Hi Members,

here is my newest project. Some guys asked for nickel plated buckles on their straps.

I thought that it couldn’t be that difficult to plate my brass buckles myself.

Bought 250ml Nickelelectrolyte from a supplier next to my hometown.

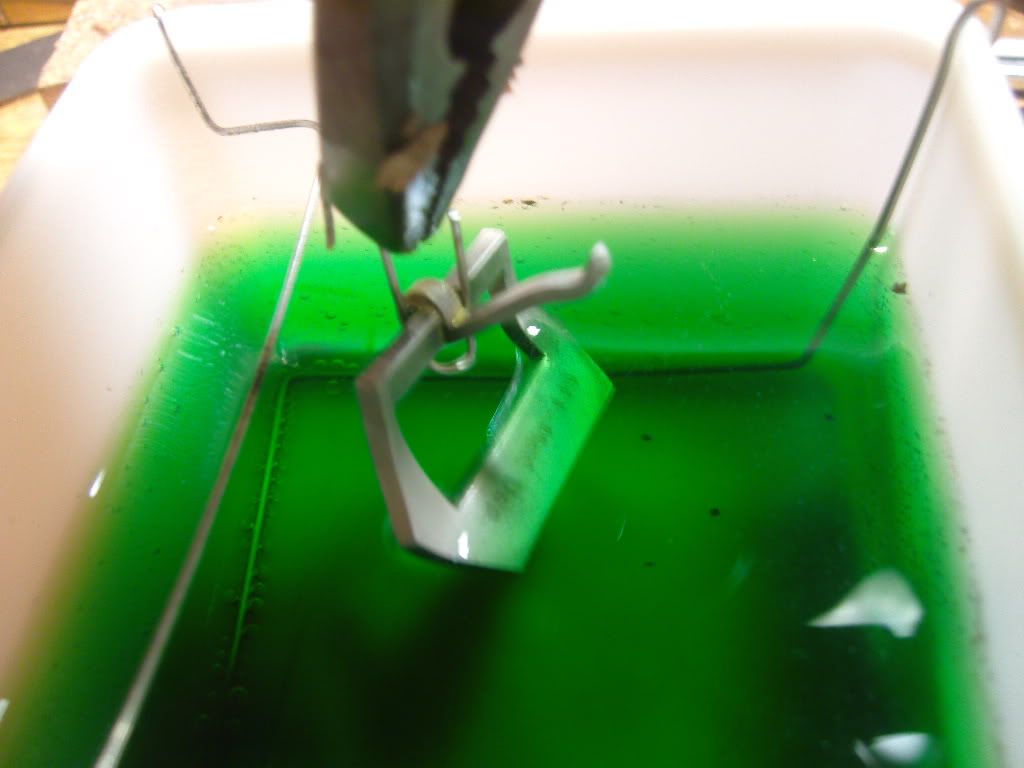

Bend some Cri Ni wire to have a plus pole in the fluid.

Bend a supporting wire to hold a hook and clamp on the batteryclamp

Bend a hook for dipping the buckle into the fluid with contact to the minus pole

Used my 12V 8A Battery charger ( for car batteries )

And an old Tupperware container, use one with a lid to store the fluid

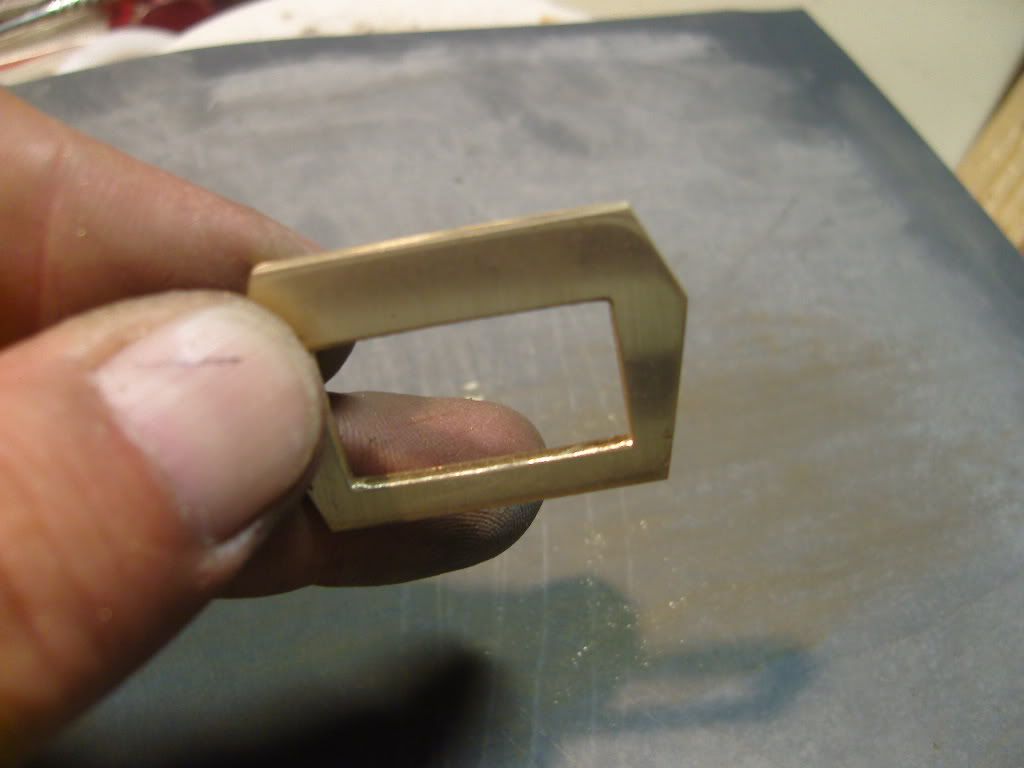

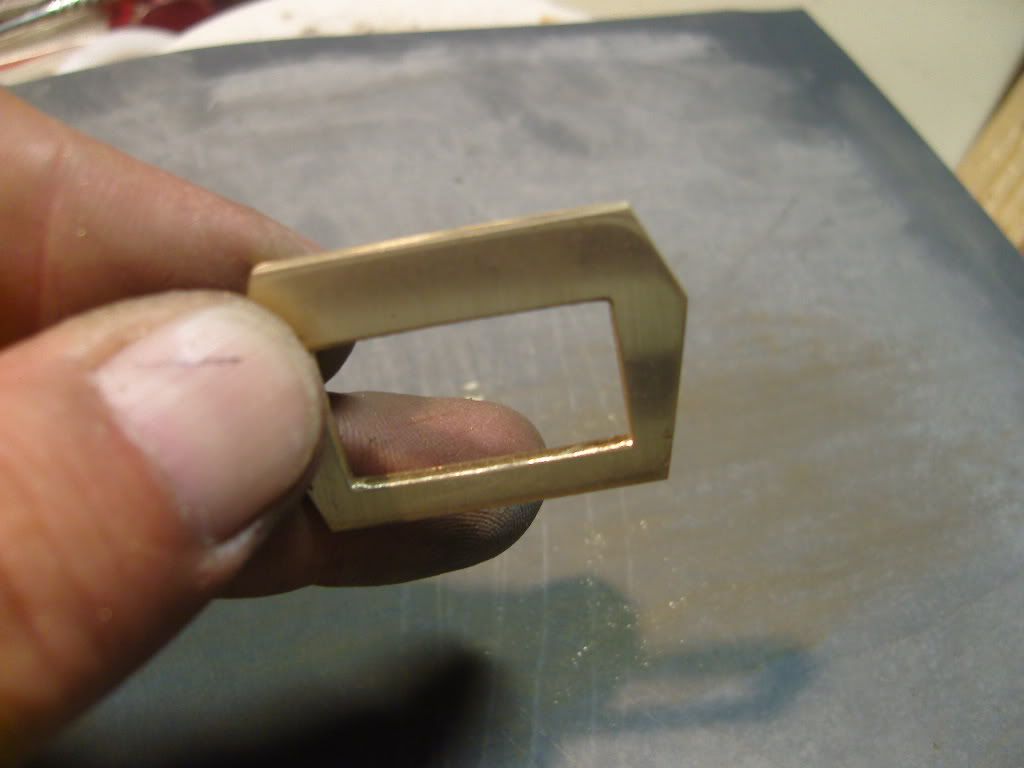

Here is the victim, a brass buckle, polished, heattreated and degreased with acetone.

The nickelelectrolyte must have a temperature from 70 degrees Celsius, I took the bin into the microwave BEFORE installing the CriNi wire.

Installed the wires in opposite to each other. Avoided contact .

Hung the buckle with a hook on the upper wire. it must be completely covered with fluid

The wire with the buckle needs contact to the minus pole, the other one is clamped to plus pole

If everything is done right and the charger works, it must look like an aspirin in green water.

I gave it 5 minutes to get plated

Switched off the charger and grabbed the hook with pliers, because it was HOT.

The hook, not the buckle.

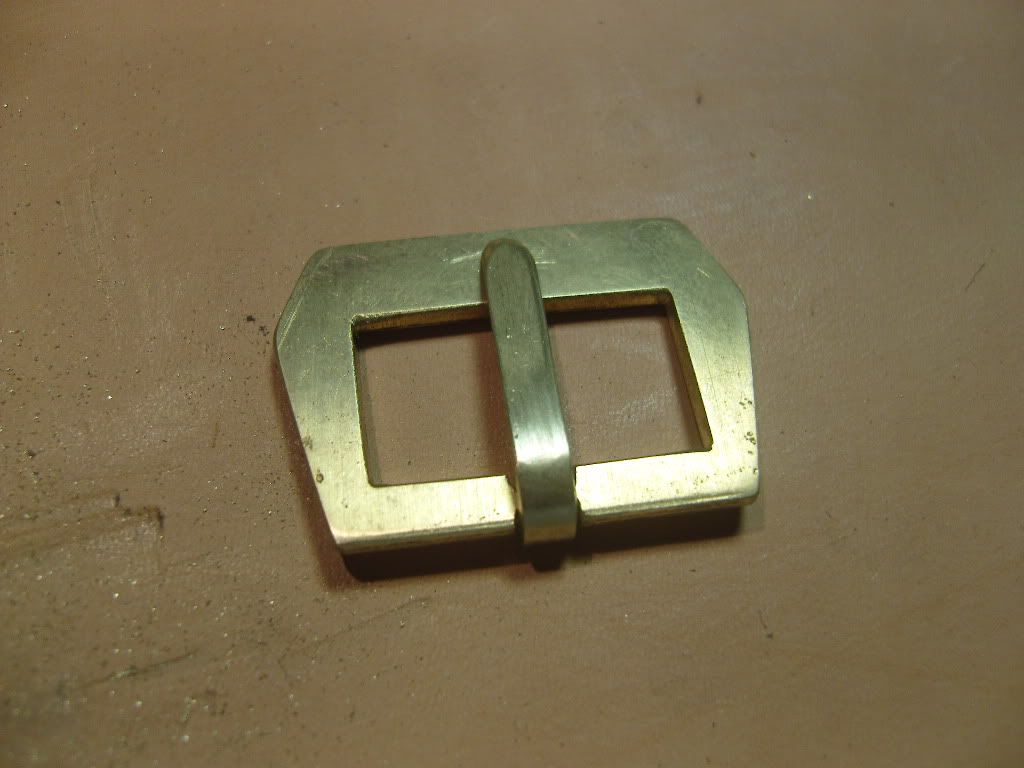

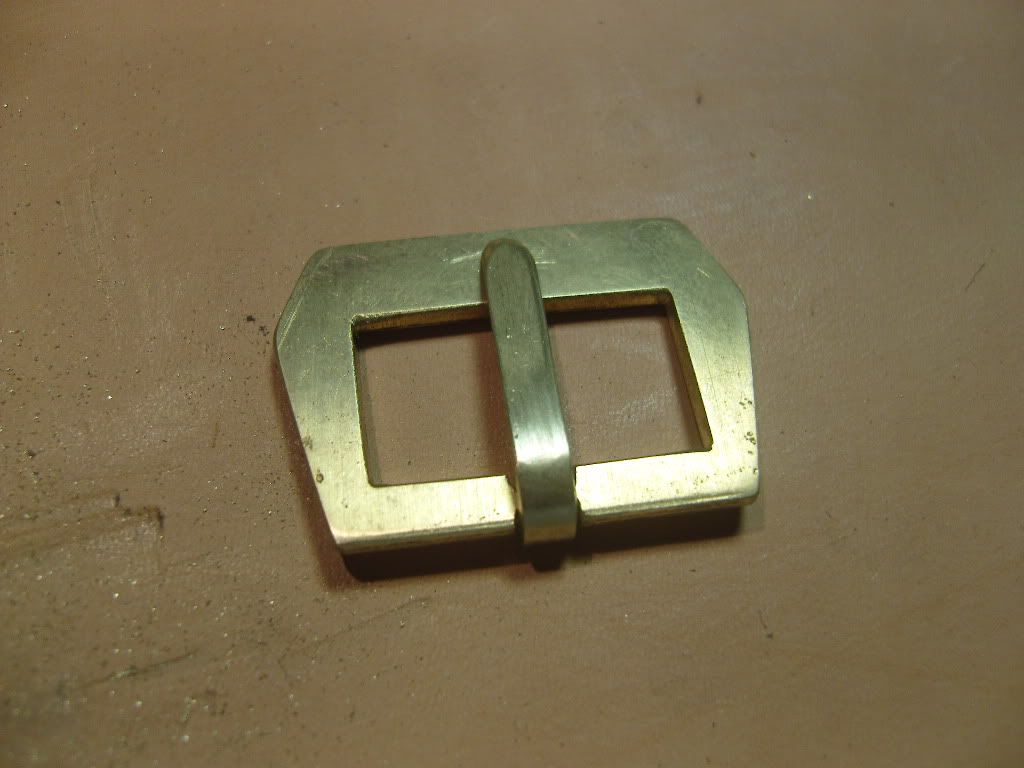

And here is the result:

Here are some other buckles I’ve plated with nickel

Wear gloves and eye protection, do this job not in closed rooms.

And don’t drink that electrolyte

Thank you for looking

Greetz

Uwe

here is my newest project. Some guys asked for nickel plated buckles on their straps.

I thought that it couldn’t be that difficult to plate my brass buckles myself.

Bought 250ml Nickelelectrolyte from a supplier next to my hometown.

Bend some Cri Ni wire to have a plus pole in the fluid.

Bend a supporting wire to hold a hook and clamp on the batteryclamp

Bend a hook for dipping the buckle into the fluid with contact to the minus pole

Used my 12V 8A Battery charger ( for car batteries )

And an old Tupperware container, use one with a lid to store the fluid

Here is the victim, a brass buckle, polished, heattreated and degreased with acetone.

The nickelelectrolyte must have a temperature from 70 degrees Celsius, I took the bin into the microwave BEFORE installing the CriNi wire.

Installed the wires in opposite to each other. Avoided contact .

Hung the buckle with a hook on the upper wire. it must be completely covered with fluid

The wire with the buckle needs contact to the minus pole, the other one is clamped to plus pole

If everything is done right and the charger works, it must look like an aspirin in green water.

I gave it 5 minutes to get plated

Switched off the charger and grabbed the hook with pliers, because it was HOT.

The hook, not the buckle.

And here is the result:

Here are some other buckles I’ve plated with nickel

Wear gloves and eye protection, do this job not in closed rooms.

And don’t drink that electrolyte

Thank you for looking

Greetz

Uwe