Author:lysanderxiii from watchuseek

I was asked to do a review and comparison of two Chinese movements, the Seagull TY2130 and Hangzhou HZ6300, the two movements were provided by Carlos of the Prometheus Watch Company. These two movements would be compared against the ubiquitous Standard grade ETA 2824-2 and a Top grade ETA 2004-1

I originally planned to do all my testing and tear down first then post the results, however with four movements, there was too much information for one initial post. So I am now going to do a running commentary of the test, disassembly and comparison as I finish each phase.

Right now, I have four parts in this study, 1) Description & Initial Timing, 2) Tear-down and Comparison of Quality, 3) Interchangeability, and 4) Assessment.

This will allow for comments to be posted after each part.

Part one: Description and Initial timing tests.

Seagull TY2130

Hangzhou HZ6300

ETA 2824-2 (Rado)

TY2130, HZ6300 and ETA 2824-2

Type: Automatic mechanical lever movement

Size: 25.60 mm (26.00 mm overall) x 4.60 mm

Frequency: 4 Hz (28,800 bph)

Analog three hand display with quick change date, three position winding/setting stem.

The ETA is a Standard grade with a gold plated nickel balance and Nivarox 2 balance spring, I do not know what material the Seagull and Hangzhou are using.

ETA 2004-1

ETA 2004-1

Type: Automatic mechanical lever movement (uni-directional winding)

Size: 23.30 mm (23.90 mm overall) x 3.60 mm

Frequency: 4 Hz (28,800 bph)

Analog three hand display with quick change date, three position winding/setting stem.

This is a Top grade ETA with a gold plated Glucydur balance and Anachron balance spring

The TY2130 and the HZ6300 were taken directly from the package, wound and placed on a Mumford MicroSet Watch Timer. Then after running (movements motionless) for 24 hours, the rate (CH only) was taken again to establish the Isochronism.

The initial results were as follows:

TY2130:

Beat error: 0.3 ms

Rate, CH (dial up): -4.8 seconds per day

Rate, 9H (crown down): +0.6 s/d

Isochronism: +9.6 s/d

HZ6300:

Beat error: 0.1 ms

Rate, CH: +15.2 s/d

Rate, 9H: +11.7 s/d

Isochronism: -3.5 s/d

ETA 2824-2 (Rado, recently serviced):

Beat error: 0.2 ms

Rate, CH: +2.7 s/d

Rate, 9H: +2.0 s/d

Isochronism: -8.2 s/d

ETA 2004-1 (loose, recently serviced):

Beat error: 0.0 ms

Rate, CH: +3.4 s/d

Rate, 9H: -3.4 s/d

Isochronism: -7.5 s/d

All the movements showed excellent rate stability and amplitude (around 310 degrees for the 2824s and 300 degrees for the 2004) over the 24 hours they were under test.

Just for comparison, the specifications from ETA for the two movements are as follows:

ETA 2824-2 (Standard grade)

Rate: +/- 12 s/d

Variation between all positions: 30 s/d

Isochronism: +/- 20 s/d

Amplitude: maximum 315 to 325 degrees; minimum 200 to 220 degrees

ETA 2004-1 (Top grade)

Rate: +/- 7 s/d

Variation between all positions: 30 s/d

Isochronism: +/- 25 s/d

Amplitude: maximum 310 degrees; minimum 190 degrees

So, we can see that the two TY2130 and HZ6300 samples, in the "as received" condition, are quite capable of meeting ETA minimum specifications, and show very good performance in the two positions tested.

Note on the finish of the movements, The Rado ETA 2824-2 is plain gold plate with a very simple pattern on the rotor, the HZ6300 is plain nickel plate with absolutely no decoration. The TY2130 is finished in a manner similar to the ETA 2004-1 with a fine nickel plate and pearlage on the visible plates and Cote-de-Geneve on the rotor. From a strict utilitarian point of view, nickel plating is the best finish, but is slightly more expensive than gold plate due to the cost of handling the chemical waste associated with nickel plating. Also, pearlage and other decorations show up better on nickel plating.

Part two: a) Tear-down.

The disassembly of the TY2130 and the HZ6300 is straight forward, and thanks to the design, there aren't many little springs to go flying (only one, in fact, the click spring, all of the other springs are integral with a larger part). This part will just show pictures the teardown of one sample, as two of the others will be the same and the teardown of the 2004-1 is not relevant to the thread.

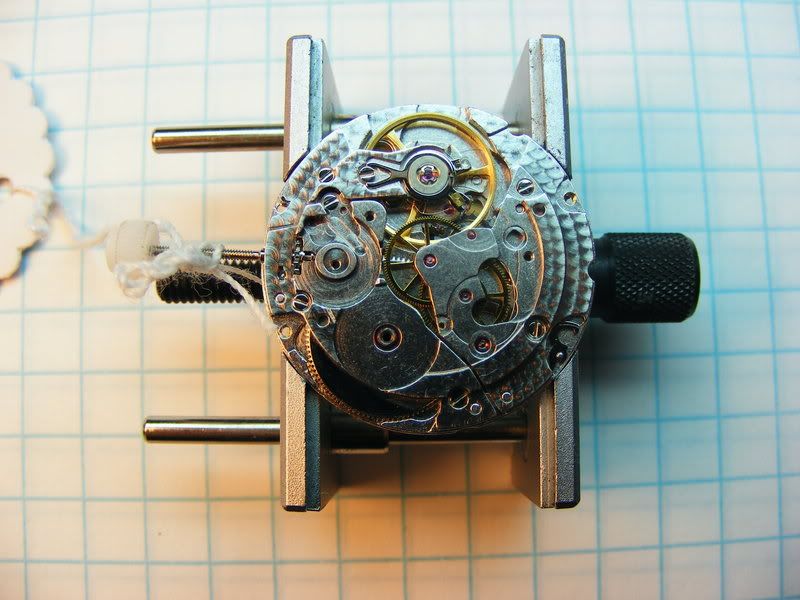

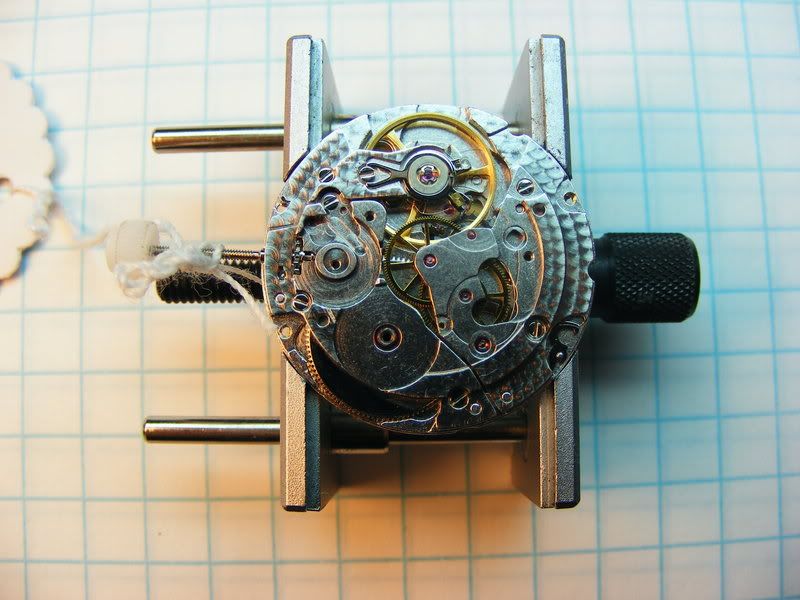

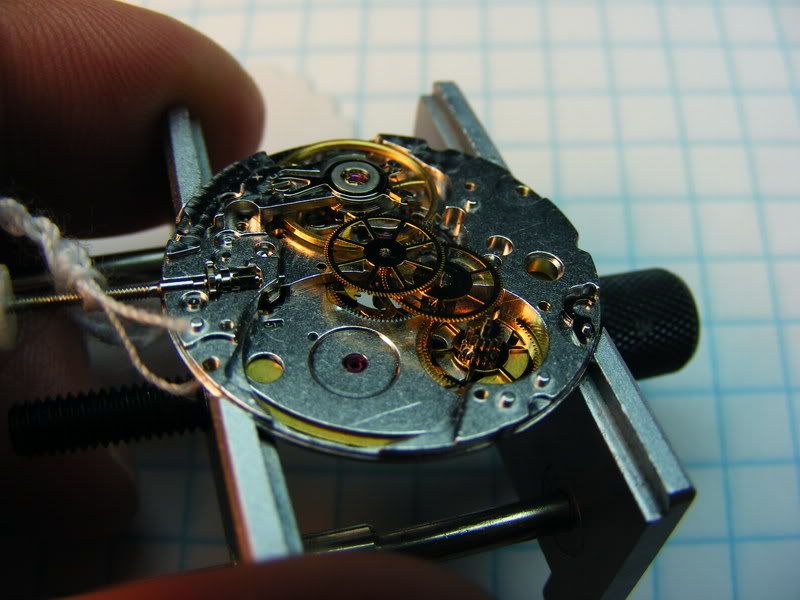

I find it easiest to start from the back and work forward. This portion will show the TY2130. First the rotor is removed.

Then the two black screws for the autowinding bridge are removed, and carefully lift it off. After the autowinding bridge is removed, the Mainspring is let down, then the ratchet wheel, crown wheel, click and click spring are removed from the barrel bridge.

Now, the barrel bridge is removed. We can see the placement of the balance stop (hack) lever.

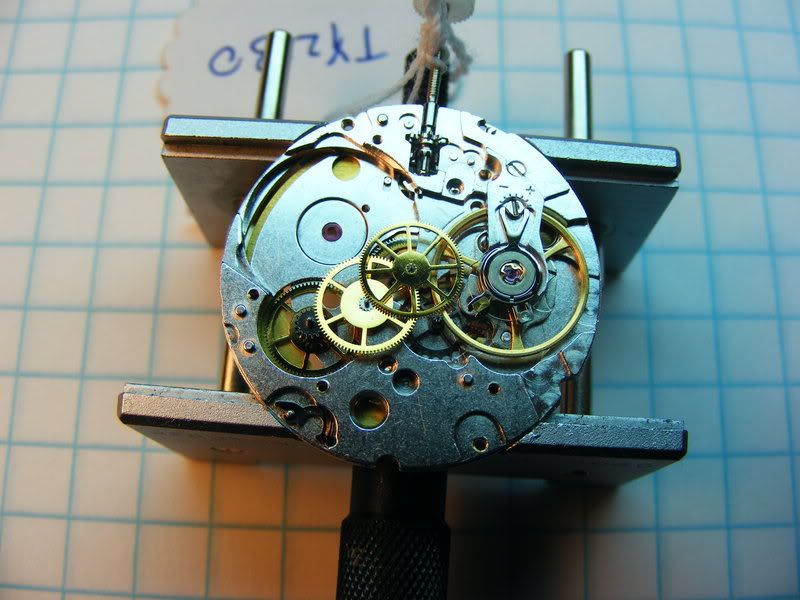

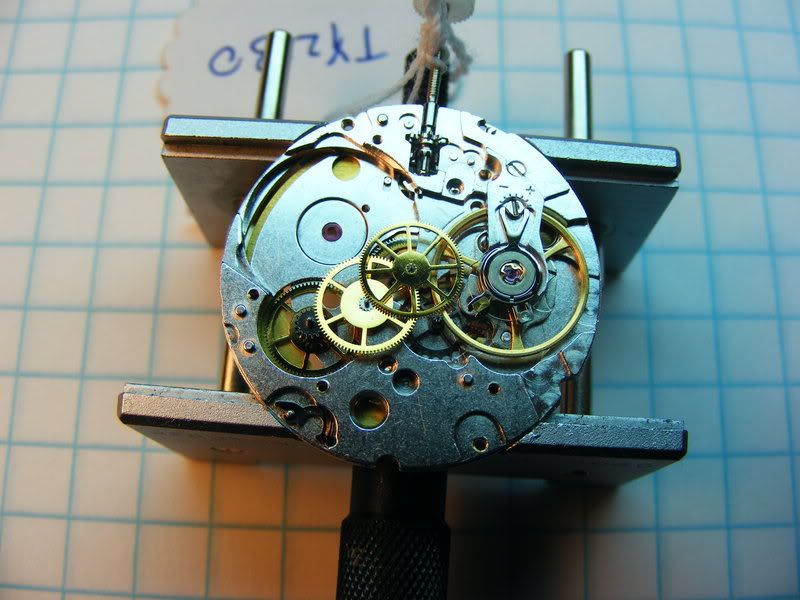

And then the train bridge comes off. Two views of the gear train.

Then the balance and pallet fork come off.

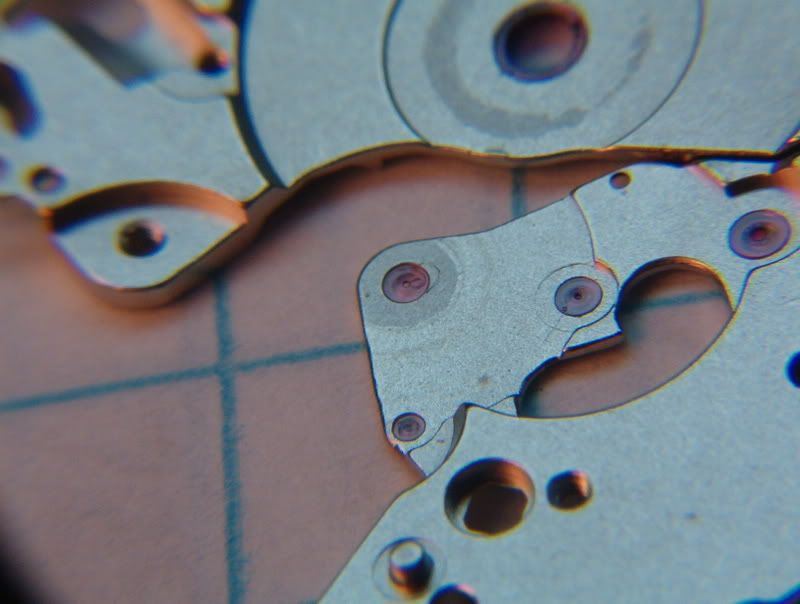

On the dial side, (this is the HZ6300) the minute train bridge is removed. The hour wheel, minute wheel, setting wheel, date corrector are removed.

Then the rest of the calendar mechanism can be removed along with the cannon pinion.

We mentioned the one loose spring in these movements, here it is, the click spring, along with the click and crown wheel.

Now that they are apart, we get some comparison shots and give a good hard look to the quality of these movements.

Here are comparison shots of the three mainplates, see if you can spot the one that is different.

Back:

Front:

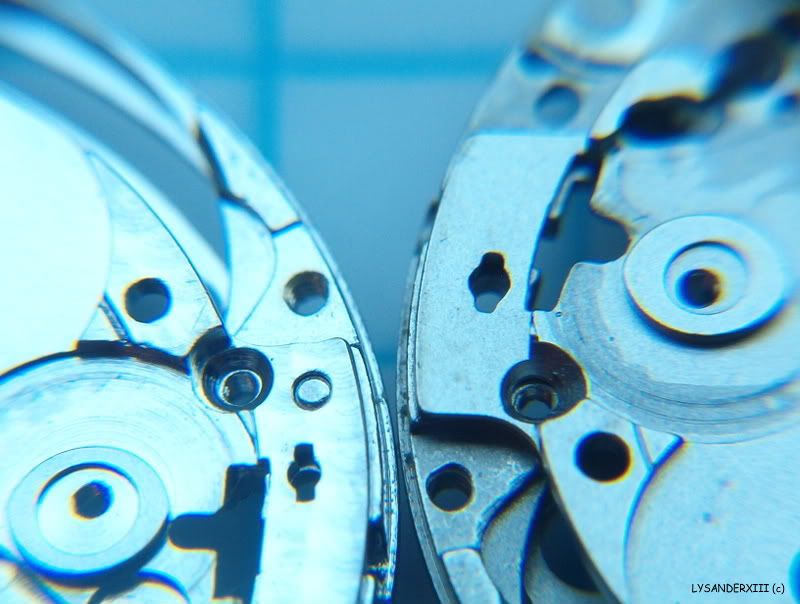

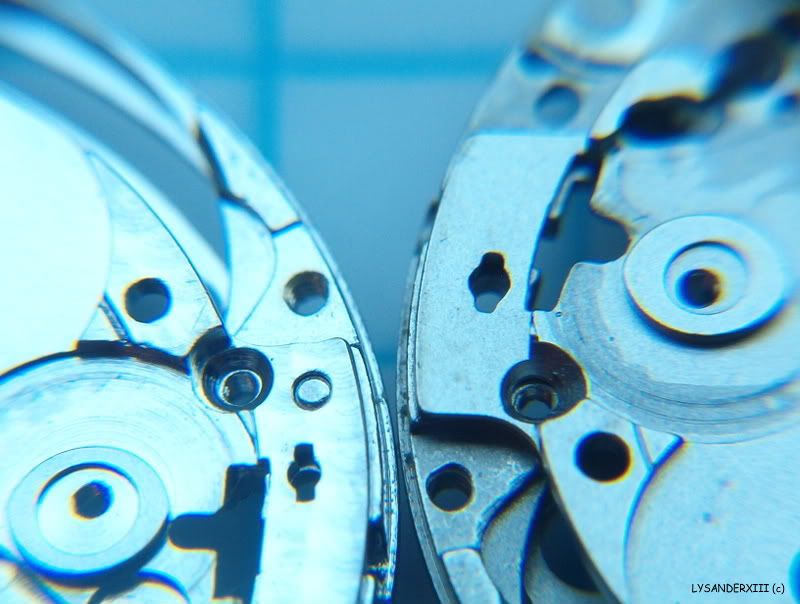

The major difference is how how the bridges are aligned to the main plate. Here are detail shots of the differences. The Hangzhou and ETA use holes in the mainplate and trepanned studs on the bridges, the Seagull uses holes in the bridges and holes with pins in the mainplate. The Seagull uses the method favored by Selitta in the SW200, except for the balance bridge, where Seagull uses the ETA method.

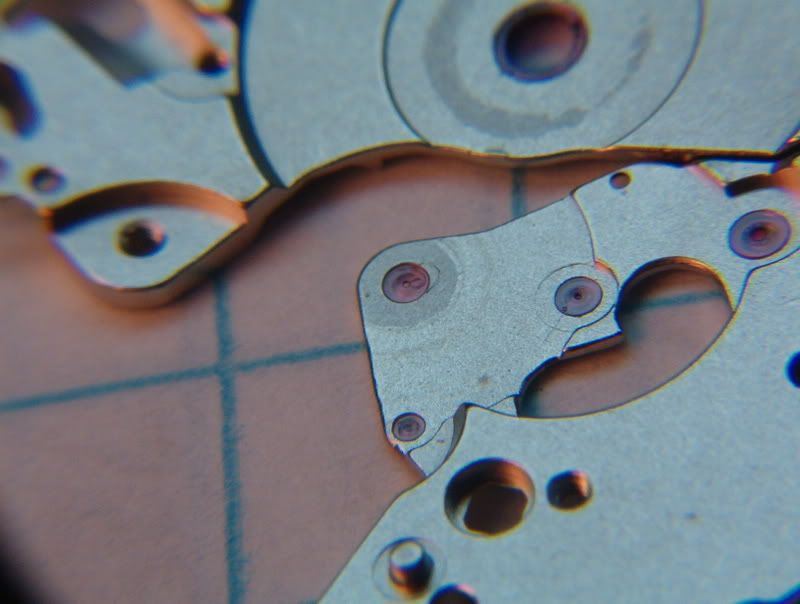

Seagull:

Hangzhou:

ETA:

Why do I find this interesting?

Putting pins in holes and controlling accuracy to a few hundredths of a millimeter is a hell of a lot easier than trepanning a stud, and saves material. The stock material for a trepanned stud must start out with sufficient material to allow for the stud to be cut out.

The Hangzhou also does have a few additional holes drilled in it, but all of these hole are non-functional, either pilot holes for a day/date mainplate, or additional holes for oiling and/or inspection.

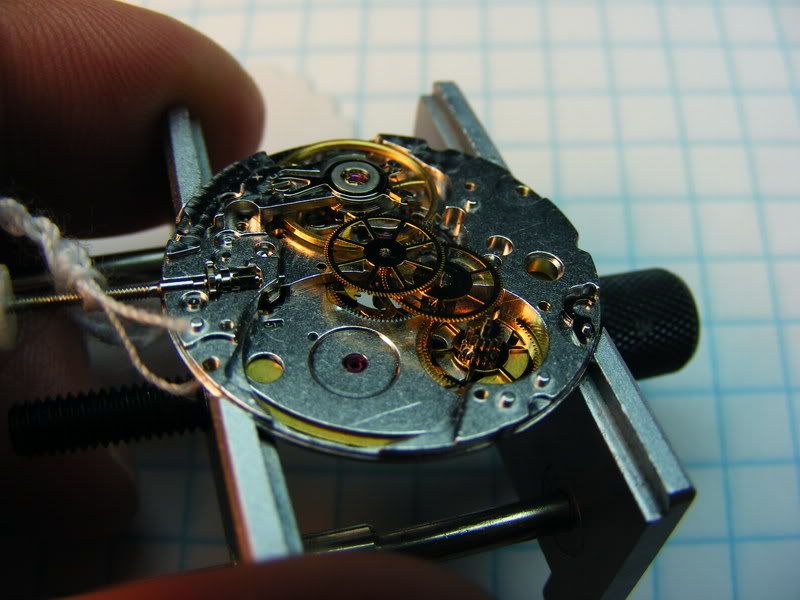

One other thing that is not readily apparent in the long range shots above is the Seagull was completely devoid of any oil. The Hangzhou was well oiled.

Seagull jewels, no oil:

Hangzhou, note the oil bead on the jewels and the oil spread discoloring the plate:

I was asked to do a review and comparison of two Chinese movements, the Seagull TY2130 and Hangzhou HZ6300, the two movements were provided by Carlos of the Prometheus Watch Company. These two movements would be compared against the ubiquitous Standard grade ETA 2824-2 and a Top grade ETA 2004-1

I originally planned to do all my testing and tear down first then post the results, however with four movements, there was too much information for one initial post. So I am now going to do a running commentary of the test, disassembly and comparison as I finish each phase.

Right now, I have four parts in this study, 1) Description & Initial Timing, 2) Tear-down and Comparison of Quality, 3) Interchangeability, and 4) Assessment.

This will allow for comments to be posted after each part.

Part one: Description and Initial timing tests.

Seagull TY2130

Hangzhou HZ6300

ETA 2824-2 (Rado)

TY2130, HZ6300 and ETA 2824-2

Type: Automatic mechanical lever movement

Size: 25.60 mm (26.00 mm overall) x 4.60 mm

Frequency: 4 Hz (28,800 bph)

Analog three hand display with quick change date, three position winding/setting stem.

The ETA is a Standard grade with a gold plated nickel balance and Nivarox 2 balance spring, I do not know what material the Seagull and Hangzhou are using.

ETA 2004-1

ETA 2004-1

Type: Automatic mechanical lever movement (uni-directional winding)

Size: 23.30 mm (23.90 mm overall) x 3.60 mm

Frequency: 4 Hz (28,800 bph)

Analog three hand display with quick change date, three position winding/setting stem.

This is a Top grade ETA with a gold plated Glucydur balance and Anachron balance spring

The TY2130 and the HZ6300 were taken directly from the package, wound and placed on a Mumford MicroSet Watch Timer. Then after running (movements motionless) for 24 hours, the rate (CH only) was taken again to establish the Isochronism.

The initial results were as follows:

TY2130:

Beat error: 0.3 ms

Rate, CH (dial up): -4.8 seconds per day

Rate, 9H (crown down): +0.6 s/d

Isochronism: +9.6 s/d

HZ6300:

Beat error: 0.1 ms

Rate, CH: +15.2 s/d

Rate, 9H: +11.7 s/d

Isochronism: -3.5 s/d

ETA 2824-2 (Rado, recently serviced):

Beat error: 0.2 ms

Rate, CH: +2.7 s/d

Rate, 9H: +2.0 s/d

Isochronism: -8.2 s/d

ETA 2004-1 (loose, recently serviced):

Beat error: 0.0 ms

Rate, CH: +3.4 s/d

Rate, 9H: -3.4 s/d

Isochronism: -7.5 s/d

All the movements showed excellent rate stability and amplitude (around 310 degrees for the 2824s and 300 degrees for the 2004) over the 24 hours they were under test.

Just for comparison, the specifications from ETA for the two movements are as follows:

ETA 2824-2 (Standard grade)

Rate: +/- 12 s/d

Variation between all positions: 30 s/d

Isochronism: +/- 20 s/d

Amplitude: maximum 315 to 325 degrees; minimum 200 to 220 degrees

ETA 2004-1 (Top grade)

Rate: +/- 7 s/d

Variation between all positions: 30 s/d

Isochronism: +/- 25 s/d

Amplitude: maximum 310 degrees; minimum 190 degrees

So, we can see that the two TY2130 and HZ6300 samples, in the "as received" condition, are quite capable of meeting ETA minimum specifications, and show very good performance in the two positions tested.

Note on the finish of the movements, The Rado ETA 2824-2 is plain gold plate with a very simple pattern on the rotor, the HZ6300 is plain nickel plate with absolutely no decoration. The TY2130 is finished in a manner similar to the ETA 2004-1 with a fine nickel plate and pearlage on the visible plates and Cote-de-Geneve on the rotor. From a strict utilitarian point of view, nickel plating is the best finish, but is slightly more expensive than gold plate due to the cost of handling the chemical waste associated with nickel plating. Also, pearlage and other decorations show up better on nickel plating.

Part two: a) Tear-down.

The disassembly of the TY2130 and the HZ6300 is straight forward, and thanks to the design, there aren't many little springs to go flying (only one, in fact, the click spring, all of the other springs are integral with a larger part). This part will just show pictures the teardown of one sample, as two of the others will be the same and the teardown of the 2004-1 is not relevant to the thread.

I find it easiest to start from the back and work forward. This portion will show the TY2130. First the rotor is removed.

Then the two black screws for the autowinding bridge are removed, and carefully lift it off. After the autowinding bridge is removed, the Mainspring is let down, then the ratchet wheel, crown wheel, click and click spring are removed from the barrel bridge.

Now, the barrel bridge is removed. We can see the placement of the balance stop (hack) lever.

And then the train bridge comes off. Two views of the gear train.

Then the balance and pallet fork come off.

On the dial side, (this is the HZ6300) the minute train bridge is removed. The hour wheel, minute wheel, setting wheel, date corrector are removed.

Then the rest of the calendar mechanism can be removed along with the cannon pinion.

We mentioned the one loose spring in these movements, here it is, the click spring, along with the click and crown wheel.

Now that they are apart, we get some comparison shots and give a good hard look to the quality of these movements.

Here are comparison shots of the three mainplates, see if you can spot the one that is different.

Back:

Front:

The major difference is how how the bridges are aligned to the main plate. Here are detail shots of the differences. The Hangzhou and ETA use holes in the mainplate and trepanned studs on the bridges, the Seagull uses holes in the bridges and holes with pins in the mainplate. The Seagull uses the method favored by Selitta in the SW200, except for the balance bridge, where Seagull uses the ETA method.

Seagull:

Hangzhou:

ETA:

Why do I find this interesting?

Putting pins in holes and controlling accuracy to a few hundredths of a millimeter is a hell of a lot easier than trepanning a stud, and saves material. The stock material for a trepanned stud must start out with sufficient material to allow for the stud to be cut out.

The Hangzhou also does have a few additional holes drilled in it, but all of these hole are non-functional, either pilot holes for a day/date mainplate, or additional holes for oiling and/or inspection.

One other thing that is not readily apparent in the long range shots above is the Seagull was completely devoid of any oil. The Hangzhou was well oiled.

Seagull jewels, no oil:

Hangzhou, note the oil bead on the jewels and the oil spread discoloring the plate: