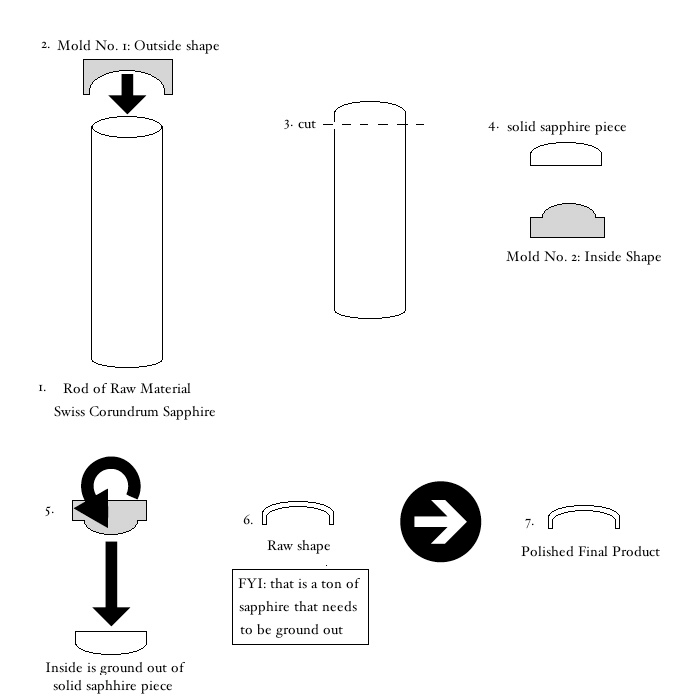

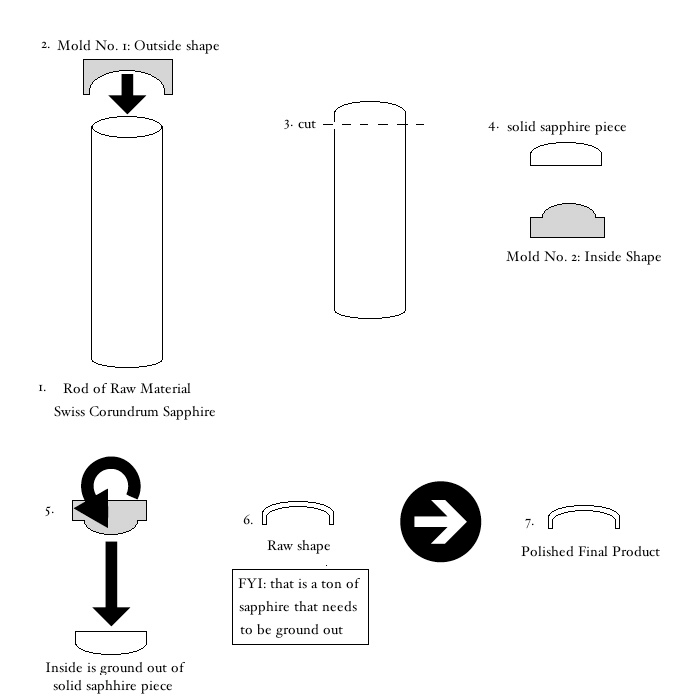

Manufacturing the Dome Crystals for PAM 212 and the larger PAM 127

Okay fellas, I thought I would pass along the information I have learned on the latest 1:1 crystal project. Below are the steps that Panerai's sub contractor uses to make one of their crystals.

The biggest hurdle, I am told, is the set labeled number 5 above. If the second mold is not lined up perfectly, the whole crystal is considered a 'reject' and is a waste of product. In mass manufacturing like this, a loss of over 5% can be disastrous to the bottom line.

This is why (I believe), this project has never been completed to anyway near 1:1 proportions with genuine sapphire.

*****

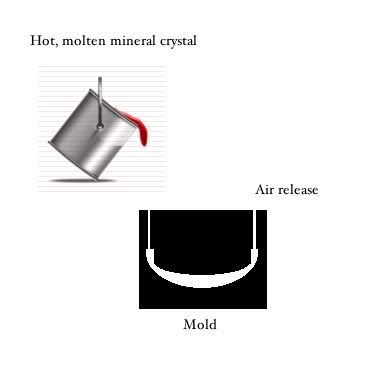

This is how a mineral crystal is made:

Obviously, the mineral crystals are easier and far cheaper. But they will break easier.

The biggest hurdle, I am told, is the set labeled number 5 above. If the second mold is not lined up perfectly, the whole crystal is considered a 'reject' and is a waste of product. In mass manufacturing like this, a loss of over 5% can be disastrous to the bottom line.

This is why (I believe), this project has never been completed to anyway near 1:1 proportions with genuine sapphire.

*****

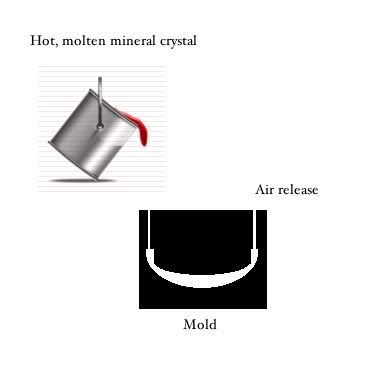

This is how a mineral crystal is made:

Obviously, the mineral crystals are easier and far cheaper. But they will break easier.