How to: relume a sandwich dial (and make it glow like a torch) [Updated]

Today a little something about the basic of reluming: the sandwich dial, and a few tips to make it glow brigther. This is the perfect job

if you're begining, because you can't really screw up

A sandwich dial is a two-plate dial, the first plate being coated with luminous material and the second plate pierced through for the indexes

and numerals. So the first step is to separate out these 2 plates using a sharp blade.

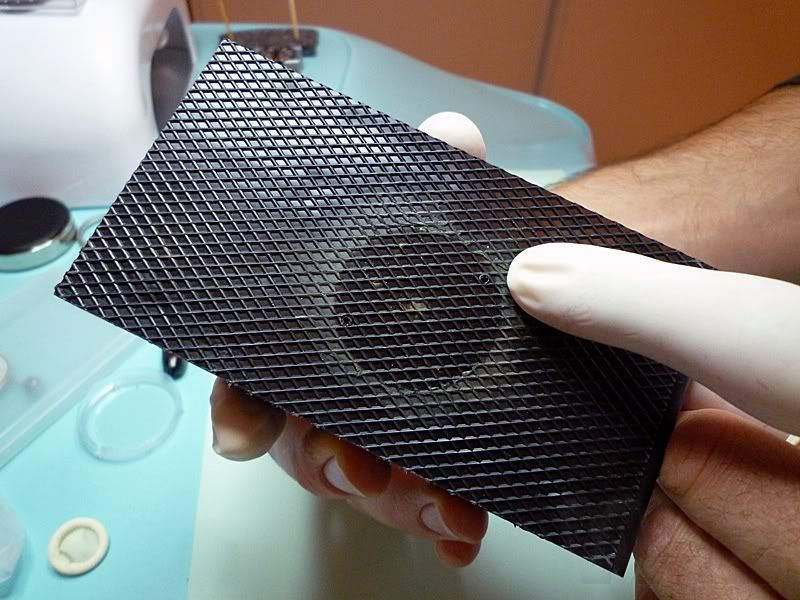

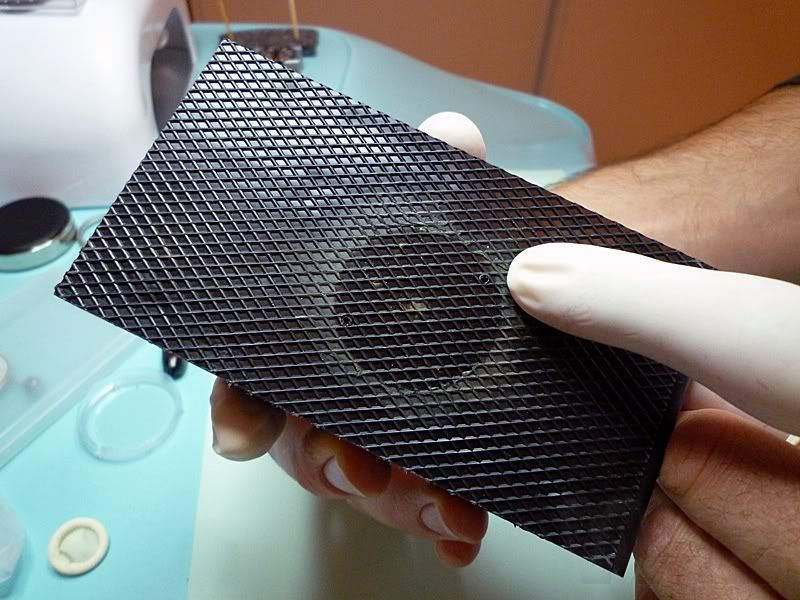

Please be carefull never to manipulate a dial with your naked fingers.

Store the top place in a safe place and fix the back plate on a stand. Here is mine it's, flat, made out of plastic, and there are 2 holes for

the dial's feet. The dial needs to stay perfectly flat so it doesn't bend.

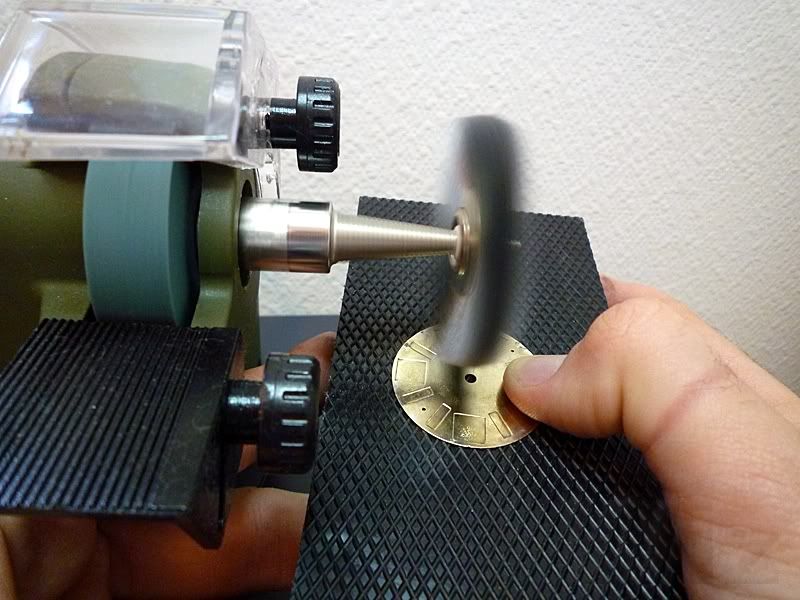

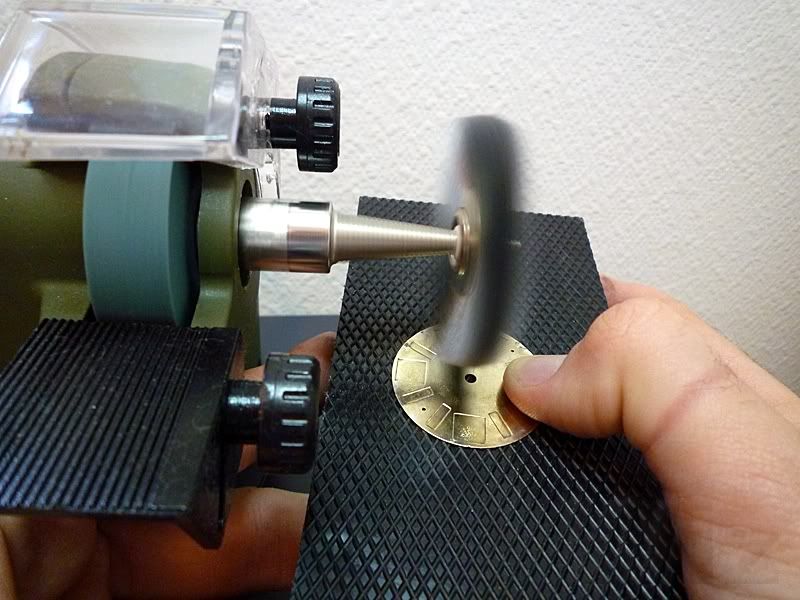

It's now time to remove the old lume and the glue from the backplate. The best thing would have been a sandblaster, but as I don't own one,

the next best thing is a ss brush on a dremel

The plate might heat when using the ss brush. If it starts heating too much, just stop and wait untill it's cool again.

Bench grinder with circular ss brush to make the finish uniform.

Now a quick polishing to be sure the finish really is uniform.

Polished back plate.

Now the thing is that we can't leave the plate polished because we'll paint it, and there is a chance the paint won't hold on a polished surface.

So again we need to take it under the ss brush.

Now that the plate is clean, we need to apply glossy white paint. This coating will allow the light from the lume to reflect,

and give the impression that it glows brigther.

Here is my homemade painting stand. A piece of sponge, 2 wood sticks, and rodico

Painting the dial with an airbrush.

You'll need 2 layers at least. Allow 30-40 minutes between each layer.

It's important to keep the plate horizontal while the paint dries.

Painting done.

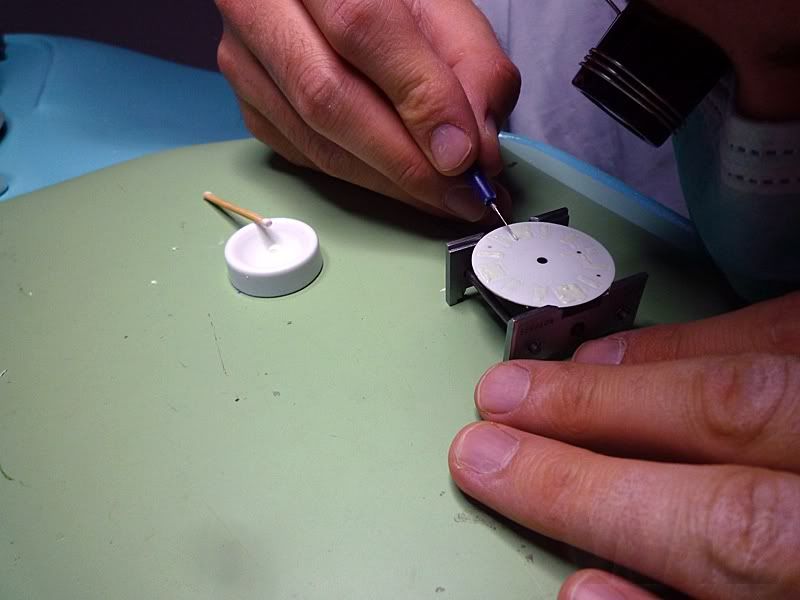

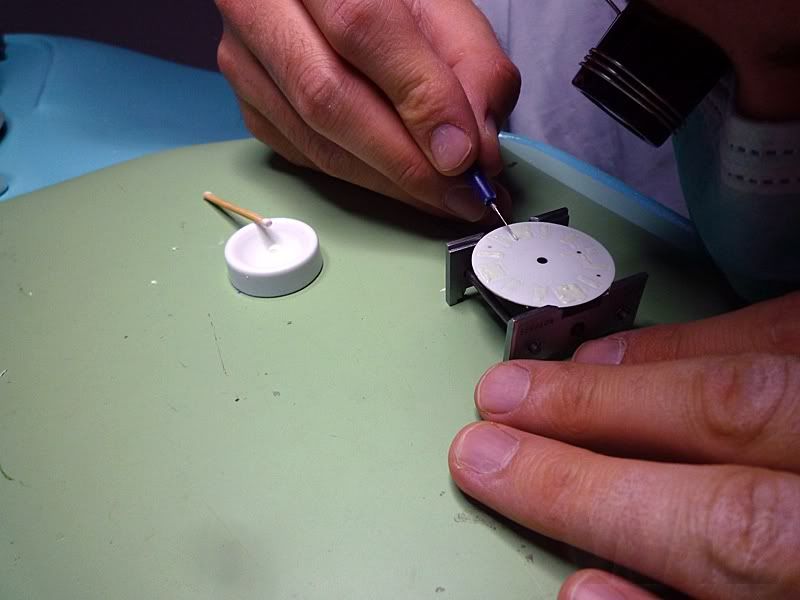

And now, the lume!

As always, I'll use w@tchlume pigments. 50% Gmax, 50% WG for the first layer, pure GMax for the second.

Now let the lume dry half way and glue the plates back together. Complete drying may take up to 24 hours depending on your binder.

Job done!

Comparison: Relumed dial with spray painted back plate on the left, relumed dial with regular ss plate on the left.

Today a little something about the basic of reluming: the sandwich dial, and a few tips to make it glow brigther. This is the perfect job

if you're begining, because you can't really screw up

A sandwich dial is a two-plate dial, the first plate being coated with luminous material and the second plate pierced through for the indexes

and numerals. So the first step is to separate out these 2 plates using a sharp blade.

Please be carefull never to manipulate a dial with your naked fingers.

Store the top place in a safe place and fix the back plate on a stand. Here is mine it's, flat, made out of plastic, and there are 2 holes for

the dial's feet. The dial needs to stay perfectly flat so it doesn't bend.

It's now time to remove the old lume and the glue from the backplate. The best thing would have been a sandblaster, but as I don't own one,

the next best thing is a ss brush on a dremel

The plate might heat when using the ss brush. If it starts heating too much, just stop and wait untill it's cool again.

Bench grinder with circular ss brush to make the finish uniform.

Now a quick polishing to be sure the finish really is uniform.

Polished back plate.

Now the thing is that we can't leave the plate polished because we'll paint it, and there is a chance the paint won't hold on a polished surface.

So again we need to take it under the ss brush.

Now that the plate is clean, we need to apply glossy white paint. This coating will allow the light from the lume to reflect,

and give the impression that it glows brigther.

Here is my homemade painting stand. A piece of sponge, 2 wood sticks, and rodico

Painting the dial with an airbrush.

You'll need 2 layers at least. Allow 30-40 minutes between each layer.

It's important to keep the plate horizontal while the paint dries.

Painting done.

And now, the lume!

As always, I'll use w@tchlume pigments. 50% Gmax, 50% WG for the first layer, pure GMax for the second.

Now let the lume dry half way and glue the plates back together. Complete drying may take up to 24 hours depending on your binder.

Job done!

Comparison: Relumed dial with spray painted back plate on the left, relumed dial with regular ss plate on the left.