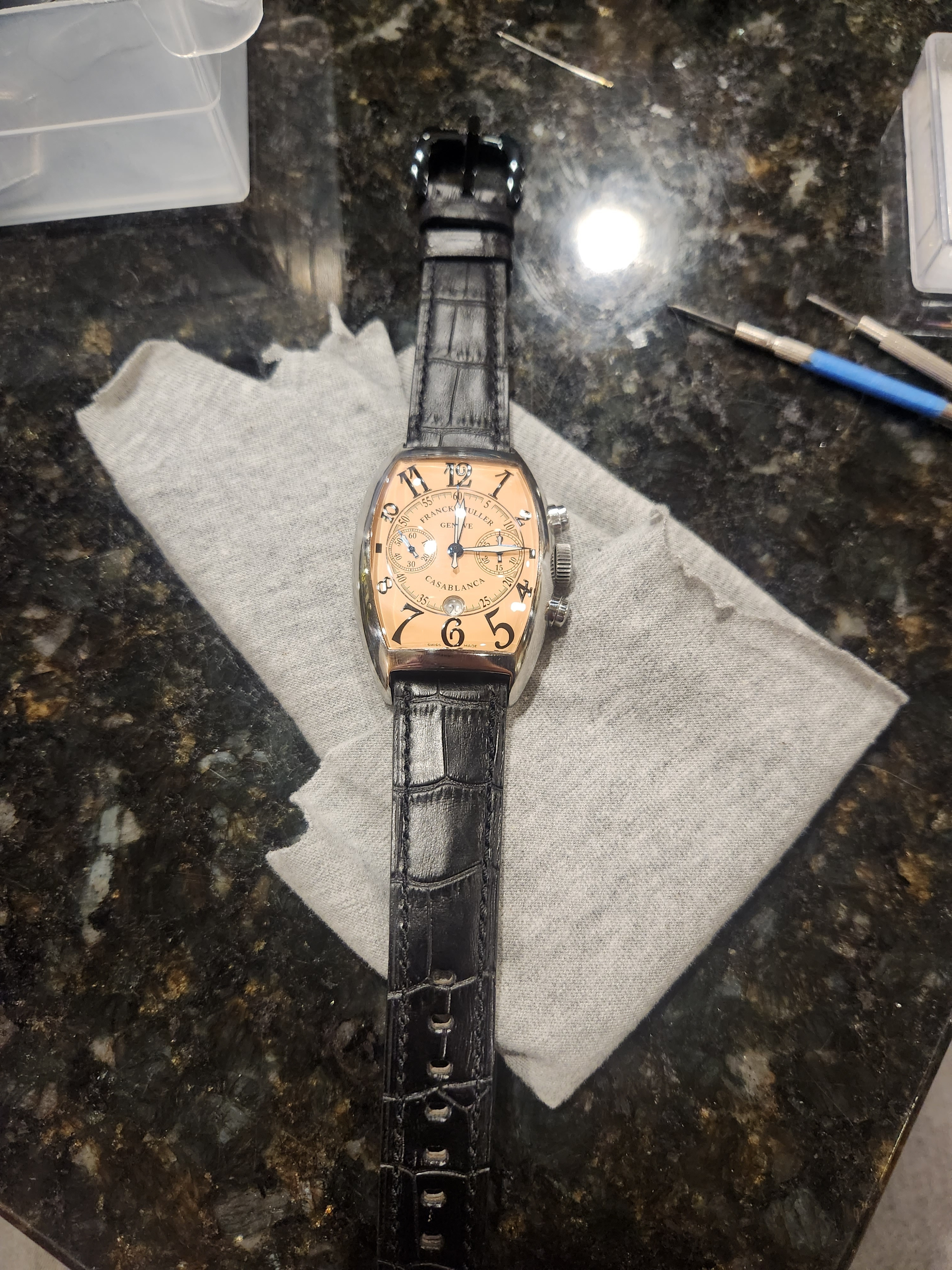

Do you hate PVD?

Do you wish that you could magically turn your PVD shitter into a glittering stainless steel box queen? Well look no further! Below I'll show you how to remove the P.utrid V.ile D.ecor that is clinging onto on your watch like a parasite.

Step 1:

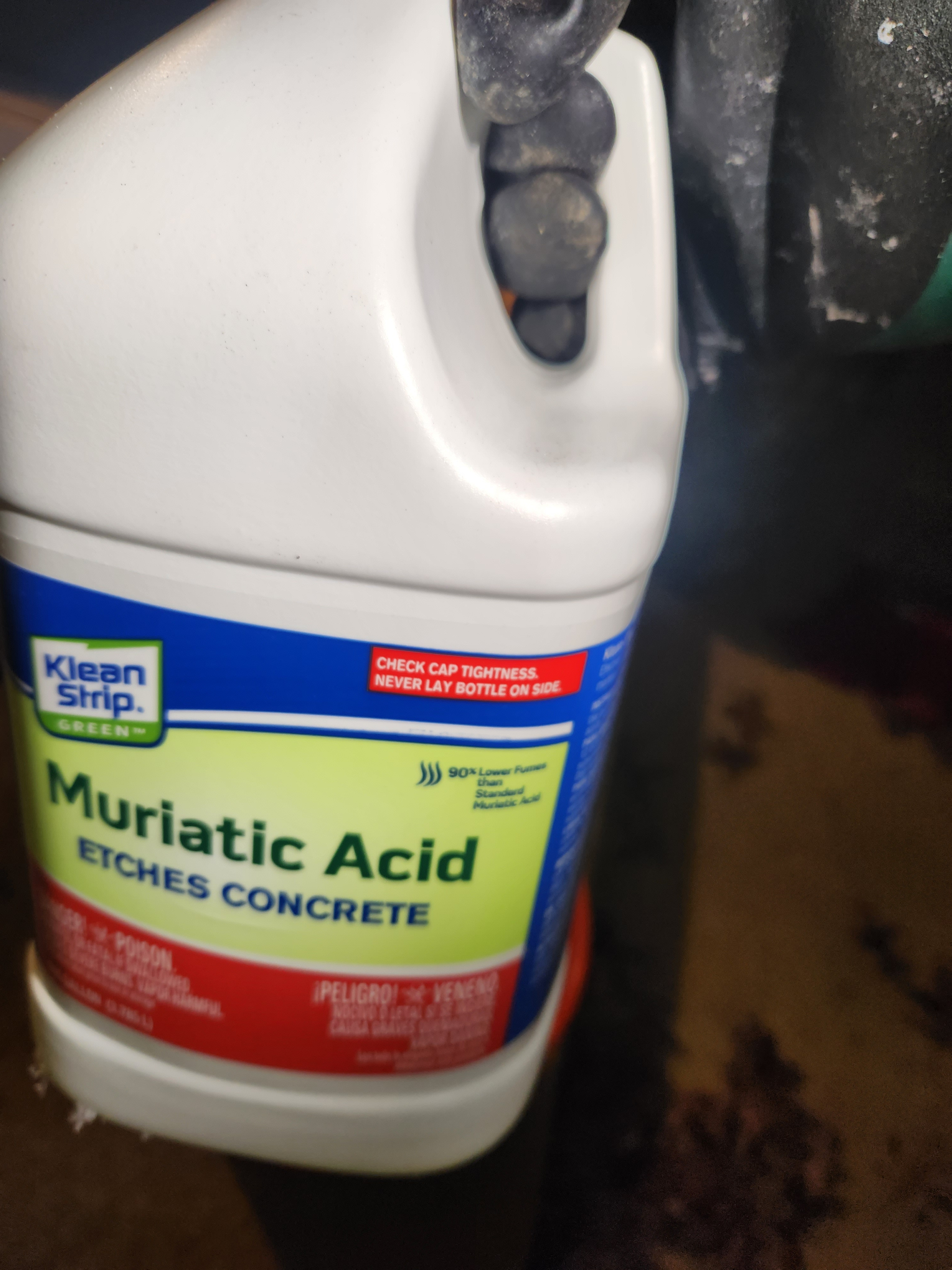

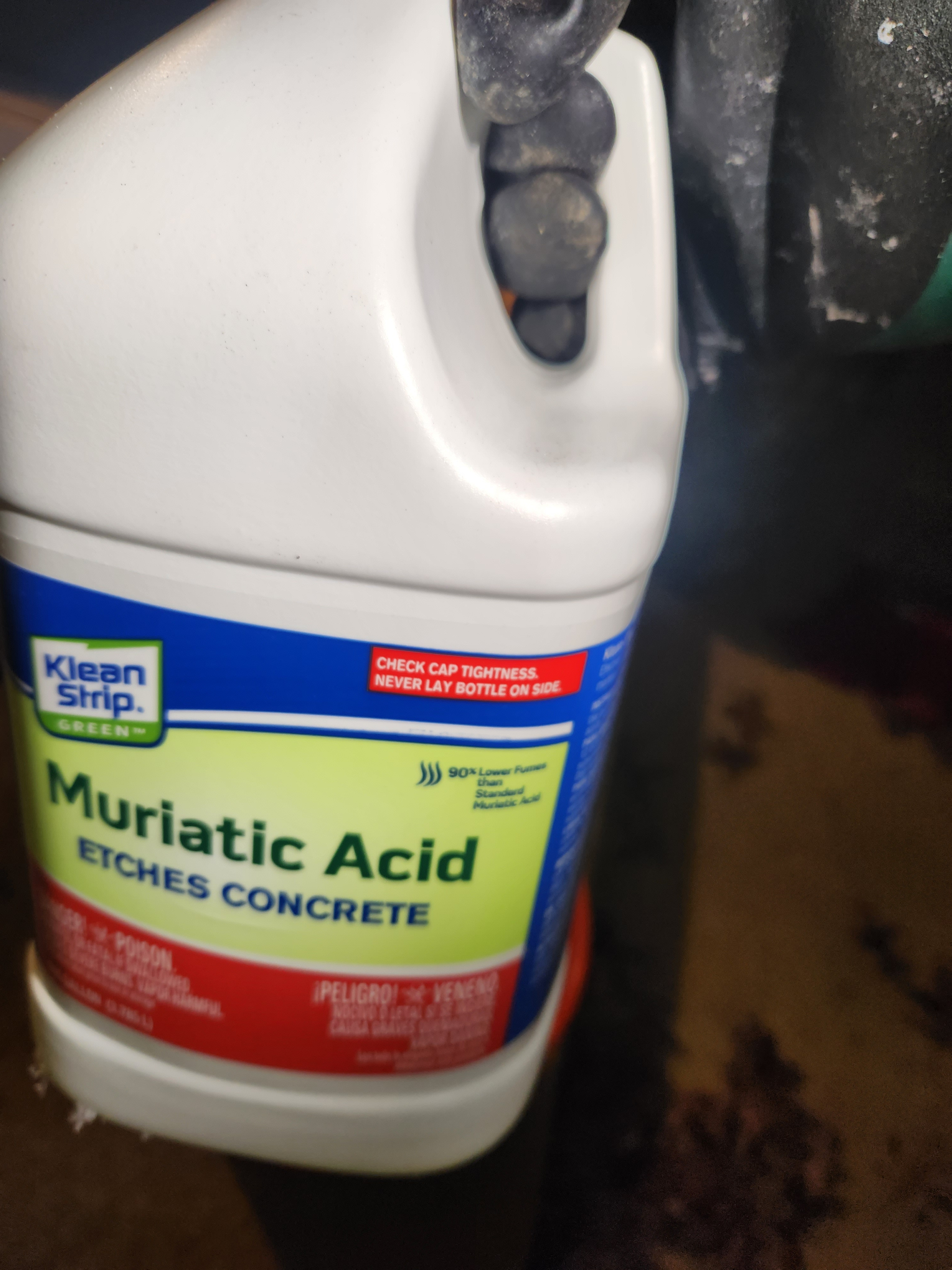

Obtain hydrochloric acid.

Muriatic acid is HCI mixed with water usually at around 30-40% strength. It's also filled with a bunch of other impurities, luckily this isn't a lab so flog off.

Step 2:

Decase your movement, dial and take your watch apart. HCI will not harm sapphire crystals but it will degrade seals, you may want to remove your crystal and any gaskets/xtal seals it may have, though HCI should not harm most plastics. Then, clean your parts with some alcohol and a stint in the Ultrasonic cleaner or use your hillbilly version.

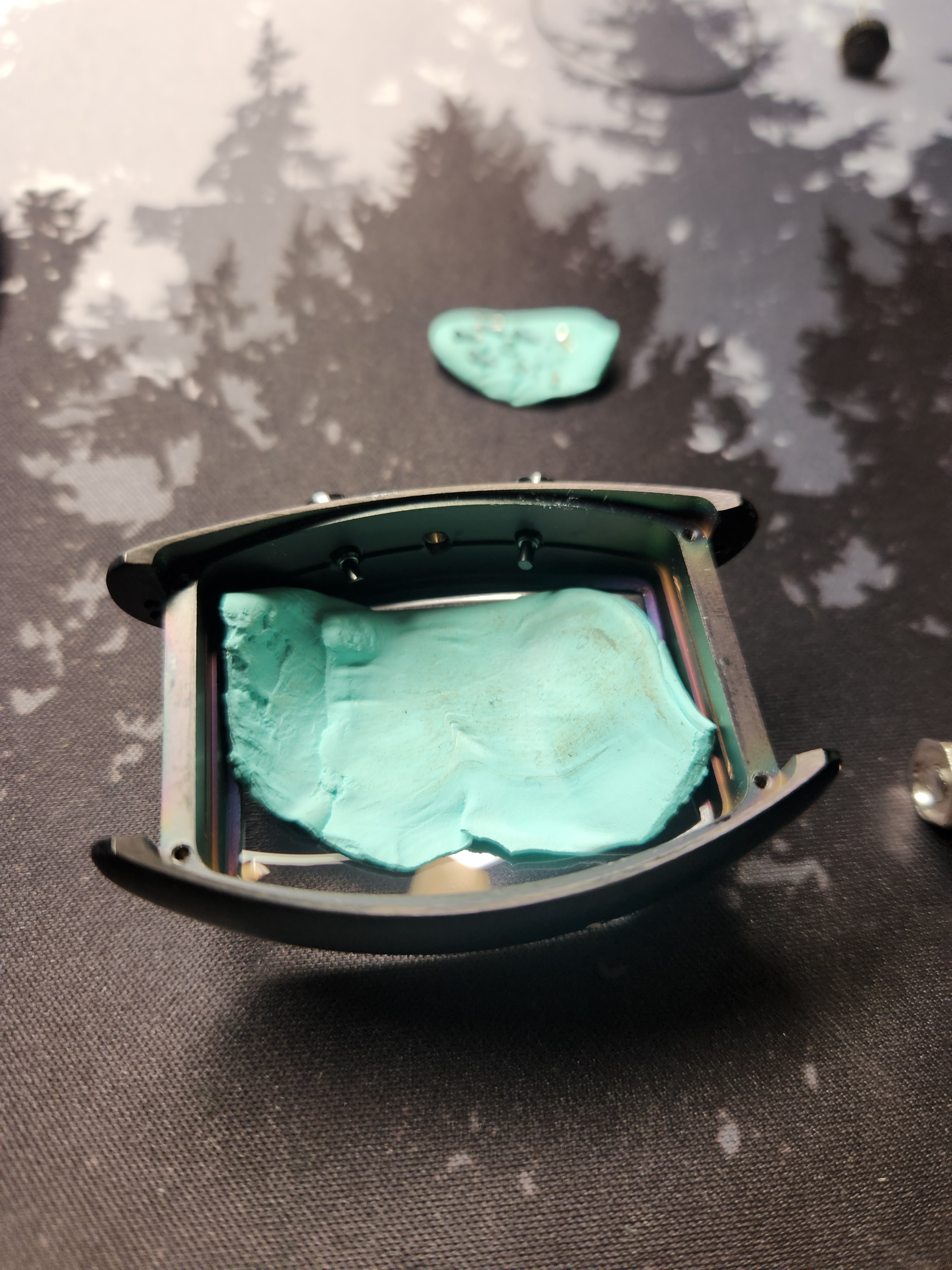

Step 3:

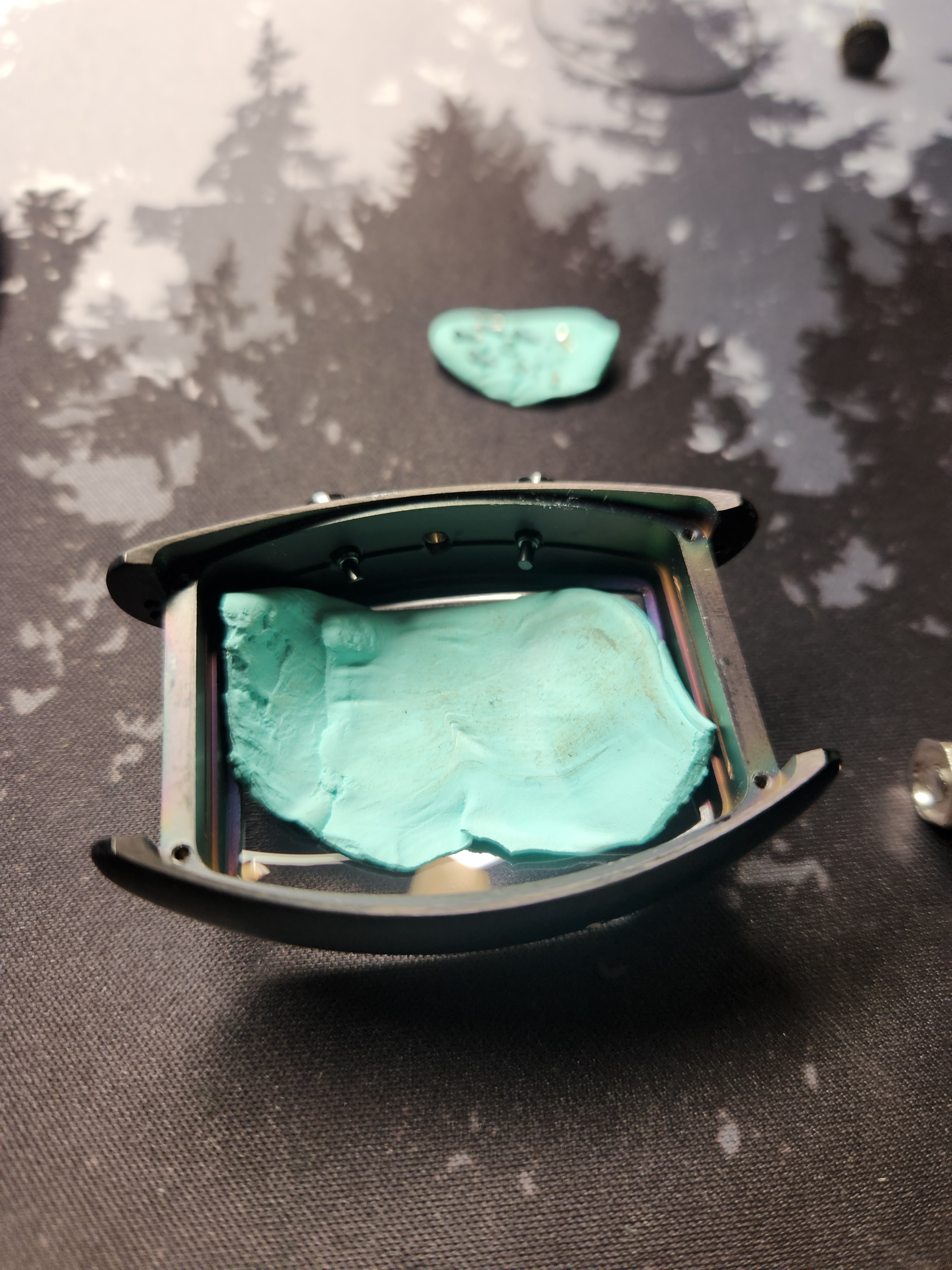

Submerge your parts in the muriatic acid. I like to use the wife's old Tupperware and then put it inside of a 5 gallon bucket. I use plastic tongs to examine the parts and manipulate them once in the solution.

*use chemical resistant gloves and goggles. Don't breathe or taste the acid solution. Hold your breath when pouring. Keep it away from the kiddos, doggos, wifos etc... this stuff will also cause surface rust on anything nearby and can also vent out of the bottle. Keep all of this in mind.

Step 4:

Make and consume double cheeseburger

Step 5:

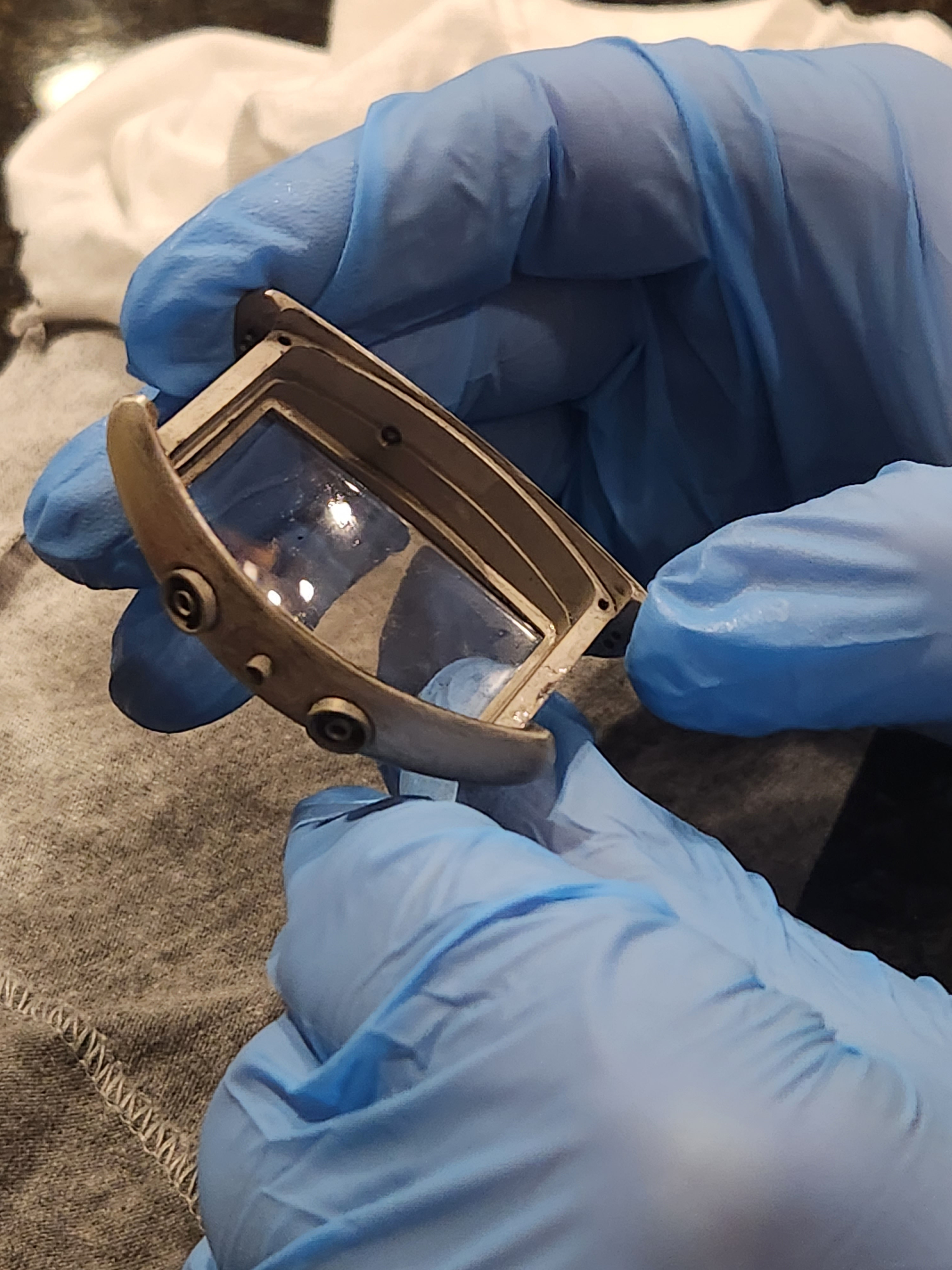

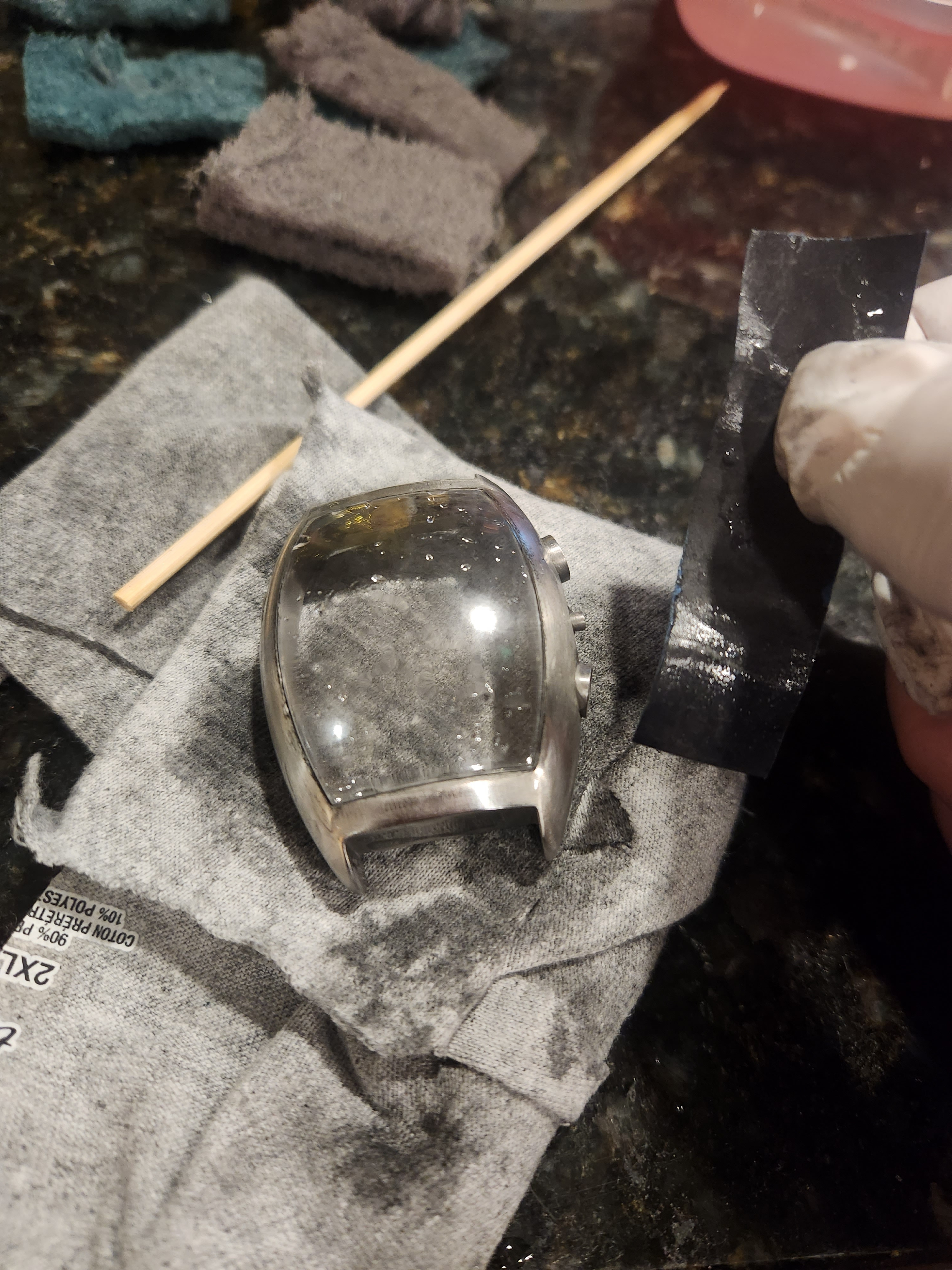

HCI will be more reactive at room temperature, less reactive at colder Temps if you are keeping your bucket in an unheated space, it may take longer to work. Here we are after about 36hrs submerged in roughly 40 degree weather. Good enough.

*mix some water with a good amount of baking soda, Submerge your parts directly into it, let them sit a little while, then rinse them thoroughly and give a good wash with some dawn dish soap.

* neutralize the acid bath with some baking soda and then fill the bucket with water, this will render the acid inert and safe for disposing.

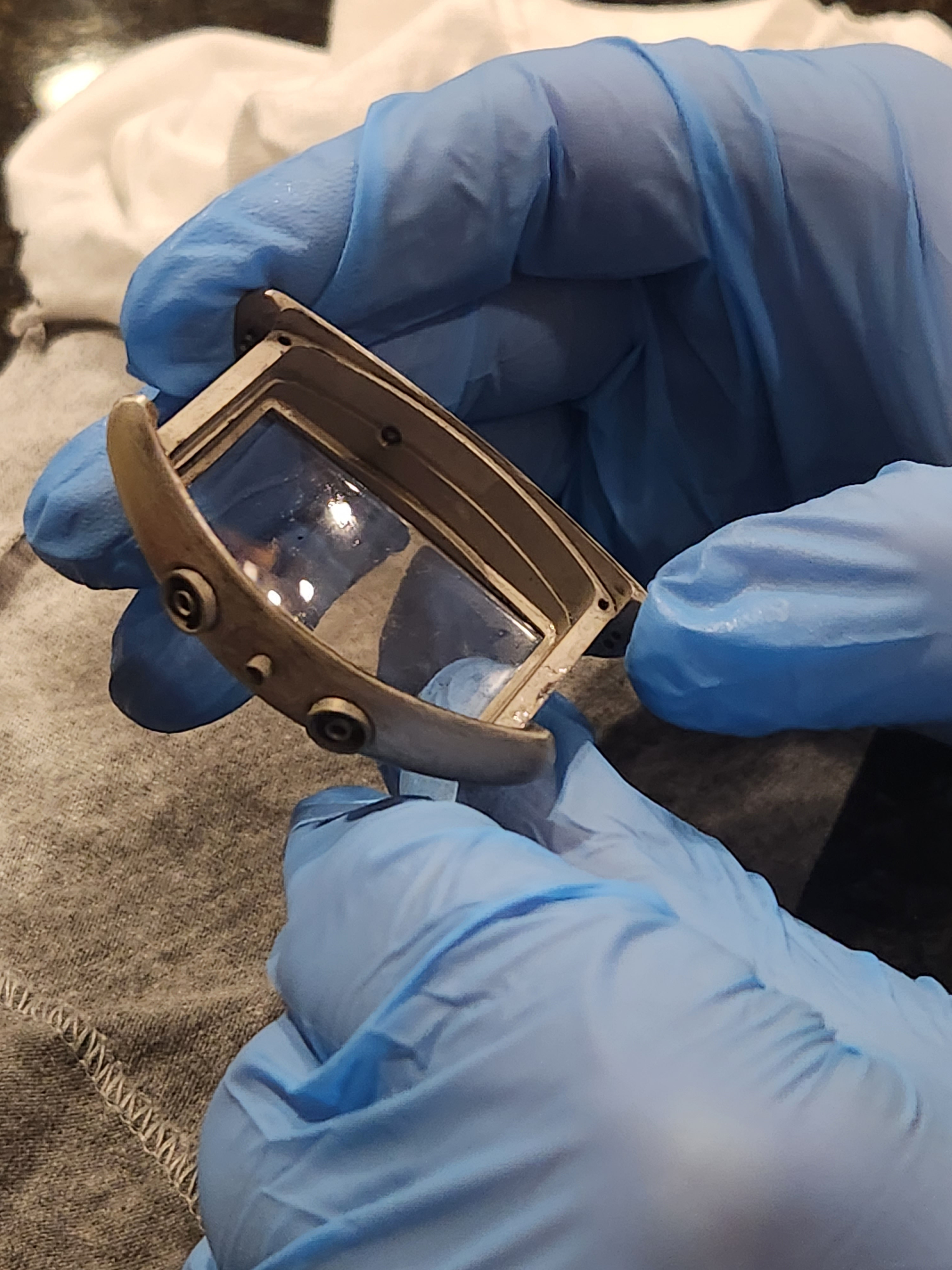

Step 6:

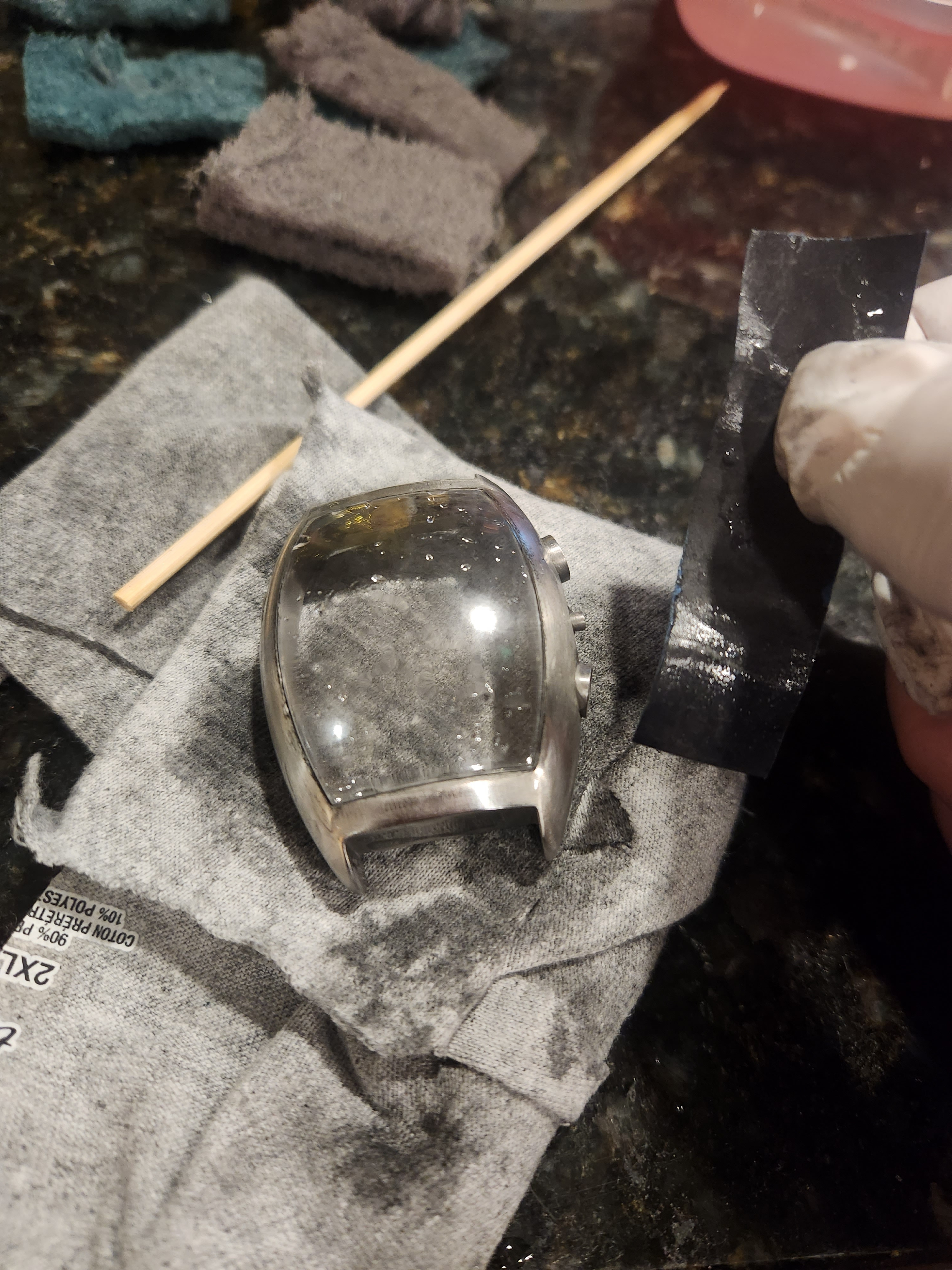

Remove the rest of the weakened coating with some ScotchBrite then Polish. The acid will degrade a thin outer layer of the steel most likely. However, this is still less damage than had I bead blasted the coating off and then polished.

I like to lightly wet sand starting with 600 grit sand paper, you want to work lengthwise, "with the grain" so to speak and keep that same direction throughout. Work your way with little pieces of sandpaper to 800, 1000, 1500, 2000 then 3000. Finish with jewelers Rouge compound on a bench polisher or dremel, then optionally another step up to extra fine blue compound. If the condition of your work peices are not too bad you may be able to skate by with just using polishing compound black, white, then red.

Use an Ultrasonic cleaner throughout to clean out the sanding slurry and particulates.

Step 6:

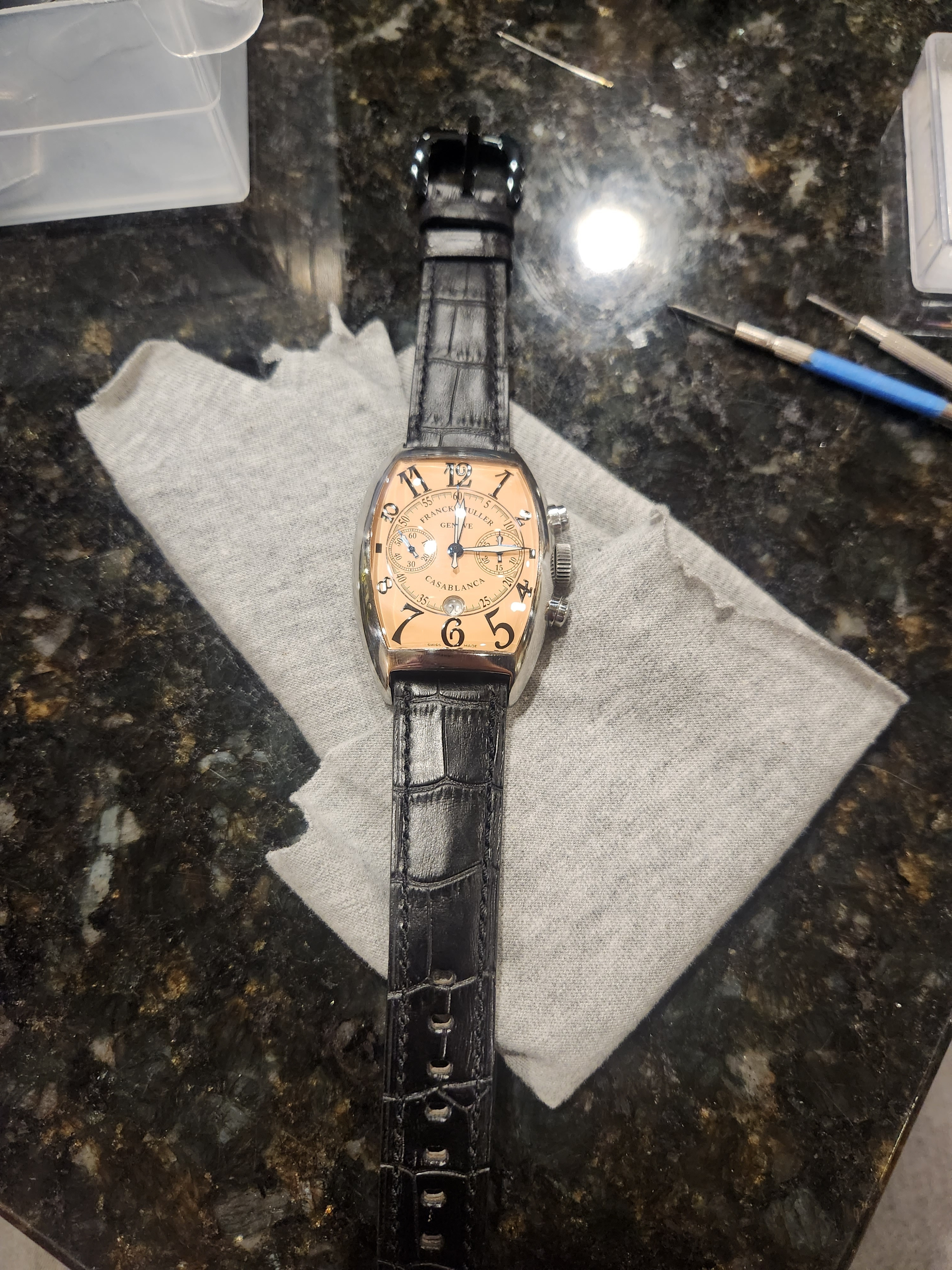

Enjoy your "new" watch, that after all of that hard work, you go to put the stem back in and somehow it's too short now and won't properly seat inside the movement so you gotta order a new stem to cut and have to wait for it to arrive before you can wear it...ahh... I digress.

@toomanywatches Look what i did to your watch dude.

Do you wish that you could magically turn your PVD shitter into a glittering stainless steel box queen? Well look no further! Below I'll show you how to remove the P.utrid V.ile D.ecor that is clinging onto on your watch like a parasite.

Step 1:

Obtain hydrochloric acid.

Muriatic acid is HCI mixed with water usually at around 30-40% strength. It's also filled with a bunch of other impurities, luckily this isn't a lab so flog off.

Step 2:

Decase your movement, dial and take your watch apart. HCI will not harm sapphire crystals but it will degrade seals, you may want to remove your crystal and any gaskets/xtal seals it may have, though HCI should not harm most plastics. Then, clean your parts with some alcohol and a stint in the Ultrasonic cleaner or use your hillbilly version.

Step 3:

Submerge your parts in the muriatic acid. I like to use the wife's old Tupperware and then put it inside of a 5 gallon bucket. I use plastic tongs to examine the parts and manipulate them once in the solution.

*use chemical resistant gloves and goggles. Don't breathe or taste the acid solution. Hold your breath when pouring. Keep it away from the kiddos, doggos, wifos etc... this stuff will also cause surface rust on anything nearby and can also vent out of the bottle. Keep all of this in mind.

Step 4:

Make and consume double cheeseburger

Step 5:

HCI will be more reactive at room temperature, less reactive at colder Temps if you are keeping your bucket in an unheated space, it may take longer to work. Here we are after about 36hrs submerged in roughly 40 degree weather. Good enough.

*mix some water with a good amount of baking soda, Submerge your parts directly into it, let them sit a little while, then rinse them thoroughly and give a good wash with some dawn dish soap.

* neutralize the acid bath with some baking soda and then fill the bucket with water, this will render the acid inert and safe for disposing.

Step 6:

Remove the rest of the weakened coating with some ScotchBrite then Polish. The acid will degrade a thin outer layer of the steel most likely. However, this is still less damage than had I bead blasted the coating off and then polished.

I like to lightly wet sand starting with 600 grit sand paper, you want to work lengthwise, "with the grain" so to speak and keep that same direction throughout. Work your way with little pieces of sandpaper to 800, 1000, 1500, 2000 then 3000. Finish with jewelers Rouge compound on a bench polisher or dremel, then optionally another step up to extra fine blue compound. If the condition of your work peices are not too bad you may be able to skate by with just using polishing compound black, white, then red.

Use an Ultrasonic cleaner throughout to clean out the sanding slurry and particulates.

Step 6:

Enjoy your "new" watch, that after all of that hard work, you go to put the stem back in and somehow it's too short now and won't properly seat inside the movement so you gotta order a new stem to cut and have to wait for it to arrive before you can wear it...ahh... I digress.

@toomanywatches Look what i did to your watch dude.

Last edited: