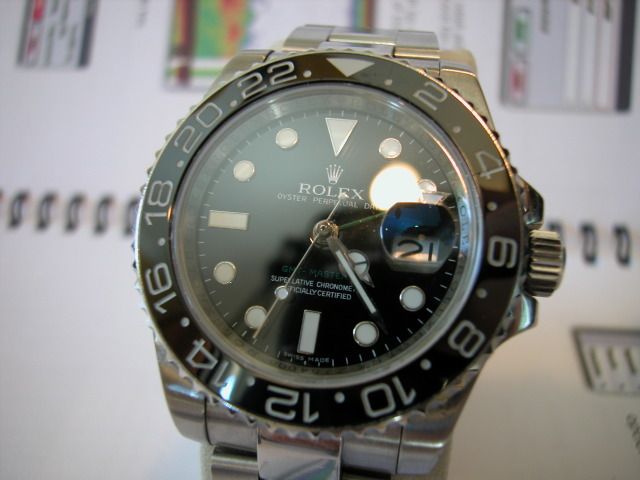

Kbh have you successfully used diamond bladed to sand a ceramic insert? Did you just do it section at a time or try and grind it back all at once to keep the thickness even?

Yes, I had the exact same problem when I ordered a new insert for my GMTIIC. It's not an easy task but I used a big ball of plumbers putty to help hold it and slowly went round and round. It puts off some nice sparks and gets pretty hot so you have to go rather slow. Probably took me about 40 minutes to get it down to where it fit. I did a mini tutorial on it at the time.

http://forum.replica-watch.info/vb/showthread.php/modifying-ceramic-bezel-60138?t=60138

I'm thinking your biggest problem is going to be at the pearl. I didn't have that to worry about.