- 6/6/09

- 260

- 0

- 16

This part follows on from part 1 of my tutorial where we have stripped the movement, inspected the parts for wear and ultrasonically cleaned the parts. It is now necessary to put the parts back together and lubricate them.

The oils I use are as follows:

Moebius 8200 - mainspring

Moebius HP 1300 - Large pivots (Centre and third wheel)

Moebius 9010 - Smaller pivots

Mobius 9415 - Escapement

Bergeon KT 22 grease - Cannon pinion

One dip - Balance

It is no surprise that on the ETA.CH website, all the recommended oils are Moebius, The swatch group owns them both, along with a number of other companies you probably wouldnt even realised they own. Omega, Rado etc.

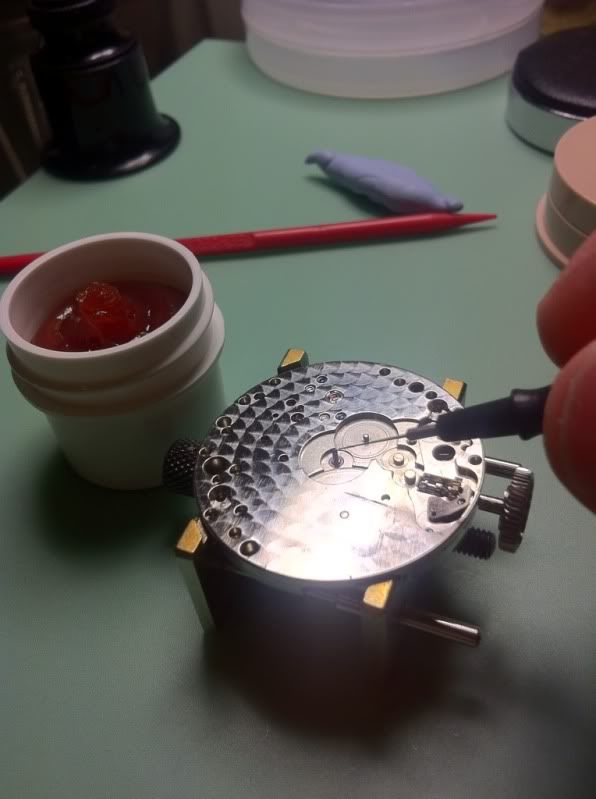

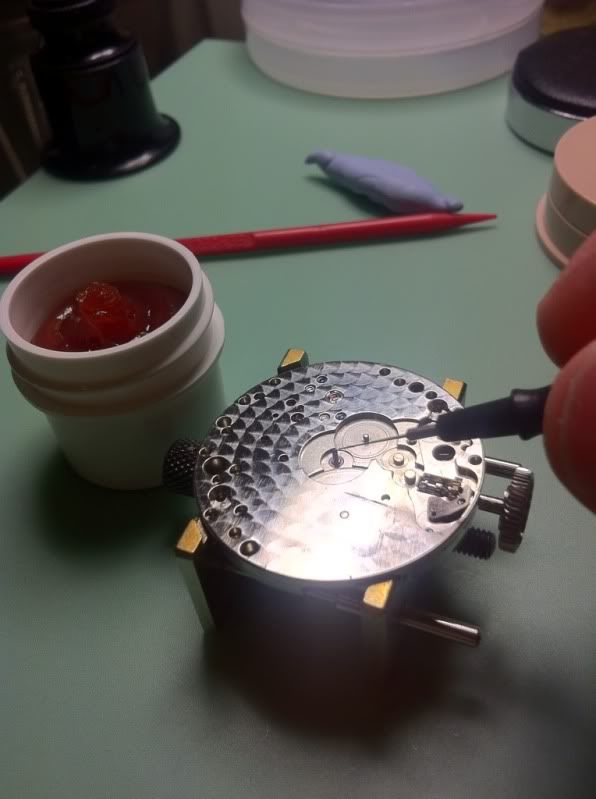

I have my oils in a pot like this

You dont need much, a little goes a long way when it comes to watches.

The first thing we need to do is oil the mainspring, sorry but I forgot to do a pic of this. Its fairly simple, leaving the mainspring in the barrel just put a couple of drops of 8200 along it and then the lid needs to be put back on.

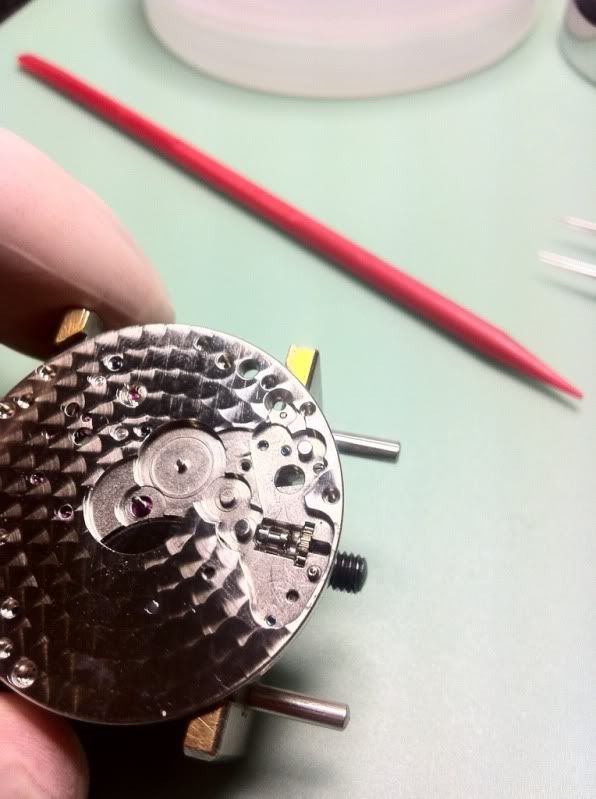

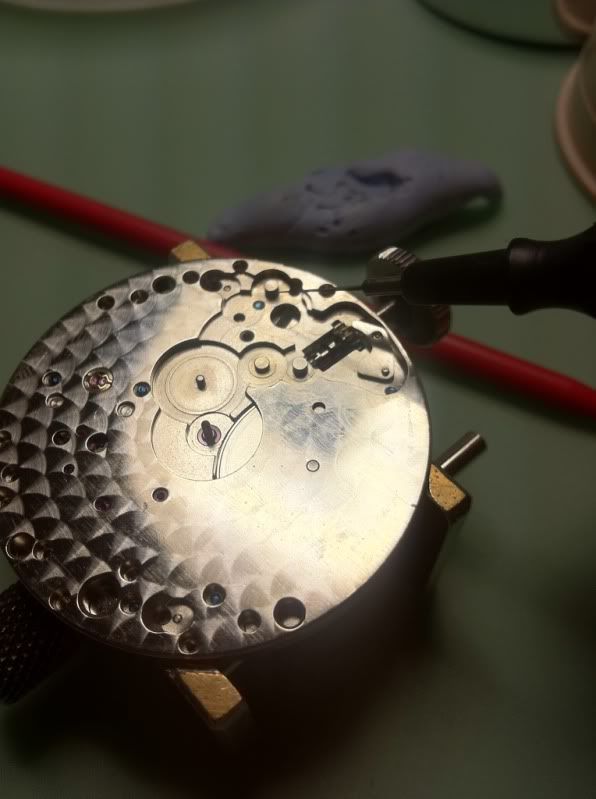

Next we need to use the HP 1300. We need to put some between the barrel and arbor and also a small amout on the arbor itself, this needs to be done both sides of the barrel

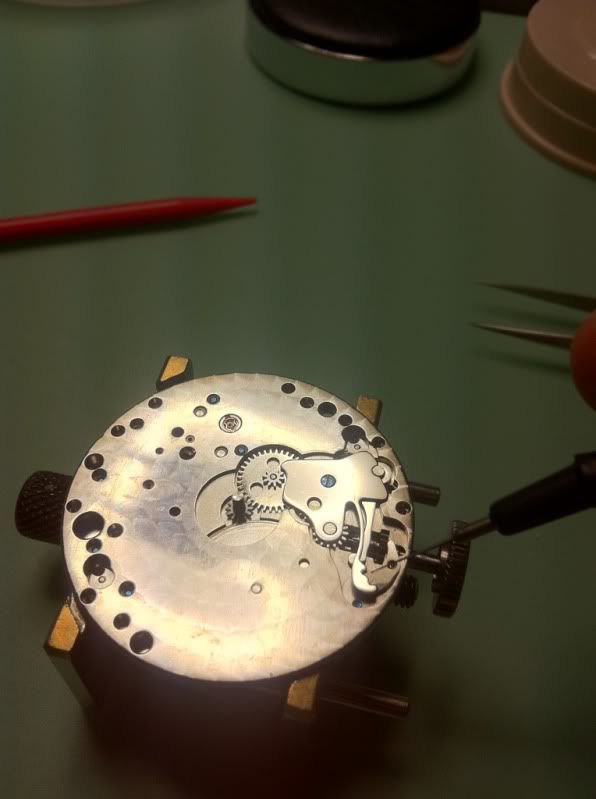

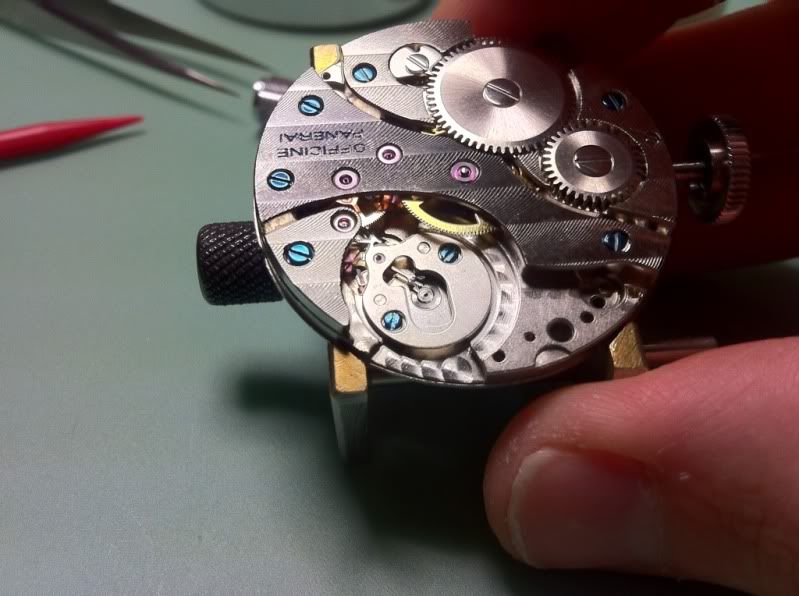

Barrel done, the next thing we need to do is put the train back in place. Use the ETA.ch website if you need to check what order to put the wheels back in.

Next is placing the train bridge back on. This can be quite tricky if you havent done it before but a bit of patience and it shouldnt take too long. The trick is to make sure the wheels are positioned correctly in the first place, then when you place the bridge on at least 2 or 3 of the pivots should be in place. You need to use an eye glass to check the pivots are showing through the jewels. On the ones that arent (usually escape and maybe fourth wheel) Use an oiler or pair of tweezers and whilst gently pushing on the bridge, move the wheel around a little till it slots in to place. Do not try to screw the bridge in if your not sure if the pivots are all lined up or you will likely snap them off.

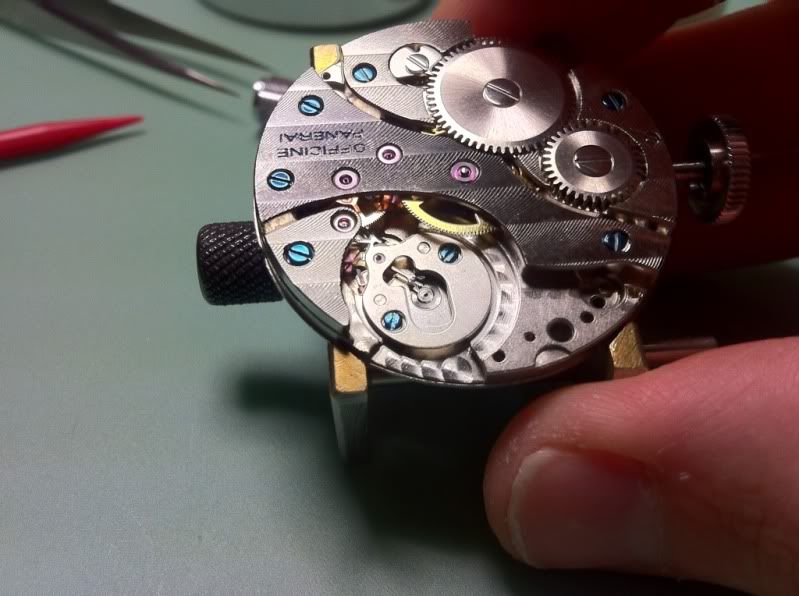

Also now put the set lever screw in place, next to go on is the barrel bridge. This is simple and should slot into place quite nicely.

Next to go on will be the crown wheel and ratchet wheel. Put the crown ring back on its post and oil the crown ring where the wheel will sit with HP 1300.

Put the crown wheel and ratchet wheel back on. Remember the crown screw threads the opposite way to usual.

Next we need to oil the centre wheel and third wheel with hp 1300. You need to use a strong eyeglass, I use the 12x. I cannot get a pic good enough to show what it looks like but it maybe worth googling. Basically it will look like a doughnut around the pivot if its right. Too much and it will look like its going to spill over, too little and it wont last as long as it could. Its very difficult to put into words exactly how it should look.

Now turn the movement over.

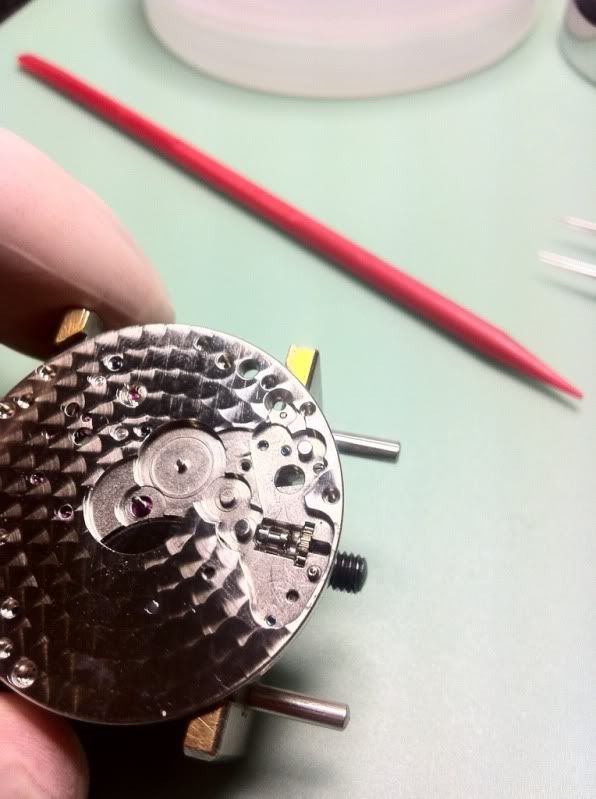

Put the winding pinion and sliding pinion back in place. Make sure they are both the right way round. Put some hp 1300 on the sliding pinion where the yoke will sit and on the teeth where it meets the winding pinion to allow it to back wind.

Now oil the stem and put it back in, again its prob easier to check the eta website to see exactly where it needs to be oiled rather than me try and explain.

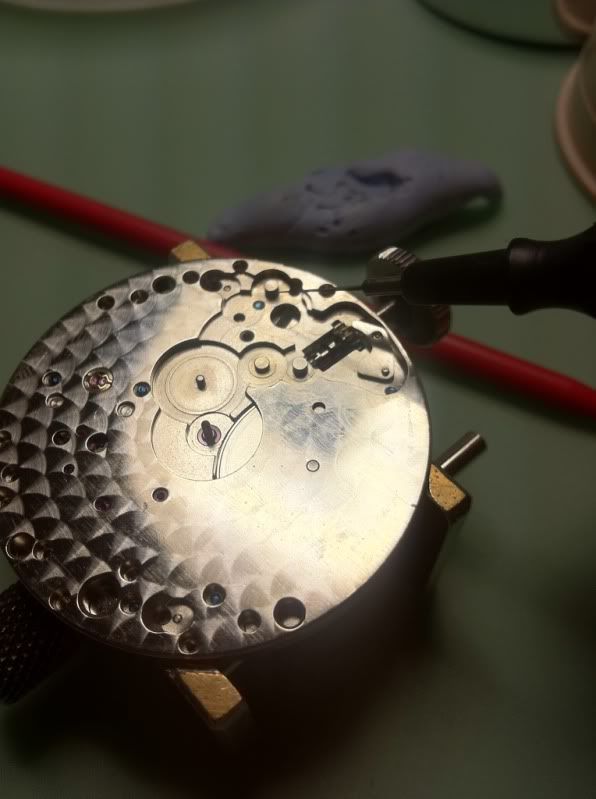

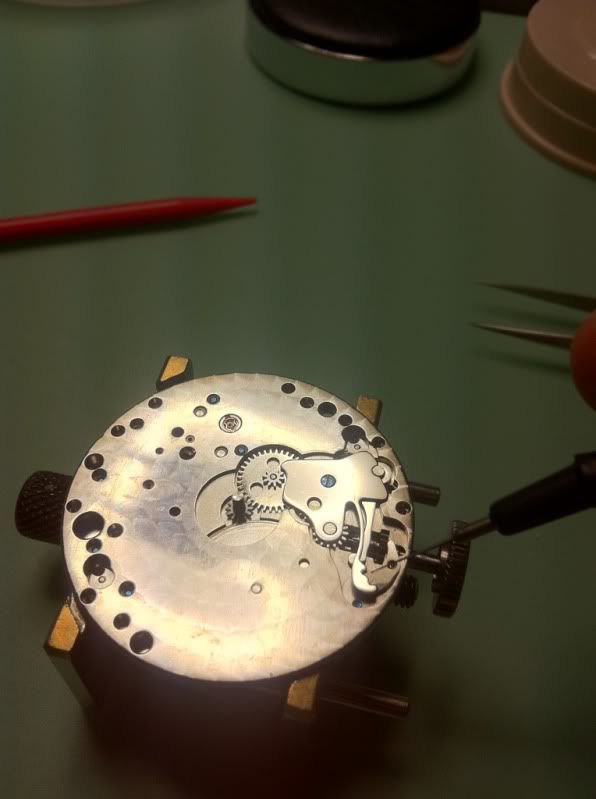

Next we need to oil all the posts with hp 1300, there is 4 in total, post for yoke (being oiled in the pic), minute wheel post, setting wheel and intermediate setting wheel post.

Next oil the centre wheel this side with hp 1300

Put some KT 22 on the centre wheel where the cannon pinion slides on to.

Put the yoke and setting lever in place (setting lever isnt screwed in yet though) and use hp 1300 to oil where the setting lever and yoke meet.

Next put the yoke spring in place. Be careful though, this could easily ping off and be lost. Also replace the cannon pinion, minute wheel and setting wheels.

Put the set lever spring in place and screw it down. The end of the spring where it meets the set lever needs to be oiled with hp 1300

Now screw down the set lever screw from the other side of the movement.

Then oil the jewels this side. Centre wheel has already been done so use hp 1300 for third wheel and 9010 for escape and fourth wheel.

Now we are getting on to the balance and probably the hardest part to do.

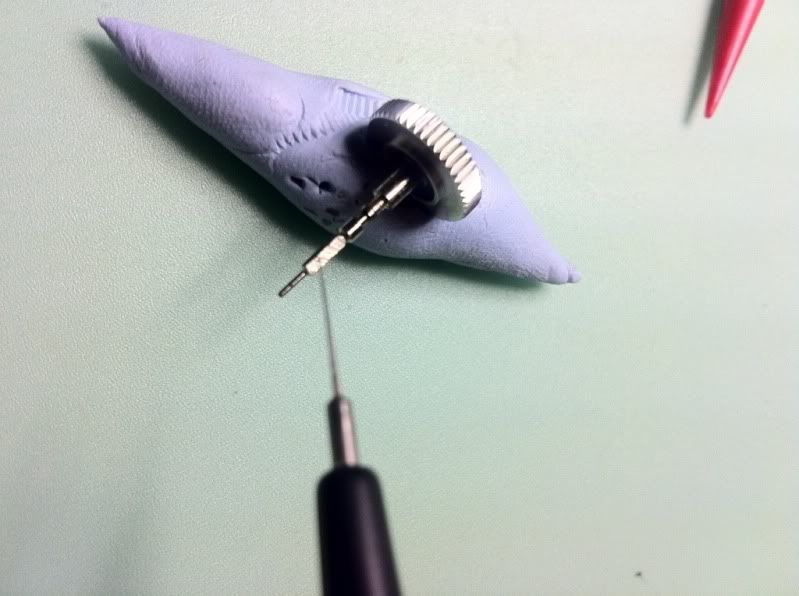

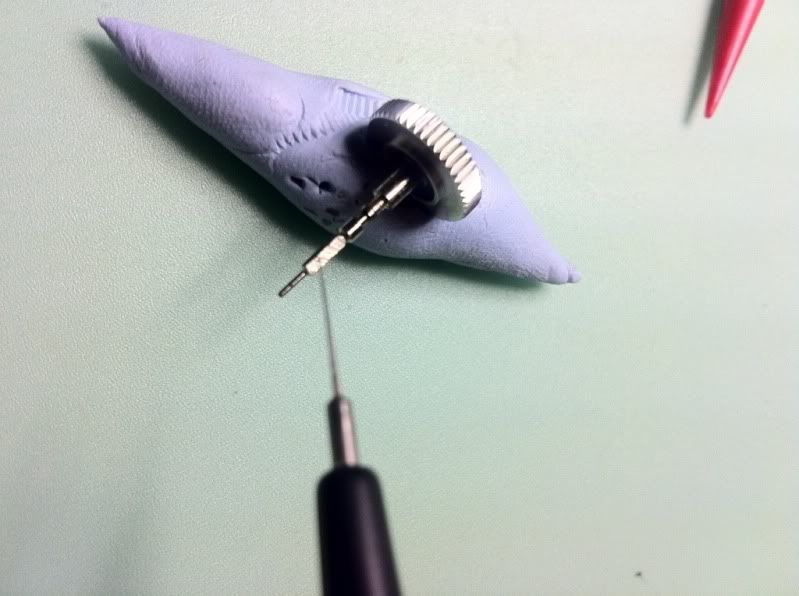

We need to remove the lower incabloc first. Use tweezers very gently to release the spring. You need to be so careful not to break or lose anything here. You will then be able to remove the incabloc.

You then need to take the cap off and oil it. the following pic shows the incabloc oiled. With the lid back on it should be about half full.

Put it back on the main plate, close the spring. Again with tweezers and being very careful, other than the hour wheel this side is now complete. Turn the movemnt back over.

Its now time to oil the pallets, probably the most important part of the watch to oil, also one of the hardest to do correctly.

We use the 9415 for pallets, basically you need to position the watch at a certain angle, probably on its side so you can see the face of the pallet, then with a tiny amount of oil on the oiler put a very small amount in the centre of the face of the pallet. Move the pallet so it advances the escape wheel by a few teeth and repeat until all are oiled. There should be no oil anywhere other than the face of the pallets and the face of the teeth on the escape wheel. To check the amount of oil, try and use either tweeezers or blue tac/ rodico to stop the escape tooth exactly in line with the pallet as it passes over. There should be a wedge of oil between the pallet and tooth. This is difficult to explain with words and again may be worth googling. In the picture you can just about see the pallet I am going to oil. This is very difficult at first and requires a great deal of practice to perfect.

Put the balance back on and repeat the process this side with the incabloc.

Other than putting the hour wheel, dial and hands back on the watch is now serviced. This has gone on for a while so im not going to post the pictures of putting the dial and hands back on. I hope its been of use to someone, the eta.ch guide is very good but I think actual pictures do some times help. Any questions feel free to ask. Cheers.

The oils I use are as follows:

Moebius 8200 - mainspring

Moebius HP 1300 - Large pivots (Centre and third wheel)

Moebius 9010 - Smaller pivots

Mobius 9415 - Escapement

Bergeon KT 22 grease - Cannon pinion

One dip - Balance

It is no surprise that on the ETA.CH website, all the recommended oils are Moebius, The swatch group owns them both, along with a number of other companies you probably wouldnt even realised they own. Omega, Rado etc.

I have my oils in a pot like this

You dont need much, a little goes a long way when it comes to watches.

The first thing we need to do is oil the mainspring, sorry but I forgot to do a pic of this. Its fairly simple, leaving the mainspring in the barrel just put a couple of drops of 8200 along it and then the lid needs to be put back on.

Next we need to use the HP 1300. We need to put some between the barrel and arbor and also a small amout on the arbor itself, this needs to be done both sides of the barrel

Barrel done, the next thing we need to do is put the train back in place. Use the ETA.ch website if you need to check what order to put the wheels back in.

Next is placing the train bridge back on. This can be quite tricky if you havent done it before but a bit of patience and it shouldnt take too long. The trick is to make sure the wheels are positioned correctly in the first place, then when you place the bridge on at least 2 or 3 of the pivots should be in place. You need to use an eye glass to check the pivots are showing through the jewels. On the ones that arent (usually escape and maybe fourth wheel) Use an oiler or pair of tweezers and whilst gently pushing on the bridge, move the wheel around a little till it slots in to place. Do not try to screw the bridge in if your not sure if the pivots are all lined up or you will likely snap them off.

Also now put the set lever screw in place, next to go on is the barrel bridge. This is simple and should slot into place quite nicely.

Next to go on will be the crown wheel and ratchet wheel. Put the crown ring back on its post and oil the crown ring where the wheel will sit with HP 1300.

Put the crown wheel and ratchet wheel back on. Remember the crown screw threads the opposite way to usual.

Next we need to oil the centre wheel and third wheel with hp 1300. You need to use a strong eyeglass, I use the 12x. I cannot get a pic good enough to show what it looks like but it maybe worth googling. Basically it will look like a doughnut around the pivot if its right. Too much and it will look like its going to spill over, too little and it wont last as long as it could. Its very difficult to put into words exactly how it should look.

Now turn the movement over.

Put the winding pinion and sliding pinion back in place. Make sure they are both the right way round. Put some hp 1300 on the sliding pinion where the yoke will sit and on the teeth where it meets the winding pinion to allow it to back wind.

Now oil the stem and put it back in, again its prob easier to check the eta website to see exactly where it needs to be oiled rather than me try and explain.

Next we need to oil all the posts with hp 1300, there is 4 in total, post for yoke (being oiled in the pic), minute wheel post, setting wheel and intermediate setting wheel post.

Next oil the centre wheel this side with hp 1300

Put some KT 22 on the centre wheel where the cannon pinion slides on to.

Put the yoke and setting lever in place (setting lever isnt screwed in yet though) and use hp 1300 to oil where the setting lever and yoke meet.

Next put the yoke spring in place. Be careful though, this could easily ping off and be lost. Also replace the cannon pinion, minute wheel and setting wheels.

Put the set lever spring in place and screw it down. The end of the spring where it meets the set lever needs to be oiled with hp 1300

Now screw down the set lever screw from the other side of the movement.

Then oil the jewels this side. Centre wheel has already been done so use hp 1300 for third wheel and 9010 for escape and fourth wheel.

Now we are getting on to the balance and probably the hardest part to do.

We need to remove the lower incabloc first. Use tweezers very gently to release the spring. You need to be so careful not to break or lose anything here. You will then be able to remove the incabloc.

You then need to take the cap off and oil it. the following pic shows the incabloc oiled. With the lid back on it should be about half full.

Put it back on the main plate, close the spring. Again with tweezers and being very careful, other than the hour wheel this side is now complete. Turn the movemnt back over.

Its now time to oil the pallets, probably the most important part of the watch to oil, also one of the hardest to do correctly.

We use the 9415 for pallets, basically you need to position the watch at a certain angle, probably on its side so you can see the face of the pallet, then with a tiny amount of oil on the oiler put a very small amount in the centre of the face of the pallet. Move the pallet so it advances the escape wheel by a few teeth and repeat until all are oiled. There should be no oil anywhere other than the face of the pallets and the face of the teeth on the escape wheel. To check the amount of oil, try and use either tweeezers or blue tac/ rodico to stop the escape tooth exactly in line with the pallet as it passes over. There should be a wedge of oil between the pallet and tooth. This is difficult to explain with words and again may be worth googling. In the picture you can just about see the pallet I am going to oil. This is very difficult at first and requires a great deal of practice to perfect.

Put the balance back on and repeat the process this side with the incabloc.

Other than putting the hour wheel, dial and hands back on the watch is now serviced. This has gone on for a while so im not going to post the pictures of putting the dial and hands back on. I hope its been of use to someone, the eta.ch guide is very good but I think actual pictures do some times help. Any questions feel free to ask. Cheers.