Hello boys... it's been awhile since i've posted anything meaningful on this board. partly because I'm lazy but mainly because I have been involved in alot of very special projects. Once project in particular requires the use of a "lapping machine". This is something that Rolex/AP and most highend watch houses use to shape/polish their cases. If you have ever seen these in action, you will know that it is capable of some amazing results.

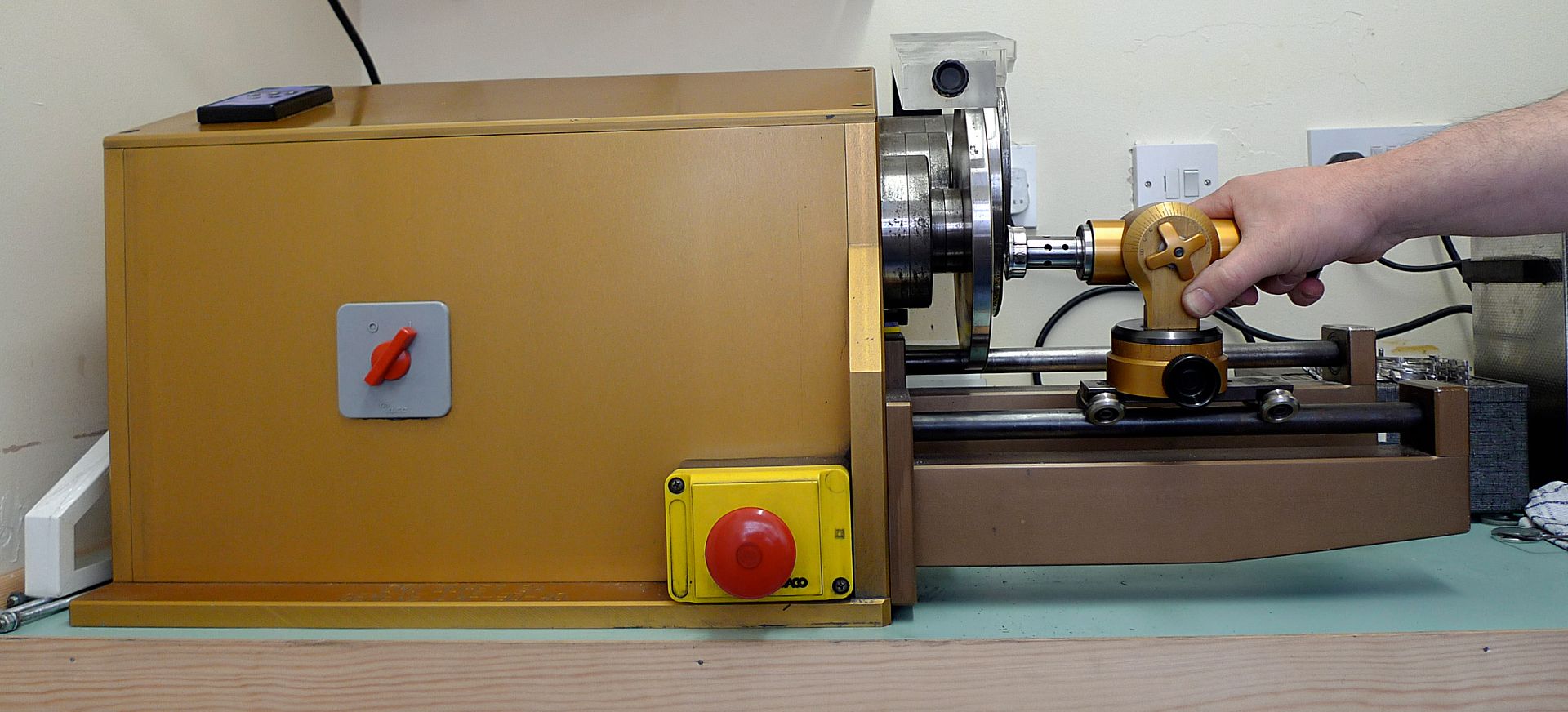

Generally, these machines look something like this:

Quite simply, its a heavy duty disk grinder with adjustable rails placed perpendicular to the grinding surface. These are very specialized machines and they are extremely expensive and very few exist in North America.

What is really unique is the machanism that holds the watch case to the abrasive surface:

Similar to a pan/tilt camera mount, this contratraption slides on the rails and maintains the case at a specific angle at all times. The case can then be rotated to create a very polished surface or even a brushed, starburst effect depending on the angle and rotation.

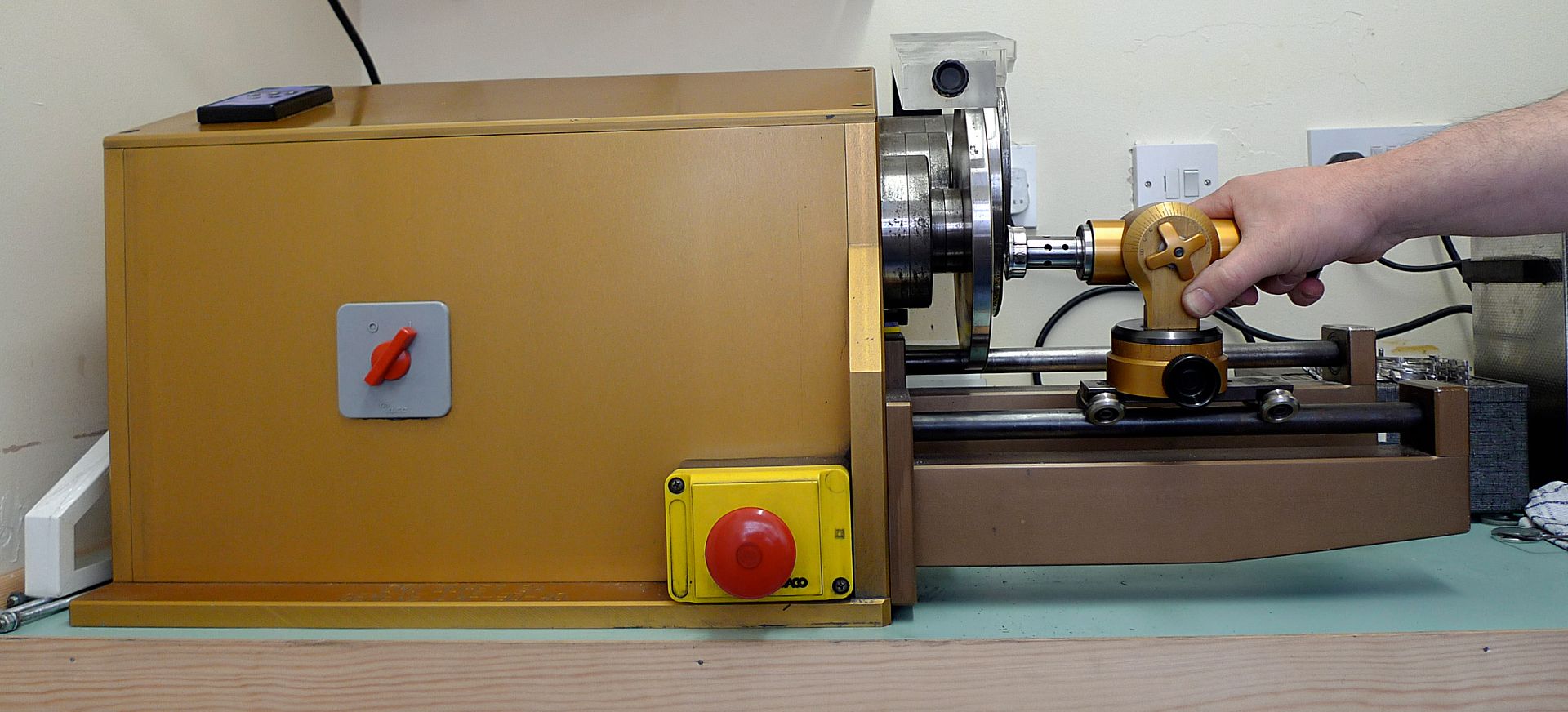

Depending on the polishing required, an adjustable work surface can be mounted to the rails as well:

Because I dont have $20k+ to blow on a power tool, I have tasked myself with building my own version of this using a Leeson motor and a KB variable speed controller. I was in Ohio earlier this week and picked up from Beaumont Metal Works a disk grinder work rest. Once installed, it will look something like this:

I think this will make a good starting point for a "ghetto" lapping machine that should produce the results I'm looking for.

I am going to fabricate the adjustable rail system as well as the watch case holder/sled in the coming months.

Here's an example of a Rolex case being laser welded and then repolished.

Before:

After:

Obviously the operator of the machine is the most important, but to get razor sharp/straight surfaces, maintaining a fixed angle is imperative.

I will update as the project progresses.

Generally, these machines look something like this:

Quite simply, its a heavy duty disk grinder with adjustable rails placed perpendicular to the grinding surface. These are very specialized machines and they are extremely expensive and very few exist in North America.

What is really unique is the machanism that holds the watch case to the abrasive surface:

Similar to a pan/tilt camera mount, this contratraption slides on the rails and maintains the case at a specific angle at all times. The case can then be rotated to create a very polished surface or even a brushed, starburst effect depending on the angle and rotation.

Depending on the polishing required, an adjustable work surface can be mounted to the rails as well:

Because I dont have $20k+ to blow on a power tool, I have tasked myself with building my own version of this using a Leeson motor and a KB variable speed controller. I was in Ohio earlier this week and picked up from Beaumont Metal Works a disk grinder work rest. Once installed, it will look something like this:

I think this will make a good starting point for a "ghetto" lapping machine that should produce the results I'm looking for.

I am going to fabricate the adjustable rail system as well as the watch case holder/sled in the coming months.

Here's an example of a Rolex case being laser welded and then repolished.

Before:

After:

Obviously the operator of the machine is the most important, but to get razor sharp/straight surfaces, maintaining a fixed angle is imperative.

I will update as the project progresses.