- 27/3/06

- 453

- 2

- 0

I am working on a new 201a dial now.

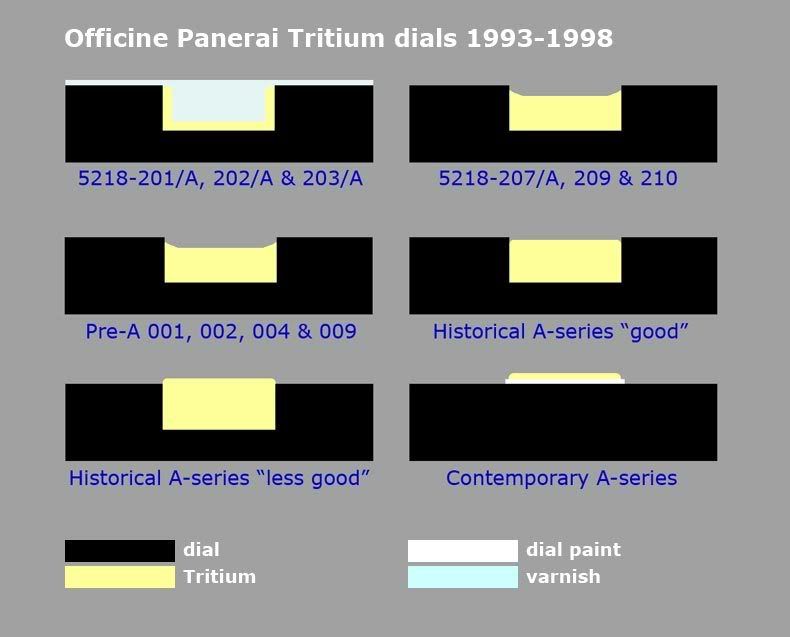

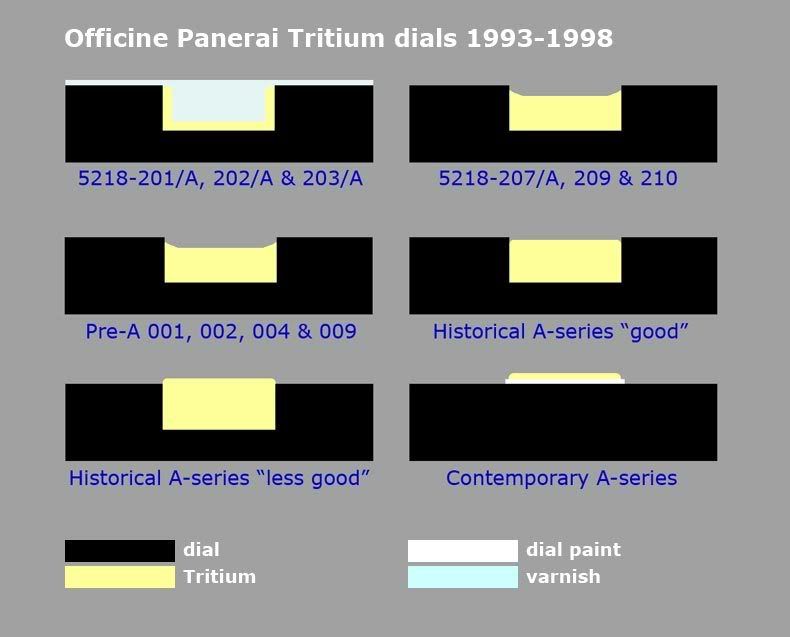

Gen 201a was made from solid disk with all nos an index were routed(cnc engraved)Lume were then

painted onto the boottom and 4 sides walls of all the nos and index.Vanish was finially filled

into the hollow aeras of the index.

With the help and assistance from Enzo.He made me some very clear and accurate artwrok file below.

In order to make a good 201a dial,

I have listed my specs clearly and exactly as bellow.

1.To make dial with cnc engrave precisely like enzo drawing.

2.To add lume to the engraved nos and index the way I described as above.

3.to print the logo like the Enzo artwork.

Initial sorucing of this dial was very discouraging.

All my current replica dial suppliers can do NO 3 task only.

Why?

1.They do not have the CNC equipment to do this kind of engraves.

2.the lume job is just too complicated to for factory mass produciton run.

What to do next?

I have to take take off the "Panerai" logo from the artwork and asked some bigger /better equipped maker to see they can make a dial

like this.

Most of them can do the engrave ok.

But still the lume job not possible.

Panerai logo printing is out of the qaestions for obvious reason.

After careful consideration, I have to split the making into 3 stages.

stage 1.

Make and order the dial with the dial maker who have the facility to make it.

Stage 2.

I have to do the lume job 100% in house one by one.

Stage 3.

Send the lumed dial for printing of logos in the rep dial factory.

This is the first run of sterlie dial .

All comments are welcomed.

Gen 201a was made from solid disk with all nos an index were routed(cnc engraved)Lume were then

painted onto the boottom and 4 sides walls of all the nos and index.Vanish was finially filled

into the hollow aeras of the index.

With the help and assistance from Enzo.He made me some very clear and accurate artwrok file below.

In order to make a good 201a dial,

I have listed my specs clearly and exactly as bellow.

1.To make dial with cnc engrave precisely like enzo drawing.

2.To add lume to the engraved nos and index the way I described as above.

3.to print the logo like the Enzo artwork.

Initial sorucing of this dial was very discouraging.

All my current replica dial suppliers can do NO 3 task only.

Why?

1.They do not have the CNC equipment to do this kind of engraves.

2.the lume job is just too complicated to for factory mass produciton run.

What to do next?

I have to take take off the "Panerai" logo from the artwork and asked some bigger /better equipped maker to see they can make a dial

like this.

Most of them can do the engrave ok.

But still the lume job not possible.

Panerai logo printing is out of the qaestions for obvious reason.

After careful consideration, I have to split the making into 3 stages.

stage 1.

Make and order the dial with the dial maker who have the facility to make it.

Stage 2.

I have to do the lume job 100% in house one by one.

Stage 3.

Send the lumed dial for printing of logos in the rep dial factory.

This is the first run of sterlie dial .

All comments are welcomed.