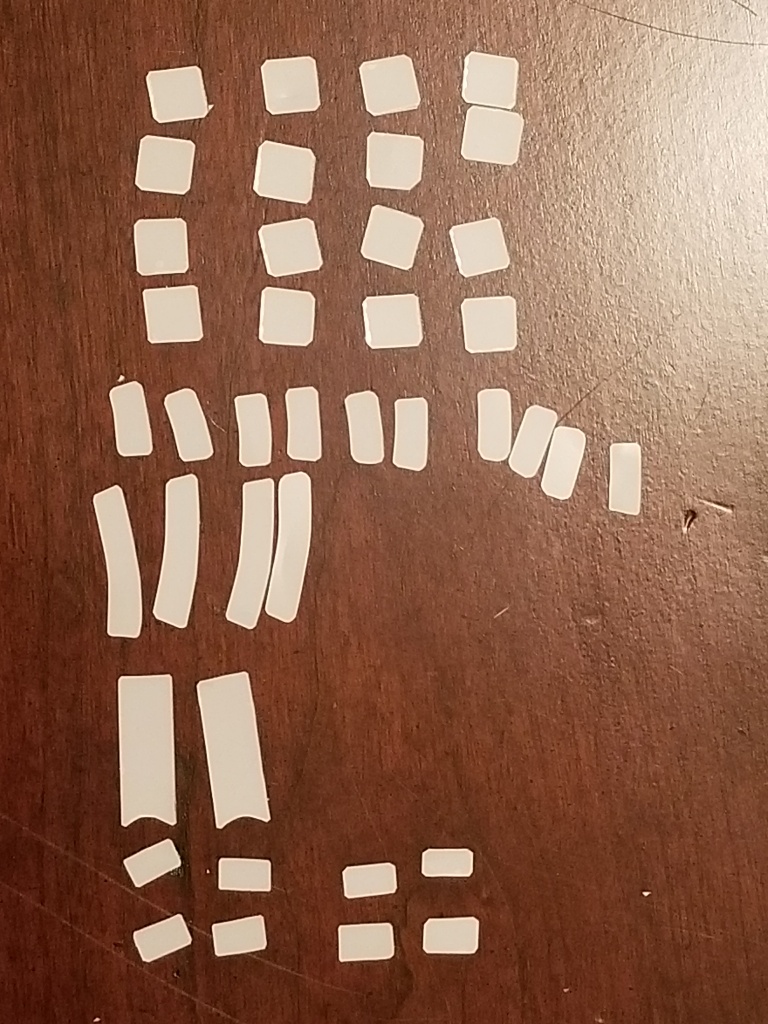

Not sure if anyone has tried ceramic coating the watch and bracelet. I am currently doing a test.

After seeing RiffRalf clasp get all worn off from his desk dives...i figured i'd try it to some clasps to see.

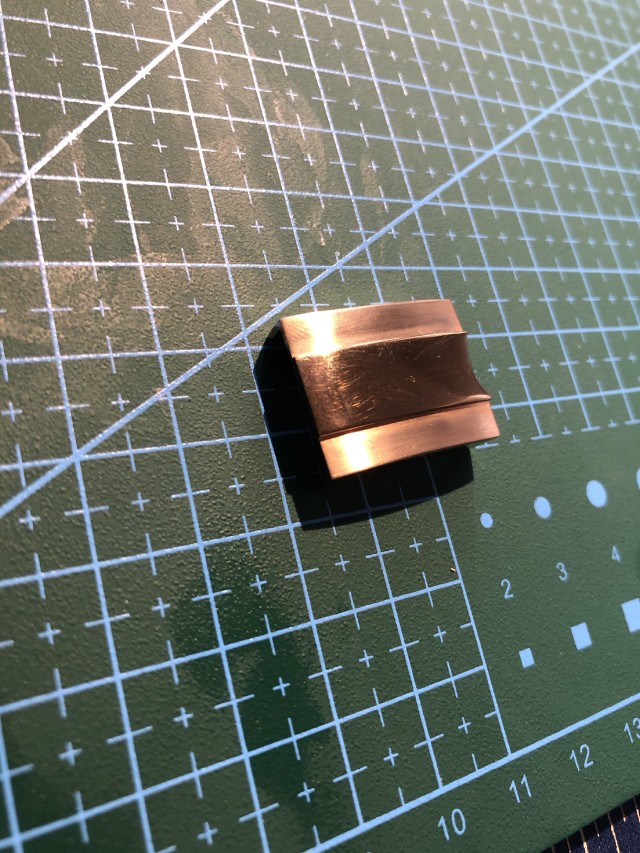

I do it on cars for protection i figure why not on a watch. So I'm testing a rose gold yatchmaster clasp to see.

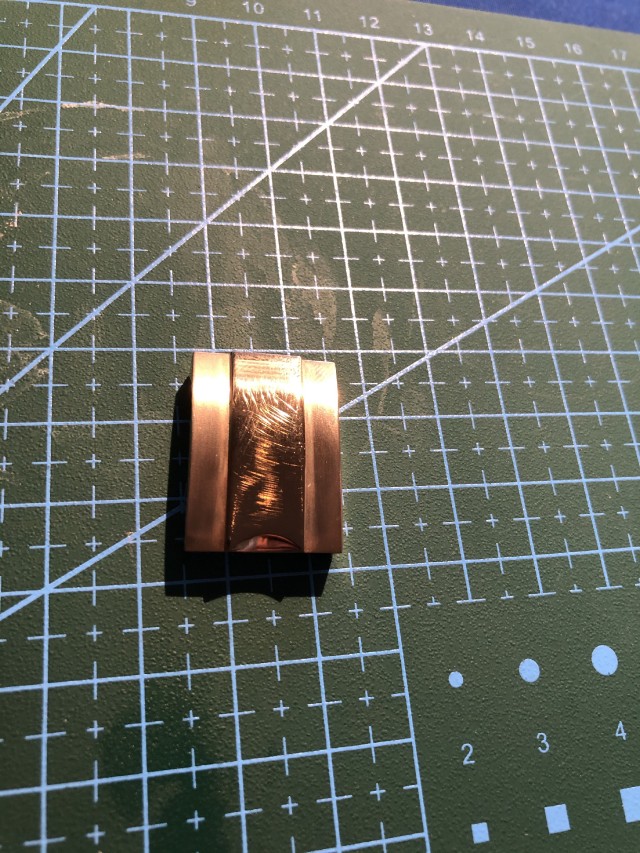

Like my cars i would do a double layer of ceramic to see if this reduces the scratching effect on them.

I think the whole purpose is really to protect the YG/RG plated watches. With one layer on right now I can't tell its there.

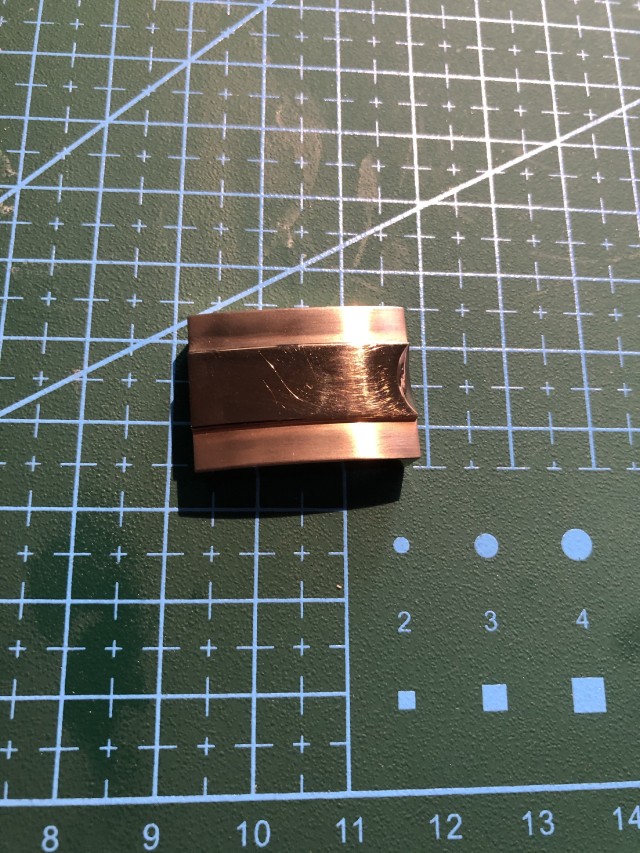

Brushed looks brushed as it was originally and polished looks polished. Its not visible. to the eye. you would follow the same procedure

as if you were ceramic coating a car. now its on its 24hr cure period....then I will hit it again with another coat and let it cure for another 24hrs.

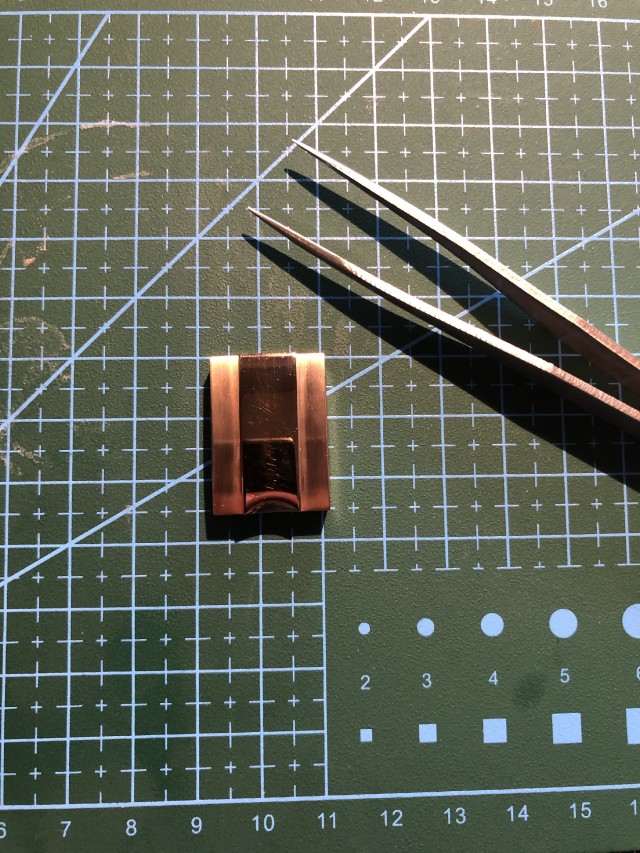

then bust out a nail and see how it hold up against scratches. if it works out...could be an answer to helping preserve YG/RG watches.

then i will move to my VR RG yahctmaster and do the full watch if i like the results but right now i have spare clasps that i order that i can test one.

visually you would never know if it was coated or not. so that is nice. but once you put it on...whatever scratches were in the watch are now locked it.

this is not a permanent fix. however can last a few years depending on use maybe longer....but its looking to be a good start in adding some protection.

if the VR RG yahctmaster turns out I bought a YG submariner that i will work out the full bracelet and watch case and bezel.

most ceramic coating is for hydrophobic purposes. salt resistance. solvent resistance. so resisting sweat and having that peel affect or fade...it could definitely

help in that category.

a big scratch...this will not protect from...maybe it will lessen the blow but if you take your time. do a dual layer....i think it will be a start at least in the fading or peeling

of the plating while adding some desk dive protection.

if anyone else has done this please chime in with your results. best on a new unworn watch for no scratches to get locked or go through more labor of love and get the scratches out.

then coat it.

After seeing RiffRalf clasp get all worn off from his desk dives...i figured i'd try it to some clasps to see.

I do it on cars for protection i figure why not on a watch. So I'm testing a rose gold yatchmaster clasp to see.

Like my cars i would do a double layer of ceramic to see if this reduces the scratching effect on them.

I think the whole purpose is really to protect the YG/RG plated watches. With one layer on right now I can't tell its there.

Brushed looks brushed as it was originally and polished looks polished. Its not visible. to the eye. you would follow the same procedure

as if you were ceramic coating a car. now its on its 24hr cure period....then I will hit it again with another coat and let it cure for another 24hrs.

then bust out a nail and see how it hold up against scratches. if it works out...could be an answer to helping preserve YG/RG watches.

then i will move to my VR RG yahctmaster and do the full watch if i like the results but right now i have spare clasps that i order that i can test one.

visually you would never know if it was coated or not. so that is nice. but once you put it on...whatever scratches were in the watch are now locked it.

this is not a permanent fix. however can last a few years depending on use maybe longer....but its looking to be a good start in adding some protection.

if the VR RG yahctmaster turns out I bought a YG submariner that i will work out the full bracelet and watch case and bezel.

most ceramic coating is for hydrophobic purposes. salt resistance. solvent resistance. so resisting sweat and having that peel affect or fade...it could definitely

help in that category.

a big scratch...this will not protect from...maybe it will lessen the blow but if you take your time. do a dual layer....i think it will be a start at least in the fading or peeling

of the plating while adding some desk dive protection.

if anyone else has done this please chime in with your results. best on a new unworn watch for no scratches to get locked or go through more labor of love and get the scratches out.

then coat it.