/goods.php?id=5512 last week. He ship and I'm waiting to recieve.....

I have buyed this http://puretime.pro/goods.php?id=5512 last week. He ship and I'm waiting to recieve.....

What? $650 for a VS126610LN?

Still, hope you will receive it as you have ordered

Post it I wonder what you got for 650$yes I know it is not trusted seller.... I'm stupid.

today ups package arrive....I hope I recieve VSF... I will post here some photo...

it is high price?

Check link of td I posted , 650 from doggy site or 468 from td ...?it is high price?

Guys Toughts on this? AS it is quite impossible getting one VSF 126610LV currently from our TD, searching in aliexpress I found a shop selling this quite cheap (less than 400$ shipping included) which is stoning. Could this even be possible?

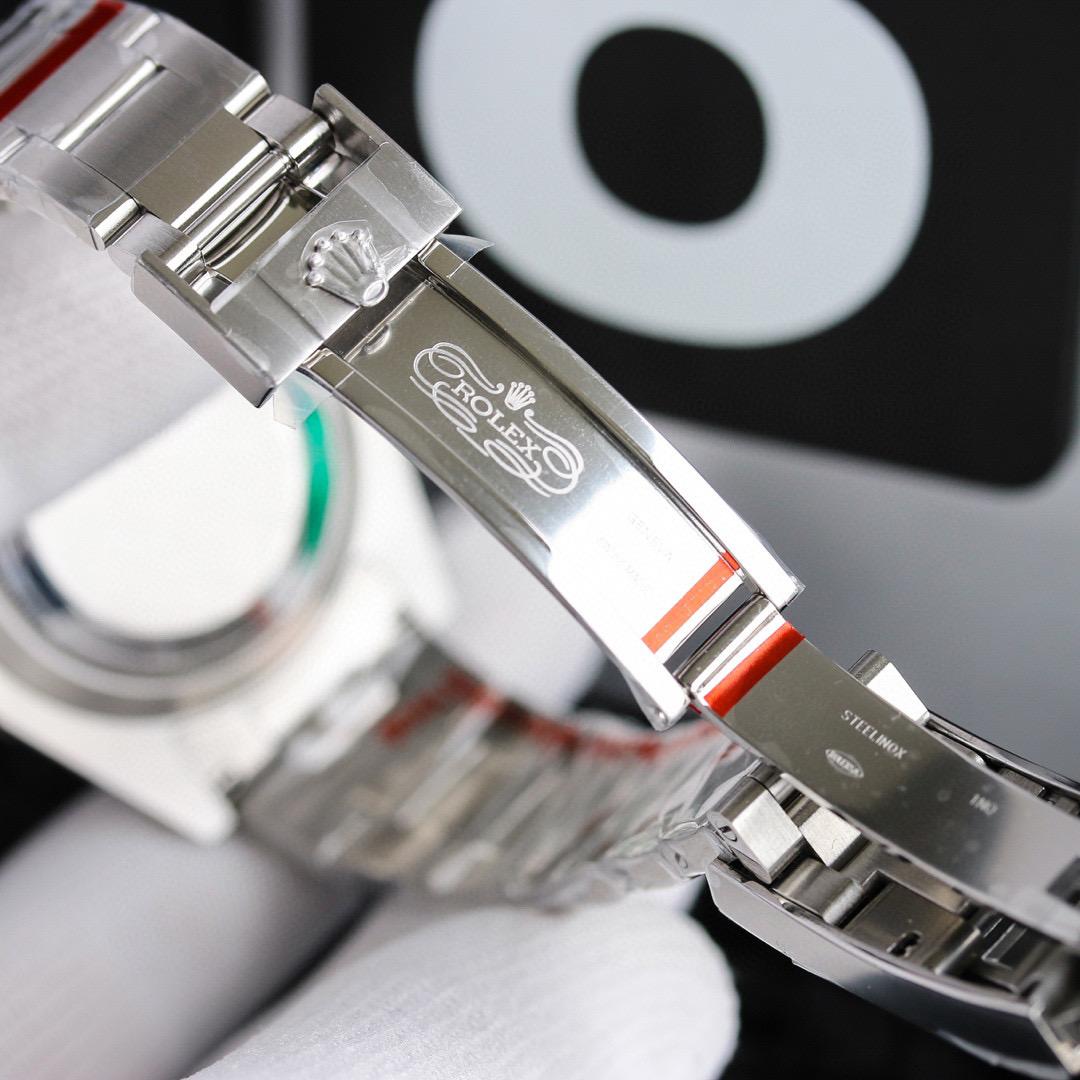

Here is just the bunch of QC pics the dealer just sent me and they look good. The LEC is a bit too visible but might be just the lighting.

I think i will gamble russian roulette and pull the triguer given the current circumstances as otherwise no doubt I would habe used my TD from the forum.

Check link of td I posted , 650 from doggy site or 468 from td ...?

Oh well ... they slowly getting vsf , im waiting for mine since Marchyes. but it is unavailable fromother trusted site so i decide to risk! i'm stupid, I know...

ARRIVED!!!

it is VSF???

There's also the 1LQ clasp, on the VSF LN I think...

As far as I know VSF serial begins with '2R'.

Noob (gold "N-094L" sticker)

Guys Toughts on this? AS it is quite impossible getting one VSF 126610LV currently from our TD, searching in aliexpress I found a shop selling this quite cheap (less than 400$ shipping included) which is stoning. Could this even be possible?

Here is just the bunch of QC pics the dealer just sent me and they look good. The LEC is a bit too visible but might be just the lighting.

I think i will gamble russian roulette and pull the triguer given the current circumstances as otherwise no doubt I would habe used my TD from the forum.