- 30/11/23

- 47

- 29

- 18

Hi all, this is neither novel nor particularly interesting but I wanted to share my first full movement teardown, cleaning, and reassembly. But most of all I wanted to give a huge thank you to the fantastic resource that is RWI and the many, many people who have so kindly shared their expertise and experience here. I've only been in the hobby for a couple months and have learned so much in that time thanks to the years of knowledge here.

I needed a A2836 for a project. The stem height of the 2824 was not appropriate. This is a no-date build, so I removed the date assembly and switched out the setting lever jumper. In the process of replacing the jumper, I managed to get a speck of something blocking the barrel, so at that point decided to do a full disassembly and cleaning.

I am a cheapskate, so I got all my tools (screwdrivers, tweezers, "rodico", hand setting tools etc) from AliX. Most are good quality, but I'd say avoid the pin vises: The collets are never tight enough and are very poorly machined.

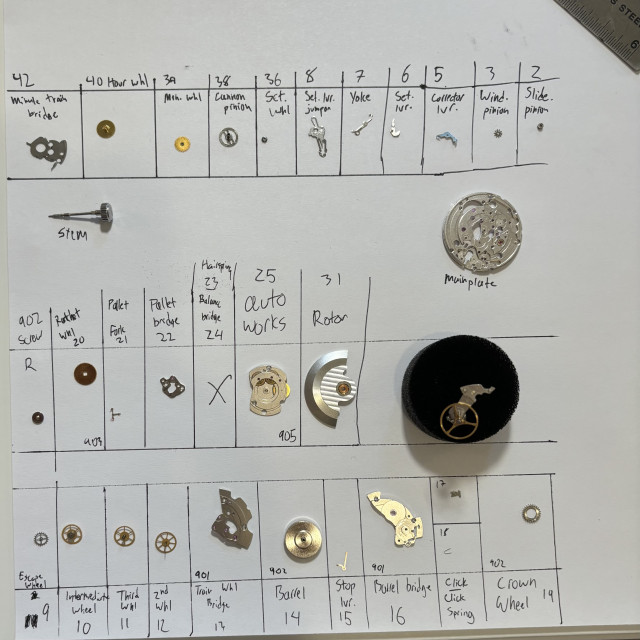

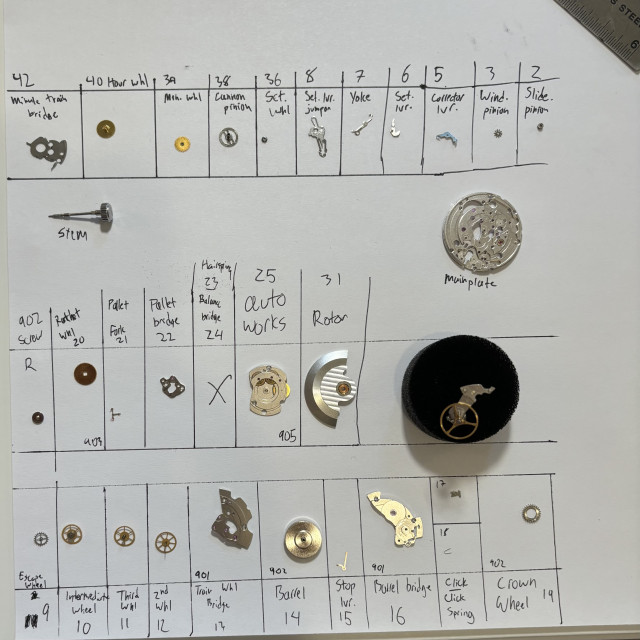

With that, I began disassembly and cleaning.

I cleaned the parts with one dip. I did not take pictures of cleaning and the reassembly process, but I followed the ETA-published technical communication. I will say it is a mystery to me why they put the reassembly of the keyless works first, since as far as I can tell it is practically impossible to get the sliding and winding pinions in place without the barrel bridge in place.

Despite my stinginess, I ended up getting Moebius oils since I didn't see an alternative. If you follow the technical publication you can spend well over $100 on oils, so I just got 9010, HP-1300, and Molykote DX. I used 9010 where fine oil was specified, HP-1300 where thick oil was specified, and Molykote DX where grease was specified (in place of the recommended 9504) . After comparing the tech sheets, I used HP-1300 in place of the recommended 9415 for the pallet stones, but there is no perfect replacement.

A few hiccups: I have very shaky hands so I lost more than a few screws. Thankfully I had a wrecked 2813 lying around and cannibalized screws from there. I also had a ton of problems with the keyless. I would keep putting it together, it would work fine, and then when I removed the stem and reinserted it it would stop working. It was a totally obvious problem in hindsight: I was using a pin instead of a screwdriver to push the stem release button (which is repeatedly warned against!), which dislodged the keyless... On the bright side, I am now an expert on resetting the keyless works of a 2824/36 .

.

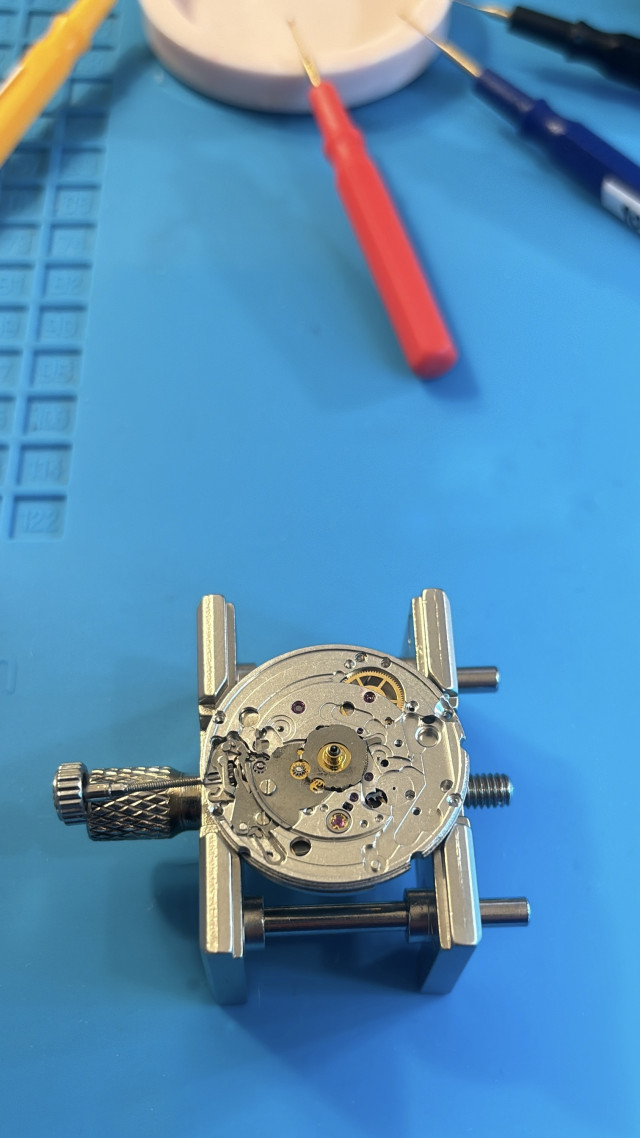

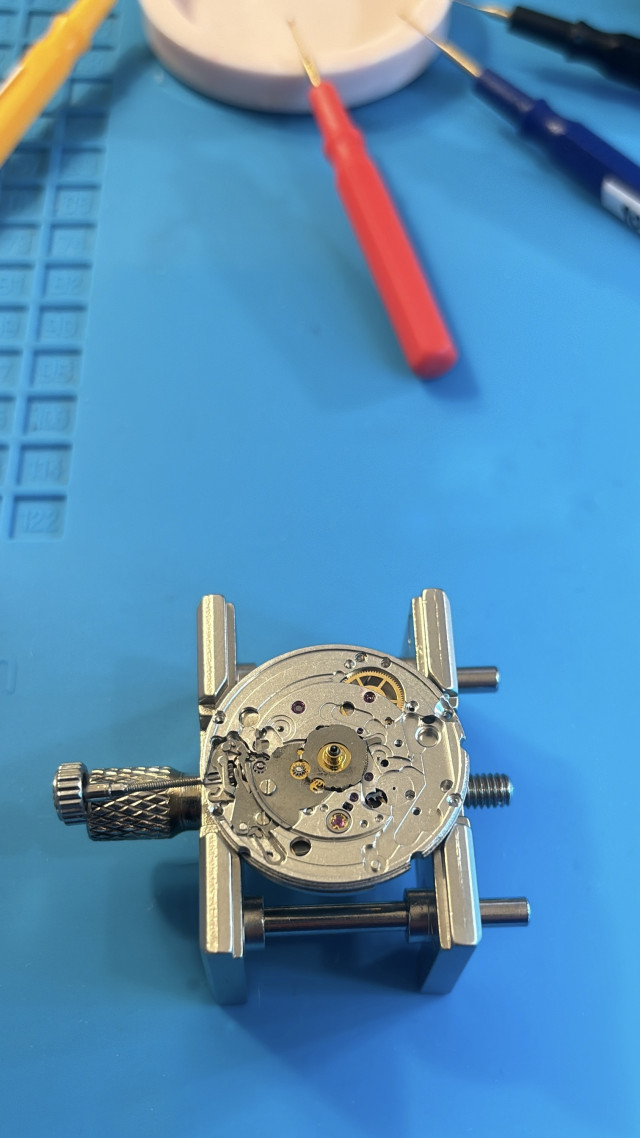

Reassembled:

My timegrapher is still shipping but it seems to be running well!

All in all, I am amazed at the elegance of the design of the movement, and the quality of engineering from the clone factories. Really cool.

Also, a very interesting animation that goes through the parts of a watch movement: https://ciechanow.ski/mechanical-watch/. He doesn't say, but that is definitely a 2824 he's using as the base. I had always wondered how the hairspring kept moving even as it moderates the output of the mainspring. It is absolutely ingenious to have the movement of the escapement feed energy back into the hairspring. Very cool.

I needed a A2836 for a project. The stem height of the 2824 was not appropriate. This is a no-date build, so I removed the date assembly and switched out the setting lever jumper. In the process of replacing the jumper, I managed to get a speck of something blocking the barrel, so at that point decided to do a full disassembly and cleaning.

I am a cheapskate, so I got all my tools (screwdrivers, tweezers, "rodico", hand setting tools etc) from AliX. Most are good quality, but I'd say avoid the pin vises: The collets are never tight enough and are very poorly machined.

With that, I began disassembly and cleaning.

I cleaned the parts with one dip. I did not take pictures of cleaning and the reassembly process, but I followed the ETA-published technical communication. I will say it is a mystery to me why they put the reassembly of the keyless works first, since as far as I can tell it is practically impossible to get the sliding and winding pinions in place without the barrel bridge in place.

Despite my stinginess, I ended up getting Moebius oils since I didn't see an alternative. If you follow the technical publication you can spend well over $100 on oils, so I just got 9010, HP-1300, and Molykote DX. I used 9010 where fine oil was specified, HP-1300 where thick oil was specified, and Molykote DX where grease was specified (in place of the recommended 9504) . After comparing the tech sheets, I used HP-1300 in place of the recommended 9415 for the pallet stones, but there is no perfect replacement.

A few hiccups: I have very shaky hands so I lost more than a few screws. Thankfully I had a wrecked 2813 lying around and cannibalized screws from there. I also had a ton of problems with the keyless. I would keep putting it together, it would work fine, and then when I removed the stem and reinserted it it would stop working. It was a totally obvious problem in hindsight: I was using a pin instead of a screwdriver to push the stem release button (which is repeatedly warned against!), which dislodged the keyless... On the bright side, I am now an expert on resetting the keyless works of a 2824/36

Reassembled:

My timegrapher is still shipping but it seems to be running well!

All in all, I am amazed at the elegance of the design of the movement, and the quality of engineering from the clone factories. Really cool.

Also, a very interesting animation that goes through the parts of a watch movement: https://ciechanow.ski/mechanical-watch/. He doesn't say, but that is definitely a 2824 he's using as the base. I had always wondered how the hairspring kept moving even as it moderates the output of the mainspring. It is absolutely ingenious to have the movement of the escapement feed energy back into the hairspring. Very cool.