Hello friends, i recently received a beutiful Omega CrPo with Asian 2836 movement. Couldnt be happier with this watch.

Slight problem tho, i need to manually wind it as the rotor is barely moving when swirling or moving the clock.

I am aware that this is sometimes to be expected in the rep game and accept it.

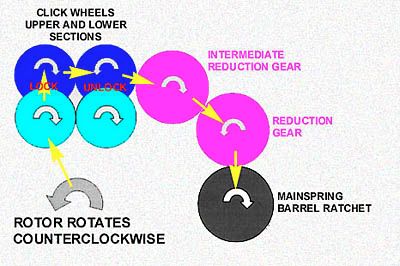

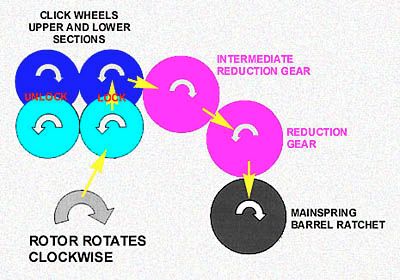

A pic to visualise and make sure i use the right words:

I am somewhat handy and can read and follow a tutorial, but also a complete beginner with this so a few pointers would be very appreciated.

I have read and watched and have three suggestions of my own:

Clean the complete movement in alcohol and lube it with some mineral oil

Clean the ball bearing connecting the rotor to the rest of the movement and lube with mineral oil

Replace the ball bearing

Im not 100% sure on how to do the first two suggestions.

All input and help greatly appreciated.

vbr

Daniel

Slight problem tho, i need to manually wind it as the rotor is barely moving when swirling or moving the clock.

I am aware that this is sometimes to be expected in the rep game and accept it.

A pic to visualise and make sure i use the right words:

I am somewhat handy and can read and follow a tutorial, but also a complete beginner with this so a few pointers would be very appreciated.

I have read and watched and have three suggestions of my own:

Clean the complete movement in alcohol and lube it with some mineral oil

Clean the ball bearing connecting the rotor to the rest of the movement and lube with mineral oil

Replace the ball bearing

Im not 100% sure on how to do the first two suggestions.

All input and help greatly appreciated.

vbr

Daniel