After some hard time trying to find the place to pressure test my CrPO, decided to build my own tester, as some other members before. I am using well known design originally from christopherwardforum.com with some modifications.

Modifications of original design:

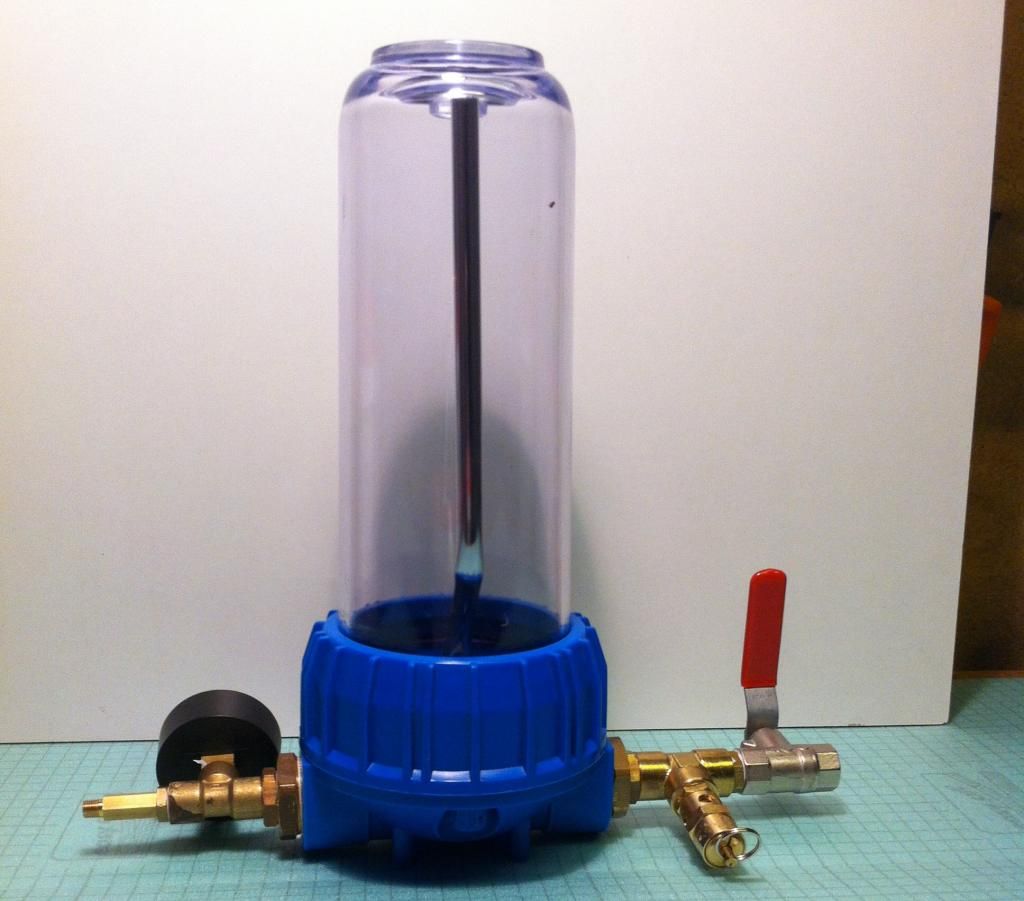

- Waterfilter housing rated to max operating pressure of 20 Bar for safety reason.

- Pressure gauge.

- Ball valve with longer handle for increased operating precision.

A – Parts:

1. Water filter housing rated to max operating pressure of 20 bar.

2. 2mm thick rubber sheet.

3. Pressure gauge.

4. Safety relief valve 8 bar.

5. Schrader air fill valve.

6. Ball valve.

7. Some fittings.

8. Rubber gaskets.

9. Chromed copper tubing 10mm.

10. Epoxy

11. Teflon tape

B – Assembly:

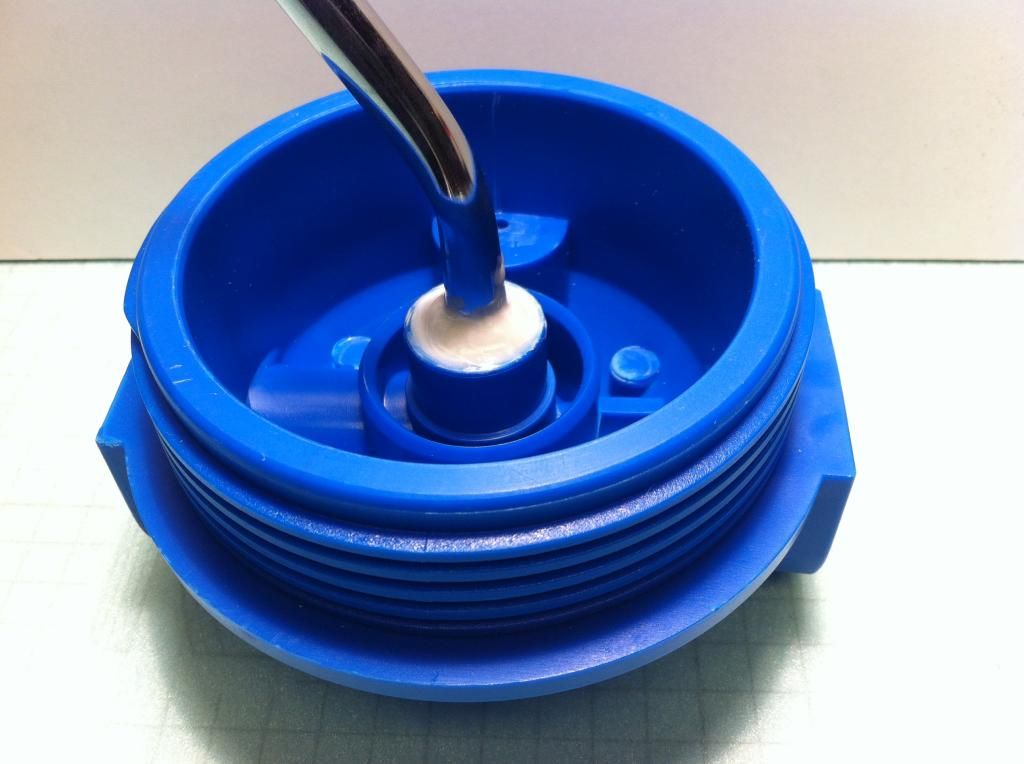

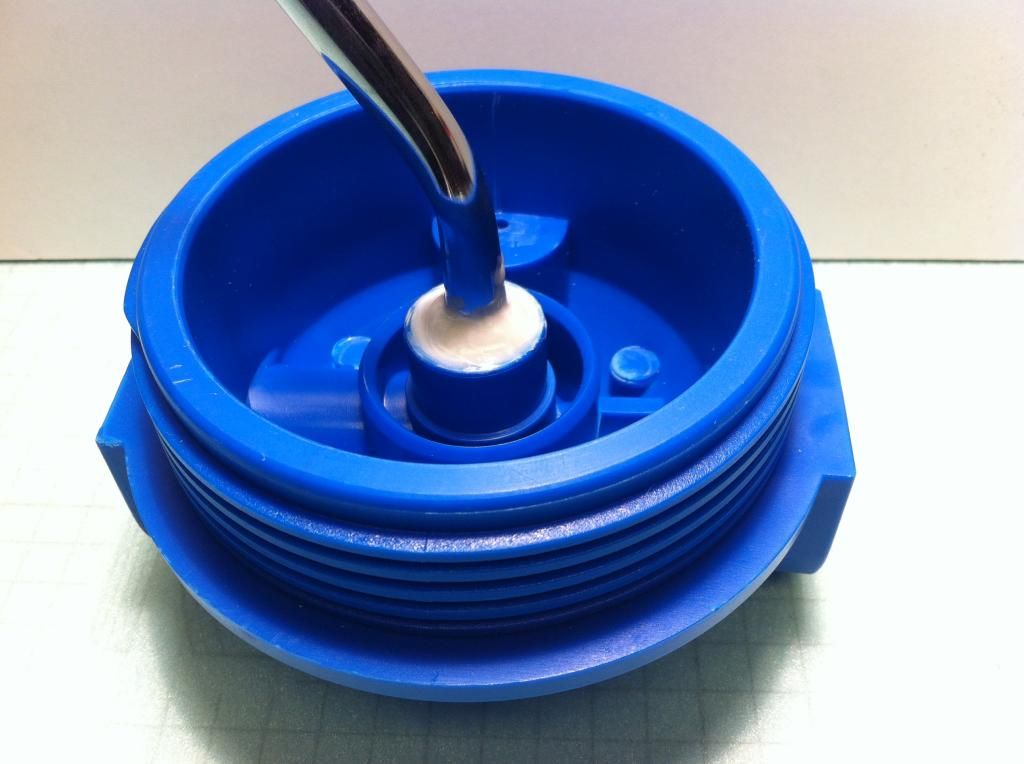

Tubing cut and bent.

Tubing installed in pressure chamber lid, using rubber gaskets and epoxy. Make sure that there is free air flow through tubing and outlet duct of the lid.

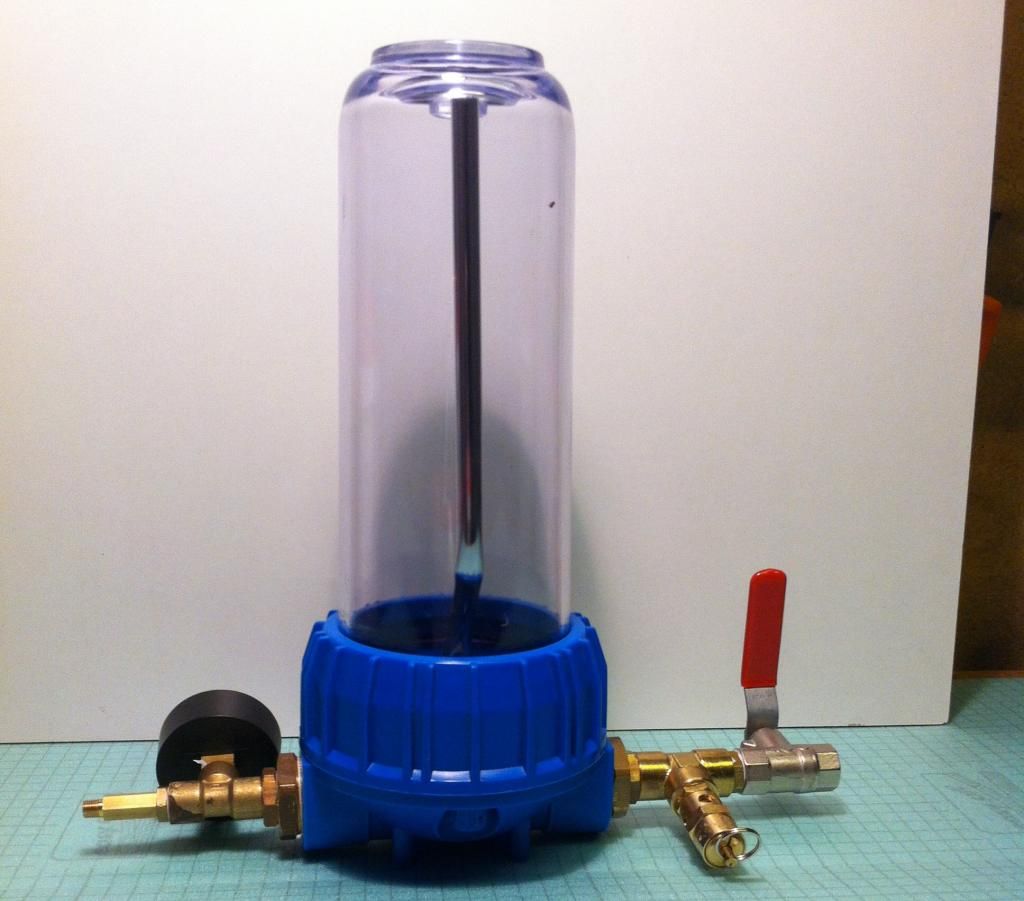

Gauge, ball valve, Schrader valve and safety relief valve installed.

Safety relief valve test. Unit pressurized to 8Bar.

Strap made of 2mm rubber. Piece of sharpened tubing used to punch 10mm holes.

C - PRESSURE TEST OF THE WATCH

Attach the watch to the tubing using rubber strap.

Fill the chamber partially with water.

Screw on and hand tighten the lid.

Pressurize the unit to 6 Bar using an air compressor or a pump.

Wait a couple of minutes to allow the internal pressure of the watch equalize with chamber pressure in case of leak.

Turn the unit upside down and start slowly relieving chamber pressure at the same time.

DO NOT DUMP THE PRESSURE as if the watch is not airtight the pressure difference between watch and chamber can blow off the crystal!!!

Look for the leak. Little air bubbles trapped under the bezel, inside the lug holes, or wherever, are going to expand as the pressure releases and will not fit there anymore. In other words, some bubbles are perfectly normal. An actual leak will appear as a steady stream of air bubbles.

In case of leak DO NOT STOP relieving chamber pressure and DO NOT LET the pressure go to zero (that is why I decided to install pressure gauge). Turn the unit back BEFORE chamber pressure hits zero.

If there is no leak, the watch is fine. Just let the pressure go to zero, than turn back the unit and remove watch.

Now, if you think that 6 Bar is not enough. Well... think again. 6 Bar means 60m depth. Watch tested at 6 Bar is good to go for every water activity you can possibly think,including recreational scuba diving. Forget the “dynamic pressure myth” stating that your movements in water will add several Bars of pressure to a watch. That is just an urban legend. To generate 1 Bar of dynamic pressure while swimming, your watch will have to move at the speed of about 15m/s or 54km/h and this will be the pressure at the watch surface “facing” water flow. Dynamic pressureat possible entry points (gaskets) will be much lower, if any. So the dynamic pressure your movements actually can cause is a very small force and will not limit your watch water resistance significantly.

For those with balls-to-brain ratio above average, still willing to test their watches at10-20 Bar using similar device:

Please! Keep in mind that 20 Bar is hell of a pressure. It’s 10 times more than your car tire!!!.

If something goes wrong, the air at 20 Bar pressure becoming within milliseconds 20 times more air carrying some high velocity plastic pieces WILL hurt you!!!

Modifications of original design:

- Waterfilter housing rated to max operating pressure of 20 Bar for safety reason.

- Pressure gauge.

- Ball valve with longer handle for increased operating precision.

A – Parts:

1. Water filter housing rated to max operating pressure of 20 bar.

2. 2mm thick rubber sheet.

3. Pressure gauge.

4. Safety relief valve 8 bar.

5. Schrader air fill valve.

6. Ball valve.

7. Some fittings.

8. Rubber gaskets.

9. Chromed copper tubing 10mm.

10. Epoxy

11. Teflon tape

B – Assembly:

Tubing cut and bent.

Tubing installed in pressure chamber lid, using rubber gaskets and epoxy. Make sure that there is free air flow through tubing and outlet duct of the lid.

Gauge, ball valve, Schrader valve and safety relief valve installed.

Safety relief valve test. Unit pressurized to 8Bar.

Strap made of 2mm rubber. Piece of sharpened tubing used to punch 10mm holes.

C - PRESSURE TEST OF THE WATCH

Attach the watch to the tubing using rubber strap.

Fill the chamber partially with water.

Screw on and hand tighten the lid.

Pressurize the unit to 6 Bar using an air compressor or a pump.

Wait a couple of minutes to allow the internal pressure of the watch equalize with chamber pressure in case of leak.

Turn the unit upside down and start slowly relieving chamber pressure at the same time.

DO NOT DUMP THE PRESSURE as if the watch is not airtight the pressure difference between watch and chamber can blow off the crystal!!!

Look for the leak. Little air bubbles trapped under the bezel, inside the lug holes, or wherever, are going to expand as the pressure releases and will not fit there anymore. In other words, some bubbles are perfectly normal. An actual leak will appear as a steady stream of air bubbles.

In case of leak DO NOT STOP relieving chamber pressure and DO NOT LET the pressure go to zero (that is why I decided to install pressure gauge). Turn the unit back BEFORE chamber pressure hits zero.

If there is no leak, the watch is fine. Just let the pressure go to zero, than turn back the unit and remove watch.

Now, if you think that 6 Bar is not enough. Well... think again. 6 Bar means 60m depth. Watch tested at 6 Bar is good to go for every water activity you can possibly think,including recreational scuba diving. Forget the “dynamic pressure myth” stating that your movements in water will add several Bars of pressure to a watch. That is just an urban legend. To generate 1 Bar of dynamic pressure while swimming, your watch will have to move at the speed of about 15m/s or 54km/h and this will be the pressure at the watch surface “facing” water flow. Dynamic pressureat possible entry points (gaskets) will be much lower, if any. So the dynamic pressure your movements actually can cause is a very small force and will not limit your watch water resistance significantly.

For those with balls-to-brain ratio above average, still willing to test their watches at10-20 Bar using similar device:

Please! Keep in mind that 20 Bar is hell of a pressure. It’s 10 times more than your car tire!!!.

If something goes wrong, the air at 20 Bar pressure becoming within milliseconds 20 times more air carrying some high velocity plastic pieces WILL hurt you!!!