- 27/3/06

- 453

- 2

- 0

Since i saw this new Panny model from the pics of the Basle Fair in april this year,I knew it is going to be my

new project after the Panny PVD serries.

That is the only pic i got on that model.the one of the left is the cremanic 183.

Luckily,we are in the world of replicas watches,I have a good friend who has made 2/3 mdoels of the Rado ceramic watches.I went to him for his assistance.

Ceramic is a very hard and rigid material.It is impossible to drill a hole or layer it down

to accomadate the movt ane other watch parts.How could i make a watch from this??

The solution is to make a stainelss steel skeleton body in which we can put the movt and other watch

parts.Then make a cremanic case jacket to cover the steel shell .

The holes on the lugs are made espcially for the lug wires and small screw.

Next step to to take precise measuments of the 183 case and to make exact cremanic JACKET to put

on the steel skeleton shell.

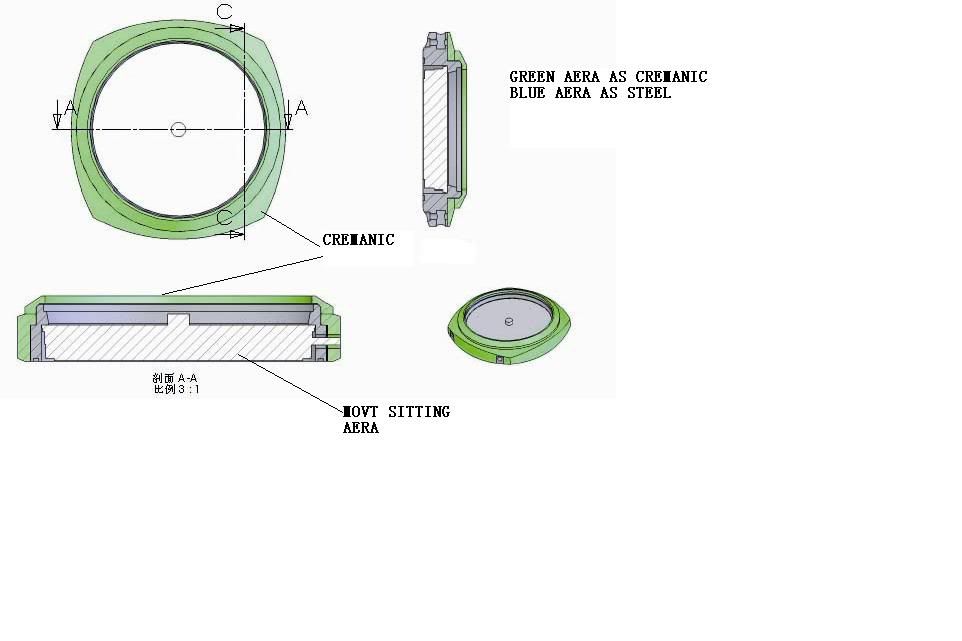

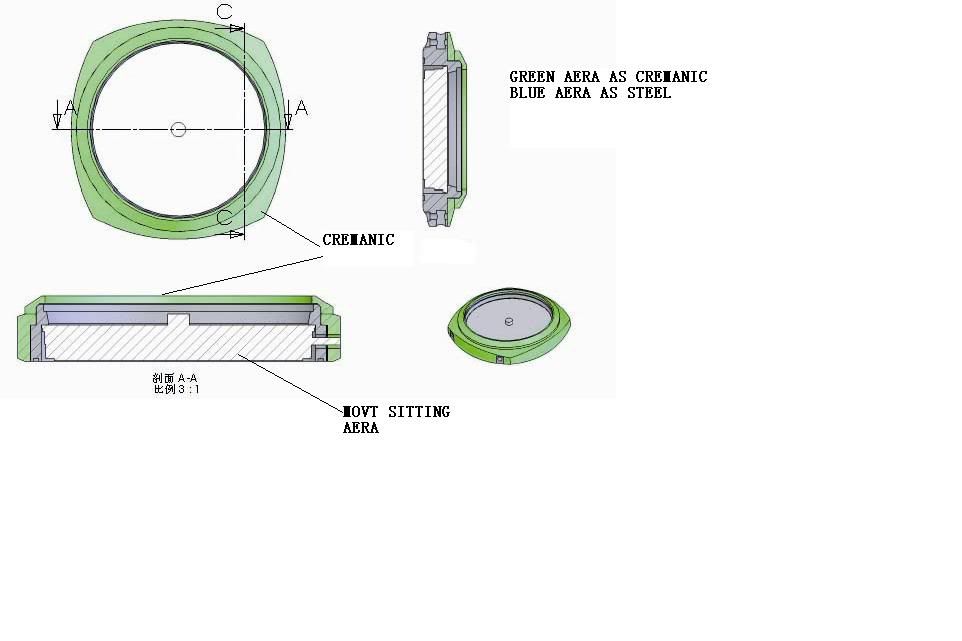

This pic shows some cross sections of the watch with the ceramic jacket fixed and secured on a steel body shell.

The design stage is realtaively easy .When i started making the mouldings and test run samples of the ceramic

jacket.It is very hard and painfully slow.2 moluldings and lots of new cremanaic jackets had to send to dustbin.

After lots of trials and errors.some thing good been made and ready!

How about the crown and lug wire?

These parts are not possible to make of ceramic.

The only way out is to make steel parts and pvd plated (high polisehed) them.

Since I am making the 183 watch already,i simply send all the parts for ion plating to match the shinny cremanic case

jacket.

I noticed that the real ceramic 183 looks similar a high polised steel 183 with High polished PVD finshing.Thus,i simiply

make a high polsihed PVD 183 and would like to compare it with the real cremanic 183.Pls note that i wil use this

shinny 183 lug wire and crowns to match it on the new ceramic 183.

Belows are pics of the HIGH POLSIED PVD 183.NOT CERAMIC 183 AT ALL.

Pics of the real ceramic 183 watch i will put a new post this Sunday.

Pls keep your eyes on here !

new project after the Panny PVD serries.

That is the only pic i got on that model.the one of the left is the cremanic 183.

Luckily,we are in the world of replicas watches,I have a good friend who has made 2/3 mdoels of the Rado ceramic watches.I went to him for his assistance.

Ceramic is a very hard and rigid material.It is impossible to drill a hole or layer it down

to accomadate the movt ane other watch parts.How could i make a watch from this??

The solution is to make a stainelss steel skeleton body in which we can put the movt and other watch

parts.Then make a cremanic case jacket to cover the steel shell .

The holes on the lugs are made espcially for the lug wires and small screw.

Next step to to take precise measuments of the 183 case and to make exact cremanic JACKET to put

on the steel skeleton shell.

This pic shows some cross sections of the watch with the ceramic jacket fixed and secured on a steel body shell.

The design stage is realtaively easy .When i started making the mouldings and test run samples of the ceramic

jacket.It is very hard and painfully slow.2 moluldings and lots of new cremanaic jackets had to send to dustbin.

After lots of trials and errors.some thing good been made and ready!

How about the crown and lug wire?

These parts are not possible to make of ceramic.

The only way out is to make steel parts and pvd plated (high polisehed) them.

Since I am making the 183 watch already,i simply send all the parts for ion plating to match the shinny cremanic case

jacket.

I noticed that the real ceramic 183 looks similar a high polised steel 183 with High polished PVD finshing.Thus,i simiply

make a high polsihed PVD 183 and would like to compare it with the real cremanic 183.Pls note that i wil use this

shinny 183 lug wire and crowns to match it on the new ceramic 183.

Belows are pics of the HIGH POLSIED PVD 183.NOT CERAMIC 183 AT ALL.

Pics of the real ceramic 183 watch i will put a new post this Sunday.

Pls keep your eyes on here !