This, have you made one or gotten a hold of something

Unfortunately not, haven't gotten ahold of one to see what it would take to make some of them.

This, have you made one or gotten a hold of something

Holy smokes, that's a breakthrough! KJ, is there nothing you can't do?Update - after working on a few more of these, I've discovered another Achilles heel in the design that can manifest whether the jumping hour click spring (JHCS) has broken or not.

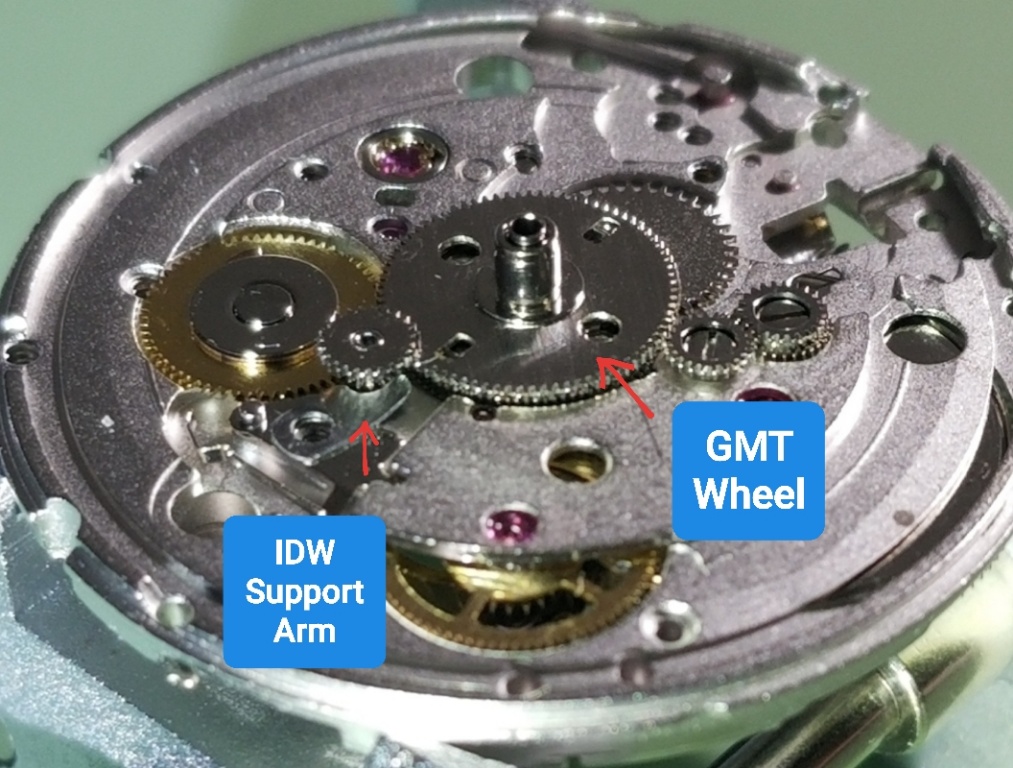

The intermediate date wheel (IDW) does not have a support arm anchoring it in position, like the 2836 one does. This can cause it to lift up slightly due to pressure on it from the date wheel driving wheel, often during a date change. When the IDW lifts up, it slips one or more teeth on the uppermost gold colored hour wheel, and the hour hand lags behind or stops until the IDW settles back into position and normal hour wheel rotation resumes.

I believe this potential for lifting of the IDW and gear slipping on the hour wheel increases when the two halves of the GMT wheel are glued together, because then there is more resistance on the IDW and it gives into this resistance by lifting up.

Here's a pic of a lifted IDW and then a normally situated one.

So I found that by making a support arm and sandwiching in under the date plate cover, you can prevent the IDW from lifting up, even after the GMT wheel has been glued. So far it seems to work.

.

OK so Auntie Em, it's a TWISTER!

Over a period of days I noticed a slow decay of amplitude after installing the support arm. It turns out the left side of the IDW support arm was imposing some pressure on the datewheel driving wheel which was being transferred to the IDW and then backwards through the whole drive train to the balance assembly. Like a gear dragging on debris or a pinion dragging in a dirty jewel, the movement was being slowed down and s/d was dropping. So I modified the support arm by amputating a finger and I believe I have corrected this issue. So far so good, finger crossed, lol. The benefit of the support arm is still achieved as the IDW doesn't budge upward even with some external lifting force applied.

You could introduce a service to fix/stabilize CHS movements! I know I'd definitely throw money at you if I could have a right proper Noob BLNRRunning perfectly for over a month now.

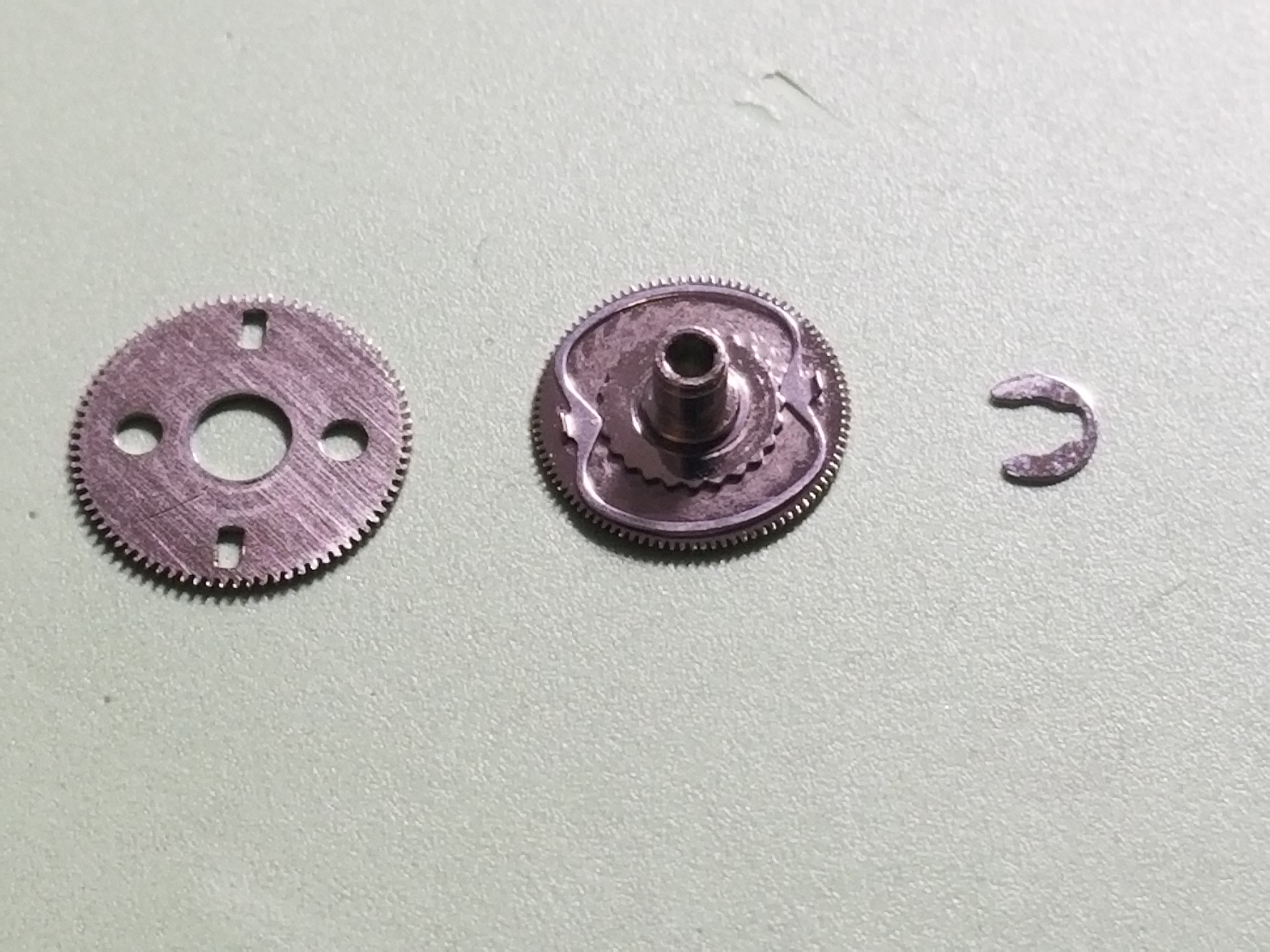

To all the expert here, is this the part where the weak spring that fail on us all the time?

The photos are from one of the movement seller, can be purchase as a part.. Seller do not have other photo of it, with my limited knowledge it looks like same, I wonder

The silver 3 piece part is the one that fails. How much does he was for it?

¥250 + 10 for PRC domestic shipping.

that's about USD 36+- ? Excluding international shipping. Not cheap for a small part, but if one is stuck with it and decline to go for movement swap this will be handy.

Fascinating, some good work gone on here, I hope this part is the way to go otherwise these watches are maybe to be avoided.

For me I seldom set the date and gmt function so would the Noob be a viable watch to own if I didn’t use these?

¥250 + 10 for PRC domestic shipping.

that's about USD 36+- ? Excluding international shipping. Not cheap for a small part, but if one is stuck with it and decline to go for movement swap this will be handy.