- 28/4/17

- 3,684

- 2,941

- 113

Dear members!

Like the title already told you - Keylog74 and me (@BIONONE) were working on something special for the past few months.

Many of you may remember us from back in the day when we developed the very first DWO (Date Wheel Overlay) for the Rep Patek line that was housing the infamous 9015 Miyota.

hings have changed and the exciting release of the 3KF 324 SC clone enriched the Patek Philippe (Rep) enthusiasts among us.

As so often - this new release was followed by a major step back by coming with a tiny and thin date font that was not only aesthetically unpleasing, but gave us also a shivering - that's how bad it remained for now almost 1.5 years since its introduction to the public.

No Change was in sight and a gen DW in good condition is rare to find and thus not the cheapest yet one of the key elements when building an overall decent watch - may it be a Franken build with a gen dial or the implementation of the clone into a case of ones choice to match ones individual preference.

So we decided to bring this well deserved change to the forum - All the effort that went into this venture should be shared with you step by step.

I will pause the speech and will please your eyes with some candy of the progress so far

Enjoy:

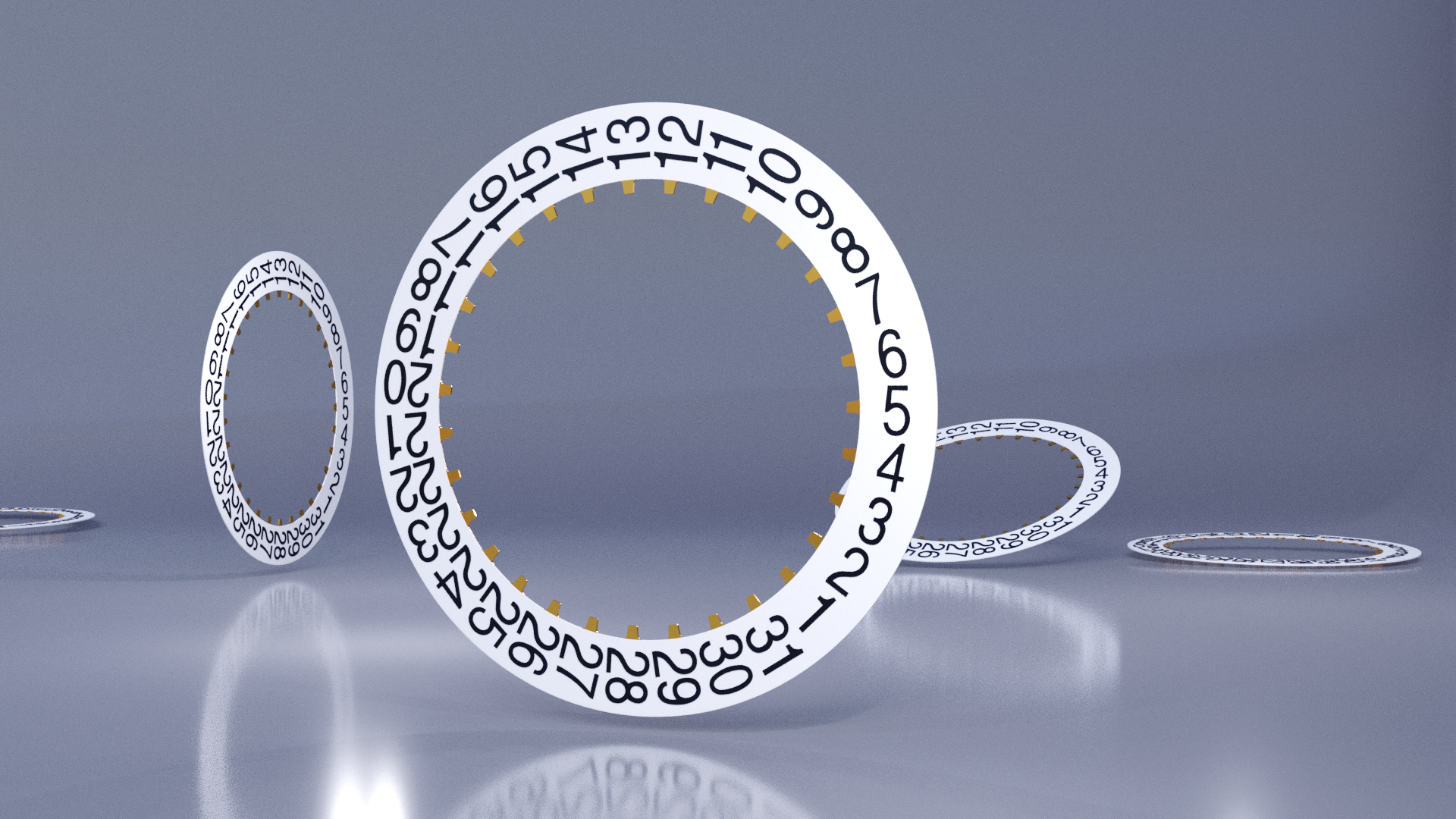

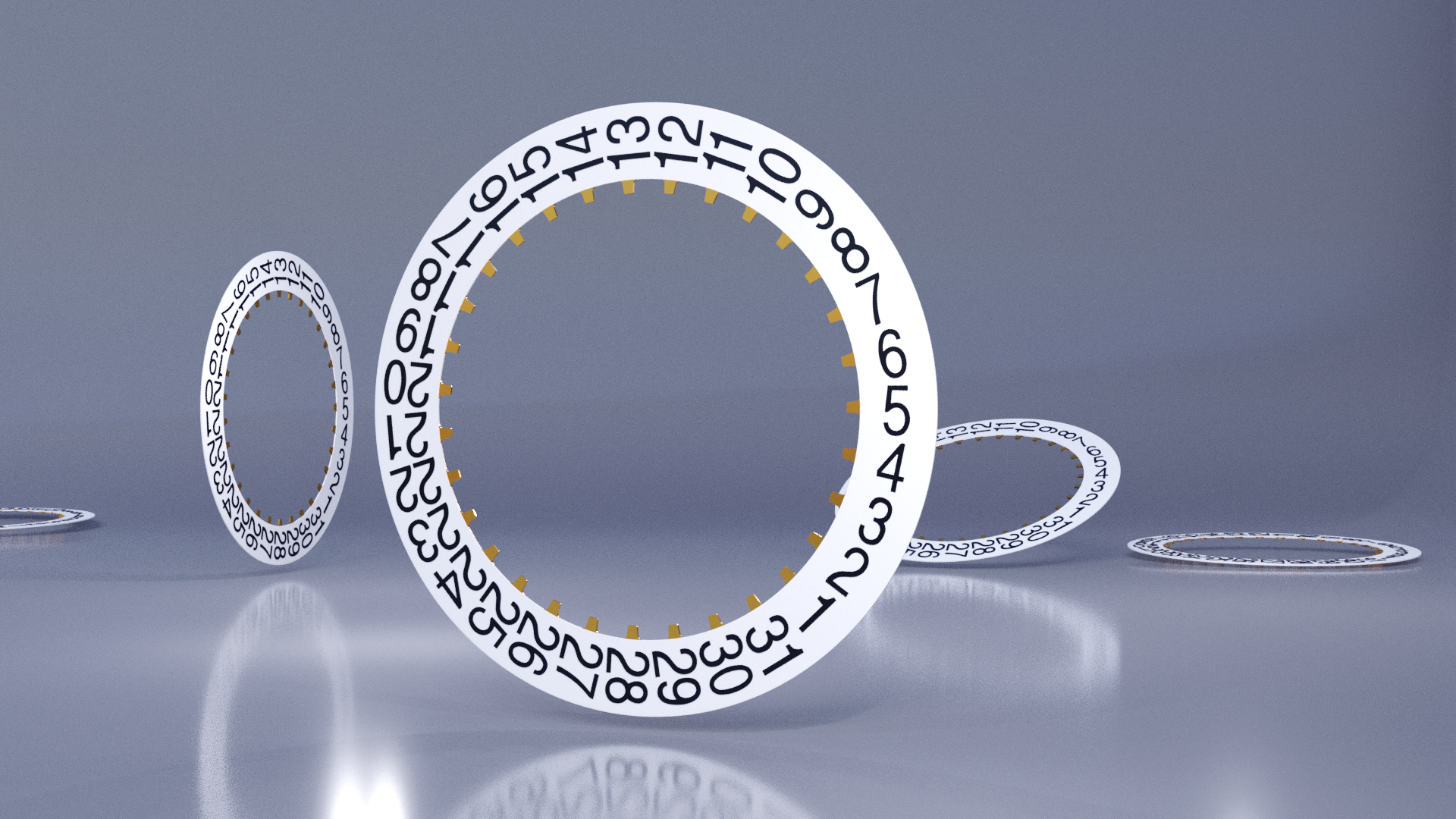

First up some fancy renders. Not needed for the production of course but for aesthetic purposes – as this is one of the main reasons we stay here day in day out hehe

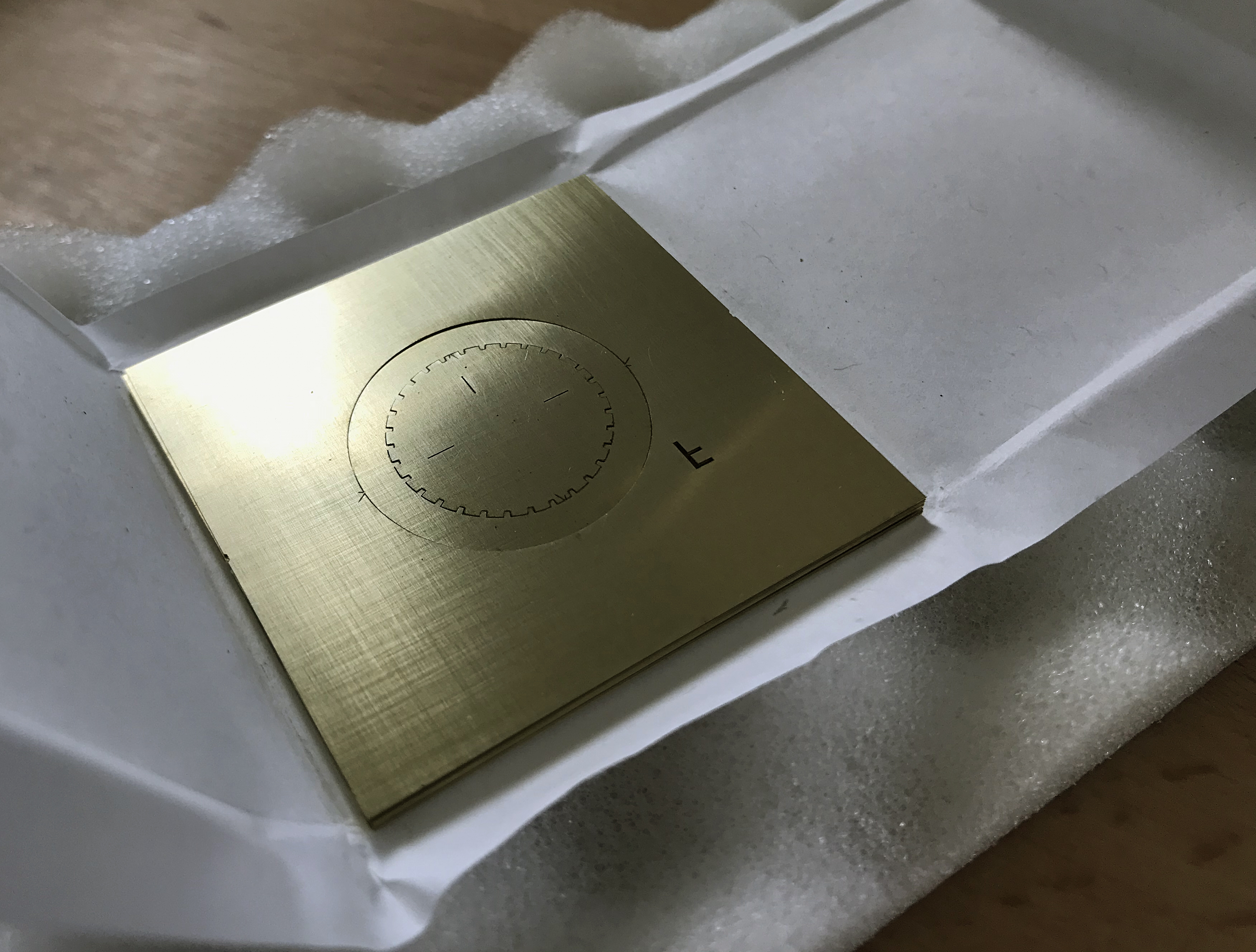

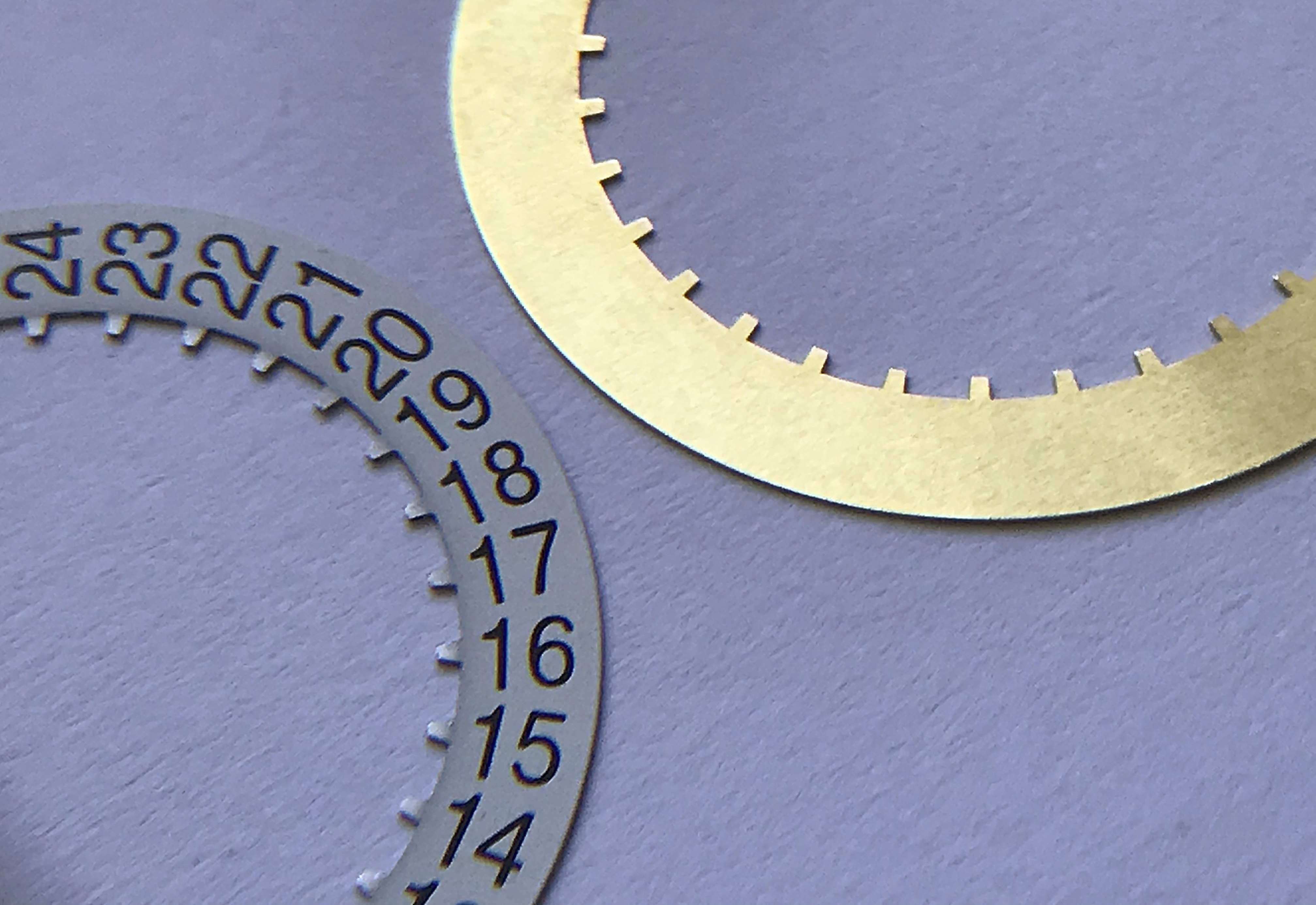

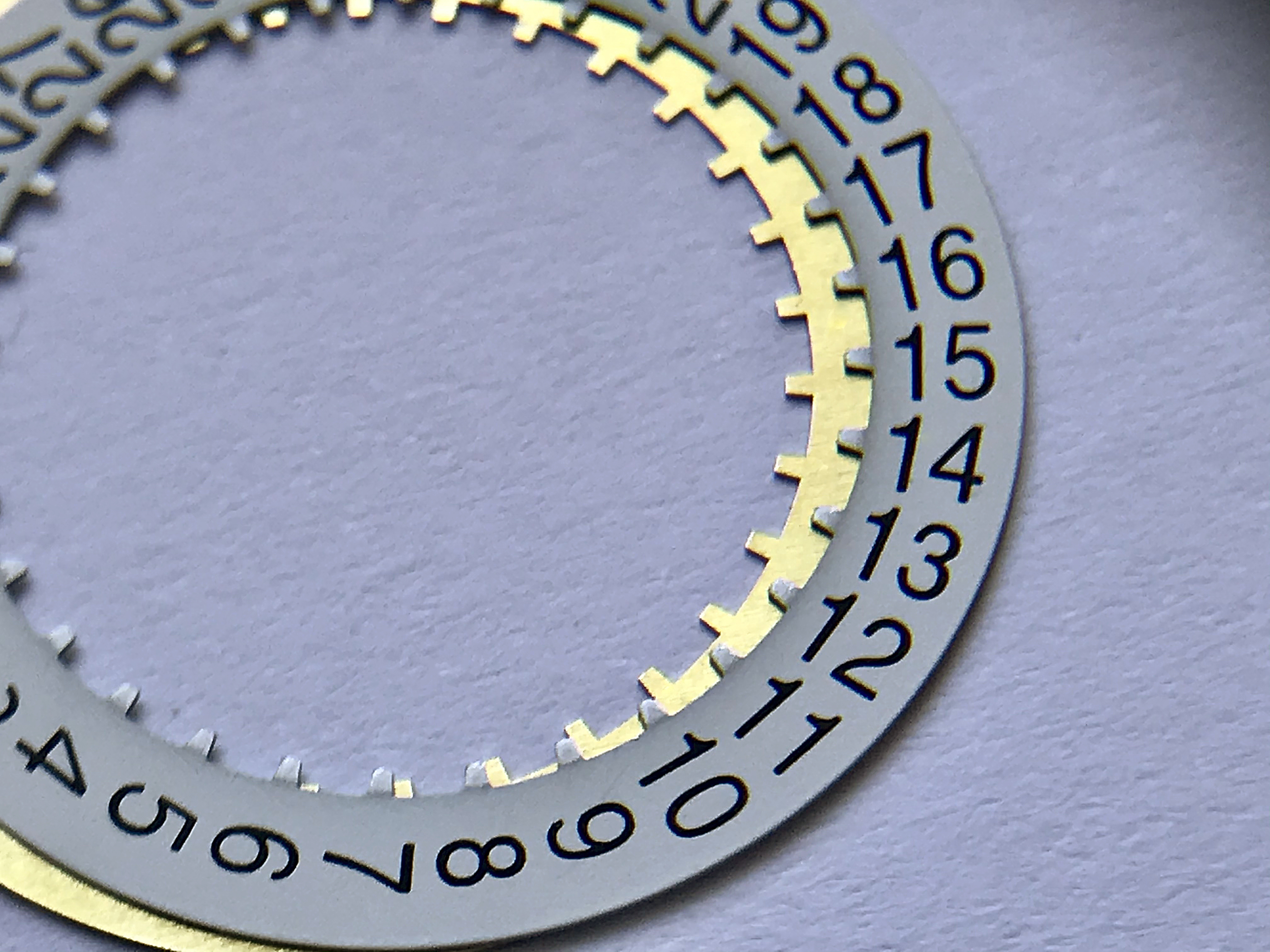

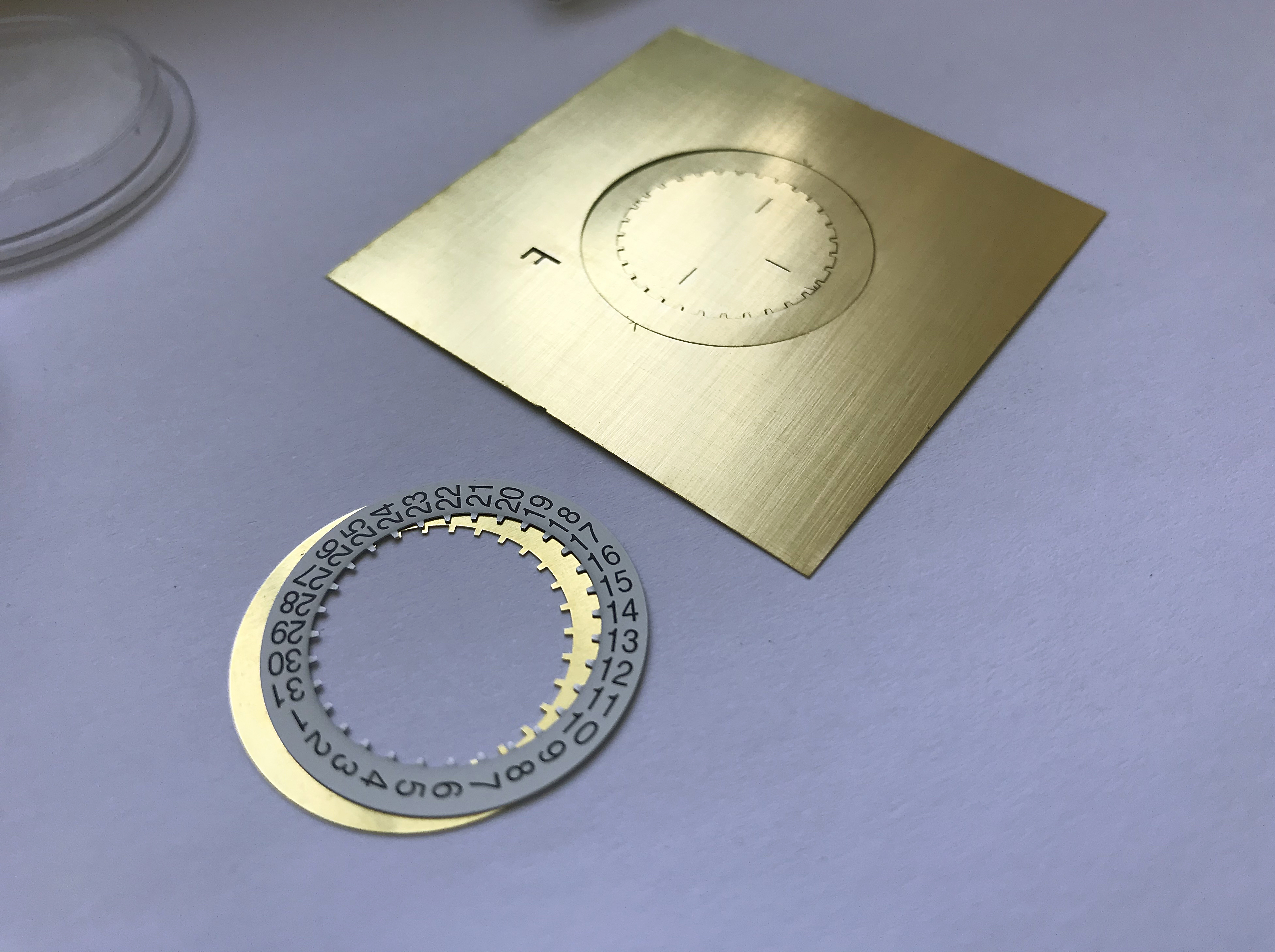

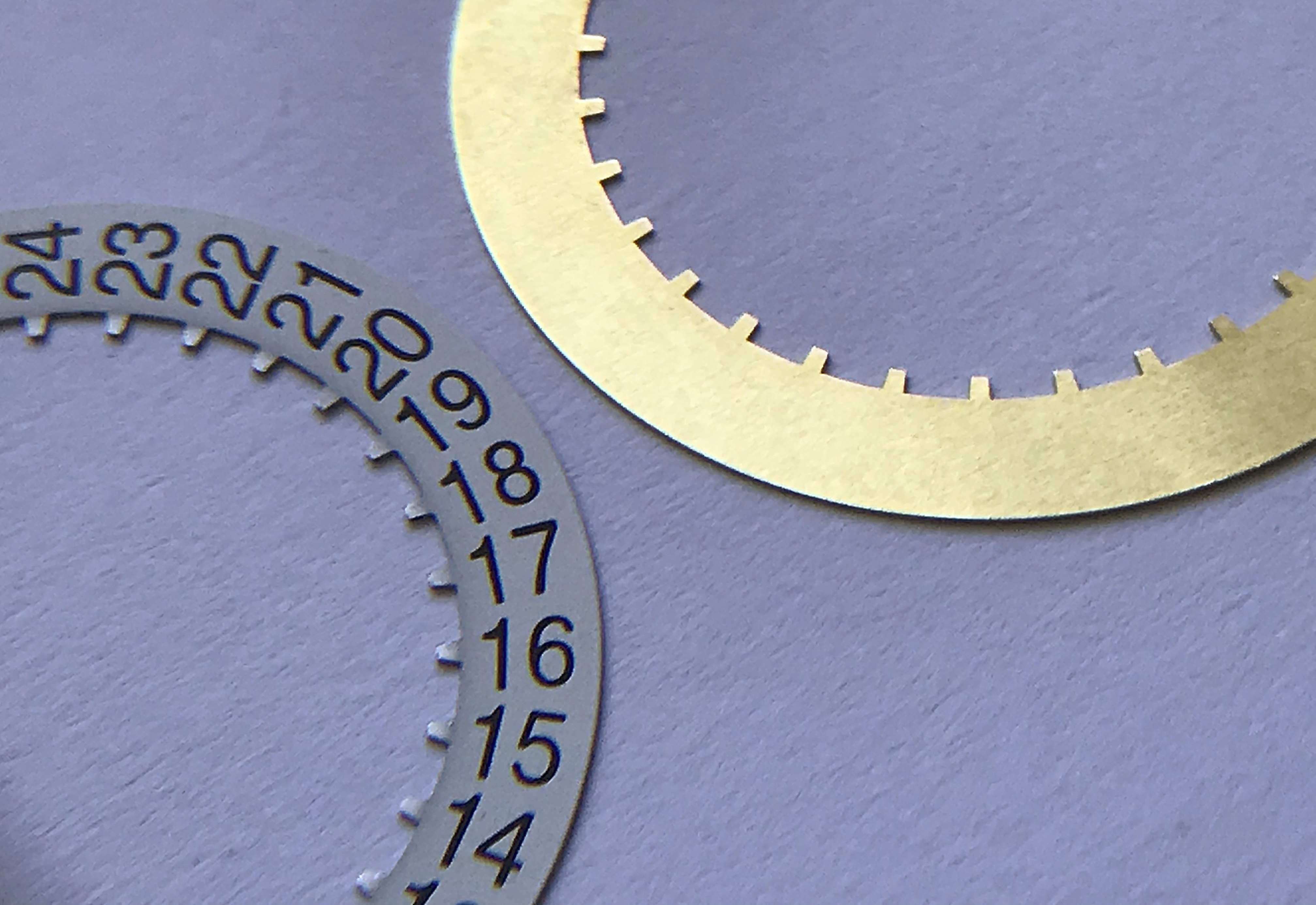

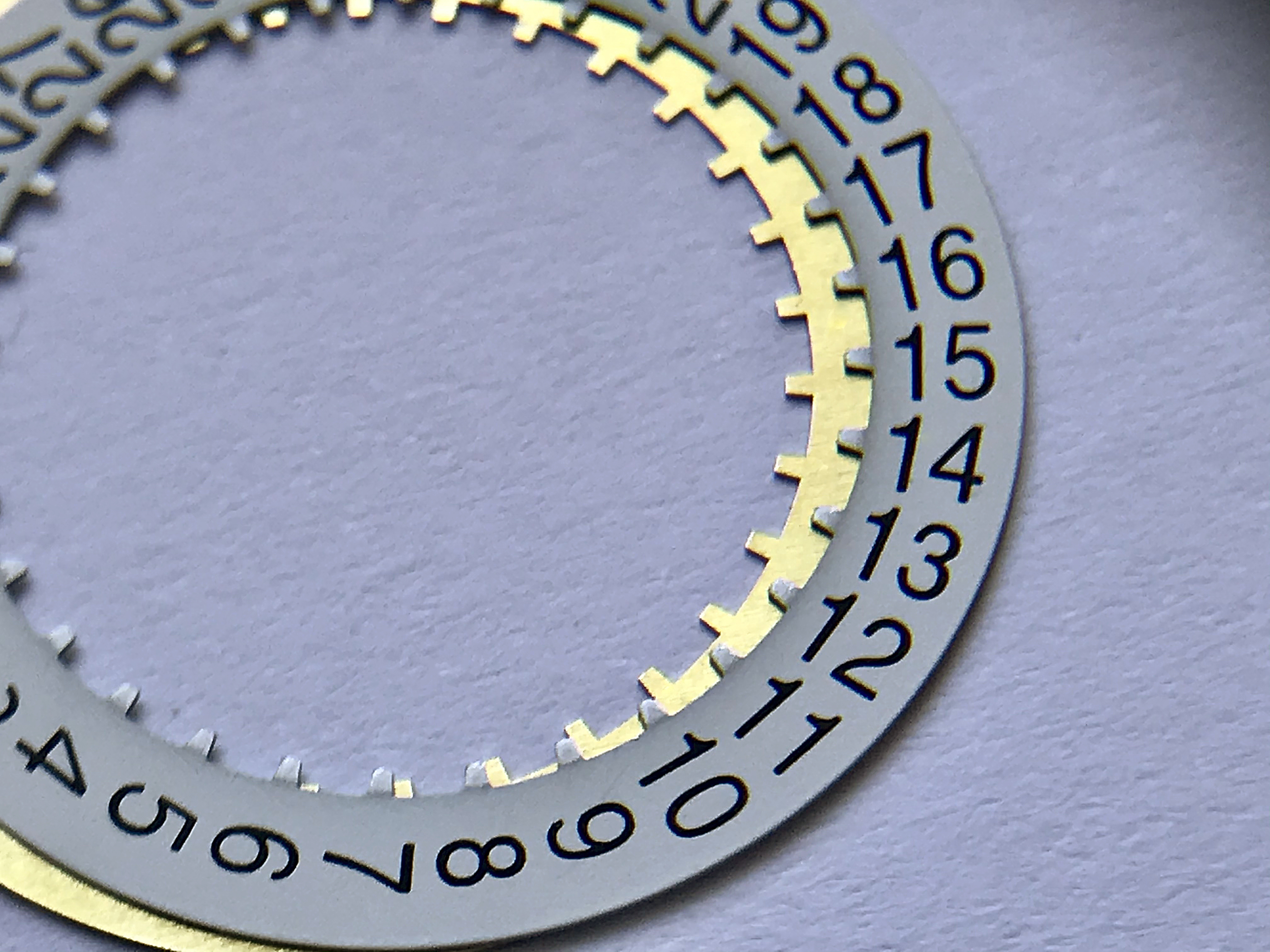

The next pictures will show you our approach to get everything perfect. We meticulously measured a gen 324 SC date wheel up to 0.00x mm then magnified our sample 50 times and reworked the geometry.

Using a gen DW is one thing - taking the 3KF stock DW out of the equation would have been careless - so we matched the exact shape of the teeth and negative space.

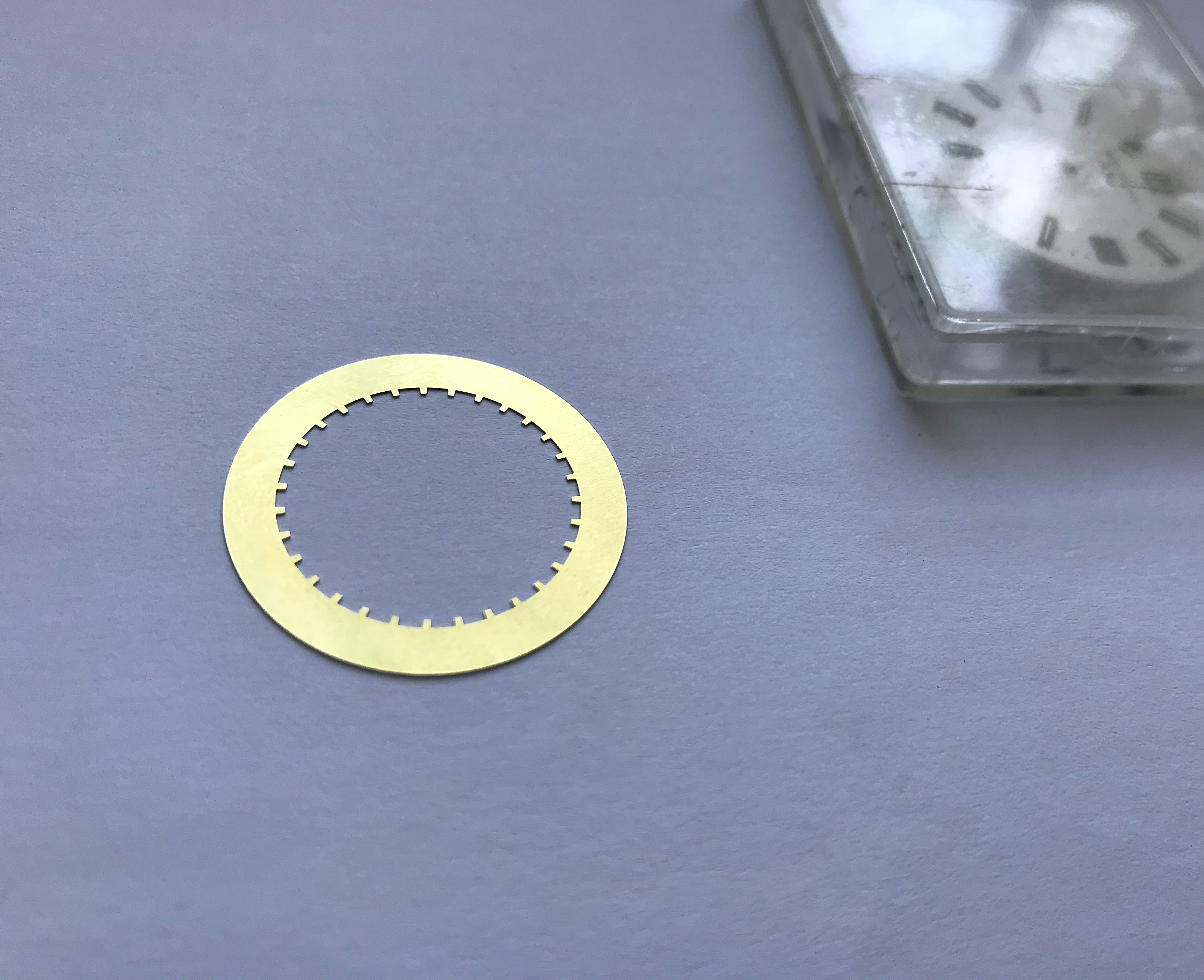

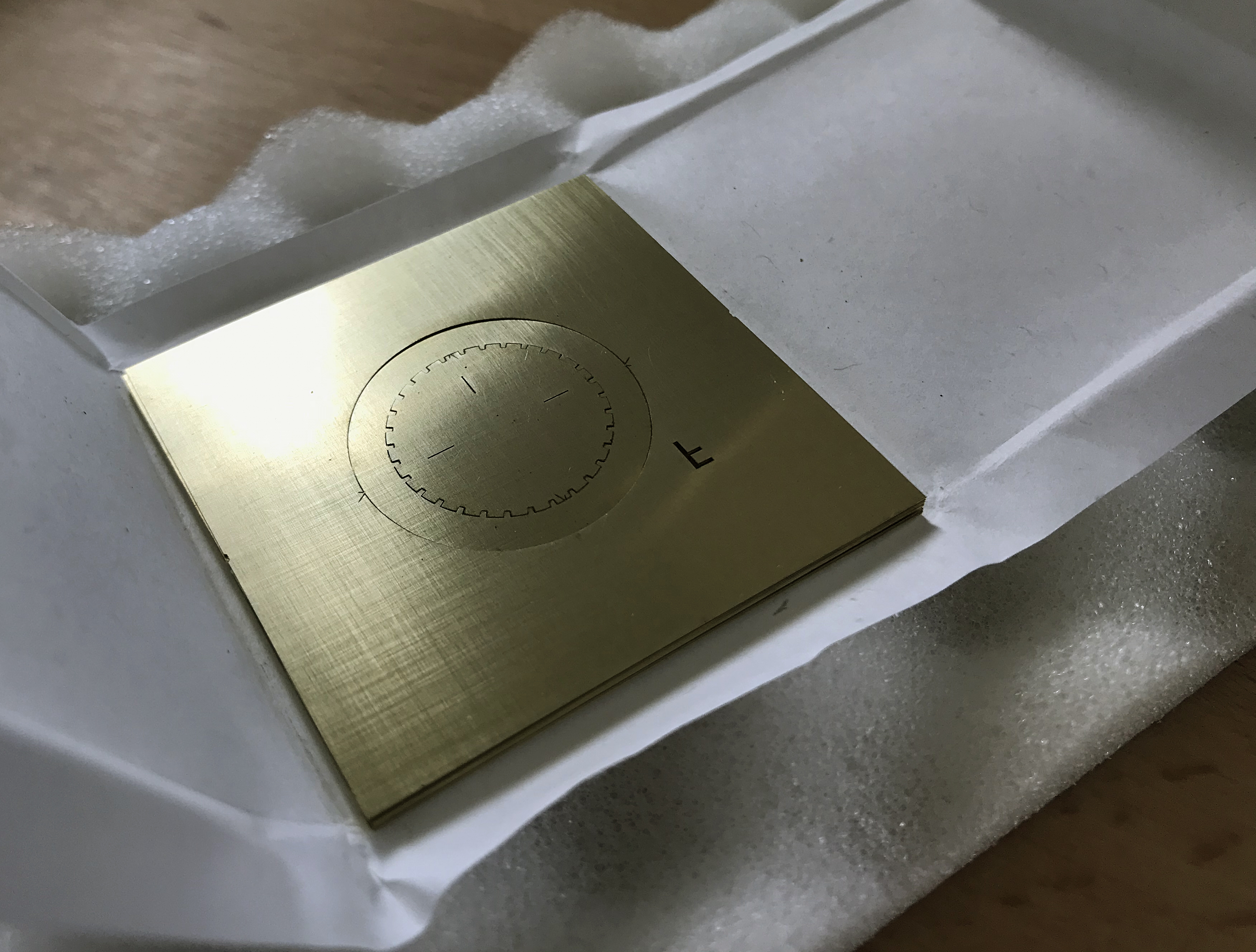

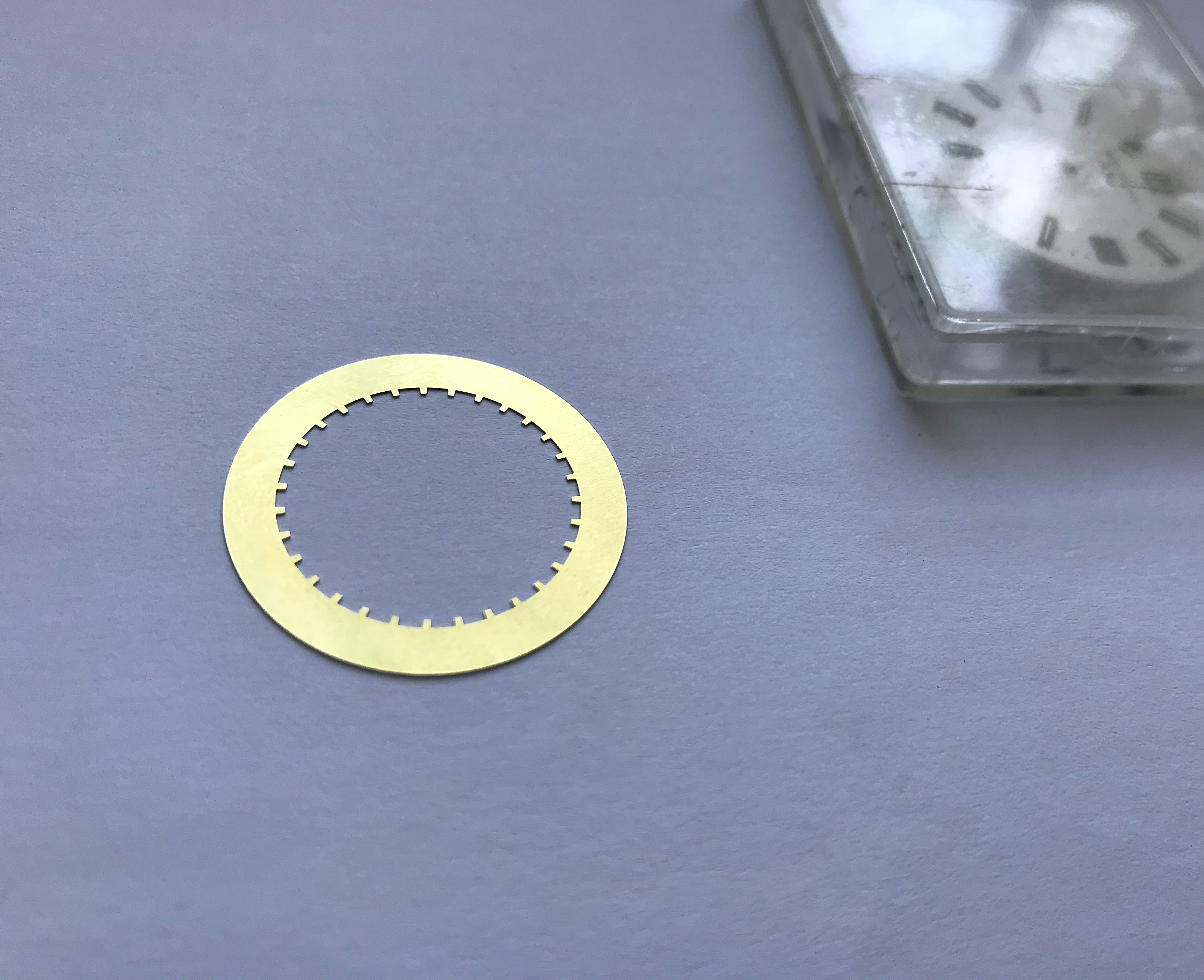

We opted for high precision laser cutting our brass parts - the high repeatability of the process, combined with a precision of 5µm (microns) or say 0.005mm is exactly what is needed for smaller runs like in this case. On a side note - the tolerances are within what we are willing to accept as there are no short cuts with micro mechanics.

As you can see we chose brass just like the older gen DW's. Some newer gen movements and our Chinese rep-makers use cheap alloys like aluminum which are easier to galvanize in bulk rather than to be painted white.

However our DW's are going to be made out of brass and will receive an eggshell textured paint job in bright white like the ordinary gen counterpart.

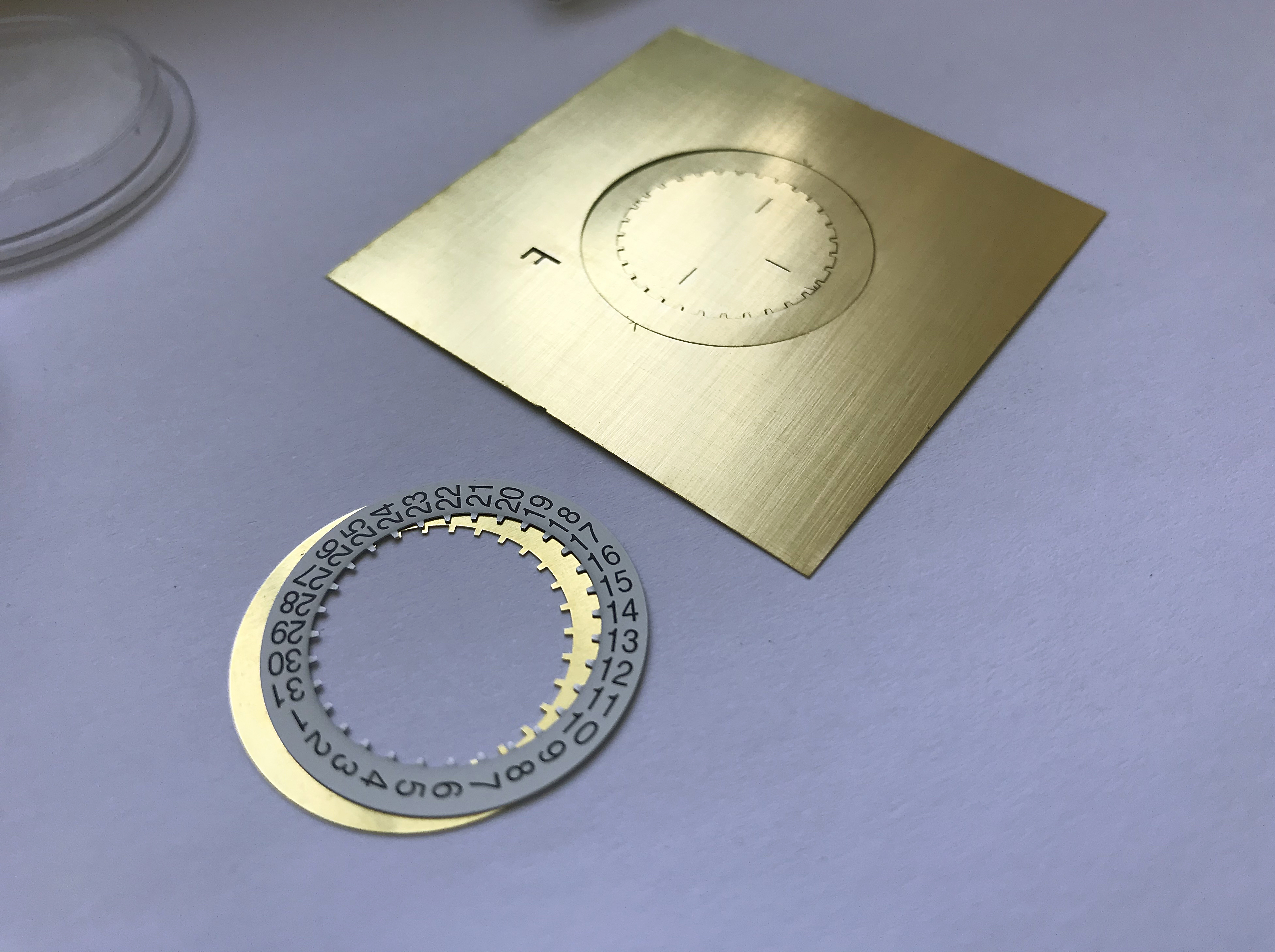

Next you will see the 3KF sample compared to our CNC parts.

Regarding the font and design that we are using - we are going with the same standard like in our first run of the PF DWOs. The font will be gen spec and will fit not only gen dials but also PPF dials and of course 3KF dials of the 324 SC range - as the cut outs are in the same location for either Nautilus 5711 or Aquanaut 5167... or any Calatrava driven by this ultra thin automatic movement

The next following steps are the painting of the DW's to prepare everything for the Tampography or better known as Pad Printing.

This week an update of the paint job will follow.

We will update this thread with news and will answer questions of course.

All our parts are made in Germany according to DIN standards to achieve the best results as possible.

Stay safe!

BIONONE

Like the title already told you - Keylog74 and me (@BIONONE) were working on something special for the past few months.

Many of you may remember us from back in the day when we developed the very first DWO (Date Wheel Overlay) for the Rep Patek line that was housing the infamous 9015 Miyota.

hings have changed and the exciting release of the 3KF 324 SC clone enriched the Patek Philippe (Rep) enthusiasts among us.

As so often - this new release was followed by a major step back by coming with a tiny and thin date font that was not only aesthetically unpleasing, but gave us also a shivering - that's how bad it remained for now almost 1.5 years since its introduction to the public.

No Change was in sight and a gen DW in good condition is rare to find and thus not the cheapest yet one of the key elements when building an overall decent watch - may it be a Franken build with a gen dial or the implementation of the clone into a case of ones choice to match ones individual preference.

So we decided to bring this well deserved change to the forum - All the effort that went into this venture should be shared with you step by step.

I will pause the speech and will please your eyes with some candy of the progress so far

Enjoy:

First up some fancy renders. Not needed for the production of course but for aesthetic purposes – as this is one of the main reasons we stay here day in day out hehe

The next pictures will show you our approach to get everything perfect. We meticulously measured a gen 324 SC date wheel up to 0.00x mm then magnified our sample 50 times and reworked the geometry.

Using a gen DW is one thing - taking the 3KF stock DW out of the equation would have been careless - so we matched the exact shape of the teeth and negative space.

We opted for high precision laser cutting our brass parts - the high repeatability of the process, combined with a precision of 5µm (microns) or say 0.005mm is exactly what is needed for smaller runs like in this case. On a side note - the tolerances are within what we are willing to accept as there are no short cuts with micro mechanics.

As you can see we chose brass just like the older gen DW's. Some newer gen movements and our Chinese rep-makers use cheap alloys like aluminum which are easier to galvanize in bulk rather than to be painted white.

However our DW's are going to be made out of brass and will receive an eggshell textured paint job in bright white like the ordinary gen counterpart.

Next you will see the 3KF sample compared to our CNC parts.

Regarding the font and design that we are using - we are going with the same standard like in our first run of the PF DWOs. The font will be gen spec and will fit not only gen dials but also PPF dials and of course 3KF dials of the 324 SC range - as the cut outs are in the same location for either Nautilus 5711 or Aquanaut 5167... or any Calatrava driven by this ultra thin automatic movement

The next following steps are the painting of the DW's to prepare everything for the Tampography or better known as Pad Printing.

This week an update of the paint job will follow.

We will update this thread with news and will answer questions of course.

All our parts are made in Germany according to DIN standards to achieve the best results as possible.

Stay safe!

BIONONE