Like most of you know, Rolex vintage dials for 15xx movements have feet positioned at 30/57min. which doesn’t fit to any ETA.

So how to can these been fitted together without cutting the Rolex dial feet (which make them worth less)? Let‘s see…

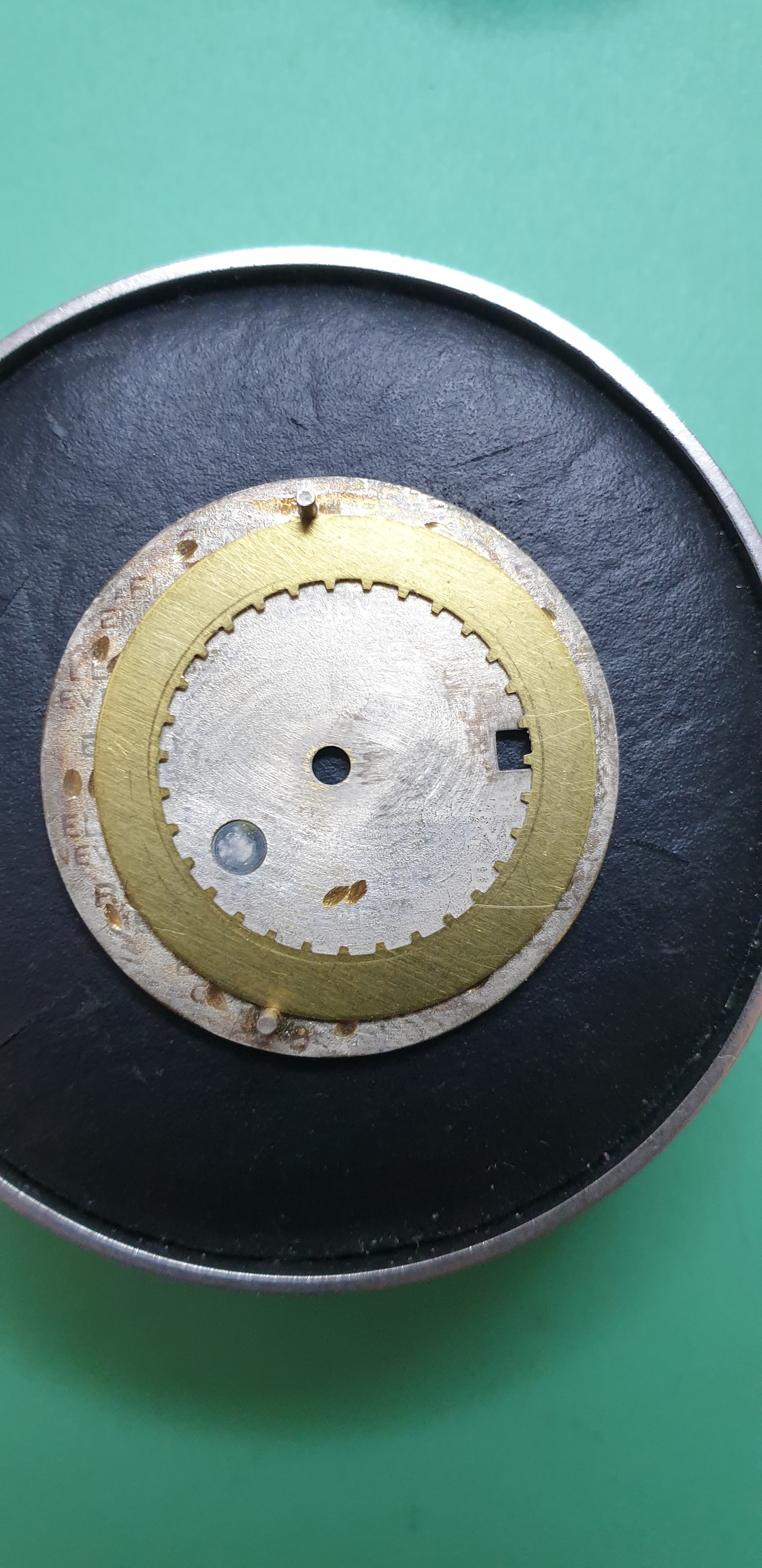

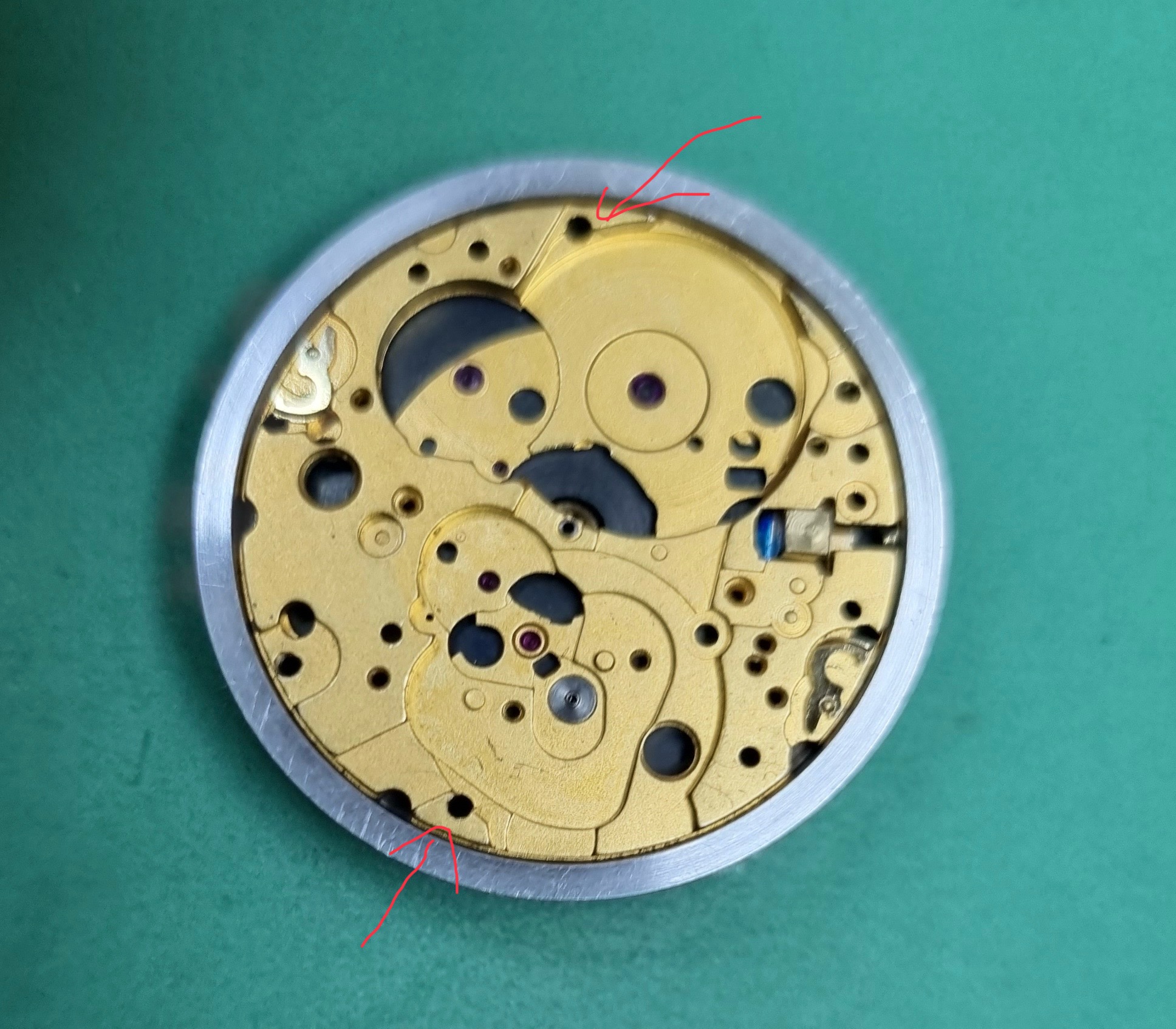

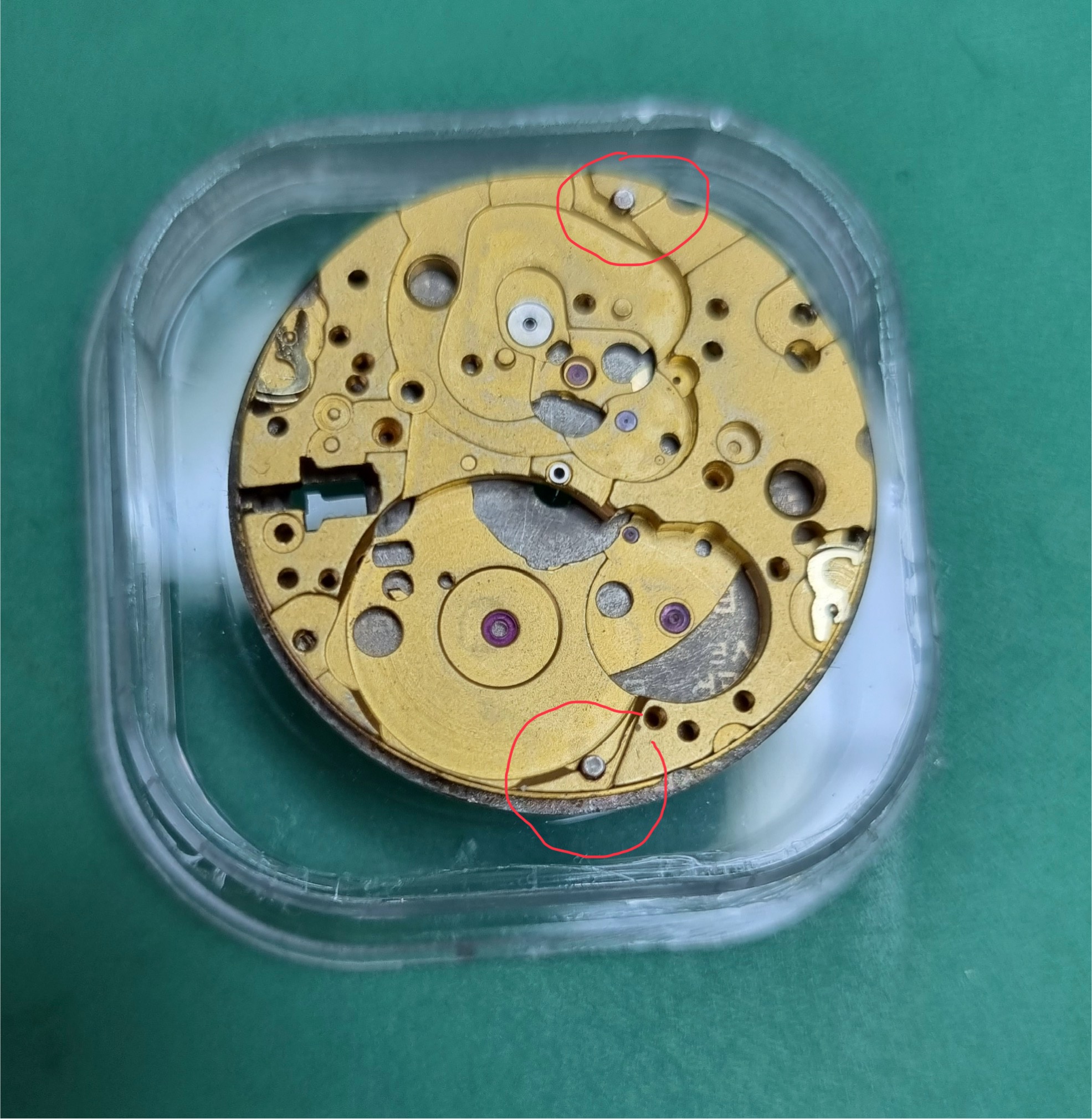

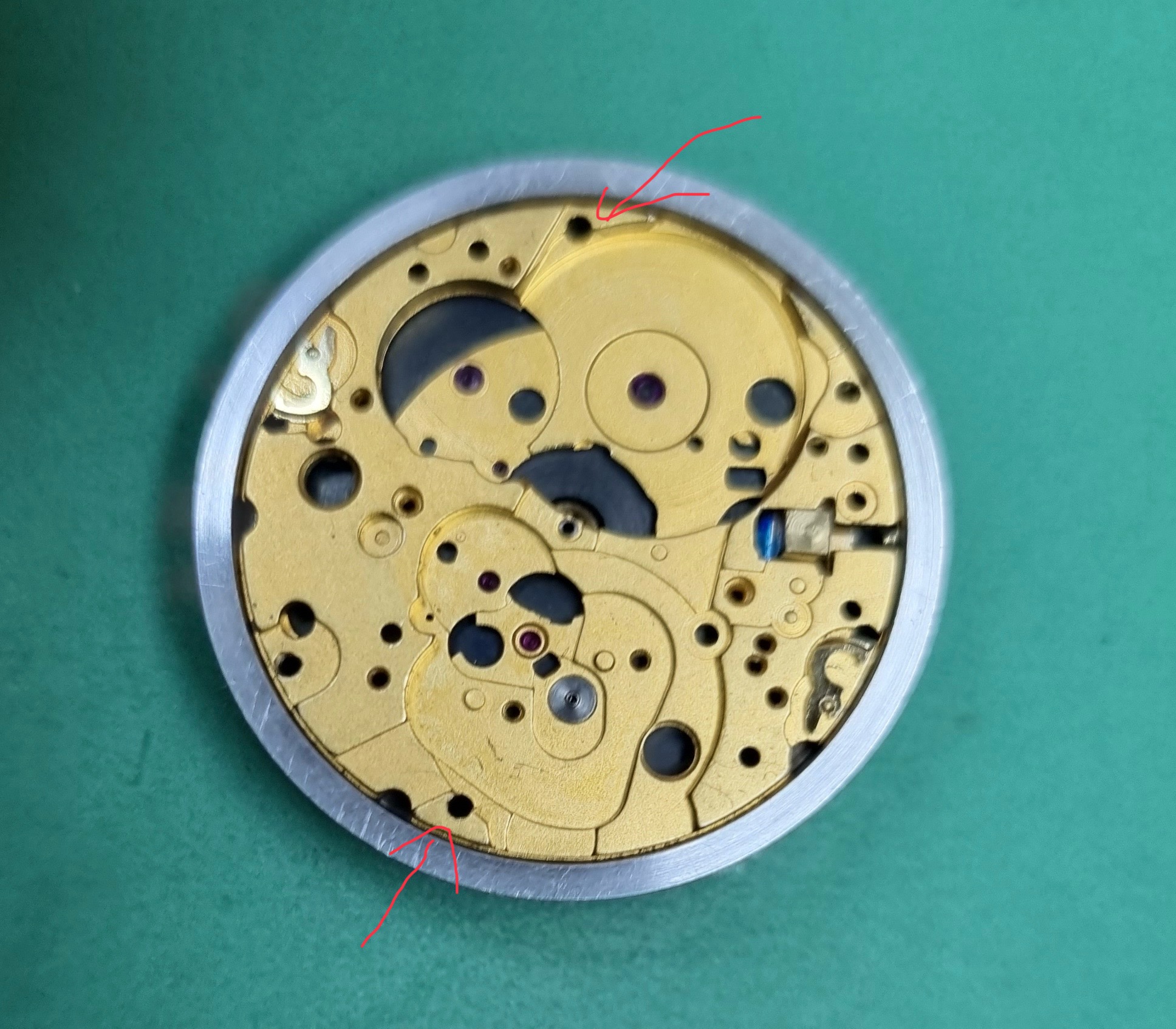

Putting dial & movement side by side shows that it’s not plug and play:

However:

- Yes, that’s doable!

&

- No, it’s not simple like cutting the feet and gluing a dial to a spacer.

Does that mean it’s complicated?

- drilling the mainplate of the ETA movement is involved.

(obviously a complete disassemble of the movement)

Plus there are differences between „Date“ or „No Date“ dials in the combo with the used ETA,

while in result a date version requires more things to be modified.

To use a Rolex dial with date window and with original dial feet on ETA

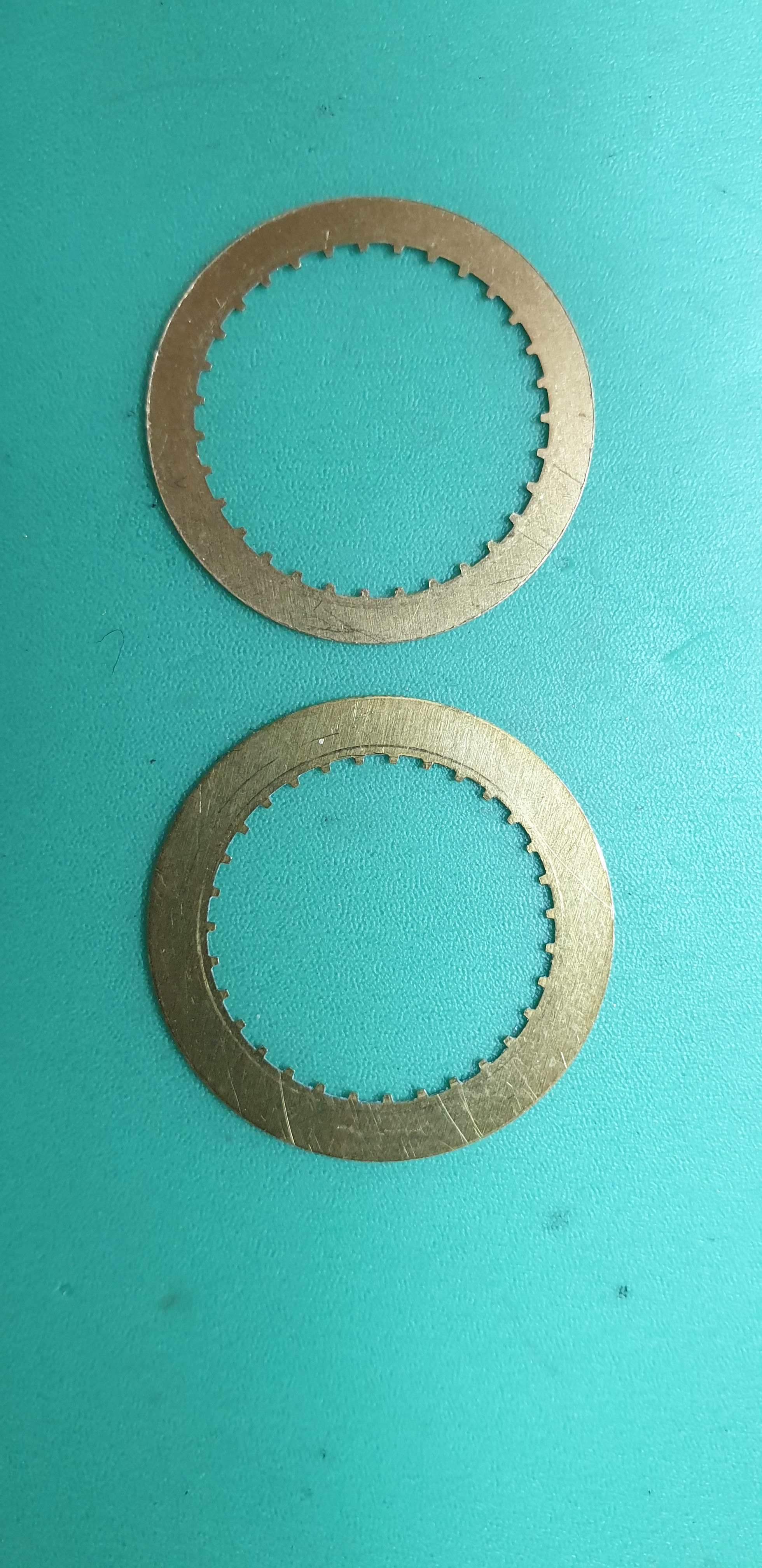

be aware that an origin ETA date-wheel doesn’t fit between the Rolex dial feet.

Therefore the ETA date-wheel need to be milled down in diameter and some additional work has to be done.

(I may showcase this at a later point)

Anyway

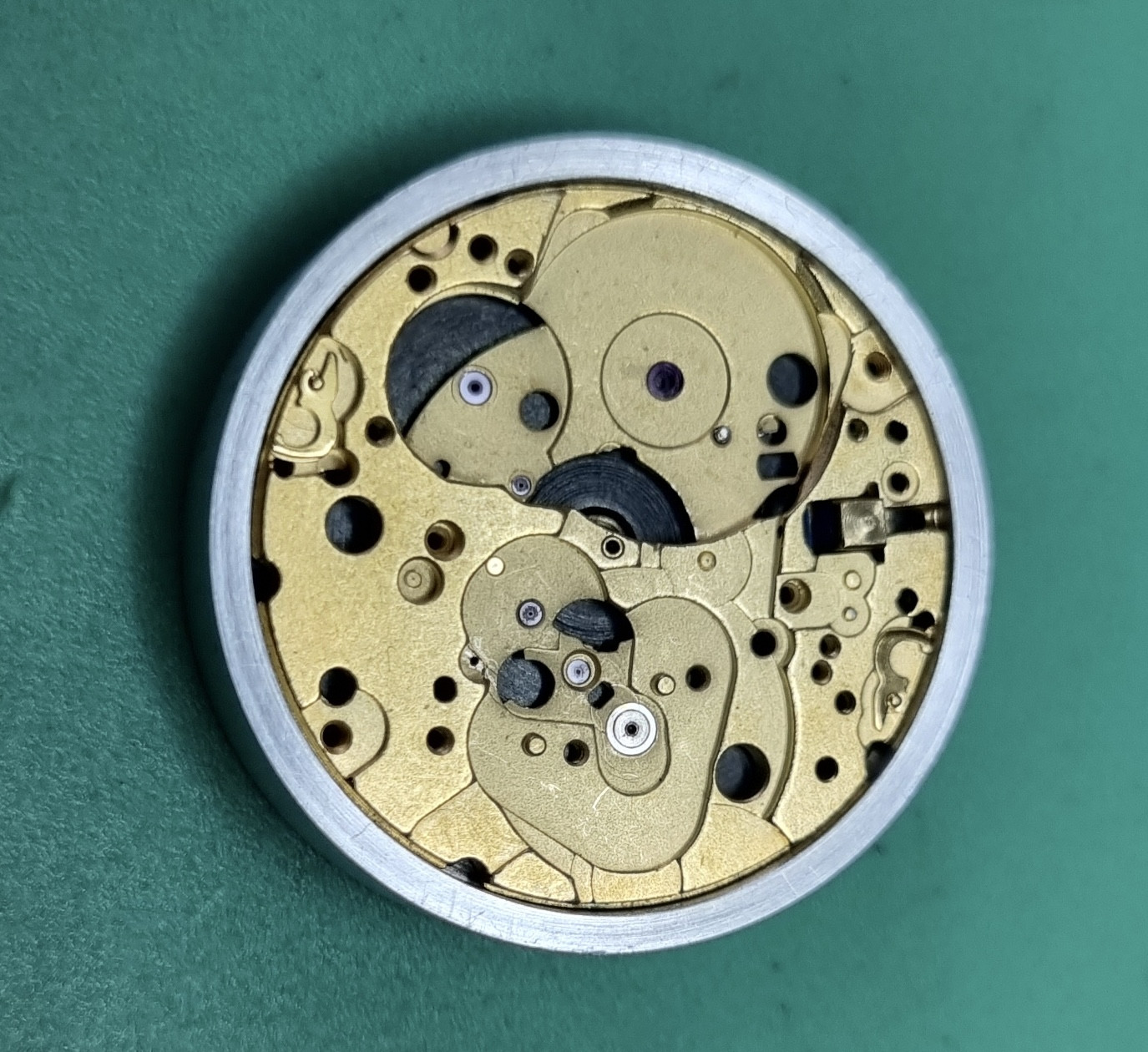

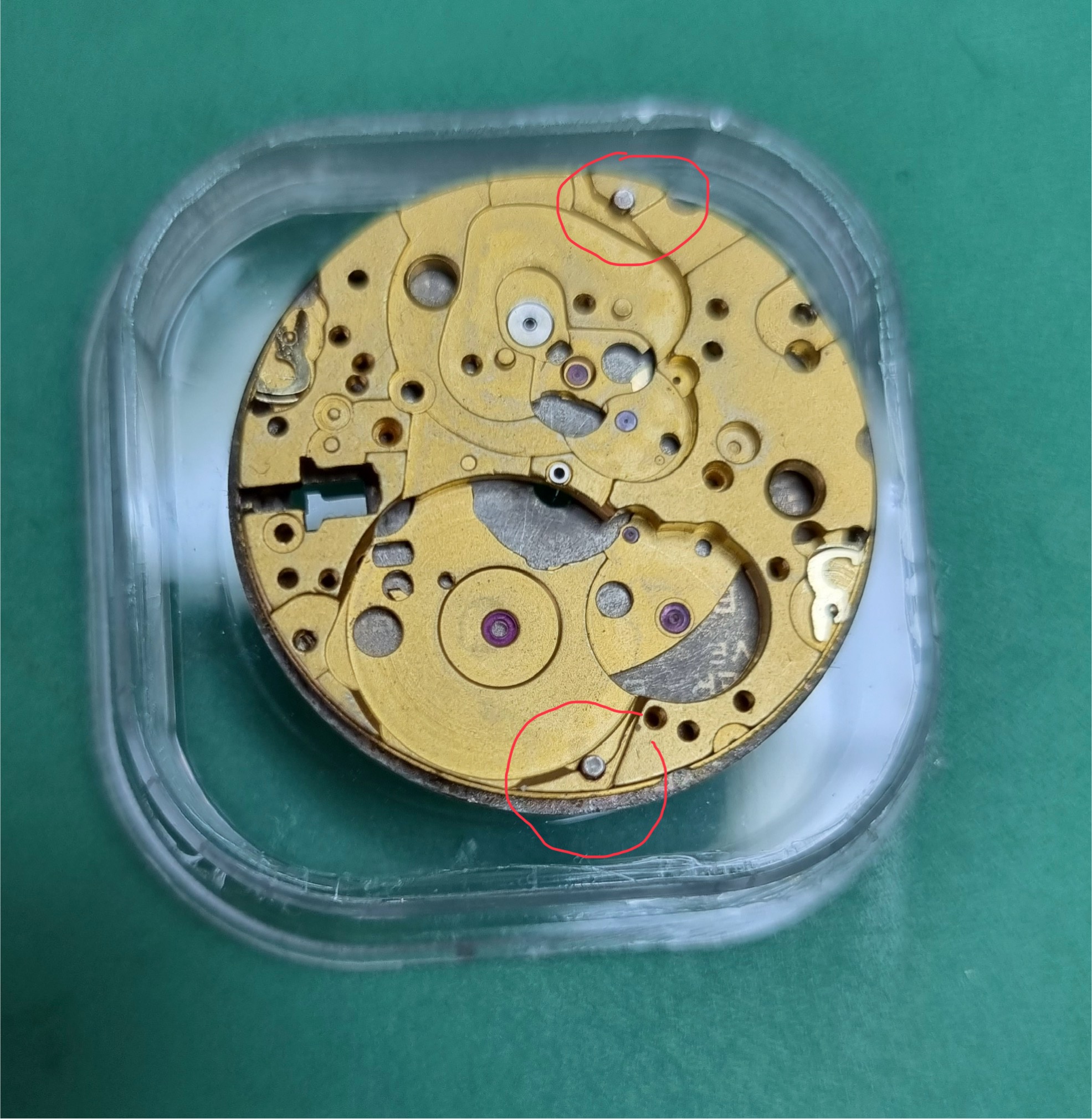

Here you see where an ETA needs new holes for the Rolex dial:

(You should have experience in disassembling and servicing of such ETA movements, incl. the right tool set.)

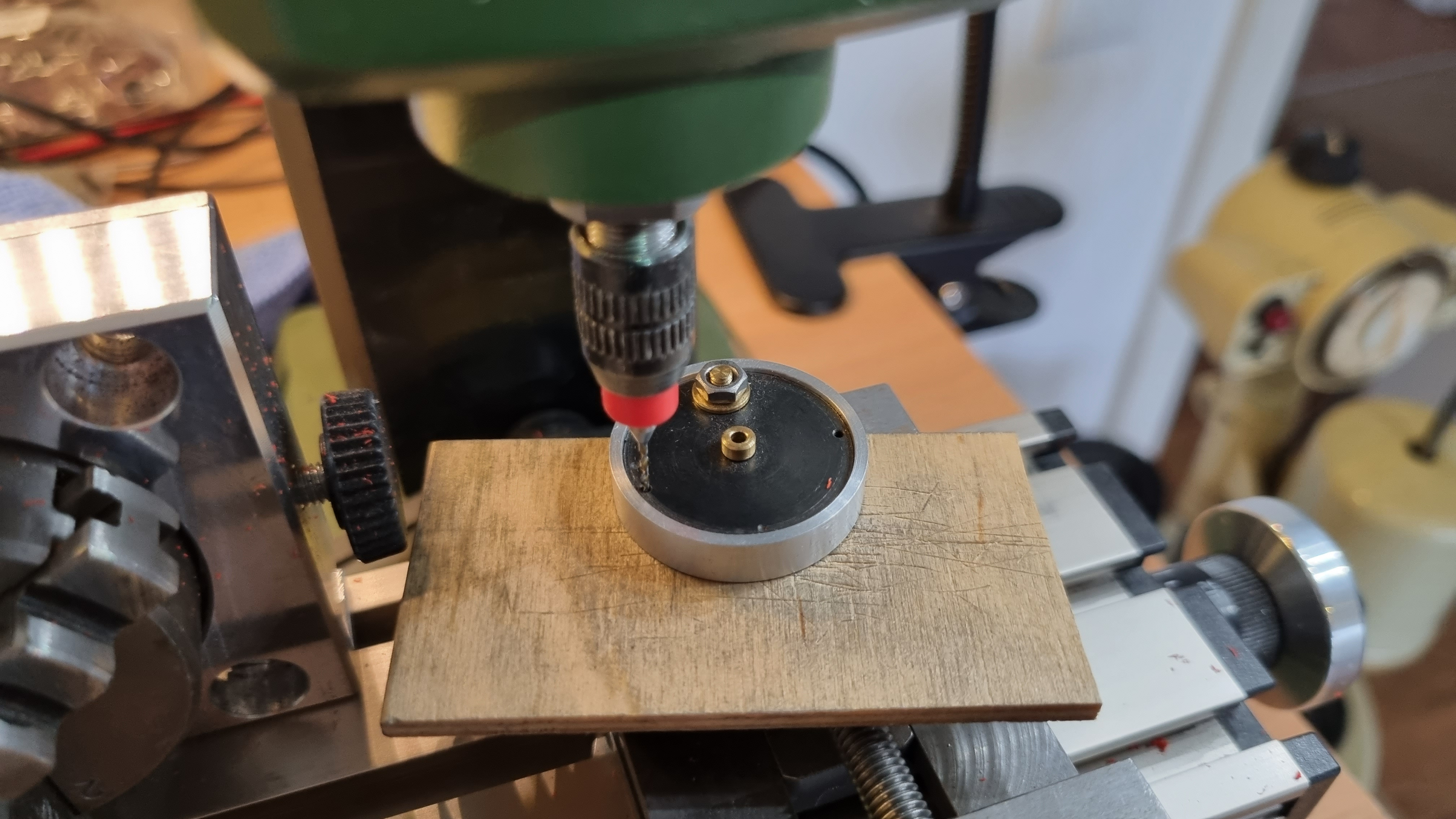

and here is „how I do this“:

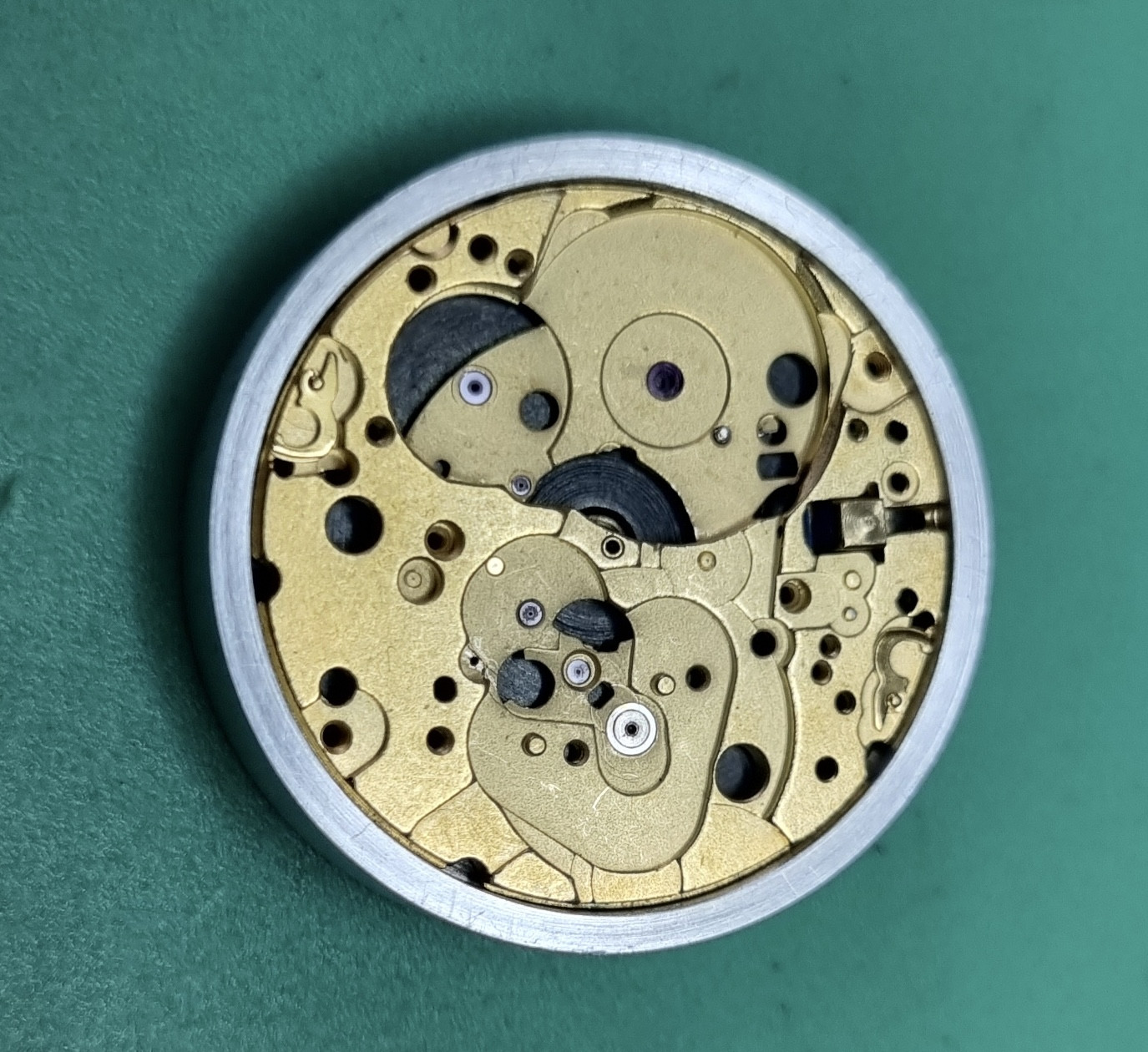

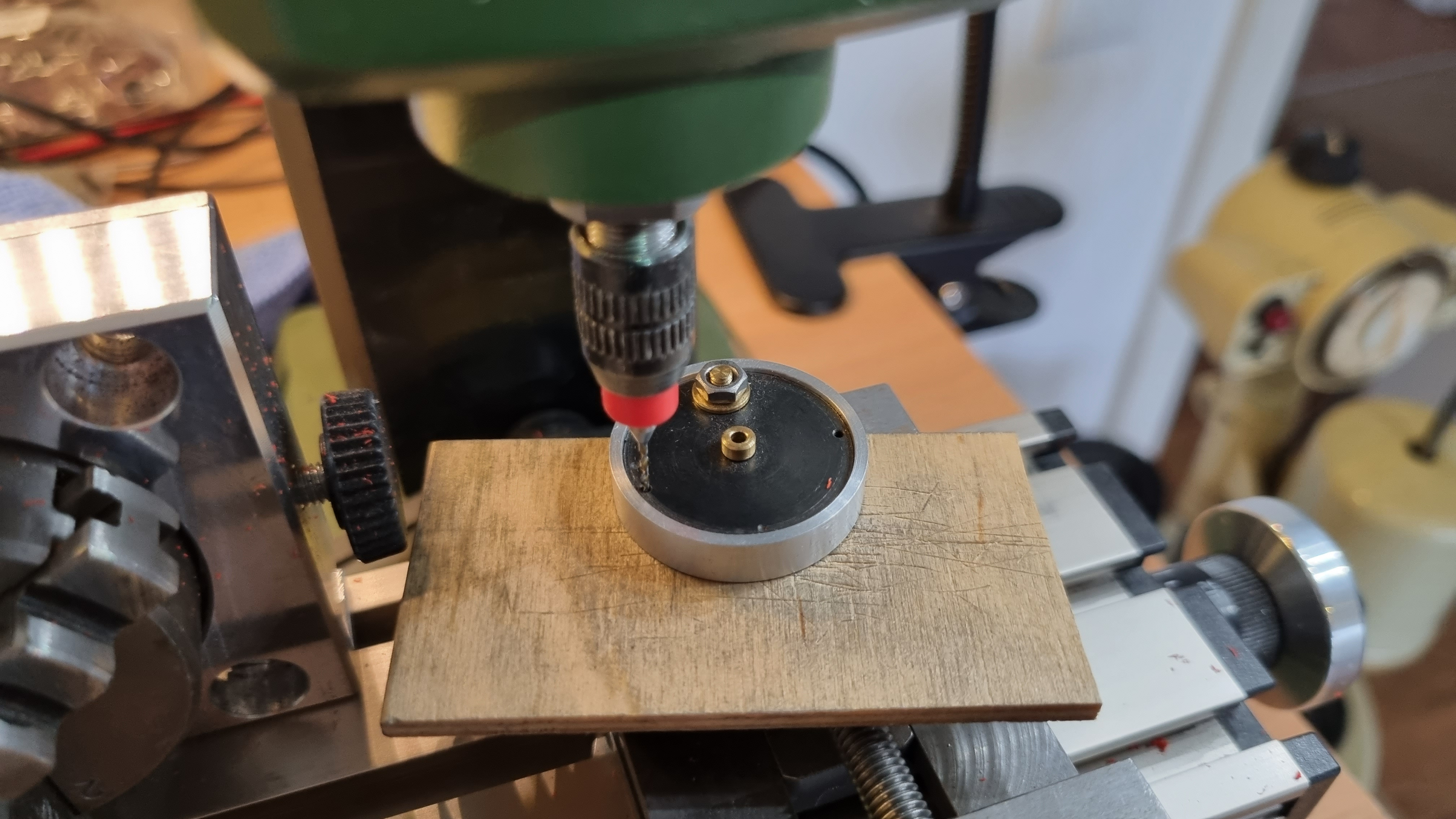

- First I strip down the ETA to the mainplate, before I add it to my drilling holder:

Here you can see how the plate is fixed in the holder:

Actually the drilling happens through the holder tool (from the opposite side):

After the drill the ETA plate has holes for Rolex dials:

Test fitting:

Rolex dial fit on ETA (there is no room for errors)

That’s it for now,

but i will continue this thread soon

So how to can these been fitted together without cutting the Rolex dial feet (which make them worth less)? Let‘s see…

Putting dial & movement side by side shows that it’s not plug and play:

However:

- Yes, that’s doable!

&

- No, it’s not simple like cutting the feet and gluing a dial to a spacer.

Does that mean it’s complicated?

- drilling the mainplate of the ETA movement is involved.

(obviously a complete disassemble of the movement)

Plus there are differences between „Date“ or „No Date“ dials in the combo with the used ETA,

while in result a date version requires more things to be modified.

To use a Rolex dial with date window and with original dial feet on ETA

be aware that an origin ETA date-wheel doesn’t fit between the Rolex dial feet.

Therefore the ETA date-wheel need to be milled down in diameter and some additional work has to be done.

(I may showcase this at a later point)

Anyway

Here you see where an ETA needs new holes for the Rolex dial:

(You should have experience in disassembling and servicing of such ETA movements, incl. the right tool set.)

and here is „how I do this“:

- First I strip down the ETA to the mainplate, before I add it to my drilling holder:

Here you can see how the plate is fixed in the holder:

Actually the drilling happens through the holder tool (from the opposite side):

After the drill the ETA plate has holes for Rolex dials:

Test fitting:

Rolex dial fit on ETA (there is no room for errors)

That’s it for now,

but i will continue this thread soon

Last edited: