- 12/3/18

- 37,543

- 80,258

- 113

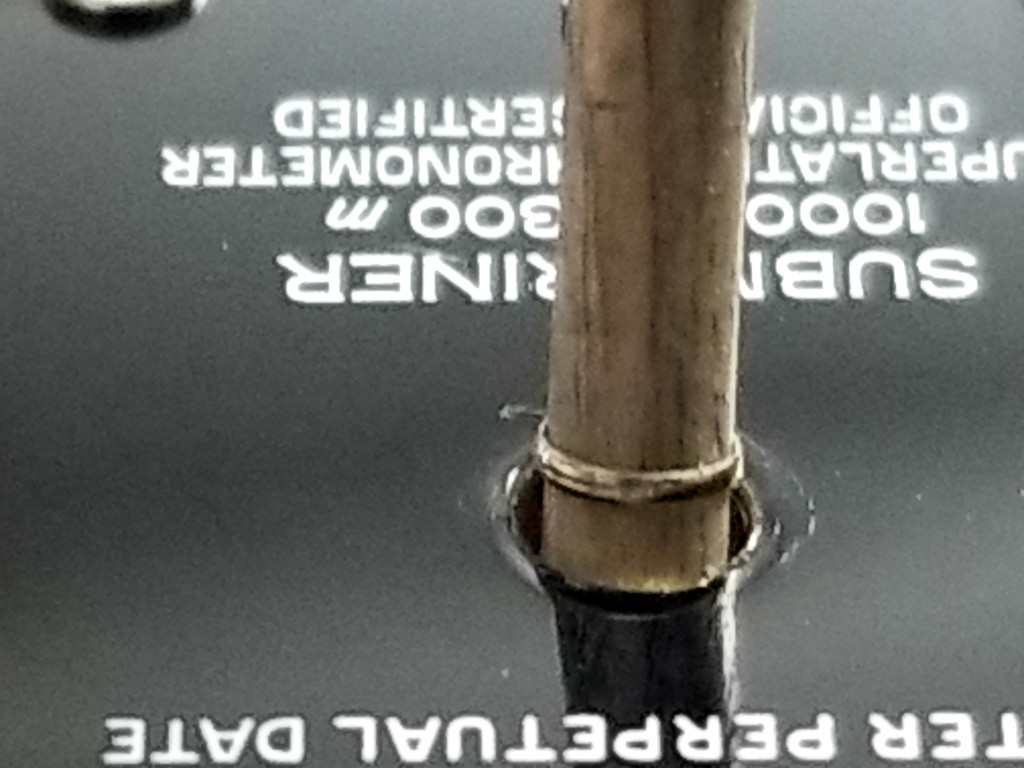

So the crystal sits too low on your GMT for whatever reason and the second hand is hitting its underside. You want to keep the gasket and crystal like they are and try to lower the second hand on its pinion. Can this be done safely?

The first thing I would try is a different second hand. The GMT reps use a “long pinion” second hand which has a longer collar hole surround. It is approximately 1.5mm long to the top of the hole surround. The Submariner reps use a much shorter collar on their second hands. This might work, I think it’s worth trying as it is the simplest potential solution.

Another potential solution is shaving off some of the GMT second hand collar and opening up the hole a bit (broaching) it so the hand will slide down further on the second hand pinion, which is slightly tapered. You can just gently tap a sewing needle into the collar if you don’t have broaching tools.

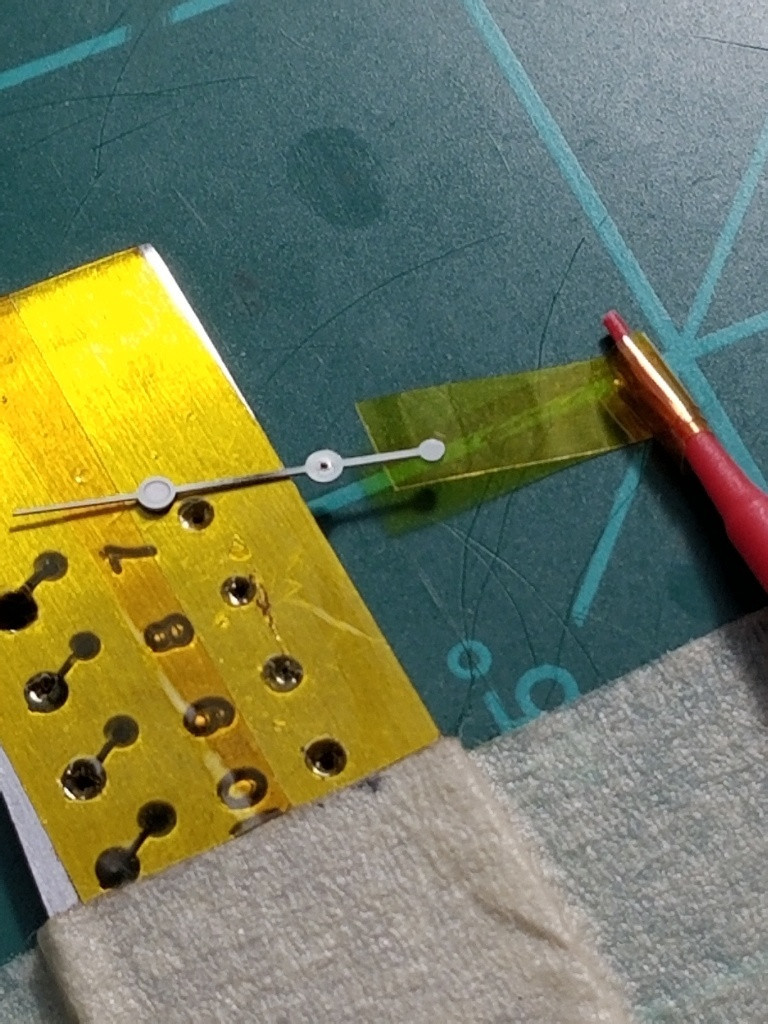

Here’s some pics of shaving the GMT “long pinion” seconds hand collar.

Starting distance from center wheel to underside of second hand hole surround on my sample was 5.50mm

Second hand starting height was ~1.50mm

I put some bracelet protective tape on the finished side of the hand and taped the hand to my mat. This worked well, I could press down gently on the hand on opposite sides of the center and sand it. I marked a toothpick at 1.0mm to know when to quit. You can put a small non-sticky side piece of tape under the lume to prevent any issue there. A 600 grit sanding stick ended up being perfect for this task.

Hand is now ~1.0mm tall

The hand hole may close a little or become shaped slightly irregularly during sanding. Vary the direction of sanding to minimize this. Restore and open up the hole a little with a needle if necessary, a couple light taps with a jeweler’s hammer. Alternately if the hole should become too large, it can be pinched closed with strong tweezers, working your way around the circle. Finally, if necessary a tiny drop of locktite or GS Hypo cement can be dropped into the collar hole for semi-permanent adhering.

Ending distance from center wheel to underside of second hand hole surround on my sample was ~5.0mm.

The other way to do this is to shorten the center wheel pinion. You CAN just snip it off a bit with some nail clippers, press your hand on and go. I consider this to be a little crude and prefer to do it more carefully and professionally, but hey it’s your watch. If done the crude way at least turn your movement upside down so debris doesn’t fall into your dial or your movement. Or you can wrap some saran wrap around the center posts. Or use a dry lens wipe with a tiny hole cut out in the middle.

The center wheel is a delicate component so it should be treated carefully.

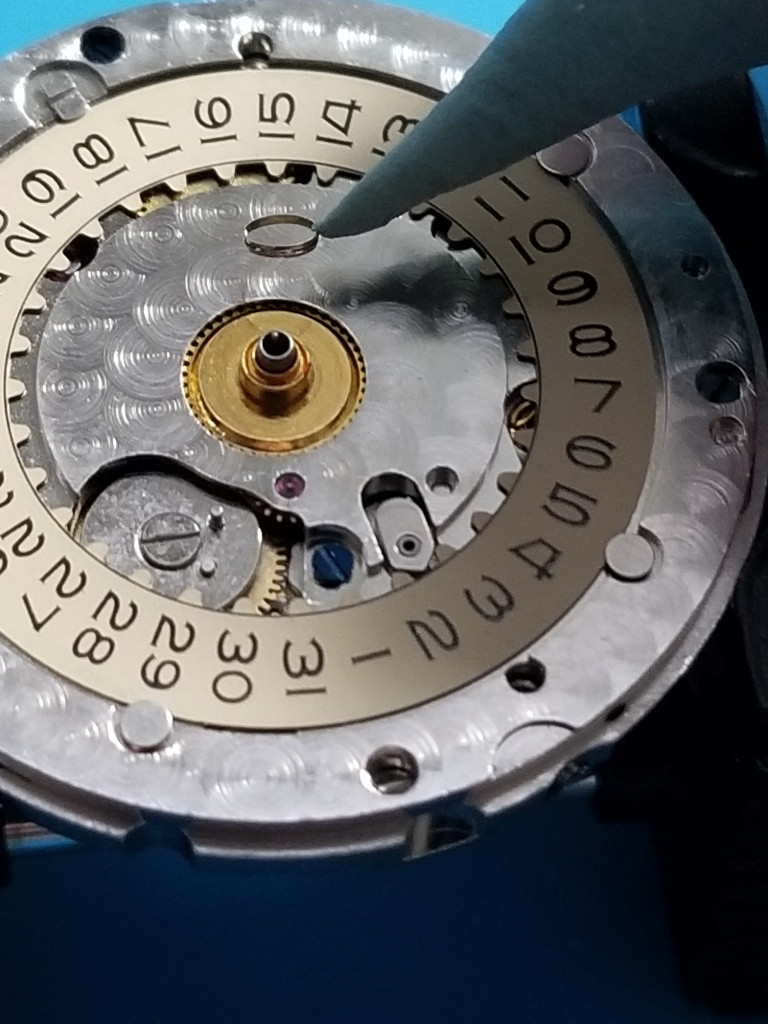

A safe way to trim it and finish it nicely is to use a staking plate. Find the smallest hole that the pinion leaves fit in and press some rodico up underneath it to protect the bottom tip of the pinion.

Snip off about .5mm or more if needed based on how much you need to lower the hand.

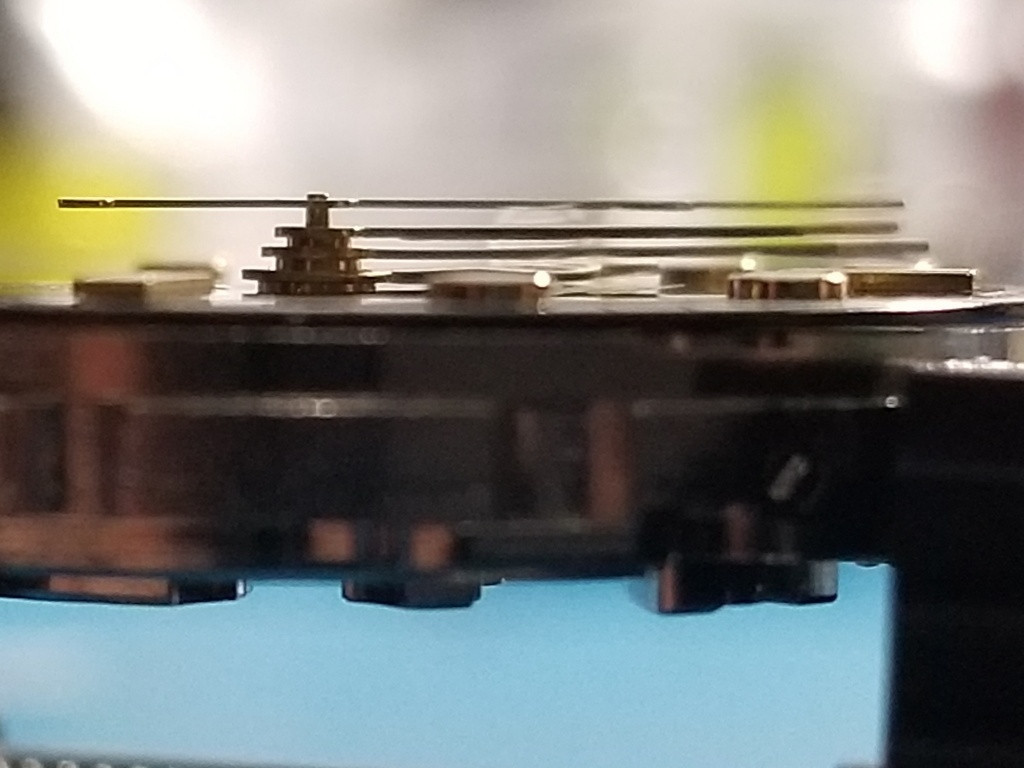

Now the pinion top can be sanded and rounded nicely. The 600 grit sanding stick worked fine here as well. Clean it up and reinstall to the watch.

Always be very careful pressing a second hand. The bottom tip of the pinion sits in a jewel under the mainplate and too much pressing force on the hand can snap that pinion bottom or crack the jewel (ask me how I know, lol).

That’s it, happy modding!

The first thing I would try is a different second hand. The GMT reps use a “long pinion” second hand which has a longer collar hole surround. It is approximately 1.5mm long to the top of the hole surround. The Submariner reps use a much shorter collar on their second hands. This might work, I think it’s worth trying as it is the simplest potential solution.

Another potential solution is shaving off some of the GMT second hand collar and opening up the hole a bit (broaching) it so the hand will slide down further on the second hand pinion, which is slightly tapered. You can just gently tap a sewing needle into the collar if you don’t have broaching tools.

Here’s some pics of shaving the GMT “long pinion” seconds hand collar.

Starting distance from center wheel to underside of second hand hole surround on my sample was 5.50mm

Second hand starting height was ~1.50mm

I put some bracelet protective tape on the finished side of the hand and taped the hand to my mat. This worked well, I could press down gently on the hand on opposite sides of the center and sand it. I marked a toothpick at 1.0mm to know when to quit. You can put a small non-sticky side piece of tape under the lume to prevent any issue there. A 600 grit sanding stick ended up being perfect for this task.

Hand is now ~1.0mm tall

The hand hole may close a little or become shaped slightly irregularly during sanding. Vary the direction of sanding to minimize this. Restore and open up the hole a little with a needle if necessary, a couple light taps with a jeweler’s hammer. Alternately if the hole should become too large, it can be pinched closed with strong tweezers, working your way around the circle. Finally, if necessary a tiny drop of locktite or GS Hypo cement can be dropped into the collar hole for semi-permanent adhering.

Ending distance from center wheel to underside of second hand hole surround on my sample was ~5.0mm.

The other way to do this is to shorten the center wheel pinion. You CAN just snip it off a bit with some nail clippers, press your hand on and go. I consider this to be a little crude and prefer to do it more carefully and professionally, but hey it’s your watch. If done the crude way at least turn your movement upside down so debris doesn’t fall into your dial or your movement. Or you can wrap some saran wrap around the center posts. Or use a dry lens wipe with a tiny hole cut out in the middle.

The center wheel is a delicate component so it should be treated carefully.

A safe way to trim it and finish it nicely is to use a staking plate. Find the smallest hole that the pinion leaves fit in and press some rodico up underneath it to protect the bottom tip of the pinion.

Snip off about .5mm or more if needed based on how much you need to lower the hand.

Now the pinion top can be sanded and rounded nicely. The 600 grit sanding stick worked fine here as well. Clean it up and reinstall to the watch.

Always be very careful pressing a second hand. The bottom tip of the pinion sits in a jewel under the mainplate and too much pressing force on the hand can snap that pinion bottom or crack the jewel (ask me how I know, lol).

That’s it, happy modding!

Last edited: