- 18/1/11

- 19,846

- 424

- 83

KW PAM382 Bronze material – Official Chemical Analysis

We all would like to know the chemical composition of PAM 382 reps bronze material. As you surely know I'm trying some months ago to get an Official chemical analysis of these materials.

Therefore in order to get the answer I contacted some months ago with KW owner Mehmet and Puretime’s Angus asking them for case samples of KW and ZFac PAM 382 respectively. In parallel I contacted with some official Spanish laboratories trying to get a free, but very reliable, chemical analysis of the samples.

KW’s Mehmet was immediately willing to send me the sample when the Laboratory was ready. But it was not able to get ZFac sample, because Puretime told me that he had already sent a sample from ZFac to another member (Pete M) in order to make the same official analysis as I wanted.

In August 2014 I got, through a good friend of mine (an engineer colleague), the possibility of a free chemical analysis from a first class Official Spanish Laboratory where he is working. I ask Mehmet for the sample and in some days I received the sample of KW PAM 382 case from Kuvarsit.

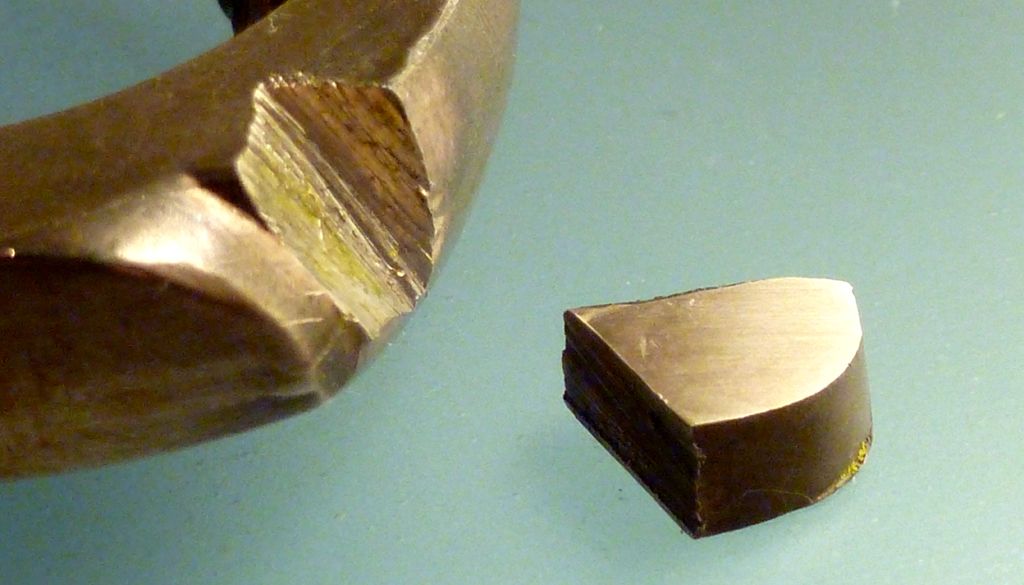

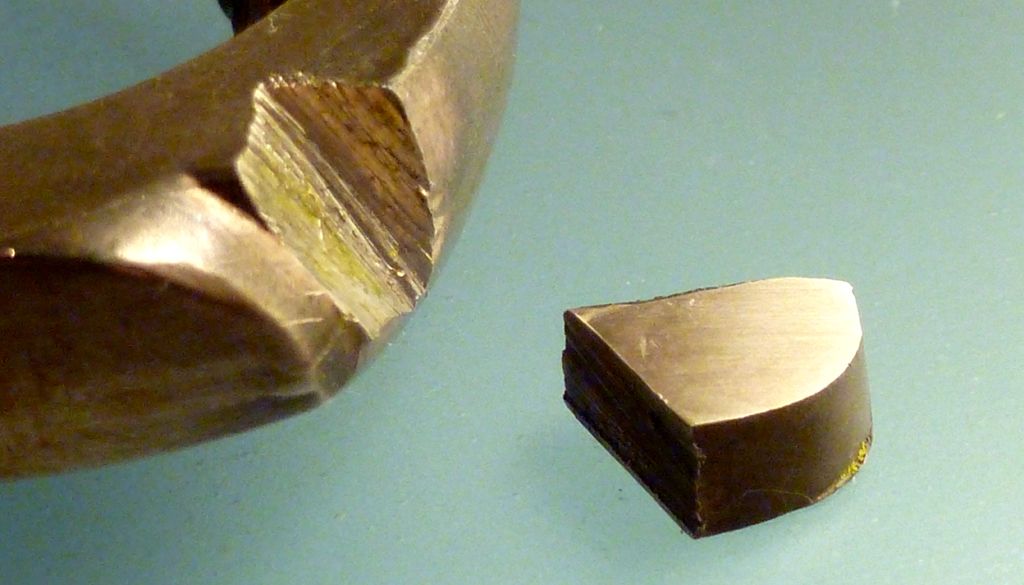

The sample was an unfinished KW PAM 382 case before machining, taken directly from the current production of the factory, as I asked to Mehmet. You can see the sample received in below pic.

SAMPLE OF KW PAM 382 CASE BEFORE MACHINING

At that moment my friend was just starting his summer vacation and I had to wait until the end of September to send him the sample.

In October my friend got the sample to start the chemical analysis of the bronze. I really have the results from about 20 October, but I have not found time to prepare this thread until this moment.

TECHNIQUE OF ANALYSIS

I wanted to get a chemical analysis by an Atomic Absorption Spectrophotometer, because that was the analysis method I was used to using when I worked in metal alloys. But my friend told me he liked to use a more modern system.

It was used one of the most modern, reliable and precise techniques available at this moment: Scanning Electron Microscopy (SEM)

See below link for more info:

http://serc.carleton.edu/research_education/geochemsheets/techniques/SEM.html

http://www.labtesting.com/services/materials-testing/metallurgical-testing/sem-analysis/

To get an idea about the sophistication of this method, you should know that the cost of the equipment to make this kind of analysis is about 3 million Euros.

Of course SEM is a very reliable method of chemical analysis and there is no doubt about the precision of the results.

PREPARATION OF THE SAMPLE

It was necessary to cut a part of the case to make the analysis. The Laboratory cut a lug of the case to prepare the final sample to be analyzed. This lug was slightly polished to be introduced in the SEM device. You can see in below pics the lug detached and prepared.

SAMPLE OF KW PAM 382 CASE WITH THE LUG DETACHED AND PREPARED TO BE INTRODUCED IN THE SEM ELECTRON MICROSCOPE

THE RESULTS

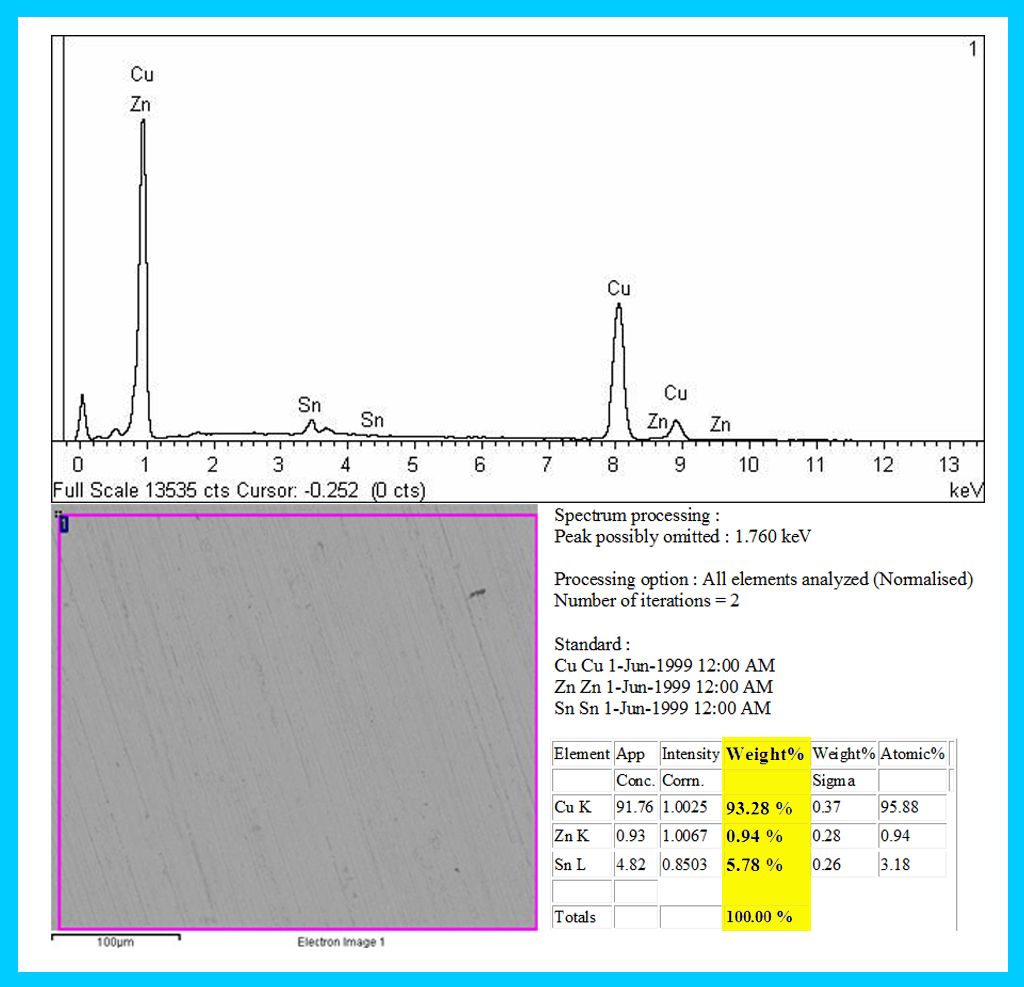

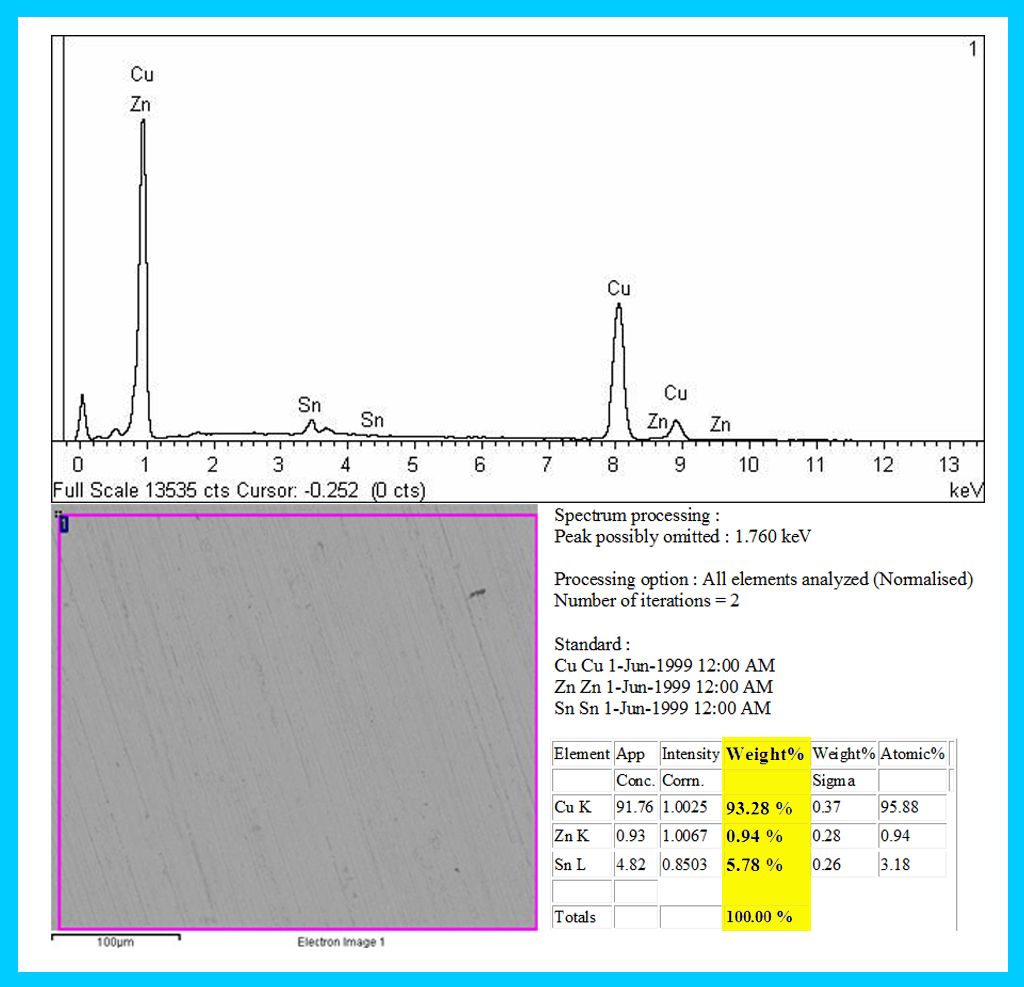

In the figure below showed you can see the results of the chemical analysis extracted from the SEM Electron Microscope.

The square marked in yellow is the chemical composition in Weight%, which is the composition we were looking for.

CONCLUSIONS

As we can see from above Figure the bronze of the sample KW PAM 382 studied has a chemical composition about as follows:

Cu (Copper)- 93%

Sn (Tin)- 6%

Zn (Zinc)- 1%

Therefore, we can state without doubts that KW PAM 382 material is a TRUE BRONZE. KW material is not at all a Brass, as many people have commented and speculated.

I have knowledge about this matter because I have worked many years (many time ago) producing Bronzes and Brass and another alloys.

KW bronze is not exactly a CuSn8 like gen, but it is very close to this material.

KW material is actually a CuSn6Zn1 bronze. It is really very similar to CuSn8 and the colour and properties are almost identical to gen bronze.

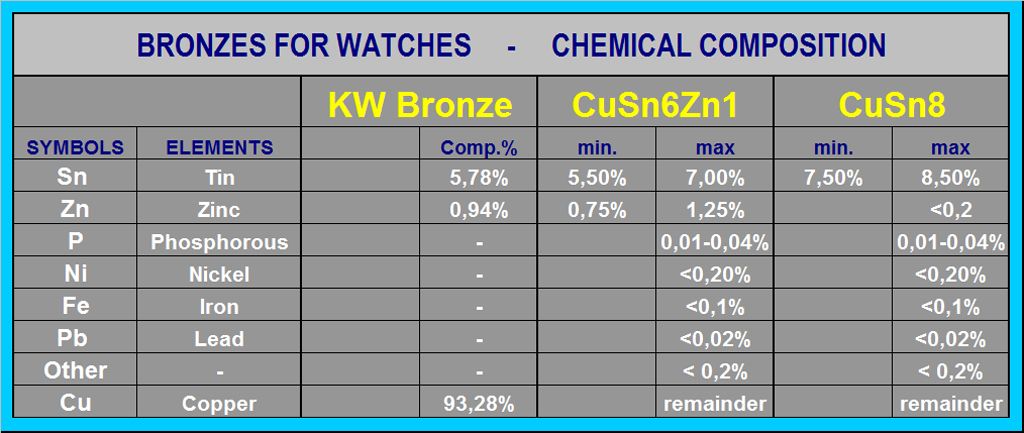

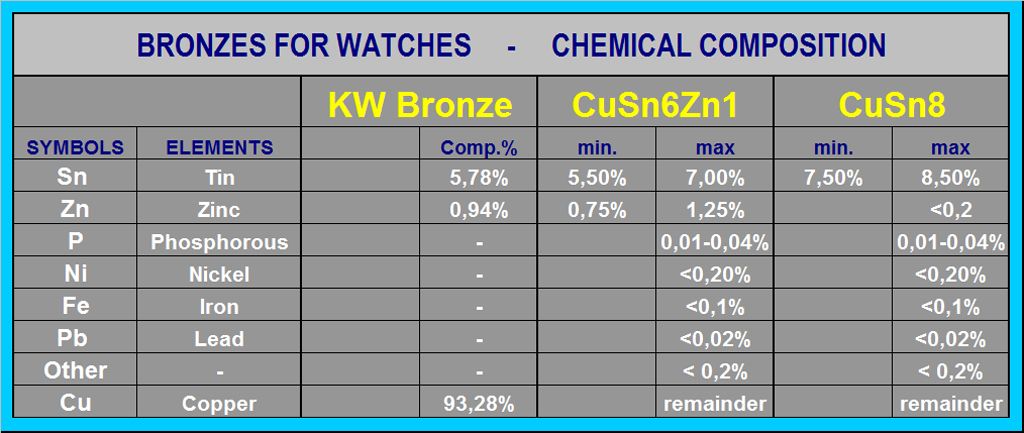

In below Figure you can see the differences between a gen bronze CuSn8, CuSn6Zn1 and KW bronze.

As you can see differences are a little less content of SN, but a bit more of Zn (less than 1%). Differences between KW bronze and CuSn6Zn1 are almost non existent. Indeed both are the same material.

In practice and bearing in mind the application in a watch case, we can say the materials are actually equivalents. In other words: We can expect from KW bronze the same properties and behaviour regarding appearance and patina creation that we will get from Gen bronze PAM 382

Besides, as you can see from the chemical analysis, KW bronze has no impurities. That means that this alloy is made from almost pure metals and using no recycling materials. Therefore, KW bronze used in KW PAM 382 is a very good quality alloy.

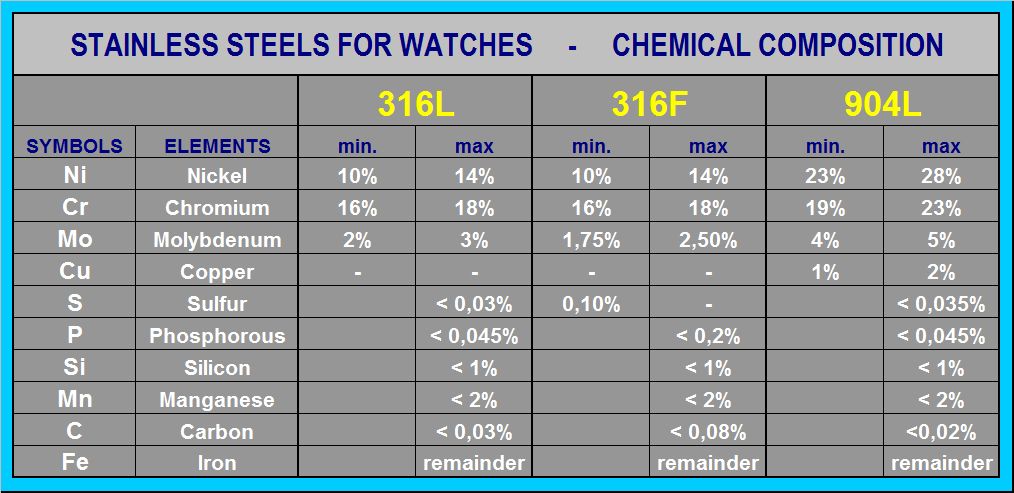

To get a better idea of above statements, you should know that we are using Stainless Steels for super reps much more different from the gen SS than the differences observed between CuSn8 and CuSn6Zn1.

To illustrate this matter read my thread about Stainless Steels in watches:

SS 316L vs. 316F vs. 904L- The final VERDICT- A technical study

http://forum.replica-watch.info/vb/showthread.php?t=82263

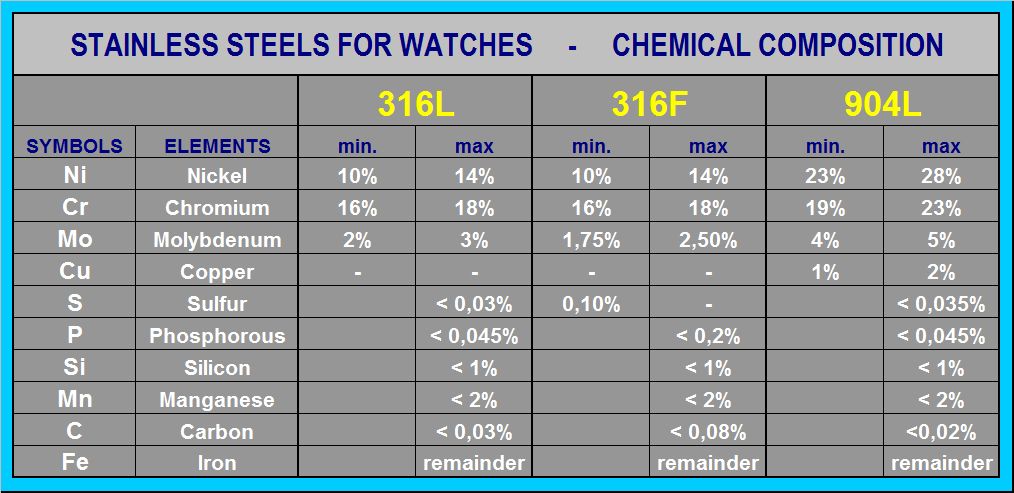

As you can see in above thread the differences between SS 316L and 316F and mainly with SS 904L used by Rolex are much bigger than differences found between CuSn8 and CuSn6Zn1.

See below figure where the differences of three SS are showed and compare these differences with the bronze table differences.

Despite above showed differences of composition, rep makers are using SS 316L in some watches made of SS 316F and vice versa. And makers are always using either PAM 316L or PAM 316F to make the super reps of Rolex whose gen watches are made of a very different SS 904L as you can see in above table.

Being the KW sample unfinished and not machined, polished or brushed I was not able to make a reliable comparison between the KW sample and the bronze of my KK PAM 382 V1 from May 2014. But cleaning and brushing a little the surface of the sample, and using my experience in these alloys, I would say that my KW PAM 382 V1 and the sample are made of the same material (it is almost impossible to get a reliable comparison by pics, because the finish was not the same and some pics seem identical and other different, just a direct visual comparison can show the materials are very close in appearance)

Unfortunately we have not the same analysis of ZFac bronze. Some people is saying, and some reviewers (remember NCcheff reviews http://www.repgeek.com/showthread.php?t=234018 & http://forum.replica-watch.info/vb/showthread.php?t=187564 ) that ZFac material is more reddish than KW bronze. From the comparison pics I have seen, I have to agree with these observations. That just means that ZFac material, most likely, has higher content of Copper (Cu) and less Tin (Sn) and other elements, what goes against the quality and properties of the bronze alloy and detaches Zfac bronze from the gen. But that is just a speculation from pics and comments.

Anyway, forget the colour on the pics, the false comparisons, the patinas, the speculations… Now we know what we are actually getting when we buy a KW PAM 382: a true bronze CuSn6Zn1 of very high quality, from which we can expect the same colour, properties and behaviour than a gen CuSn8 bronze

*************************************************

I would like taking this opportunity to say many thanks to KW’s owner Mehmet for being so kind (and even brave, why not to say it) sending me the sample of the KW case to make the analysis, and congratulations to KW for the good results of this chemical analysis.

Thanks for reading

ALE

We all would like to know the chemical composition of PAM 382 reps bronze material. As you surely know I'm trying some months ago to get an Official chemical analysis of these materials.

Therefore in order to get the answer I contacted some months ago with KW owner Mehmet and Puretime’s Angus asking them for case samples of KW and ZFac PAM 382 respectively. In parallel I contacted with some official Spanish laboratories trying to get a free, but very reliable, chemical analysis of the samples.

KW’s Mehmet was immediately willing to send me the sample when the Laboratory was ready. But it was not able to get ZFac sample, because Puretime told me that he had already sent a sample from ZFac to another member (Pete M) in order to make the same official analysis as I wanted.

In August 2014 I got, through a good friend of mine (an engineer colleague), the possibility of a free chemical analysis from a first class Official Spanish Laboratory where he is working. I ask Mehmet for the sample and in some days I received the sample of KW PAM 382 case from Kuvarsit.

The sample was an unfinished KW PAM 382 case before machining, taken directly from the current production of the factory, as I asked to Mehmet. You can see the sample received in below pic.

SAMPLE OF KW PAM 382 CASE BEFORE MACHINING

At that moment my friend was just starting his summer vacation and I had to wait until the end of September to send him the sample.

In October my friend got the sample to start the chemical analysis of the bronze. I really have the results from about 20 October, but I have not found time to prepare this thread until this moment.

TECHNIQUE OF ANALYSIS

I wanted to get a chemical analysis by an Atomic Absorption Spectrophotometer, because that was the analysis method I was used to using when I worked in metal alloys. But my friend told me he liked to use a more modern system.

It was used one of the most modern, reliable and precise techniques available at this moment: Scanning Electron Microscopy (SEM)

See below link for more info:

http://serc.carleton.edu/research_education/geochemsheets/techniques/SEM.html

http://www.labtesting.com/services/materials-testing/metallurgical-testing/sem-analysis/

To get an idea about the sophistication of this method, you should know that the cost of the equipment to make this kind of analysis is about 3 million Euros.

Of course SEM is a very reliable method of chemical analysis and there is no doubt about the precision of the results.

PREPARATION OF THE SAMPLE

It was necessary to cut a part of the case to make the analysis. The Laboratory cut a lug of the case to prepare the final sample to be analyzed. This lug was slightly polished to be introduced in the SEM device. You can see in below pics the lug detached and prepared.

SAMPLE OF KW PAM 382 CASE WITH THE LUG DETACHED AND PREPARED TO BE INTRODUCED IN THE SEM ELECTRON MICROSCOPE

THE RESULTS

In the figure below showed you can see the results of the chemical analysis extracted from the SEM Electron Microscope.

The square marked in yellow is the chemical composition in Weight%, which is the composition we were looking for.

CONCLUSIONS

As we can see from above Figure the bronze of the sample KW PAM 382 studied has a chemical composition about as follows:

Cu (Copper)- 93%

Sn (Tin)- 6%

Zn (Zinc)- 1%

Therefore, we can state without doubts that KW PAM 382 material is a TRUE BRONZE. KW material is not at all a Brass, as many people have commented and speculated.

I have knowledge about this matter because I have worked many years (many time ago) producing Bronzes and Brass and another alloys.

KW bronze is not exactly a CuSn8 like gen, but it is very close to this material.

KW material is actually a CuSn6Zn1 bronze. It is really very similar to CuSn8 and the colour and properties are almost identical to gen bronze.

In below Figure you can see the differences between a gen bronze CuSn8, CuSn6Zn1 and KW bronze.

As you can see differences are a little less content of SN, but a bit more of Zn (less than 1%). Differences between KW bronze and CuSn6Zn1 are almost non existent. Indeed both are the same material.

In practice and bearing in mind the application in a watch case, we can say the materials are actually equivalents. In other words: We can expect from KW bronze the same properties and behaviour regarding appearance and patina creation that we will get from Gen bronze PAM 382

Besides, as you can see from the chemical analysis, KW bronze has no impurities. That means that this alloy is made from almost pure metals and using no recycling materials. Therefore, KW bronze used in KW PAM 382 is a very good quality alloy.

To get a better idea of above statements, you should know that we are using Stainless Steels for super reps much more different from the gen SS than the differences observed between CuSn8 and CuSn6Zn1.

To illustrate this matter read my thread about Stainless Steels in watches:

SS 316L vs. 316F vs. 904L- The final VERDICT- A technical study

http://forum.replica-watch.info/vb/showthread.php?t=82263

As you can see in above thread the differences between SS 316L and 316F and mainly with SS 904L used by Rolex are much bigger than differences found between CuSn8 and CuSn6Zn1.

See below figure where the differences of three SS are showed and compare these differences with the bronze table differences.

Despite above showed differences of composition, rep makers are using SS 316L in some watches made of SS 316F and vice versa. And makers are always using either PAM 316L or PAM 316F to make the super reps of Rolex whose gen watches are made of a very different SS 904L as you can see in above table.

Being the KW sample unfinished and not machined, polished or brushed I was not able to make a reliable comparison between the KW sample and the bronze of my KK PAM 382 V1 from May 2014. But cleaning and brushing a little the surface of the sample, and using my experience in these alloys, I would say that my KW PAM 382 V1 and the sample are made of the same material (it is almost impossible to get a reliable comparison by pics, because the finish was not the same and some pics seem identical and other different, just a direct visual comparison can show the materials are very close in appearance)

Unfortunately we have not the same analysis of ZFac bronze. Some people is saying, and some reviewers (remember NCcheff reviews http://www.repgeek.com/showthread.php?t=234018 & http://forum.replica-watch.info/vb/showthread.php?t=187564 ) that ZFac material is more reddish than KW bronze. From the comparison pics I have seen, I have to agree with these observations. That just means that ZFac material, most likely, has higher content of Copper (Cu) and less Tin (Sn) and other elements, what goes against the quality and properties of the bronze alloy and detaches Zfac bronze from the gen. But that is just a speculation from pics and comments.

Anyway, forget the colour on the pics, the false comparisons, the patinas, the speculations… Now we know what we are actually getting when we buy a KW PAM 382: a true bronze CuSn6Zn1 of very high quality, from which we can expect the same colour, properties and behaviour than a gen CuSn8 bronze

*************************************************

I would like taking this opportunity to say many thanks to KW’s owner Mehmet for being so kind (and even brave, why not to say it) sending me the sample of the KW case to make the analysis, and congratulations to KW for the good results of this chemical analysis.

Thanks for reading

ALE