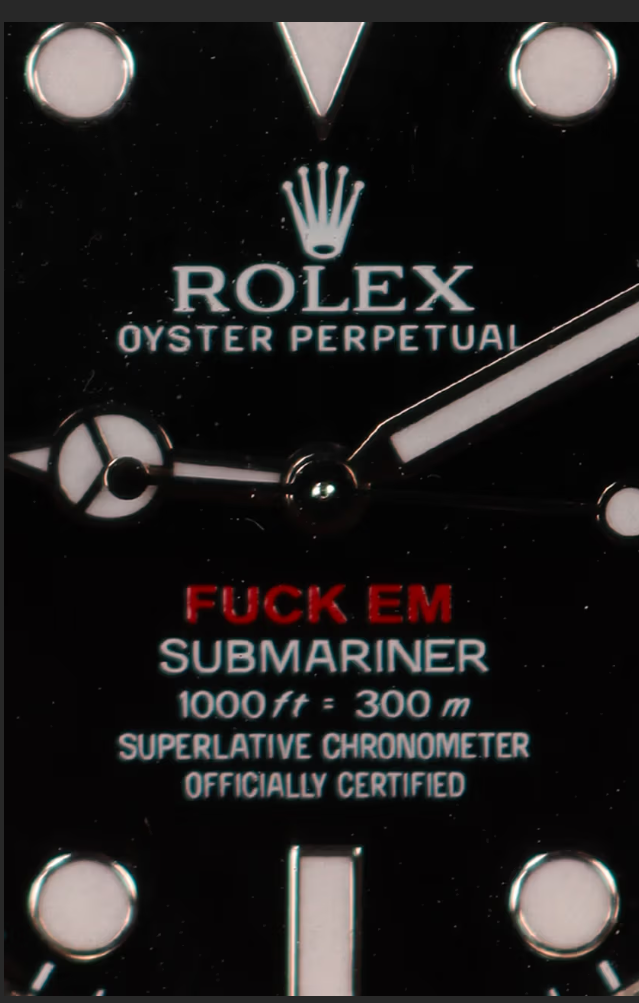

Rolex Sub NoDate 114060 "Supreme – Fuck’Em” project: an 1/1 star was born

Hi guys,

I thought to show you the evolution of one of my latest projects which made it happen with my partner in crime expert buddy watchsmith and his unlimited perseverance along this journey @hungaryrolex

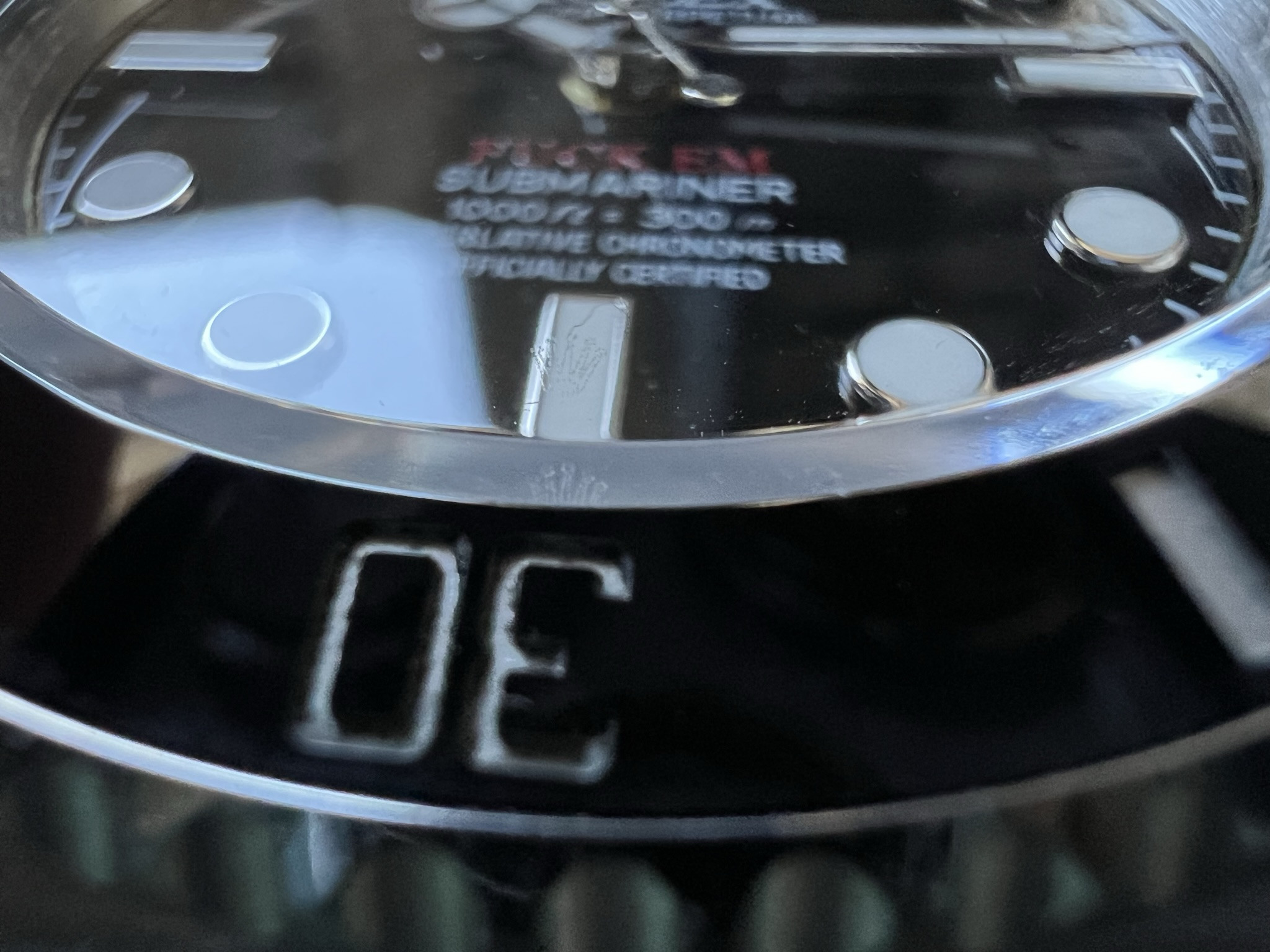

It all started with a random sales I noticed of a quite shitty CS 114060 having that outstanding Fuck’em dial making me think to fully upgrade it

The best donor was supposed to be a VSF pre-raid 114060 (blasphemy I know LOL) but not really avail within EU..

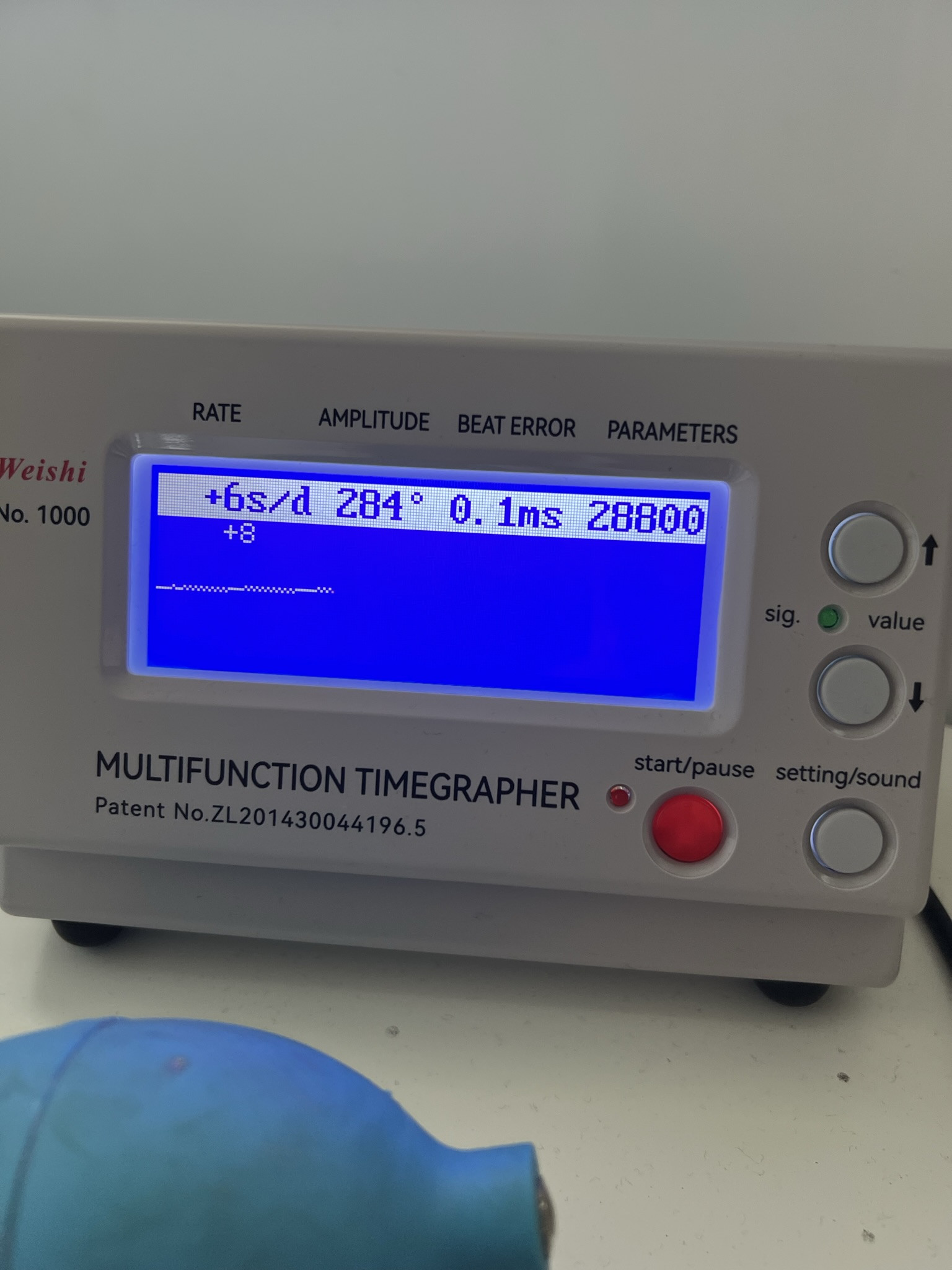

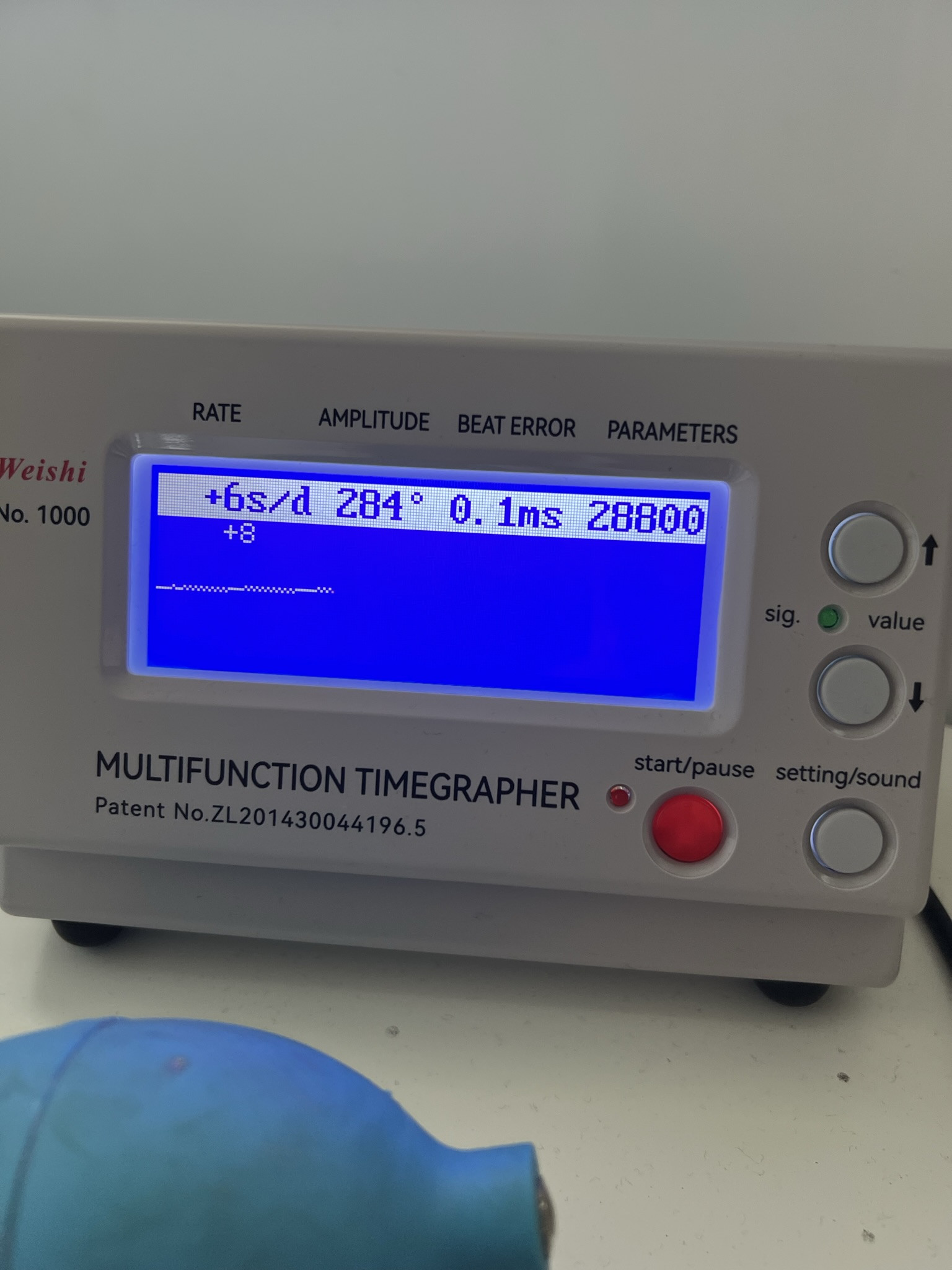

Managed to source at the end one pristine piece with a brand new untouched bracelet (watch was used with an Oysterflex) just having some issues with the VS movement, which stopped sometimes for an unknown reason, so it was needed to service that as well.

[/url

[/url

]

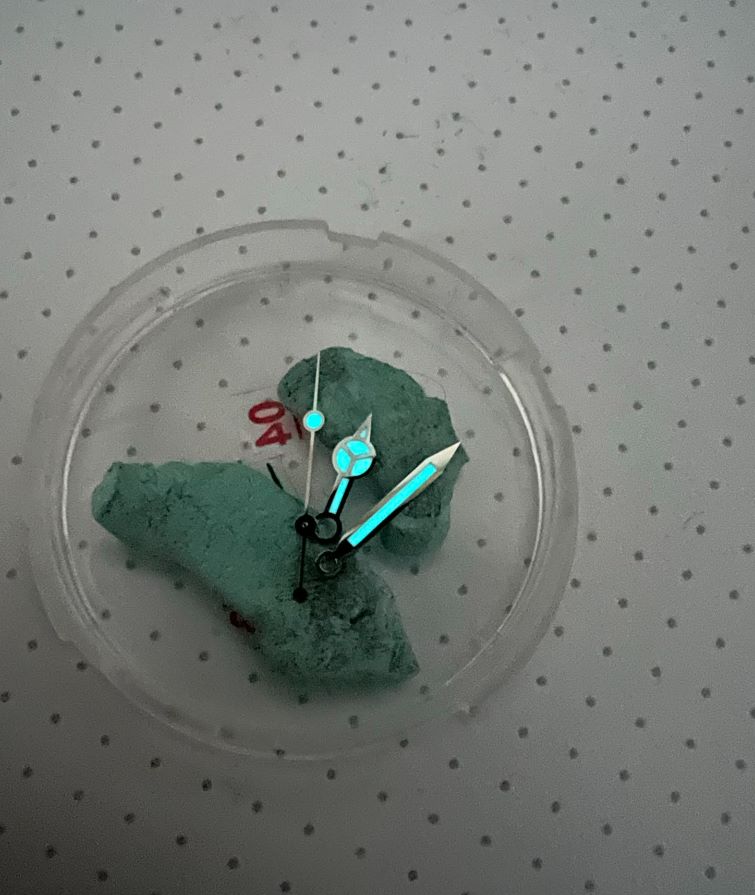

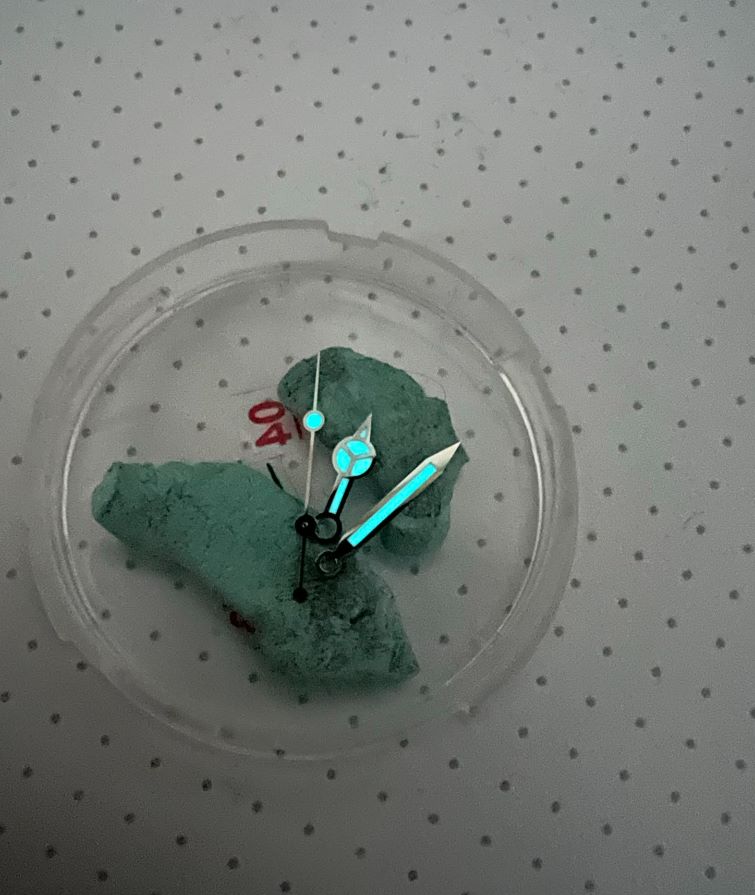

The idea was to put that nice dial into a case+shoes she deserves, equipped with matching correct lumed hands and pip, last but not least run by a mvm she also deserves, literally changing everything around

As expected none of the steps was smooth several obstacles arose such as:

Finally -after almost 4 months of processes- the project has come to an end resulting

Thx

Hi guys,

I thought to show you the evolution of one of my latest projects which made it happen with my partner in crime expert buddy watchsmith and his unlimited perseverance along this journey @hungaryrolex

It all started with a random sales I noticed of a quite shitty CS 114060 having that outstanding Fuck’em dial making me think to fully upgrade it

The best donor was supposed to be a VSF pre-raid 114060 (blasphemy I know LOL) but not really avail within EU..

Managed to source at the end one pristine piece with a brand new untouched bracelet (watch was used with an Oysterflex) just having some issues with the VS movement, which stopped sometimes for an unknown reason, so it was needed to service that as well.

[/url

[/url]

The idea was to put that nice dial into a case+shoes she deserves, equipped with matching correct lumed hands and pip, last but not least run by a mvm she also deserves, literally changing everything around

As expected none of the steps was smooth several obstacles arose such as:

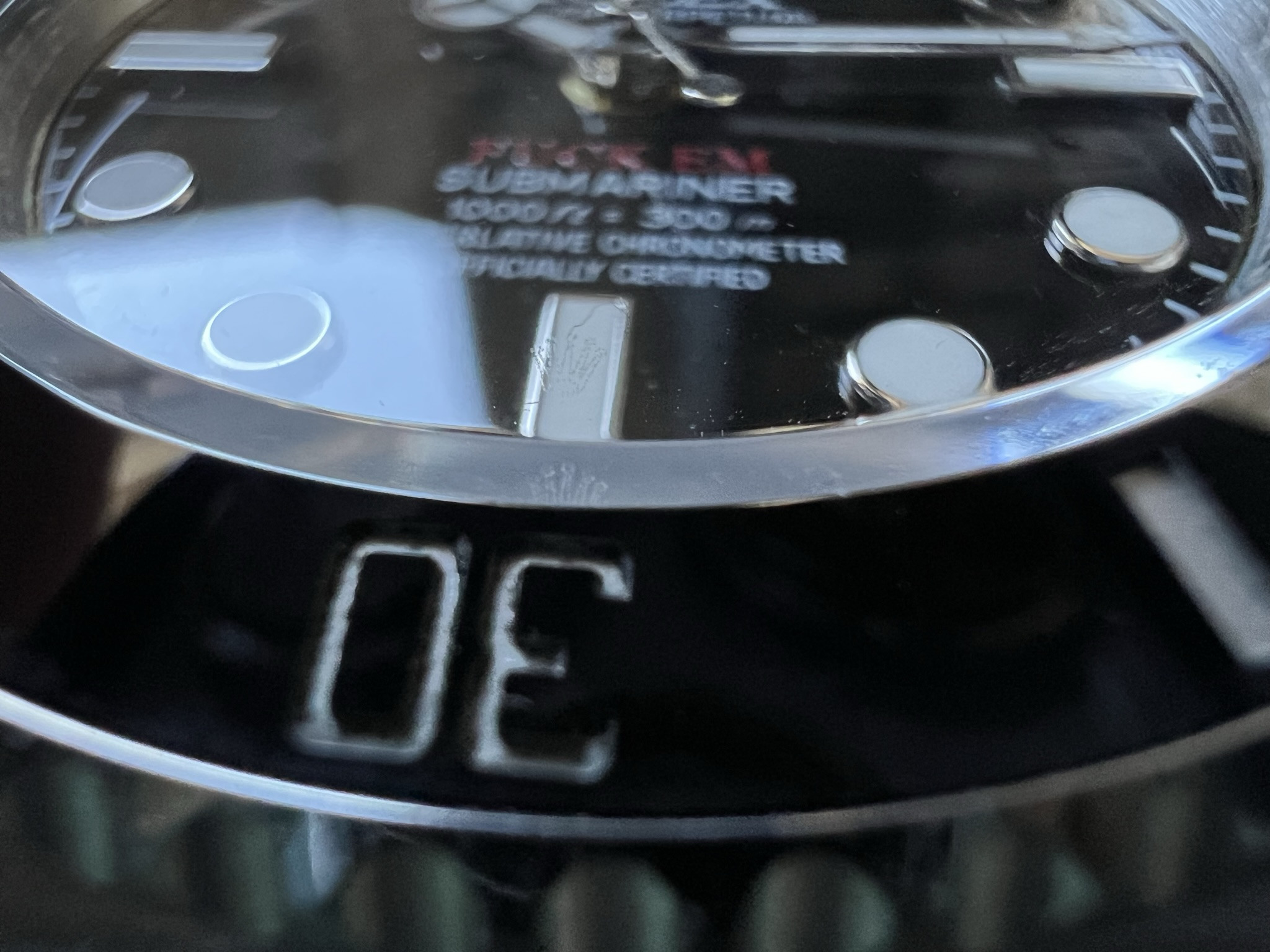

- the Fuckem dial was definitely wider than the VSF case would accept so it had to be shaved with approx. 1mm closely watching to also avoid damaging the surface and the lacquer layer of the dial;

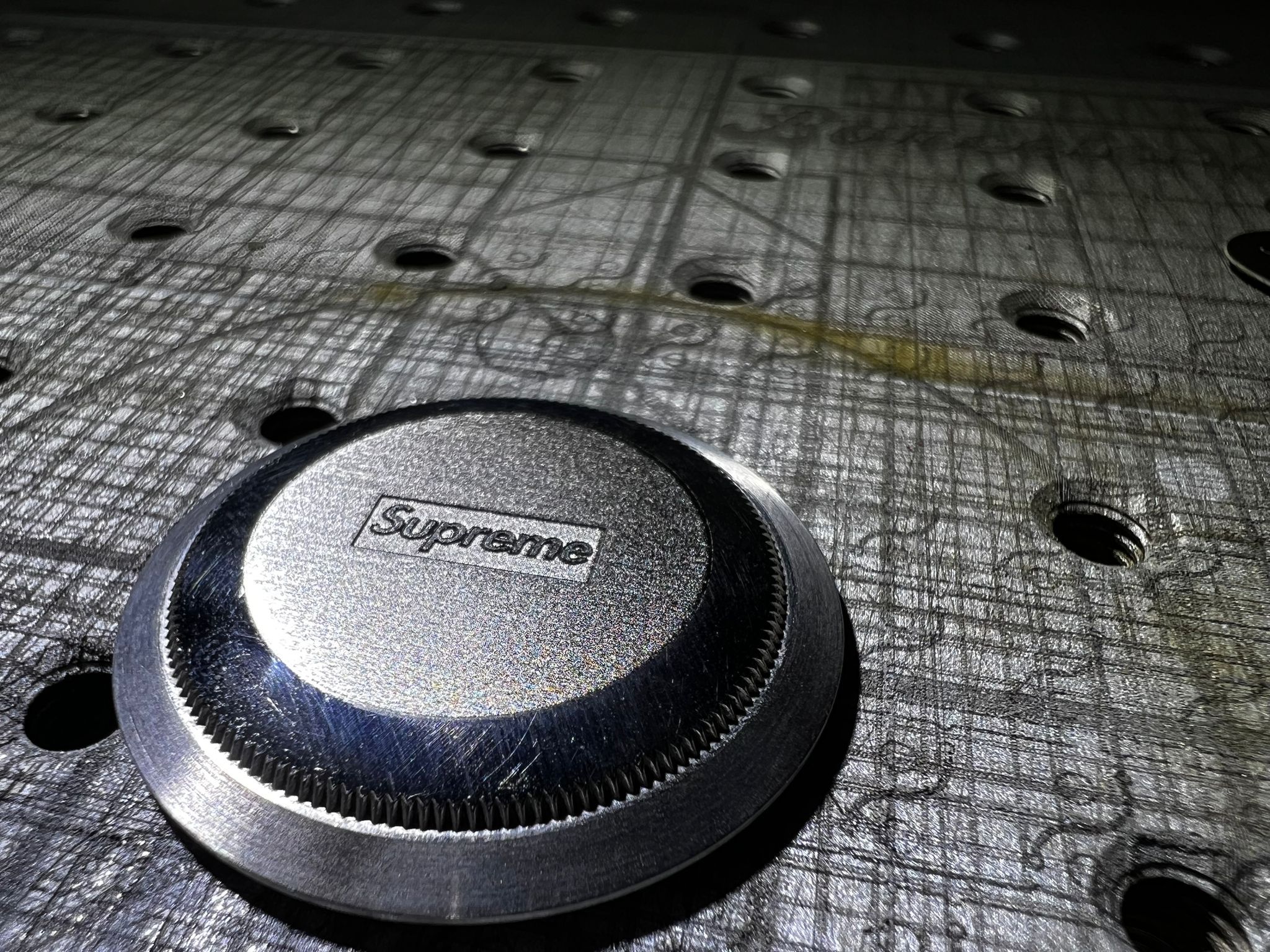

- the engraved caseback coming from the original case construction also didn’t fit with the VSF case, so had to be machined and finished also in order to keep its WR properties;

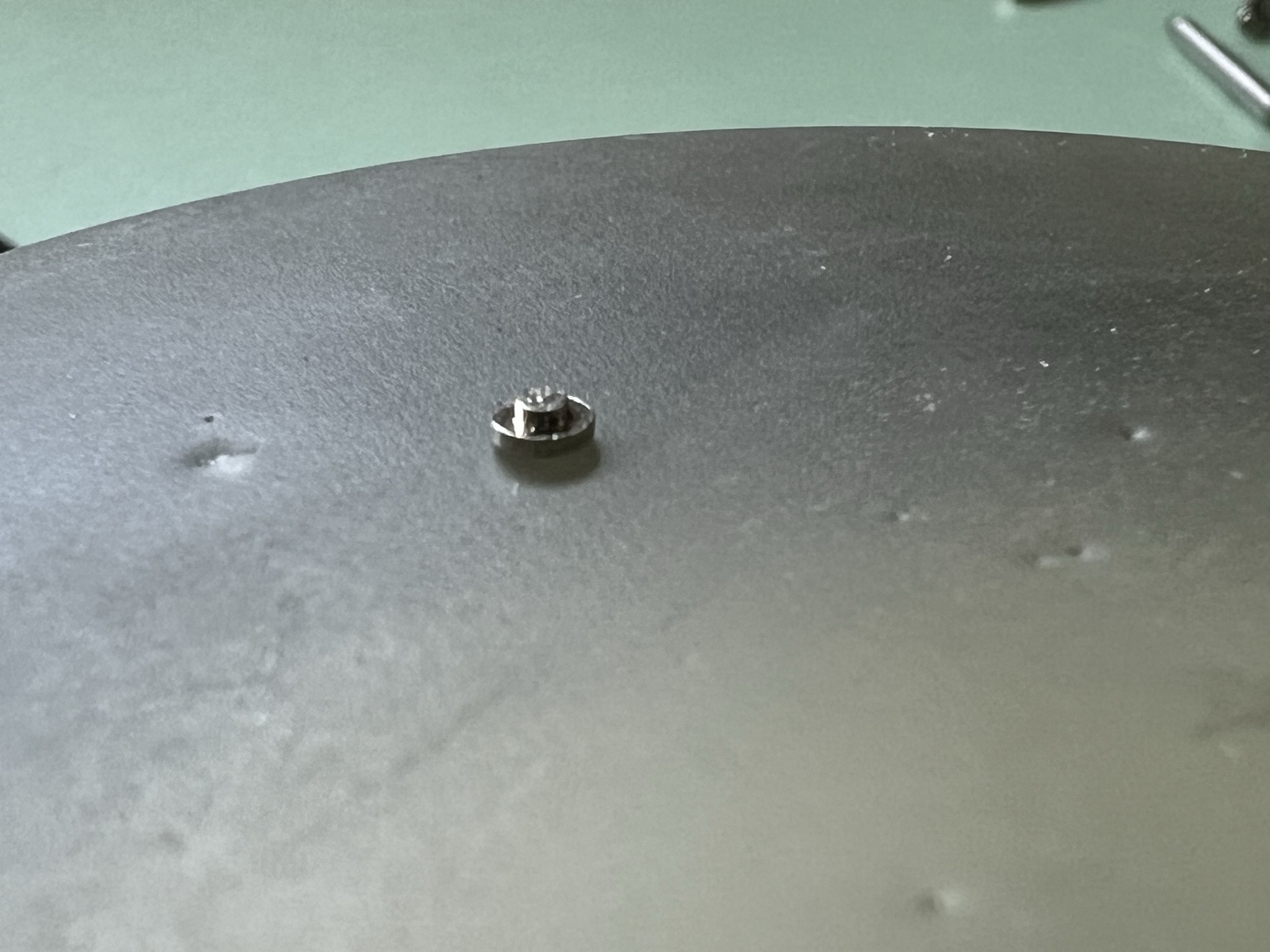

- the default VSF bezel had different pip lume color than the correct, newly sourced hands set, so it had to be also upgraded.

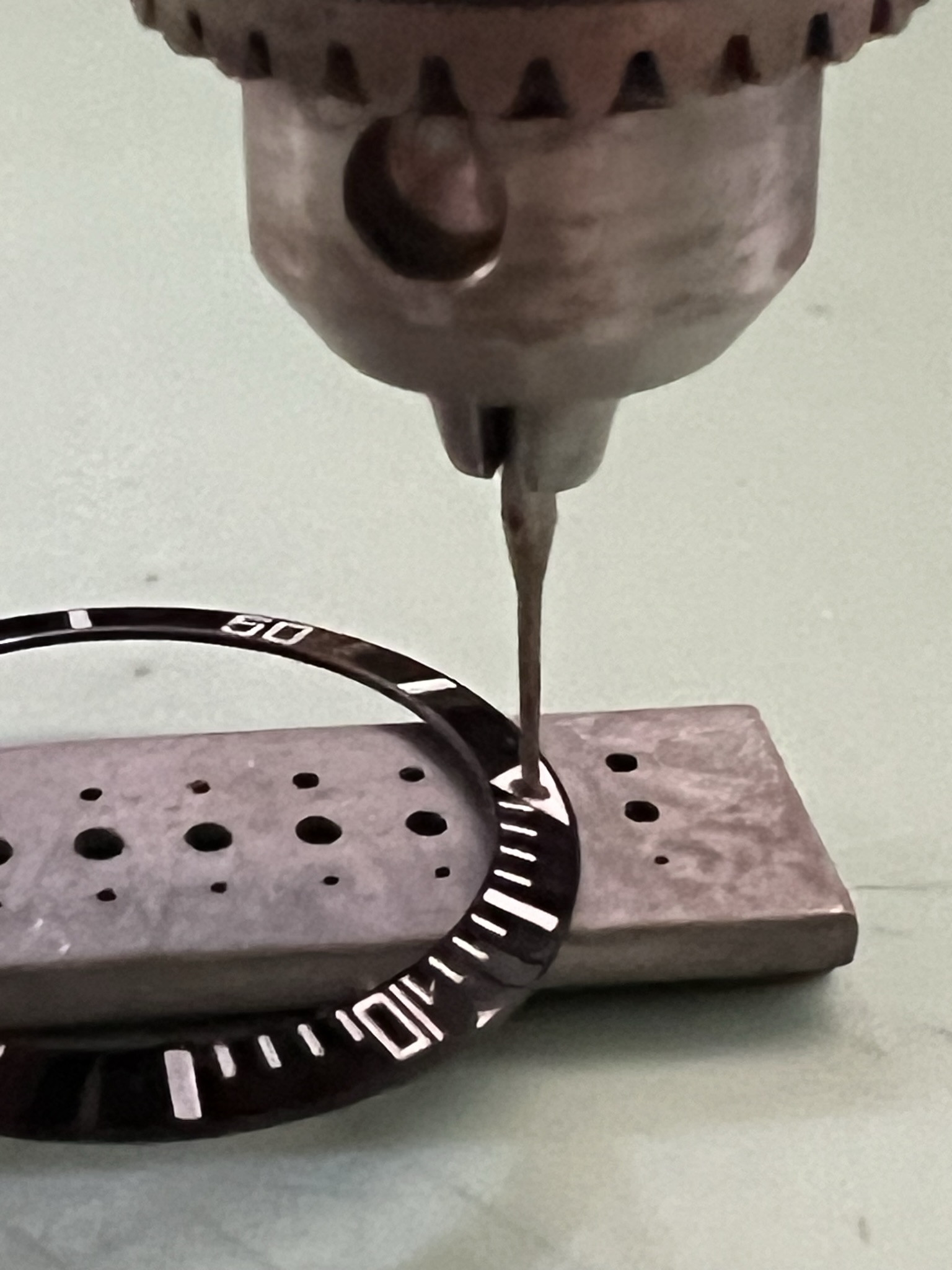

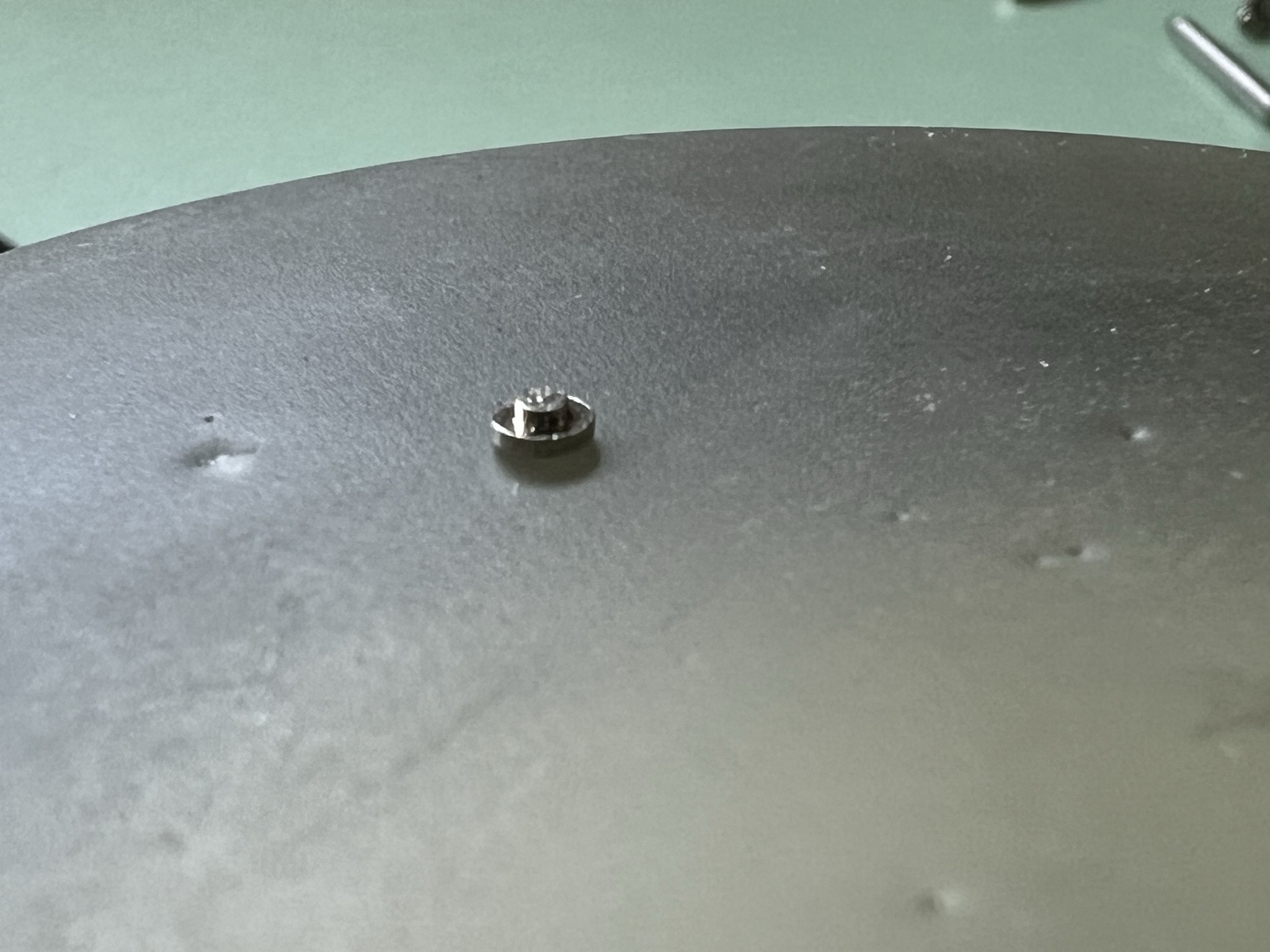

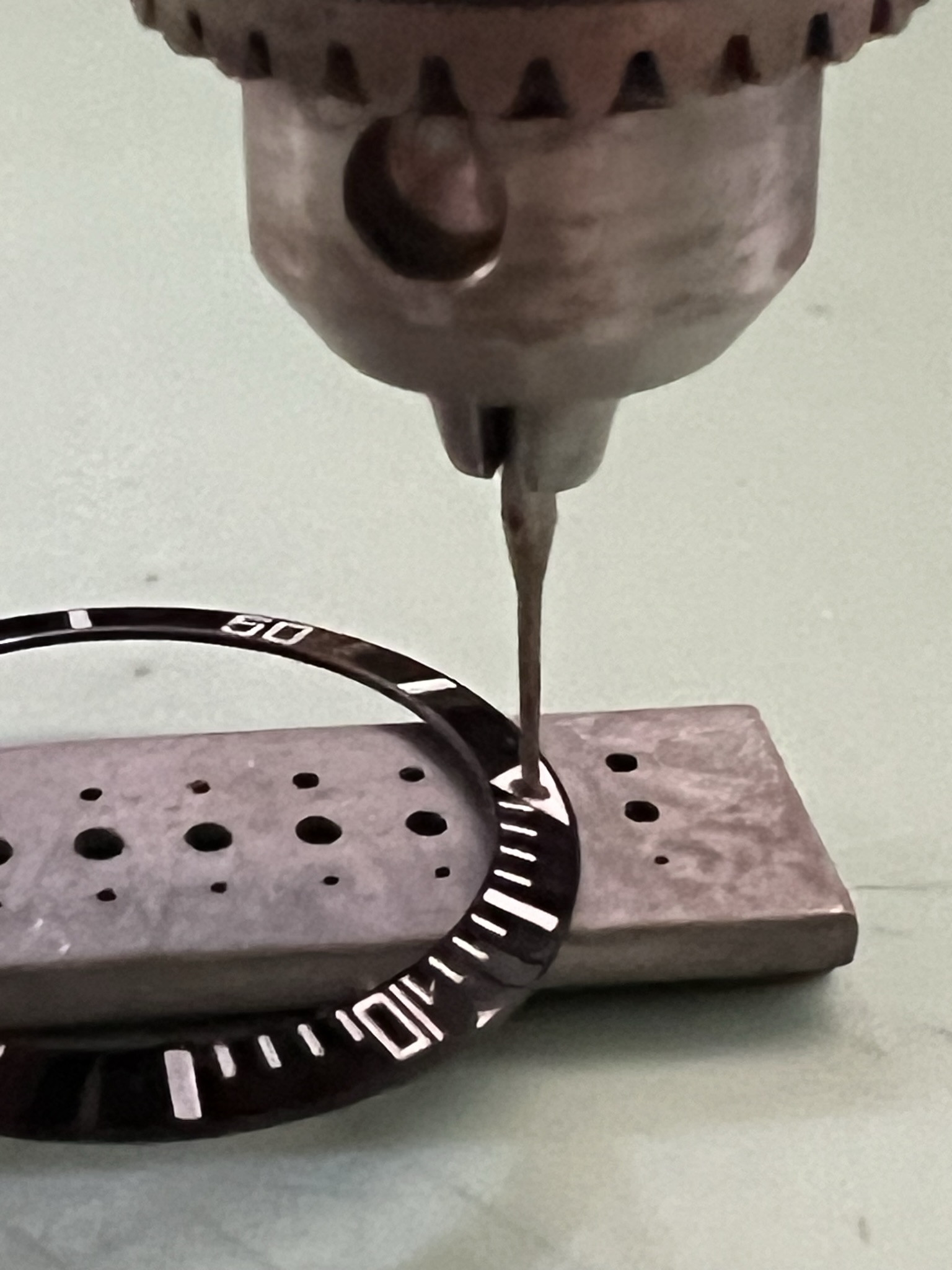

- sourced a new pip, but sh#t happened again, the VSF bezel broke also the new pip couldn’t be fixed the ordinary regular way, so we were thinking to drill the ceramic (!

) with an 0,8mm head, making it sure for the new pip to sit safe.

Finally -after almost 4 months of processes- the project has come to an end resulting

a true 1/1 Fuckem best scenario fun

Thx

Last edited: