DISCLAIMER: I am posting this procedure as an explanation of how I created my own tester. This device operates under high pressures and can be dangerous if manufactured or used improperly. Always wear eye protection while using any pressurized device. I am in no way responsible for any damage or injury that may result from the construction or use of any device not created by myself.

Ok, now that that is over with on to the tutorial, sorry for the crappy pictures.

The shopping list:

One wide mouth Nalgene bottle: $15 in college bookstore, $9 here: http://www.nalgene-outdoor.com/store/detail.aspx?ID=53

Be sure you get an actual Nalgene brand, Made in the USA bottle. These are made out of a shatter proof polycarbonate that will withstand the required pressure. It also has a lid design that does not require any additional seals.

One bicycle inner tube: $3.95

Cut a three inch circle out of the inner tube with the valve directly in the center. After trimming the valve wash the rubber thoroughly. As it comes the rubber has a coating on it that will keep the adhesive from sticking.

One foot operated bicycle pump with gauge: $10

Be sure that the pump has the type of filler attachment that locks on to the valve stem. An integrated gauge is also very helpful.

The Procedure:

1.) Drill a 5/16" hole through the center of the lid. The lid already has a dimple in the top center which makes it very easy to properly locate the hole.

2.) Using a silicone adhesive sealant (Not my favorite but it seals well and dries fairly quickly) glue the valve to the inside of the lid. The rubber circle has to stay inside the ring that sticks out from the lid to seal it to the canister. Its hard to see on the picture but is obvious when you have the lid. As a helpful tip, i used the top of an aerosol can to apply even pressure to the rubber valve while the adhesive was drying. If you can't find one the right size, the top to a small can of RemOil gun lubricant is the perfect size to fit within the lip on the lid and hold the valve in place.

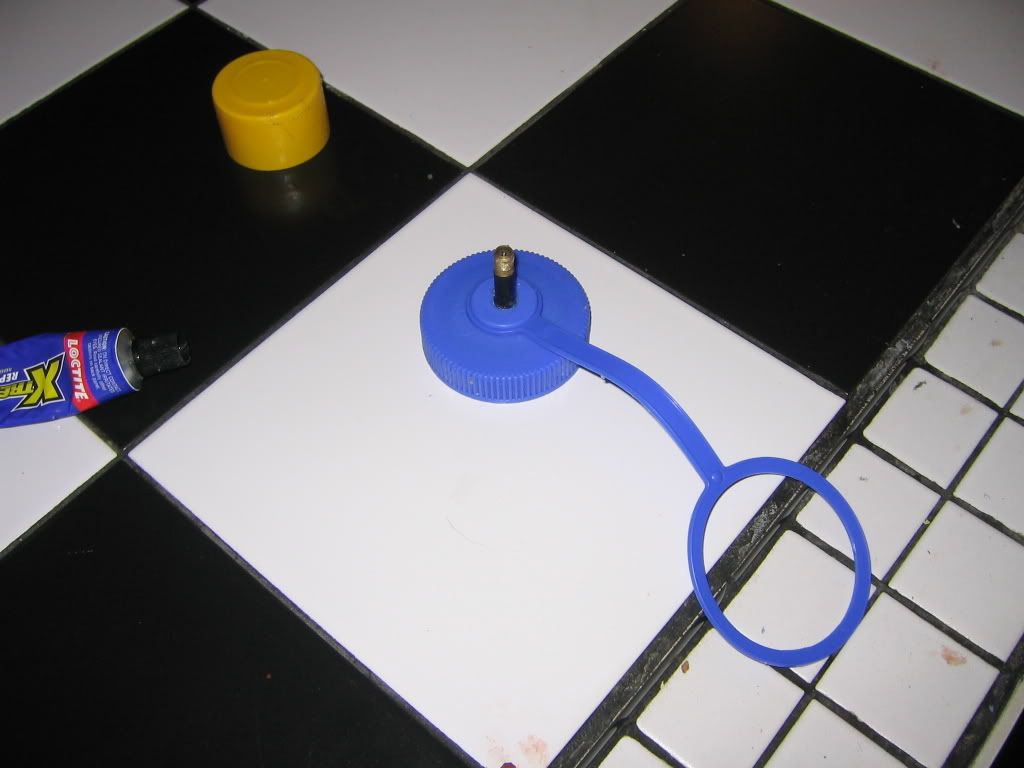

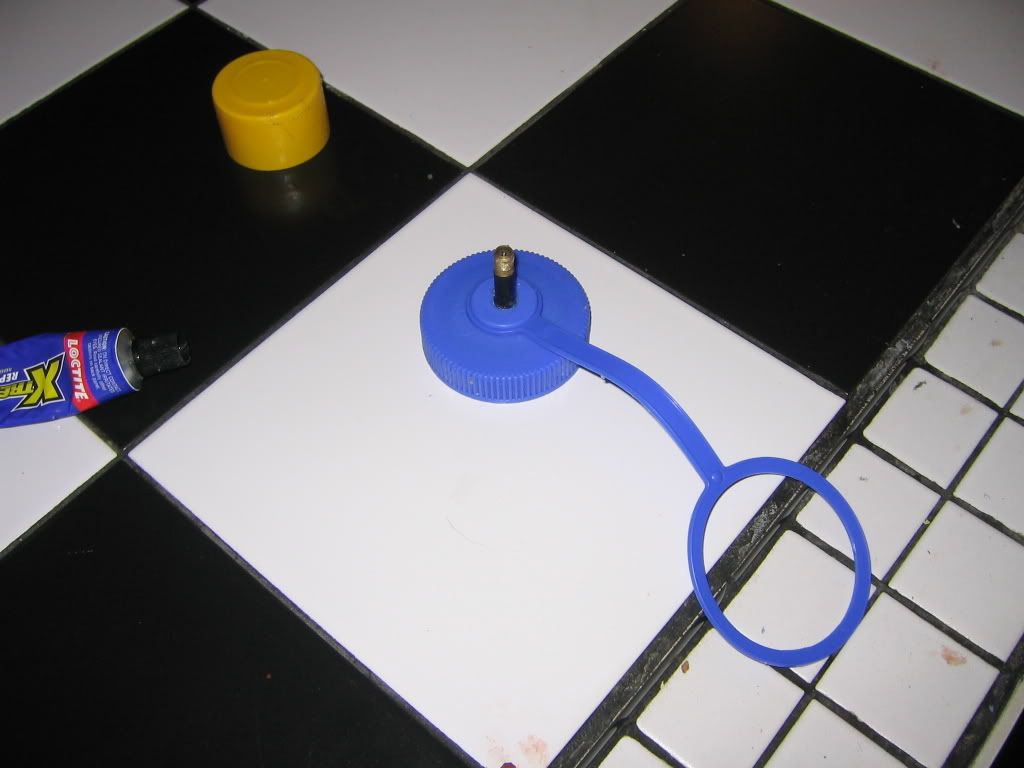

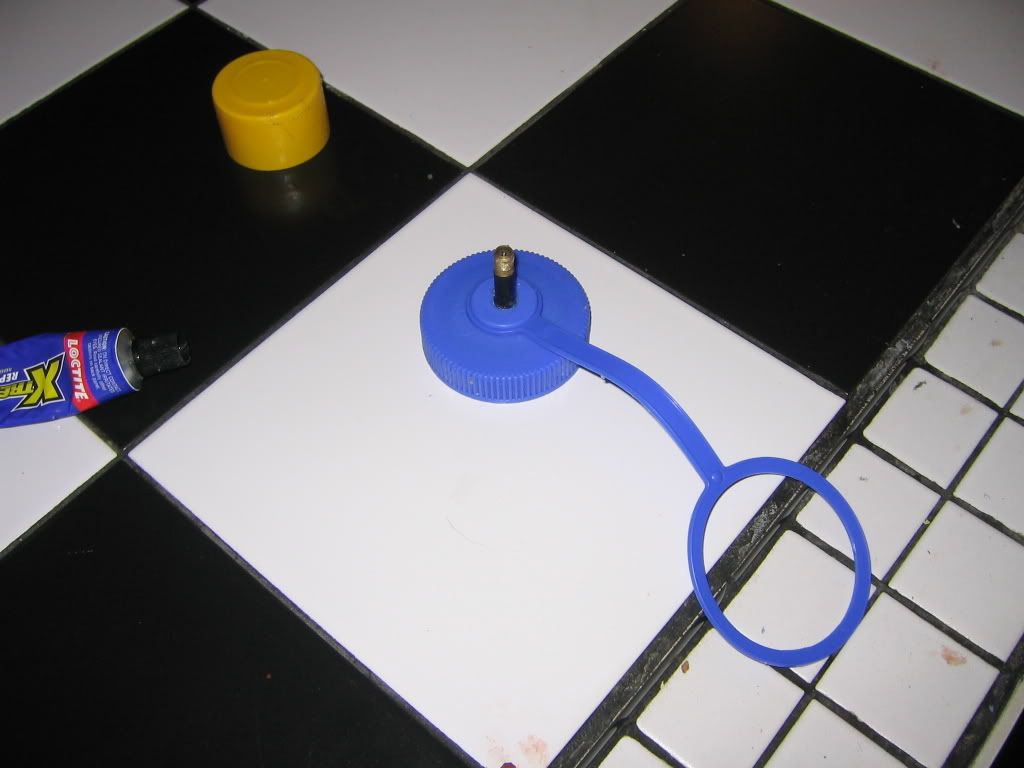

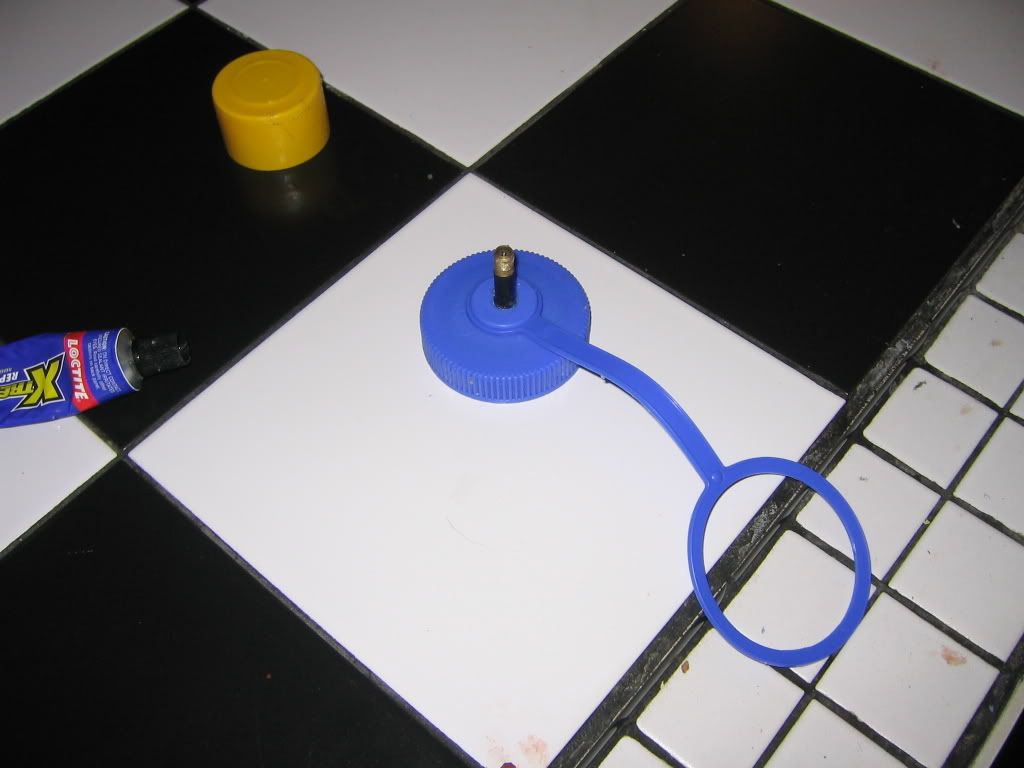

The finished lid should look like this when it is done curing.

Now for the testing procedure:

1.) Fill the bottle with about 400 CC of water.

2.) Select your test subject, in this case an MBW DRSD

3.) Attach a length of scotch tape through one of the spring bars, this is how you will hang the watch in the canister.

4.) Tape the watch so it hangs in about the middle of the canister, above the level of the water. Tape the watch to the mouth of the canister, this way it will be easier to retrieve. Keep the tape slightly below the very top of the mouth because the lid seals to the inside top surface.

5.) Next tightly close the lid on the canister, then attach the pump to the valve stem. Hold the stem while you put the pump on. Too much downward pressure can cause the valve to come loose.

6.) Pump up the canister while listening for leaks. As the pressure increases the lid will become slightly domed. As this slightly changes the shape of the sealing surface, it is necessary to tweak the lid tighter a few times while increasing the pressure. A very minor tightening will quickly re-seal the lid. I pressurized this test to 85 PSI, which is about 5.8 ATM.

7.) Allow the watch to sit pressurized for a few minutes in order for it to equalize, if it is going to. Keep an eye on the pressure, it may need a pump or two to maintain pressure depending on how well everything is sealed up. In this test, the canister held 85 PSI for five minutes while i left to run an errand.

8.) After waiting, remove the pump connector from the valve. Then use the end of a ballpoint pen, the kind with a retractable tip, with tip retracted to slowly release pressure. While releasing pressure tip the canister on its side so the watch is submerged. Continue to slowly release the pressure in the canister. The idea is to watch for a steady stream of bubbles that would indicate a leak.

In this picture I had a small bubble come from under the bezel, keep in mind that almost six times as much air that is normally under the bezel is now inside that space. As this air expands it will show up as bubbles, this does not indicate a leak. A leak will be an obvious steady stream, imagine 5 times the air volume of the inside of the watch case escaping. If you have a leak, you will know it.

9.) As the air in the canister is almost released tip the canister back up while still de-pressurizing until no pressure remains. Do not release all of the pressure with the watch still submerged, if you have a leak, this will allow water in.

Thats all there is to it, this watch passed as you can see by the picture of the test. The watch has been upgraded with a Clark superdome, and all seals have been checked and greased. A gen crown and tube are in the works as soon as I can locate the proper tap for the case hole. As a side note, if anyone has a tap to lend, I would greatly appreciate it.

If anyone has any questions about the construction, or testing procedure feel free to PM me.

I hope this has been helpful,

-Mike

Ok, now that that is over with on to the tutorial, sorry for the crappy pictures.

The shopping list:

One wide mouth Nalgene bottle: $15 in college bookstore, $9 here: http://www.nalgene-outdoor.com/store/detail.aspx?ID=53

Be sure you get an actual Nalgene brand, Made in the USA bottle. These are made out of a shatter proof polycarbonate that will withstand the required pressure. It also has a lid design that does not require any additional seals.

One bicycle inner tube: $3.95

Cut a three inch circle out of the inner tube with the valve directly in the center. After trimming the valve wash the rubber thoroughly. As it comes the rubber has a coating on it that will keep the adhesive from sticking.

One foot operated bicycle pump with gauge: $10

Be sure that the pump has the type of filler attachment that locks on to the valve stem. An integrated gauge is also very helpful.

The Procedure:

1.) Drill a 5/16" hole through the center of the lid. The lid already has a dimple in the top center which makes it very easy to properly locate the hole.

2.) Using a silicone adhesive sealant (Not my favorite but it seals well and dries fairly quickly) glue the valve to the inside of the lid. The rubber circle has to stay inside the ring that sticks out from the lid to seal it to the canister. Its hard to see on the picture but is obvious when you have the lid. As a helpful tip, i used the top of an aerosol can to apply even pressure to the rubber valve while the adhesive was drying. If you can't find one the right size, the top to a small can of RemOil gun lubricant is the perfect size to fit within the lip on the lid and hold the valve in place.

The finished lid should look like this when it is done curing.

Now for the testing procedure:

1.) Fill the bottle with about 400 CC of water.

2.) Select your test subject, in this case an MBW DRSD

3.) Attach a length of scotch tape through one of the spring bars, this is how you will hang the watch in the canister.

4.) Tape the watch so it hangs in about the middle of the canister, above the level of the water. Tape the watch to the mouth of the canister, this way it will be easier to retrieve. Keep the tape slightly below the very top of the mouth because the lid seals to the inside top surface.

5.) Next tightly close the lid on the canister, then attach the pump to the valve stem. Hold the stem while you put the pump on. Too much downward pressure can cause the valve to come loose.

6.) Pump up the canister while listening for leaks. As the pressure increases the lid will become slightly domed. As this slightly changes the shape of the sealing surface, it is necessary to tweak the lid tighter a few times while increasing the pressure. A very minor tightening will quickly re-seal the lid. I pressurized this test to 85 PSI, which is about 5.8 ATM.

7.) Allow the watch to sit pressurized for a few minutes in order for it to equalize, if it is going to. Keep an eye on the pressure, it may need a pump or two to maintain pressure depending on how well everything is sealed up. In this test, the canister held 85 PSI for five minutes while i left to run an errand.

8.) After waiting, remove the pump connector from the valve. Then use the end of a ballpoint pen, the kind with a retractable tip, with tip retracted to slowly release pressure. While releasing pressure tip the canister on its side so the watch is submerged. Continue to slowly release the pressure in the canister. The idea is to watch for a steady stream of bubbles that would indicate a leak.

In this picture I had a small bubble come from under the bezel, keep in mind that almost six times as much air that is normally under the bezel is now inside that space. As this air expands it will show up as bubbles, this does not indicate a leak. A leak will be an obvious steady stream, imagine 5 times the air volume of the inside of the watch case escaping. If you have a leak, you will know it.

9.) As the air in the canister is almost released tip the canister back up while still de-pressurizing until no pressure remains. Do not release all of the pressure with the watch still submerged, if you have a leak, this will allow water in.

Thats all there is to it, this watch passed as you can see by the picture of the test. The watch has been upgraded with a Clark superdome, and all seals have been checked and greased. A gen crown and tube are in the works as soon as I can locate the proper tap for the case hole. As a side note, if anyone has a tap to lend, I would greatly appreciate it.

If anyone has any questions about the construction, or testing procedure feel free to PM me.

I hope this has been helpful,

-Mike