- 9/12/18

- 2,752

- 11,786

- 113

I don't consider this to be a revelation or even a necessary modification for most, however I wanted to figure out how to achieve what I consider to be the perfect strap fitment for my Panerai. My preference is for there to be minimal gap between the lug ends of the strap and the case of the watch, with pronounced rounded definition of the strap where the tube passes through it. The OEM sized tubes are too thin to achieve this and provide little definition. I did some thinking on best methods & materials and after some trial and error I developed what I think is a really great result. Just thought I'd share as I know that there are others out there that enjoy their straps.

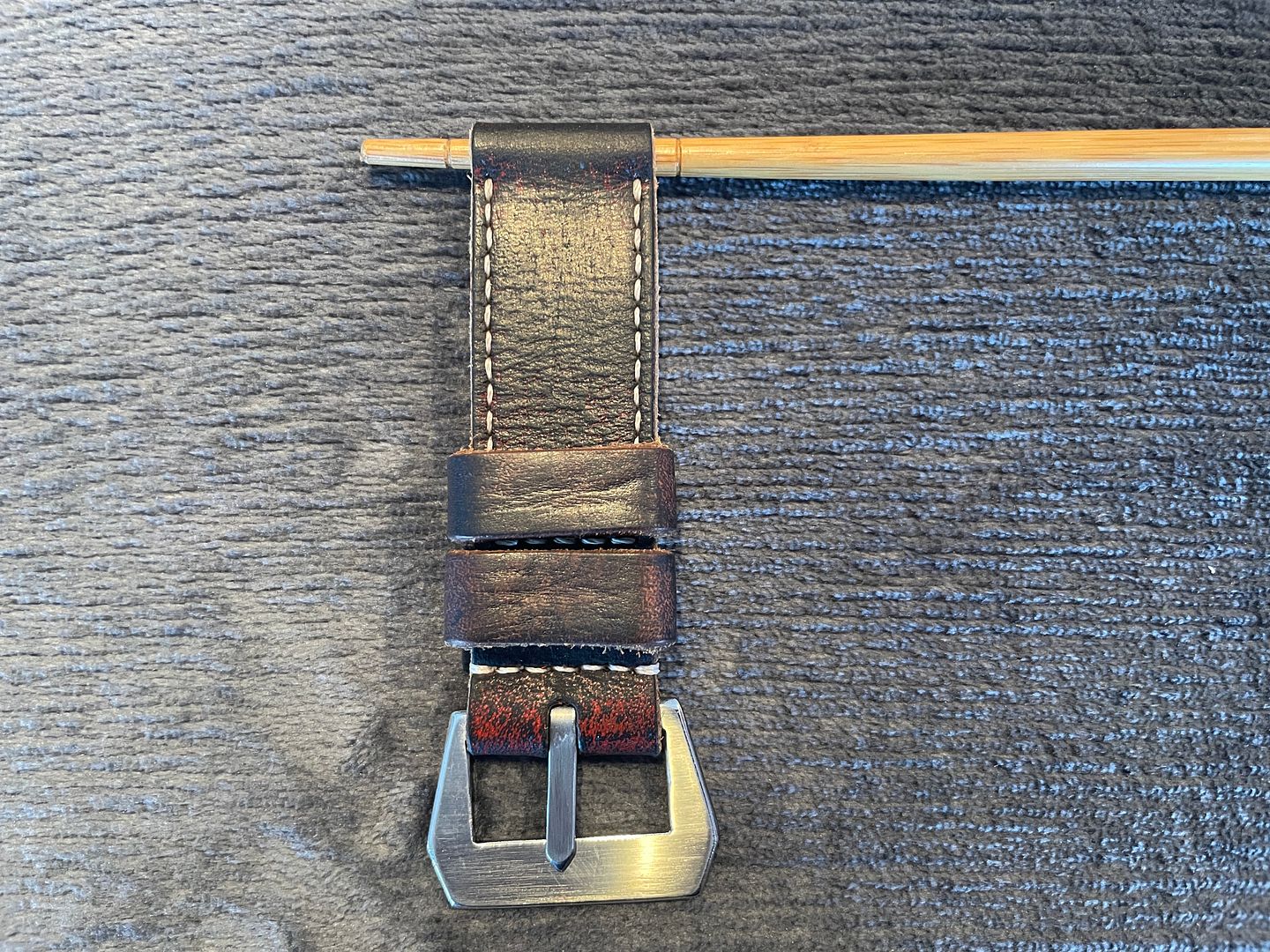

PLEASE note that it's very important to understand that not all straps are suitable or going to be able to support this mod. I developed this method to be used on primarily vintage style 'folded' straps where the leather loop at the lug ends has sufficient space for the increased tube size. If you plan to give this mod a try - I encourage you to study your strap closely so that you understand how it is constructed. For example, some makers will use a piece of fabric or similar material to line the inside of the lug end loop - it would be easy to compromise this if you didn't realize it was there.

The equipment is very simple and everything is easy found on Amazon:

Brass tube in either 3mm or 4mm OD with a wall size of 0.2mm - in this tutorial I am using 4mm

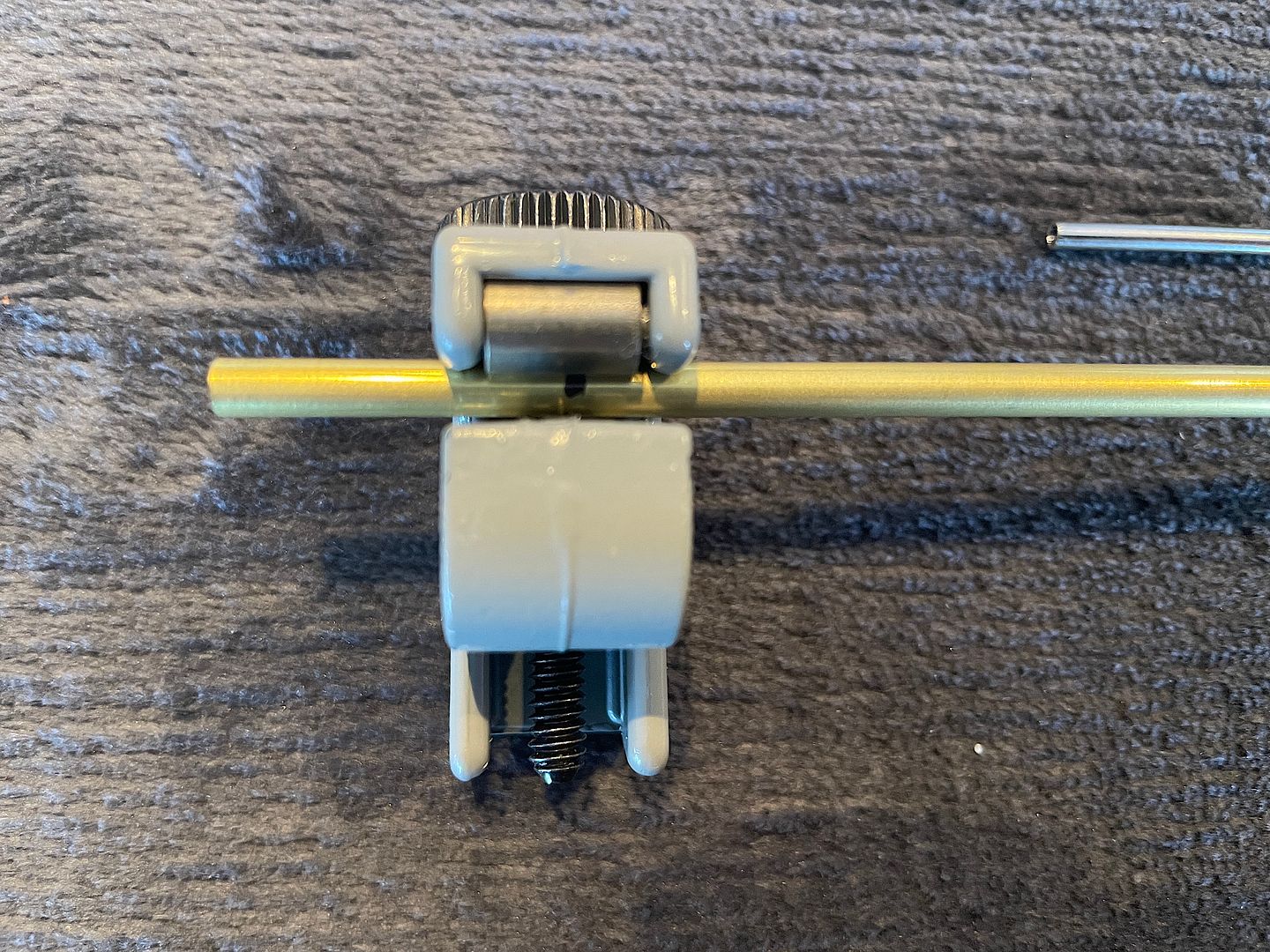

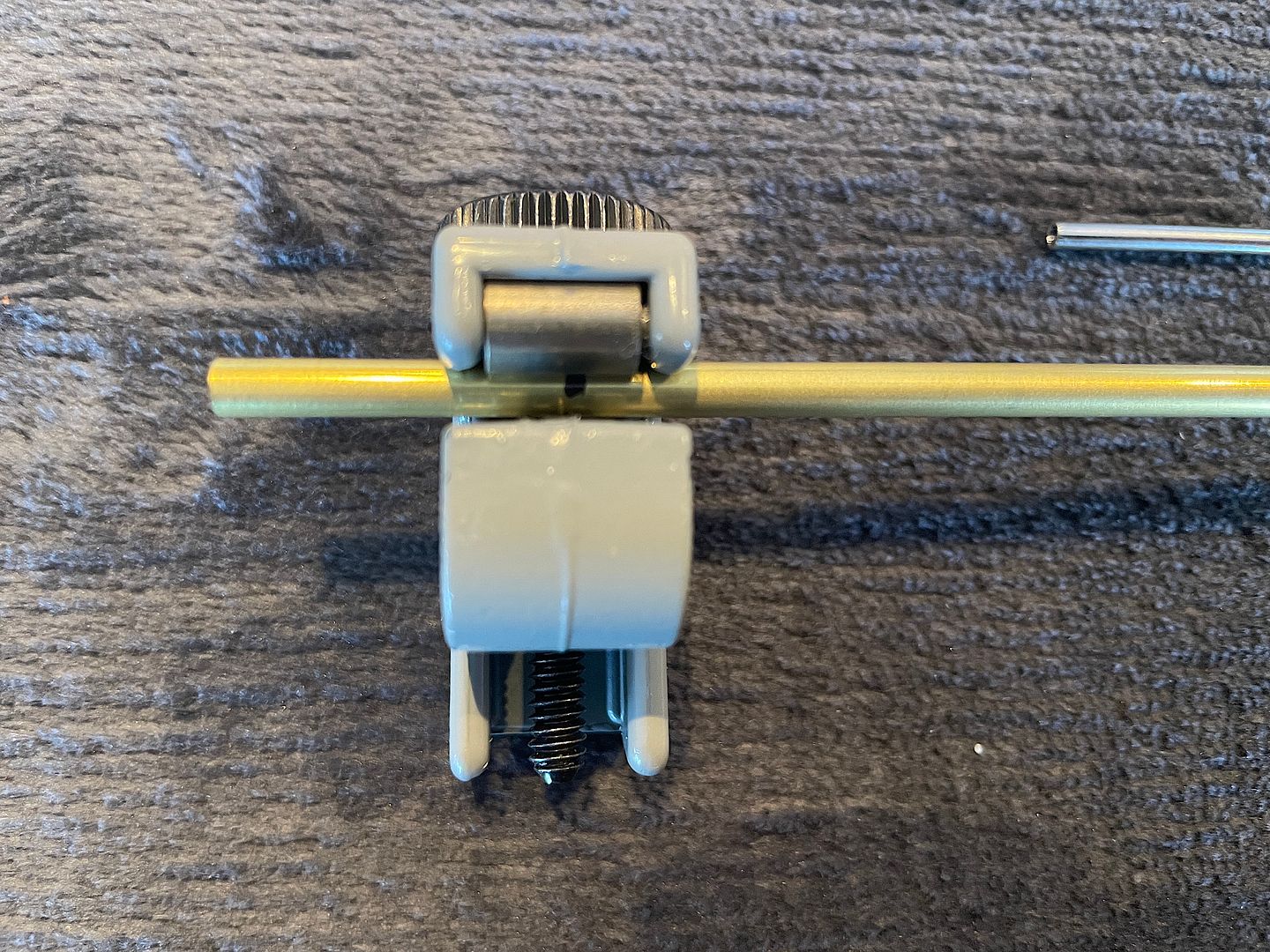

Small tube cutter

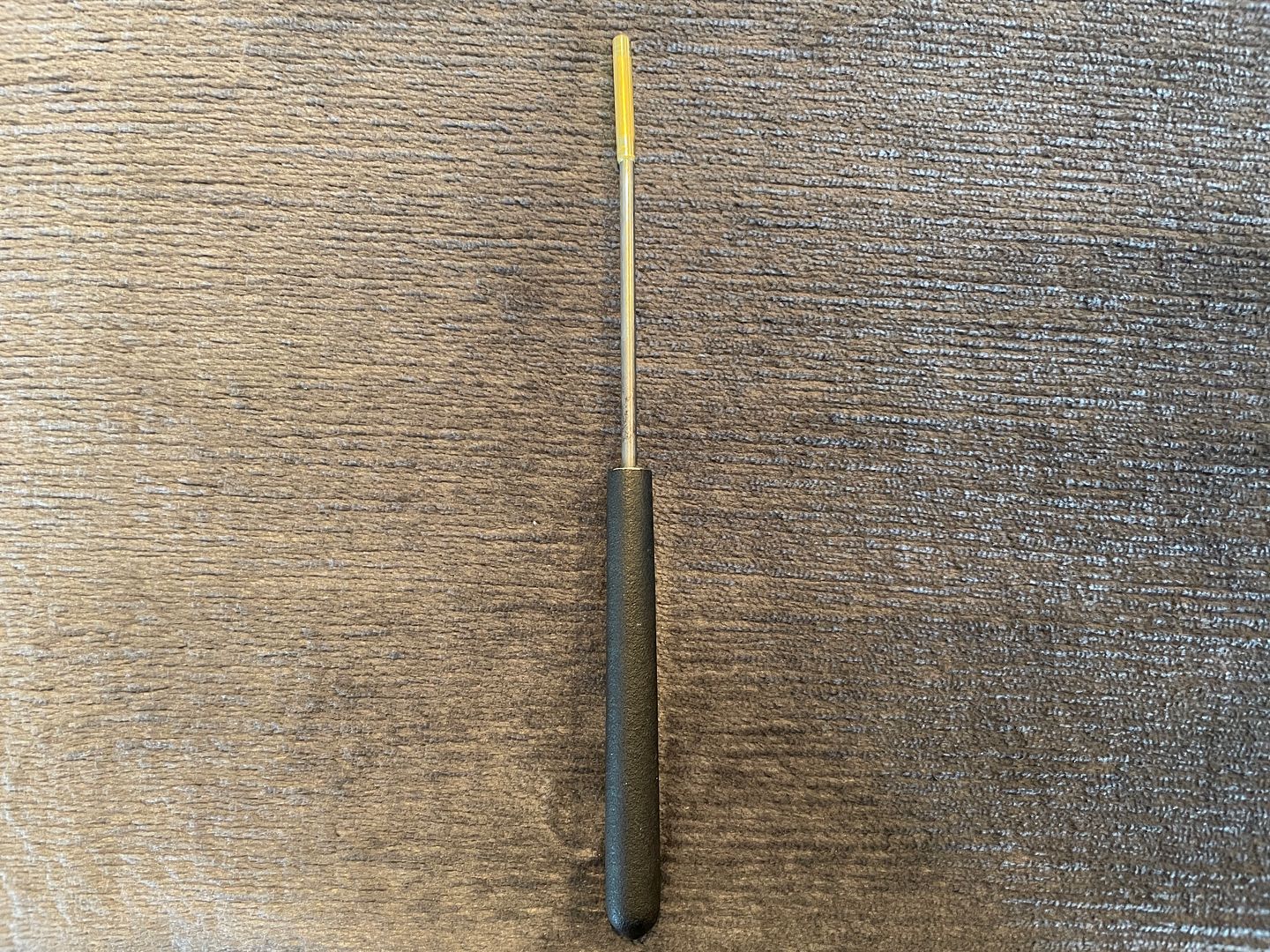

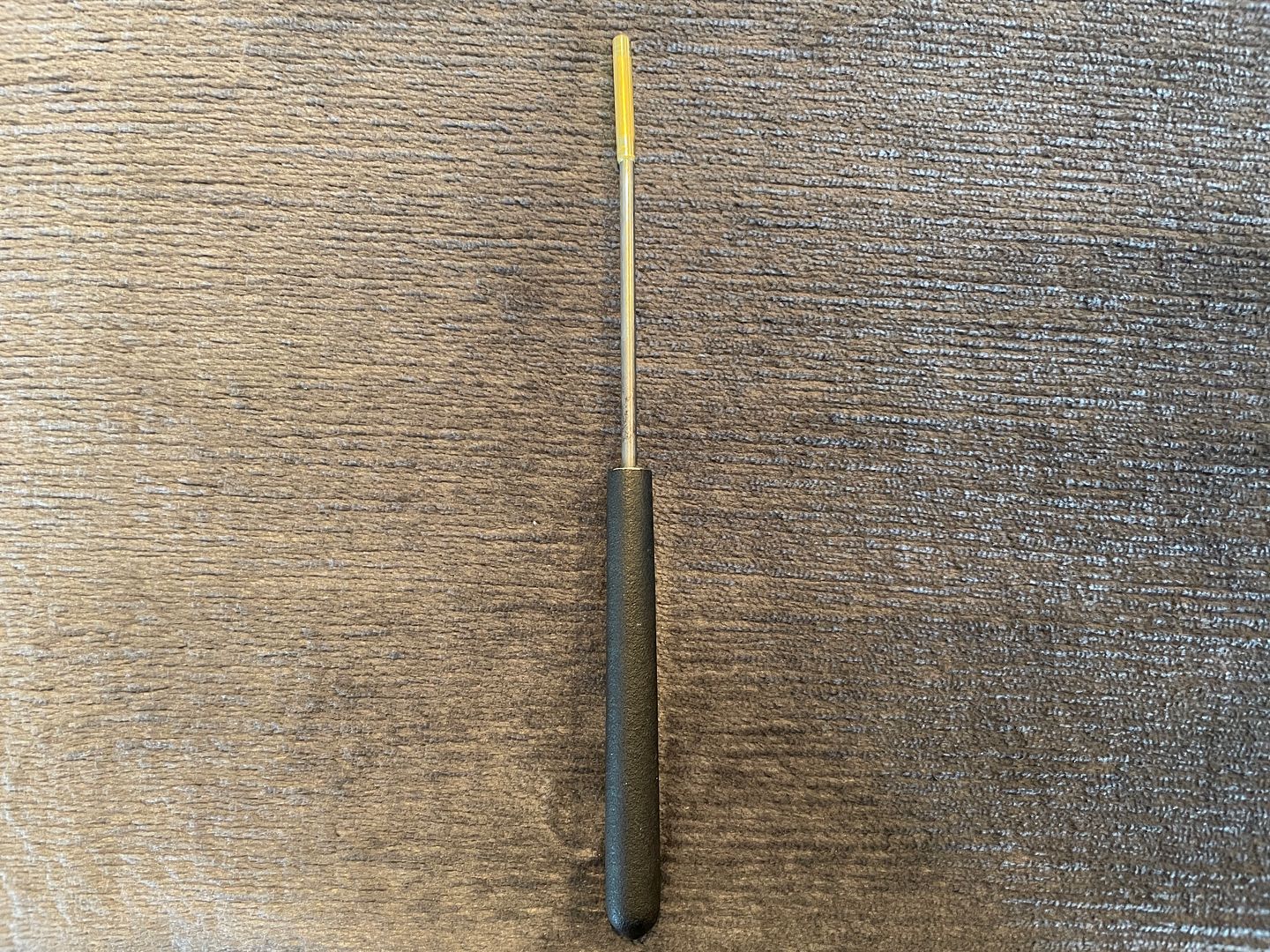

Steel spike / pick

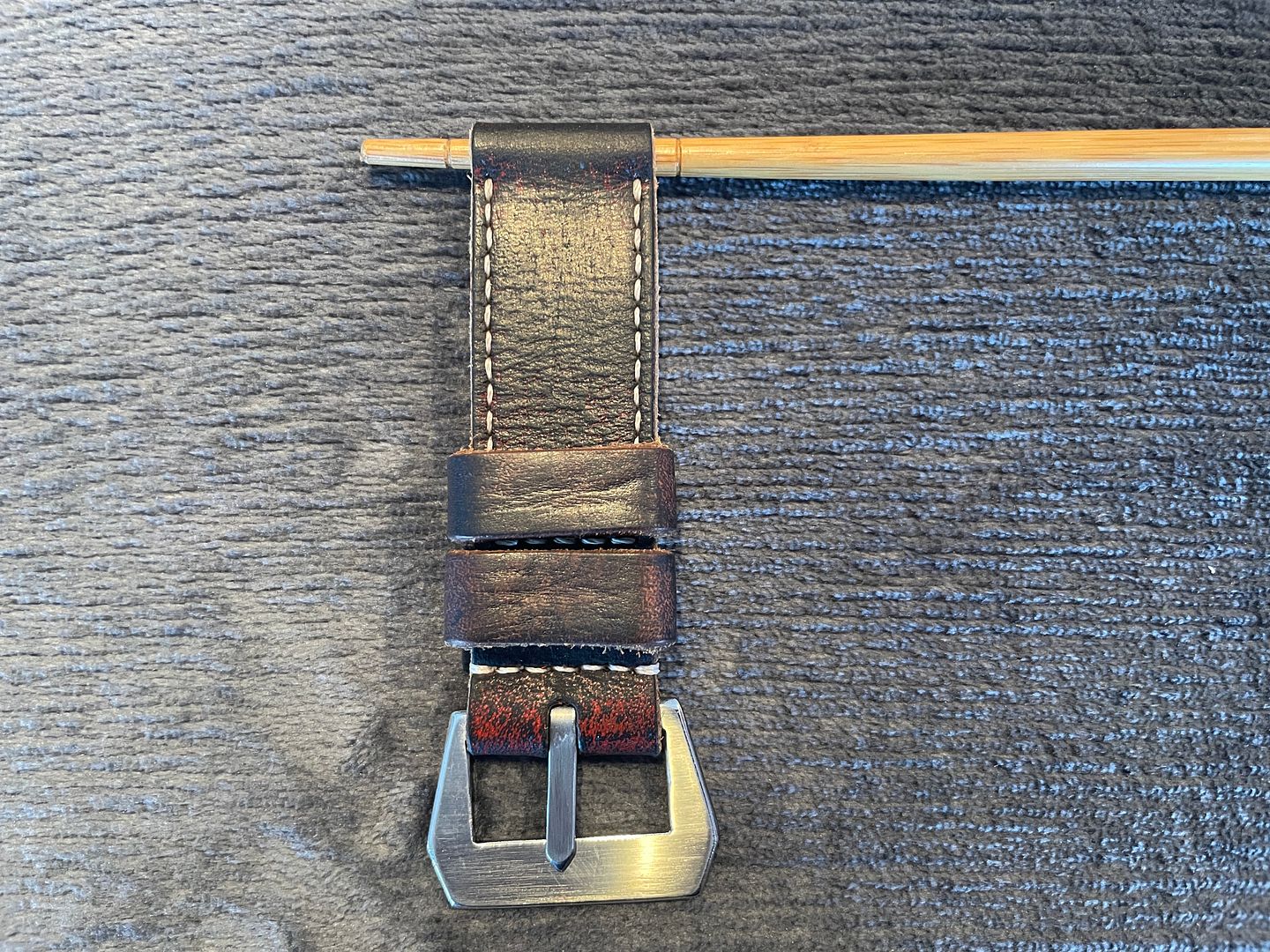

Sturdy / tapered round bamboo stick (chopsticks work well)

Small vice grips (only necessary when the brass tube gets too short to hold firmly with your hand)

Sandpaper / nail file

OEM / rep strap tube for measuring

If the leather of your strap is stiff and needs softening - add a hair dryer to this list so that you can gently heat the ends to allow the loop to widen sufficiently

The process is simple - just use the stock strap tube as a measuring guide and mark the brass tube. Note that the brass will stretch slightly ad the ends so you can be a little narrower with the mark. I also found that it's best to cut the tubes just a little bit smaller than the stock ones (23mm or 25mm works well)

Use the tube cutting wheel to cut the tube - be patient and just tighten the wheel 1/4 turn for each revolution so that you get an even cut

You can see after cutting, the brass tube has a slight taper - this is good as it allows the tube to pass through the strap easily. Use the nail file to sand off any rough edges. You can also use a heavier grit sandpaper or file to reduce the size of the tube if necessary.

Once the tubes are cut, use the tapered steel pick to round the ends out by simply pressing it in to them and twisting

Take the tapered bamboo stick and use it to widen the holes of the straps sufficiently (heat if necessary) - do not use excessive force

Then 'thread' the straps on to a piece of the brass tube - I do this and let them sit for a while for the leather to 'settle'

Then just insert the new fatty tubes and install on your watch... You can see the additional / rounded dimension created by the 4mm tubes

And installed on my 024a

PLEASE note that it's very important to understand that not all straps are suitable or going to be able to support this mod. I developed this method to be used on primarily vintage style 'folded' straps where the leather loop at the lug ends has sufficient space for the increased tube size. If you plan to give this mod a try - I encourage you to study your strap closely so that you understand how it is constructed. For example, some makers will use a piece of fabric or similar material to line the inside of the lug end loop - it would be easy to compromise this if you didn't realize it was there.

The equipment is very simple and everything is easy found on Amazon:

Brass tube in either 3mm or 4mm OD with a wall size of 0.2mm - in this tutorial I am using 4mm

Small tube cutter

Steel spike / pick

Sturdy / tapered round bamboo stick (chopsticks work well)

Small vice grips (only necessary when the brass tube gets too short to hold firmly with your hand)

Sandpaper / nail file

OEM / rep strap tube for measuring

If the leather of your strap is stiff and needs softening - add a hair dryer to this list so that you can gently heat the ends to allow the loop to widen sufficiently

The process is simple - just use the stock strap tube as a measuring guide and mark the brass tube. Note that the brass will stretch slightly ad the ends so you can be a little narrower with the mark. I also found that it's best to cut the tubes just a little bit smaller than the stock ones (23mm or 25mm works well)

Use the tube cutting wheel to cut the tube - be patient and just tighten the wheel 1/4 turn for each revolution so that you get an even cut

You can see after cutting, the brass tube has a slight taper - this is good as it allows the tube to pass through the strap easily. Use the nail file to sand off any rough edges. You can also use a heavier grit sandpaper or file to reduce the size of the tube if necessary.

Once the tubes are cut, use the tapered steel pick to round the ends out by simply pressing it in to them and twisting

Take the tapered bamboo stick and use it to widen the holes of the straps sufficiently (heat if necessary) - do not use excessive force

Then 'thread' the straps on to a piece of the brass tube - I do this and let them sit for a while for the leather to 'settle'

Then just insert the new fatty tubes and install on your watch... You can see the additional / rounded dimension created by the 4mm tubes

And installed on my 024a