Hello everyone! I'm gauging interest in a potential CNC 3700 micro run, and I would love some community input before moving anything forward. To preface, this post has been approved by the mods.

Some time ago, I secured a vintage 3700 case. I've procured most of the necessary parts to restore the watch with vintage parts, but finding a NOS bezel to match the case would be rarer than hens teen on a unicorn horn. I spent some time designing a CNC bezel for myself, and through that process I connected with a handful of people who asked if I could do a CNC case as well.

Being that I already had a rough model of the case to design the bezel around, it wasn't a stretch to update the case for production. As I am a businessperson outside the RWI, and in a country that does not allow counterfeiting, I want to be clear that this project does not aim to create counterfeit parts. Anything manufactured is done so with the goal it will serve as an OEM replacement part when parts can not be procured from the OEM. As such, no parts will bear a brand name, serial number, or enough components in a single order to assemble a complete unit resembling a copy of an existing product. If someone were to use my parts in conjunction with other aftermarket and vintage parts to create such a thing, it is simply beyond my control.

TL;DR: I'm considering a run of 10 3700 case/bezel combos. I'm asking questions about the finishing, modding, and assembly. Input is requested! I personally have no use for a case, but I would be remiss to have the opportunity to offer it and decline.

Now, on to the details, and the questions. My models are done based on true vintage parts. There are some parts I can make, and some I cannot. Moreover, as this is a vintage item, there are some production methods that would be changed to allow for more realistic modern manufacturing.

-The bezel:

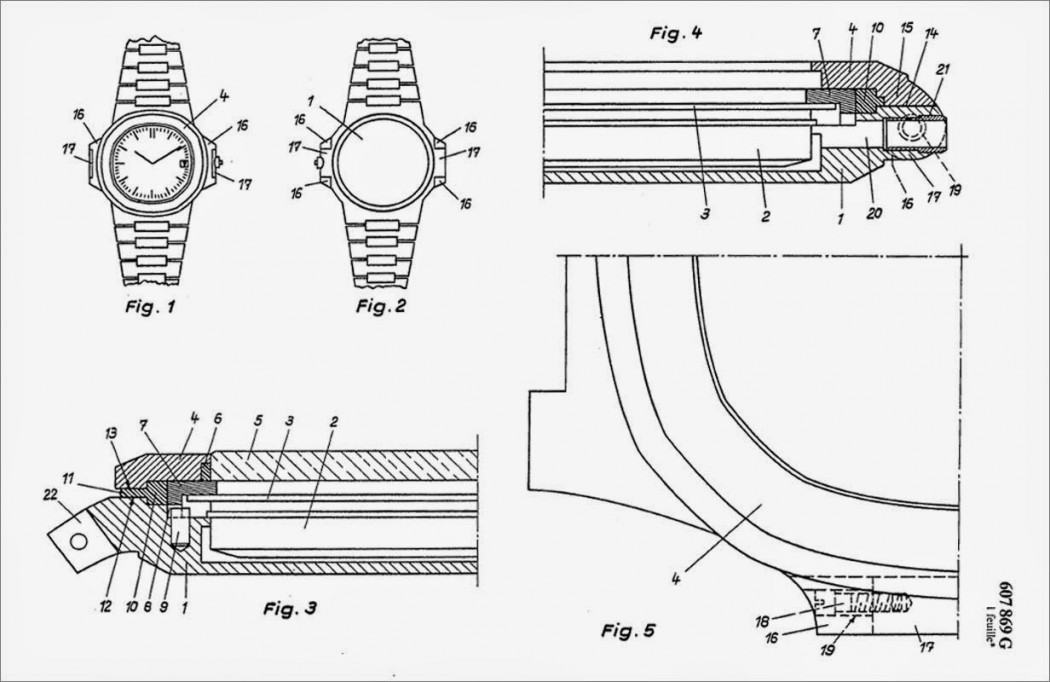

The design of the bezel is quite complex. I know someone who owns a true vintage 3700 and is willing to lend me his bezel to corroborate measurements. This mostly is in relation to the system for the crystal, as it is difficult to ascertain the exact dimensions and assembly from photos. I had my gen crystal scanned with optical metrology equipment for an extremely precise DWG file, so the dimensions of the bezel itself are extremely precise, but the tolerances for the gasket and slight inner lip should be confirmed before anything is manufactured. Anyways, as it stands, the bezel will be essentially a 1:1 replacement part for the vintage bezel.

-The rehaut:

fitting over the dial, inside the gasket, and between the case and bezel is a metal rehaut of the same material as the bezel (in the event of a two tone 3700, this part was gold). This is a simple part, and easy enough to acquire online from vintage suppliers. However, at $500+, it makes the most sense for me to include this with the other parts, as it is a very simple design.

-The case: This is where things get a bit complicated. Please read this part thoroughly.

The case is a monoblock, but it is actually made of, to my understanding, two or three components. The crown tube is soldered in. This is not something my usual cnc shop can do, nor does it make sense to do nowadays. I'm leaning towards a threaded crown tube. This entails a few things of note. First, the tube must be modded. It has a cutout on the portion that protrudes into the case. As it is very expensive to have threads align perfectly, it makes sense to have the builder simply file out a section of the crown tube dependent on its fit. Once assembled, the tube can be held in with loctite 648, or a similar product. 648 is what would be used on smooth bore press fit crowns (I know Omega did this in the past). I'm not a pro at waterproofing, so I would recommend researching what loctite is best for this application. There may be some who favor a soldered crown tube. I would proceed according to the majority, bearing in mind that you would need to solder your own crown tube. Either way, it will be gen-spec and work with a gen crown, stem, and movement.

The case also appears to have an inner ring. Whether this is a separate part, press fit, adhered, or otherwise assembled, I cannot tell. Manufacturing has changed greatly in the last 50 years and I don't know how this would have been made back then. As far as I can tell, this inner ring is a separate part that is press fit, or snap fit as it could be sort of spring-clamp shaped. The reasoning for this is likely to make the bead blasting easier. The ring creates a slight overhand compared to the case bore. I have checked with my movement, test fit parts, and I cannot find a logical reason for this overhang. My best guess is that it is there to allow the rotor more space to rotate in the event of shocks or something like that. For my cnc case, I would integrate this ring, and include the overhang. With modern cutters it's not a difficult task to bore it out that way. However, if consensus is that I should have a separate part made for true accuracy, I could price that out.

Lastly, the case has a small notch between 6 and 9. I am leaning towards excluding this, for three reasons. Please read carefully. To my understanding, all JLC 920 base movements have a threaded hole at this position. ONLY THE PATEK 3700 VARIANTS HAVE A PART THAT GOES IN THIS HOLE. The 3700 specific movements have a nub that sticks out and fits this notch. Any 920 base caliber will fit a 3700 case, though. My guess is this is to aid with movement alignment. However, it is extremely unlikely that anyone assembling these parts actually will use a 3700 specific cal 28-255C, so I am opting to leave it out. Firstly, because it won't be needed for 99% of builders. The nub can also be removed from the movement easily in the event someone does have the 3700 specific variant. Secondly, it will increase manufacturing cost significantly, as it would require a specific tool and specific operation. Thirdly, I'm having difficulty measuring exactly where it is positioned.; it looks to be 135 degrees counterclockwise from 12 o clock, but to confirm this I would need to make a nub to fit my movement to test the fit of the nub in the slot. This is especially difficult as I don't have a measurement for the part, and I would need to estimate from photos. Unless someone here has one they can measure for me! So to summarize, I will exclude this notch unless the majority requests it.

The Crystal Gasket:

I cannot find anywhere that sells a crystal gasket. It's a specially shaped gasket. Most likely I will find a place to make the gaskets, or make them myself. Hytrel can be 3D printed, so if the tolerances check out I can go this route.

The other parts: case screws, case gasket, bracelet, crystal, crown, stem, movement, and so on.

Most likely I will provide case screws. I may provide the case gasket if requested. My only concern is that the more I include, the more of a counterfeit item it is. As just the bezel and case with no branding, it has zero legal issue and can fly through customs. I will not be providing a bracelet, crown, stem, movement, crystal, hands, etc. The parts will be gen-spec so vintage parts will fit.

The finishing:

My cnc shop does not offer the premium finishing needed for these parts. They can do the bead blasting, but no brushing or polishing. Since I am sending my case set to a professional finisher, this was not a concern for just a bezel for me. There are three routes I am exploring, and this is where I would like some input!

Option 1: No finishing. It will be up to you to have a modder do your finishing. This means, however, a much lower cost.

Option 2: I am reaching out to a few modders to see if they're interested in taking on a bulk order for this run. My only concern is that I can't be responsible for what happens once it gets in their hands, so this would be an option at buyers risk with a well-vetted and trusted modder.

Option 3: Have me send it to your preferred modder.

Option 4: find a cnc shop who will do the finishing. I'm not inclined to this, as I have a good relationship with my current shop and trust their work.

Estimated Price and Lead Time:

$1000-1500: Estimated price for case, bezel, crystal gasket, and case screws. Threaded crown tube, integrated case ring, no case notch.

I have not received an estimate for a soldered tube, separate ring, case notch, or premium finishing. I will get quotes depending on majority preference.

CLOSING STATEMENT:

To be clear, the parts are not ready for manufacturing, and no money will be collected. This post serves to gather information and interest, and will be updated as things progress. Once we are ready to begin production, meaning we have determined options, pricing, etc, this is the process: I will open the run up. A 50% deposit is required to secure your spot. This will be open for two weeks. If the actual sign-ups vastly differs from the interest list, and there are not enough to proceed, the run will be terminated and you will be refunded. The estimated completion time is under 6 months, so you will be able to pay through secure methods such as paypal G&S or credit card. Again, this only works if this is an aftermarket part, not a replica or counterfeit.

No matter the interest, I have no intention of doing more than 10 sets. I may stretch it if there are 11-12 people who want one. I have done many micro-runs of parts for my business in the past without issue, but it is not something I really enjoy doing on a larger scale, so if there is enough interest I would do a raffle or spin a wheel for the slots or something like that.

Please bear in mind, if you do decide to go the franken route, this is not a cheap project. There are few replica options for this. A 3kf 5711 bracelet fits. No rep dial fits. No rep movement fits. No rep hand fits. No rep crown fits. I have no idea about crystals as I went gen. All of these vintage parts are expensive, and finishing this project will end up costing you 5-figures without exception.

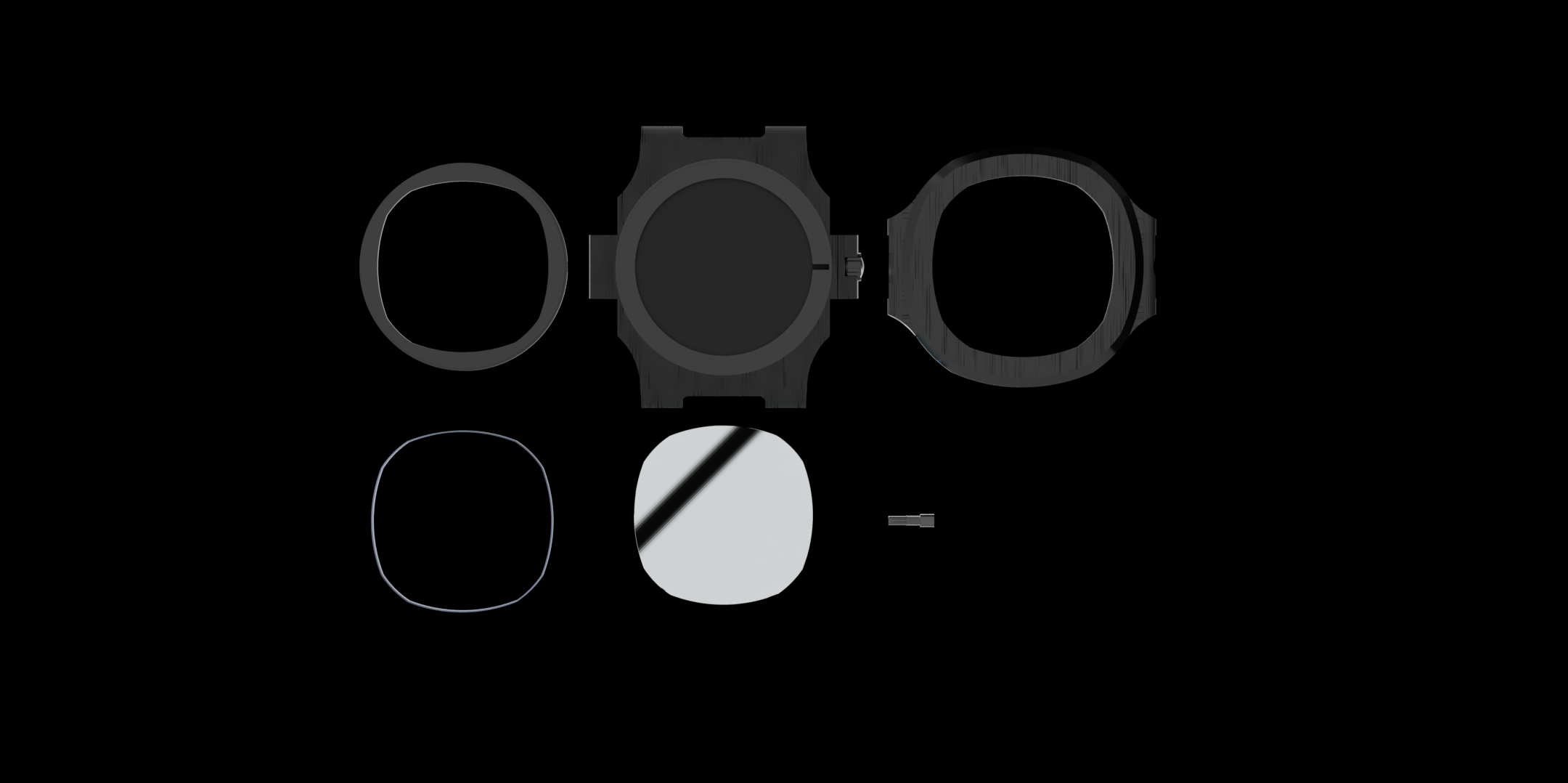

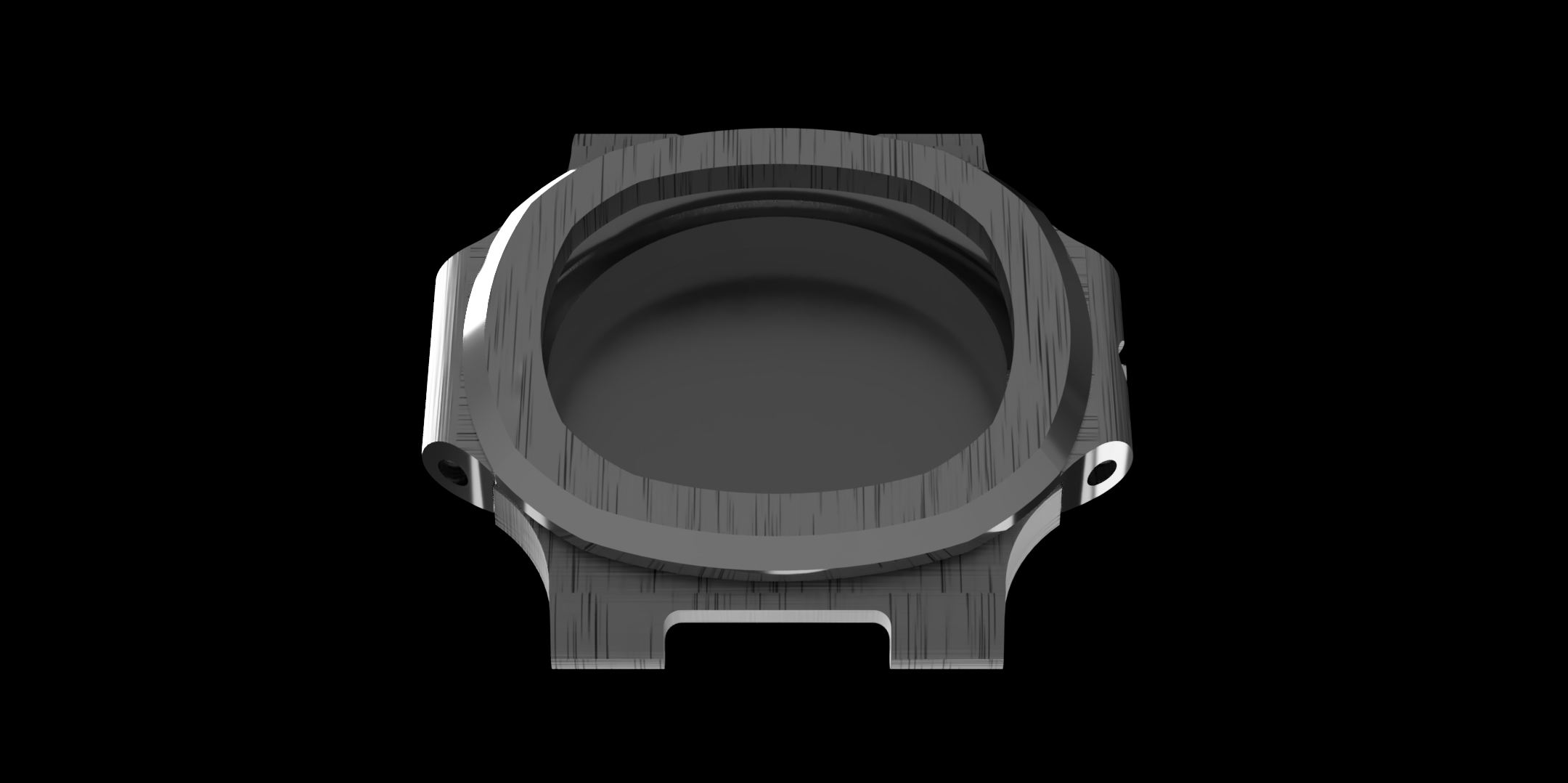

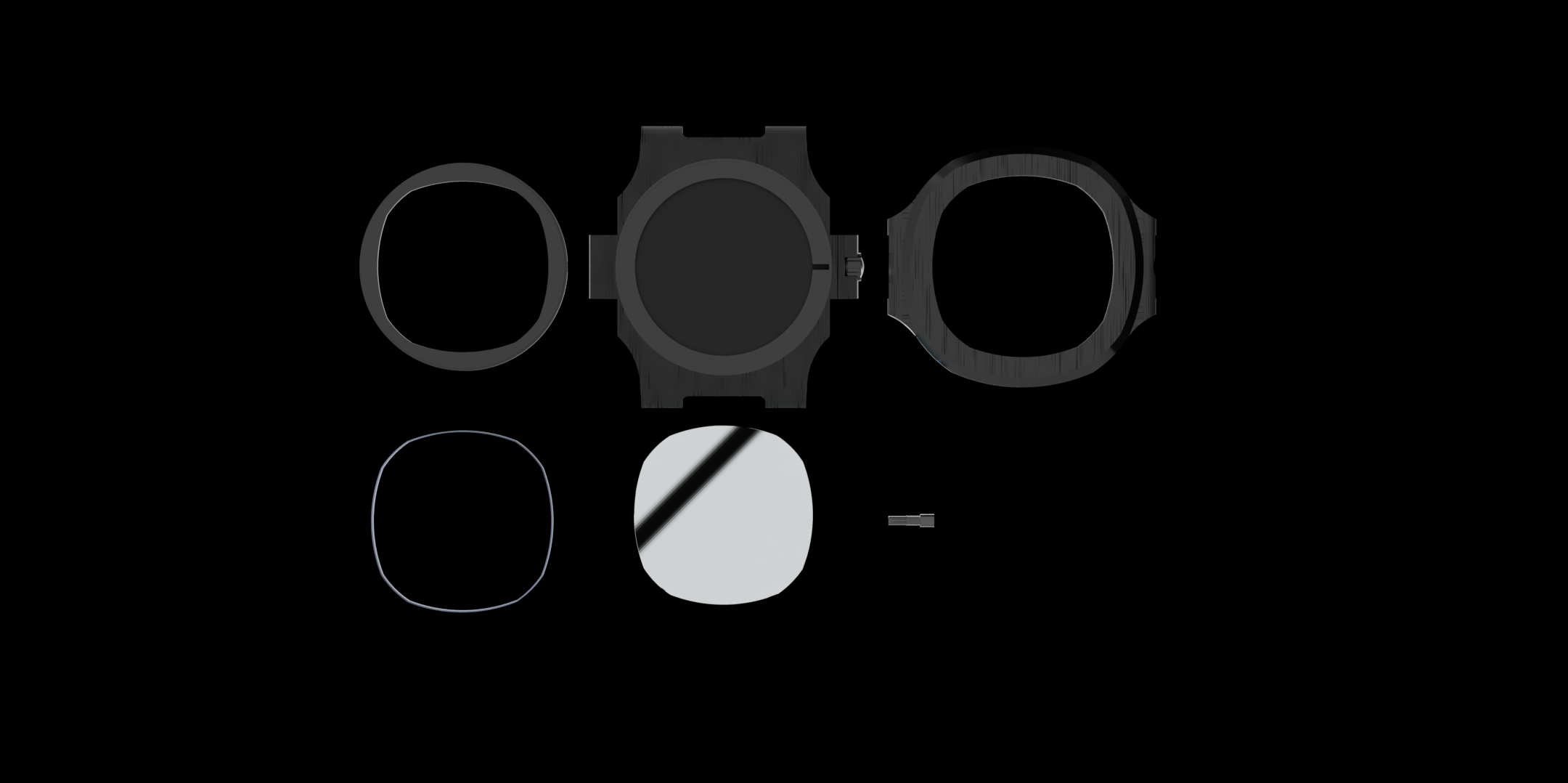

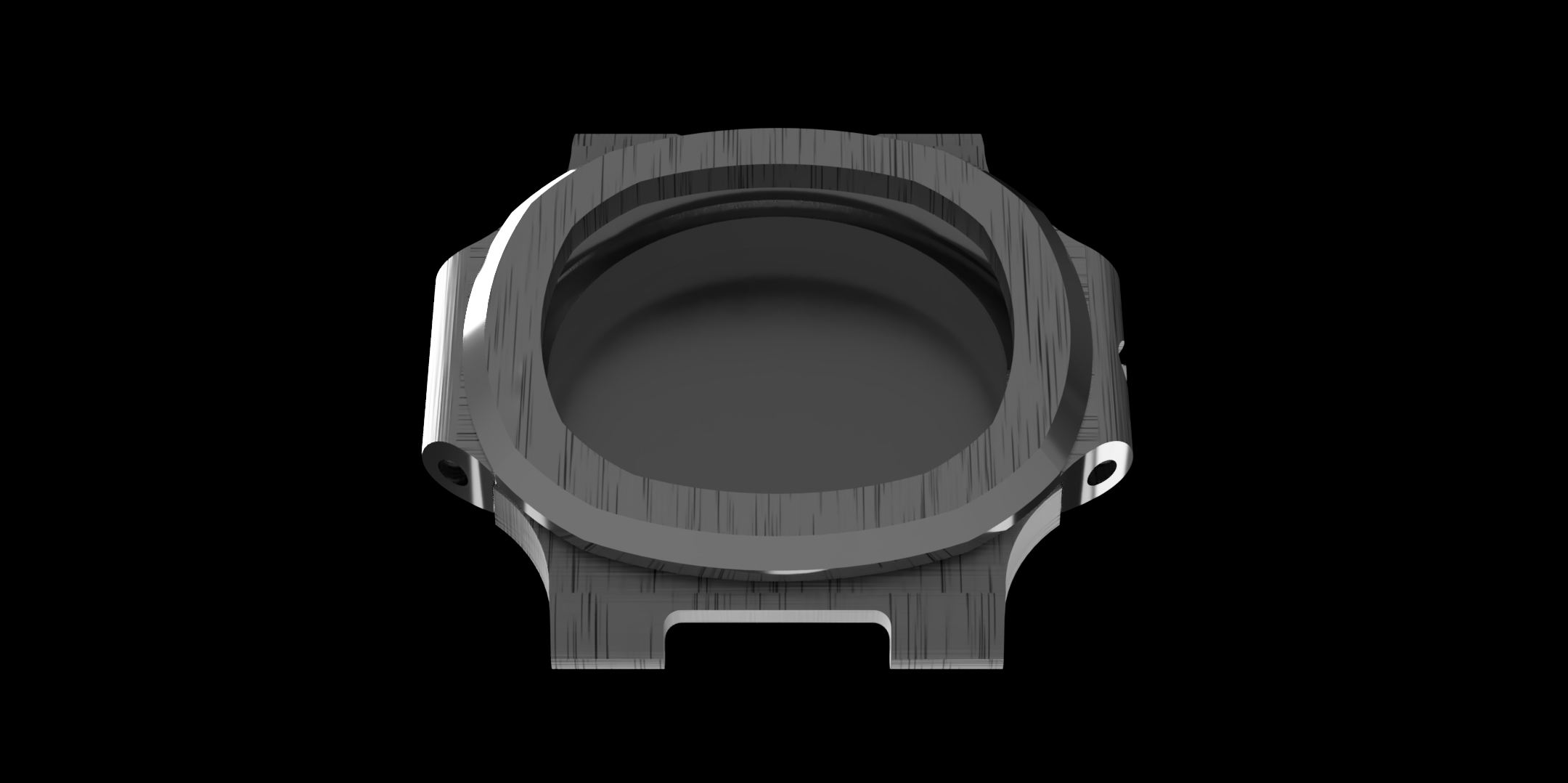

Attached are renders. They are not the latest model, but they give an idea of what's up. I welcome questions, comments, and especially input! Again, right now I am not taking any money or moving forward with anything concrete until I have my models finished and we have determined the ideal production options.

Some time ago, I secured a vintage 3700 case. I've procured most of the necessary parts to restore the watch with vintage parts, but finding a NOS bezel to match the case would be rarer than hens teen on a unicorn horn. I spent some time designing a CNC bezel for myself, and through that process I connected with a handful of people who asked if I could do a CNC case as well.

Being that I already had a rough model of the case to design the bezel around, it wasn't a stretch to update the case for production. As I am a businessperson outside the RWI, and in a country that does not allow counterfeiting, I want to be clear that this project does not aim to create counterfeit parts. Anything manufactured is done so with the goal it will serve as an OEM replacement part when parts can not be procured from the OEM. As such, no parts will bear a brand name, serial number, or enough components in a single order to assemble a complete unit resembling a copy of an existing product. If someone were to use my parts in conjunction with other aftermarket and vintage parts to create such a thing, it is simply beyond my control.

TL;DR: I'm considering a run of 10 3700 case/bezel combos. I'm asking questions about the finishing, modding, and assembly. Input is requested! I personally have no use for a case, but I would be remiss to have the opportunity to offer it and decline.

Now, on to the details, and the questions. My models are done based on true vintage parts. There are some parts I can make, and some I cannot. Moreover, as this is a vintage item, there are some production methods that would be changed to allow for more realistic modern manufacturing.

-The bezel:

The design of the bezel is quite complex. I know someone who owns a true vintage 3700 and is willing to lend me his bezel to corroborate measurements. This mostly is in relation to the system for the crystal, as it is difficult to ascertain the exact dimensions and assembly from photos. I had my gen crystal scanned with optical metrology equipment for an extremely precise DWG file, so the dimensions of the bezel itself are extremely precise, but the tolerances for the gasket and slight inner lip should be confirmed before anything is manufactured. Anyways, as it stands, the bezel will be essentially a 1:1 replacement part for the vintage bezel.

-The rehaut:

fitting over the dial, inside the gasket, and between the case and bezel is a metal rehaut of the same material as the bezel (in the event of a two tone 3700, this part was gold). This is a simple part, and easy enough to acquire online from vintage suppliers. However, at $500+, it makes the most sense for me to include this with the other parts, as it is a very simple design.

-The case: This is where things get a bit complicated. Please read this part thoroughly.

The case is a monoblock, but it is actually made of, to my understanding, two or three components. The crown tube is soldered in. This is not something my usual cnc shop can do, nor does it make sense to do nowadays. I'm leaning towards a threaded crown tube. This entails a few things of note. First, the tube must be modded. It has a cutout on the portion that protrudes into the case. As it is very expensive to have threads align perfectly, it makes sense to have the builder simply file out a section of the crown tube dependent on its fit. Once assembled, the tube can be held in with loctite 648, or a similar product. 648 is what would be used on smooth bore press fit crowns (I know Omega did this in the past). I'm not a pro at waterproofing, so I would recommend researching what loctite is best for this application. There may be some who favor a soldered crown tube. I would proceed according to the majority, bearing in mind that you would need to solder your own crown tube. Either way, it will be gen-spec and work with a gen crown, stem, and movement.

The case also appears to have an inner ring. Whether this is a separate part, press fit, adhered, or otherwise assembled, I cannot tell. Manufacturing has changed greatly in the last 50 years and I don't know how this would have been made back then. As far as I can tell, this inner ring is a separate part that is press fit, or snap fit as it could be sort of spring-clamp shaped. The reasoning for this is likely to make the bead blasting easier. The ring creates a slight overhand compared to the case bore. I have checked with my movement, test fit parts, and I cannot find a logical reason for this overhang. My best guess is that it is there to allow the rotor more space to rotate in the event of shocks or something like that. For my cnc case, I would integrate this ring, and include the overhang. With modern cutters it's not a difficult task to bore it out that way. However, if consensus is that I should have a separate part made for true accuracy, I could price that out.

Lastly, the case has a small notch between 6 and 9. I am leaning towards excluding this, for three reasons. Please read carefully. To my understanding, all JLC 920 base movements have a threaded hole at this position. ONLY THE PATEK 3700 VARIANTS HAVE A PART THAT GOES IN THIS HOLE. The 3700 specific movements have a nub that sticks out and fits this notch. Any 920 base caliber will fit a 3700 case, though. My guess is this is to aid with movement alignment. However, it is extremely unlikely that anyone assembling these parts actually will use a 3700 specific cal 28-255C, so I am opting to leave it out. Firstly, because it won't be needed for 99% of builders. The nub can also be removed from the movement easily in the event someone does have the 3700 specific variant. Secondly, it will increase manufacturing cost significantly, as it would require a specific tool and specific operation. Thirdly, I'm having difficulty measuring exactly where it is positioned.; it looks to be 135 degrees counterclockwise from 12 o clock, but to confirm this I would need to make a nub to fit my movement to test the fit of the nub in the slot. This is especially difficult as I don't have a measurement for the part, and I would need to estimate from photos. Unless someone here has one they can measure for me! So to summarize, I will exclude this notch unless the majority requests it.

The Crystal Gasket:

I cannot find anywhere that sells a crystal gasket. It's a specially shaped gasket. Most likely I will find a place to make the gaskets, or make them myself. Hytrel can be 3D printed, so if the tolerances check out I can go this route.

The other parts: case screws, case gasket, bracelet, crystal, crown, stem, movement, and so on.

Most likely I will provide case screws. I may provide the case gasket if requested. My only concern is that the more I include, the more of a counterfeit item it is. As just the bezel and case with no branding, it has zero legal issue and can fly through customs. I will not be providing a bracelet, crown, stem, movement, crystal, hands, etc. The parts will be gen-spec so vintage parts will fit.

The finishing:

My cnc shop does not offer the premium finishing needed for these parts. They can do the bead blasting, but no brushing or polishing. Since I am sending my case set to a professional finisher, this was not a concern for just a bezel for me. There are three routes I am exploring, and this is where I would like some input!

Option 1: No finishing. It will be up to you to have a modder do your finishing. This means, however, a much lower cost.

Option 2: I am reaching out to a few modders to see if they're interested in taking on a bulk order for this run. My only concern is that I can't be responsible for what happens once it gets in their hands, so this would be an option at buyers risk with a well-vetted and trusted modder.

Option 3: Have me send it to your preferred modder.

Option 4: find a cnc shop who will do the finishing. I'm not inclined to this, as I have a good relationship with my current shop and trust their work.

Estimated Price and Lead Time:

$1000-1500: Estimated price for case, bezel, crystal gasket, and case screws. Threaded crown tube, integrated case ring, no case notch.

I have not received an estimate for a soldered tube, separate ring, case notch, or premium finishing. I will get quotes depending on majority preference.

CLOSING STATEMENT:

To be clear, the parts are not ready for manufacturing, and no money will be collected. This post serves to gather information and interest, and will be updated as things progress. Once we are ready to begin production, meaning we have determined options, pricing, etc, this is the process: I will open the run up. A 50% deposit is required to secure your spot. This will be open for two weeks. If the actual sign-ups vastly differs from the interest list, and there are not enough to proceed, the run will be terminated and you will be refunded. The estimated completion time is under 6 months, so you will be able to pay through secure methods such as paypal G&S or credit card. Again, this only works if this is an aftermarket part, not a replica or counterfeit.

No matter the interest, I have no intention of doing more than 10 sets. I may stretch it if there are 11-12 people who want one. I have done many micro-runs of parts for my business in the past without issue, but it is not something I really enjoy doing on a larger scale, so if there is enough interest I would do a raffle or spin a wheel for the slots or something like that.

Please bear in mind, if you do decide to go the franken route, this is not a cheap project. There are few replica options for this. A 3kf 5711 bracelet fits. No rep dial fits. No rep movement fits. No rep hand fits. No rep crown fits. I have no idea about crystals as I went gen. All of these vintage parts are expensive, and finishing this project will end up costing you 5-figures without exception.

Attached are renders. They are not the latest model, but they give an idea of what's up. I welcome questions, comments, and especially input! Again, right now I am not taking any money or moving forward with anything concrete until I have my models finished and we have determined the ideal production options.