I have worked on three different Chinese Unitas movements and each of them has a winding problem.

I realize that three is hardly a fair number of samples to make a solid decision about all Chinese Unitas but the Swiss movements really are cheap enough that it doesn't make much since taking the chance in the first place.

The first Chinese Unitas I had with this problem was the normal Unitas bridgework model with the foil Panerai graffiti on it.

The second one was the Panerai style bridgework model with the graffiti on it.

This latest model is one of the fixed cannon pinion/ hour wheel models with the Panerai style bridgework from davidsen.

All three of these movements were purchased at very different times and the davidsen movement even has different machining so it’s not a case of one bad lot of these movements.

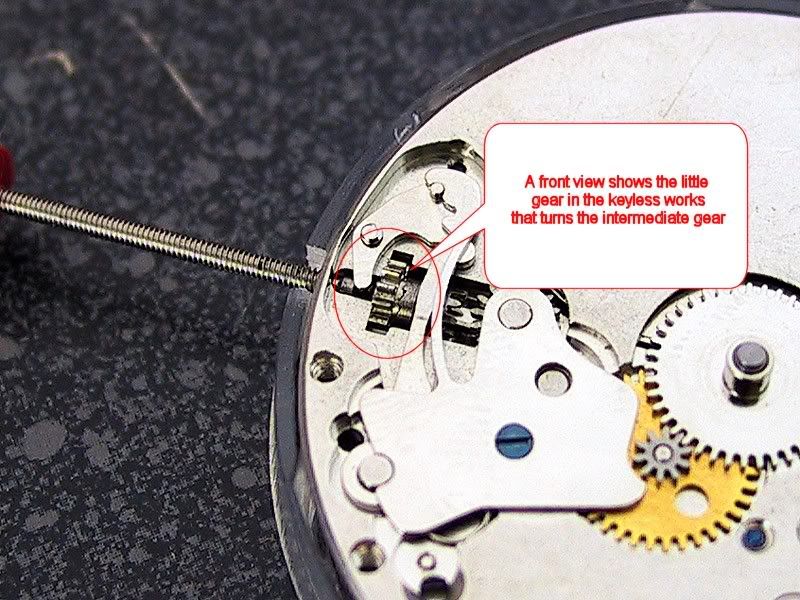

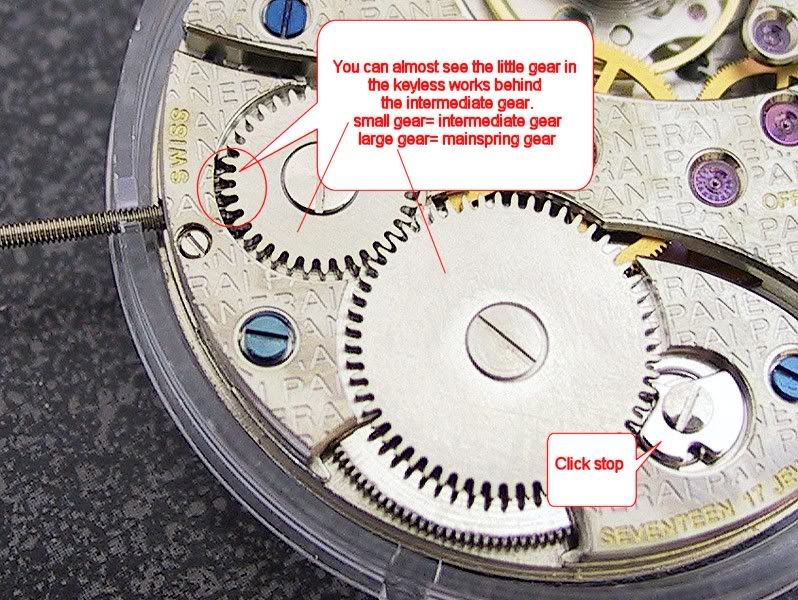

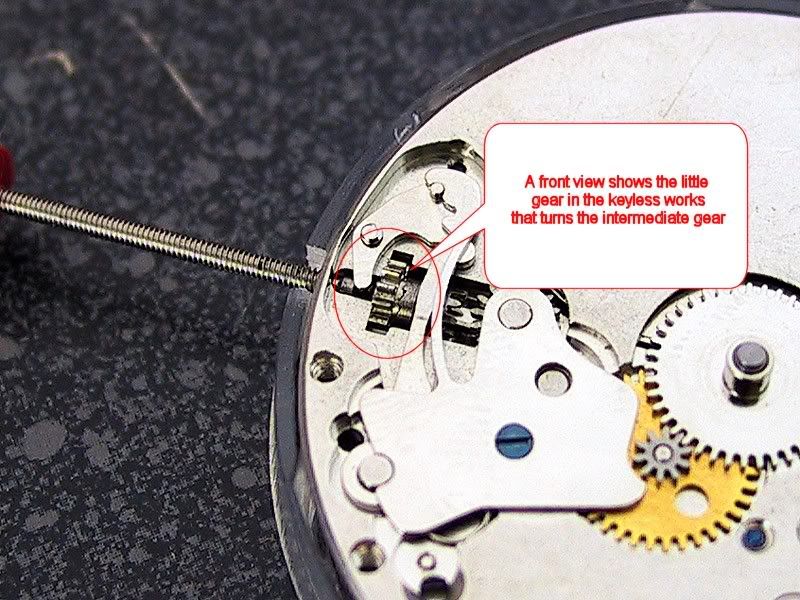

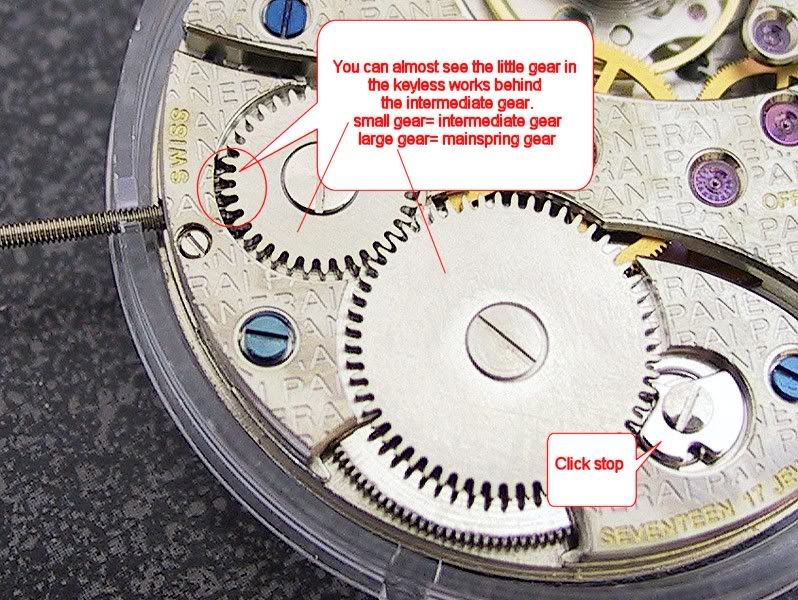

The problem is with the geometry between the little gear in the keyless works (the gear that the crown/stem actually turns when you wind the watch you can’t see this gear with the dial installed) and the intermediate gear (the smaller of the two gears that are visible on the back of the movement). When there is enough tension from the main spring but well before it’s fully wound, the intermediate gear can lift away from the watch slightly due to loose tolerances. This by itself isn't a problem even the real Unitas does this a little.

The problem is the tolerances between that intermediate gear and the gear in the keyless works. When the intermediate gear lifts away from the movement there isn’t enough mesh between the intermediate gear and the gear in the keyless works to maintain contact when they separate the intermediate gear and mainspring gear unwind until the click stop on the mainspring gear catches. The slipping makes a ratcheting noise as the gear in the keyless works and the intermediate gear slip past each other. Over time this slipping causes wear that leads to more and more difficulty winding the watch until eventually the two gears will wear enough of themselves down that the movement won’t wind anymore and you have a nice looking paperweight.

The tolerances in the Swiss Unitas are such that the intermediate gear can lift away from the keyless gear slightly and they still mesh properly even when the parts age from normal use these two gears rarely wear enough to separate completely like the Chinese Unitas are doing.

Your more than welcome to take your chances with Chinese movements but with all the trouble you can have just to get a decent working replica on your wrist why knowingly add one more potential problem to the process?

Just save your money and buy the Swiss movement models!

I realize that three is hardly a fair number of samples to make a solid decision about all Chinese Unitas but the Swiss movements really are cheap enough that it doesn't make much since taking the chance in the first place.

The first Chinese Unitas I had with this problem was the normal Unitas bridgework model with the foil Panerai graffiti on it.

The second one was the Panerai style bridgework model with the graffiti on it.

This latest model is one of the fixed cannon pinion/ hour wheel models with the Panerai style bridgework from davidsen.

All three of these movements were purchased at very different times and the davidsen movement even has different machining so it’s not a case of one bad lot of these movements.

The problem is with the geometry between the little gear in the keyless works (the gear that the crown/stem actually turns when you wind the watch you can’t see this gear with the dial installed) and the intermediate gear (the smaller of the two gears that are visible on the back of the movement). When there is enough tension from the main spring but well before it’s fully wound, the intermediate gear can lift away from the watch slightly due to loose tolerances. This by itself isn't a problem even the real Unitas does this a little.

The problem is the tolerances between that intermediate gear and the gear in the keyless works. When the intermediate gear lifts away from the movement there isn’t enough mesh between the intermediate gear and the gear in the keyless works to maintain contact when they separate the intermediate gear and mainspring gear unwind until the click stop on the mainspring gear catches. The slipping makes a ratcheting noise as the gear in the keyless works and the intermediate gear slip past each other. Over time this slipping causes wear that leads to more and more difficulty winding the watch until eventually the two gears will wear enough of themselves down that the movement won’t wind anymore and you have a nice looking paperweight.

The tolerances in the Swiss Unitas are such that the intermediate gear can lift away from the keyless gear slightly and they still mesh properly even when the parts age from normal use these two gears rarely wear enough to separate completely like the Chinese Unitas are doing.

Your more than welcome to take your chances with Chinese movements but with all the trouble you can have just to get a decent working replica on your wrist why knowingly add one more potential problem to the process?

Just save your money and buy the Swiss movement models!