- 18/9/19

- 580

- 499

- 63

I've talked with some of you on here about someone making a quartz RM11 so we can have a gen-spec case thickness with a working, reliable movement that isn't going to explode if you play with the chronos like a 7750. I've been looking around for suitable parts and I think I may have come on a (partial) solution. I'd like to run it by some of the more experienced folks here to see if it's feasible or if anyone would be interested in supporting the project.

Here's what I've come up with so far:

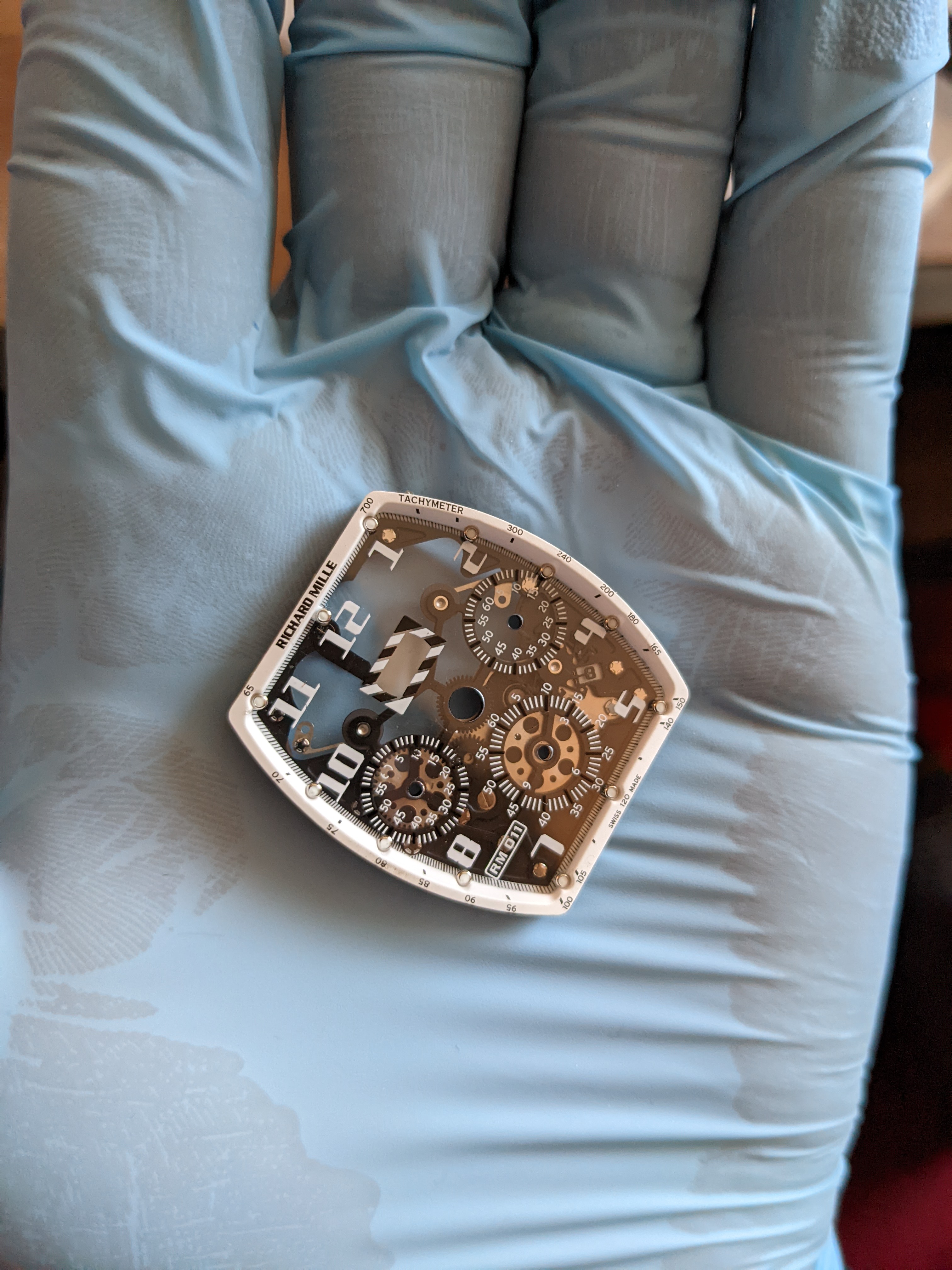

Movement - Miyota 6S50. Mecaquartz chronos, big date at 12, with the subdials in the right location (except for subseconds). Other option is a Ronda 5040b, which trades the correct subdial locations for a big date that looks way too high to look proportional. Date font is a problem but more likely to be modifiable on the Miyota.

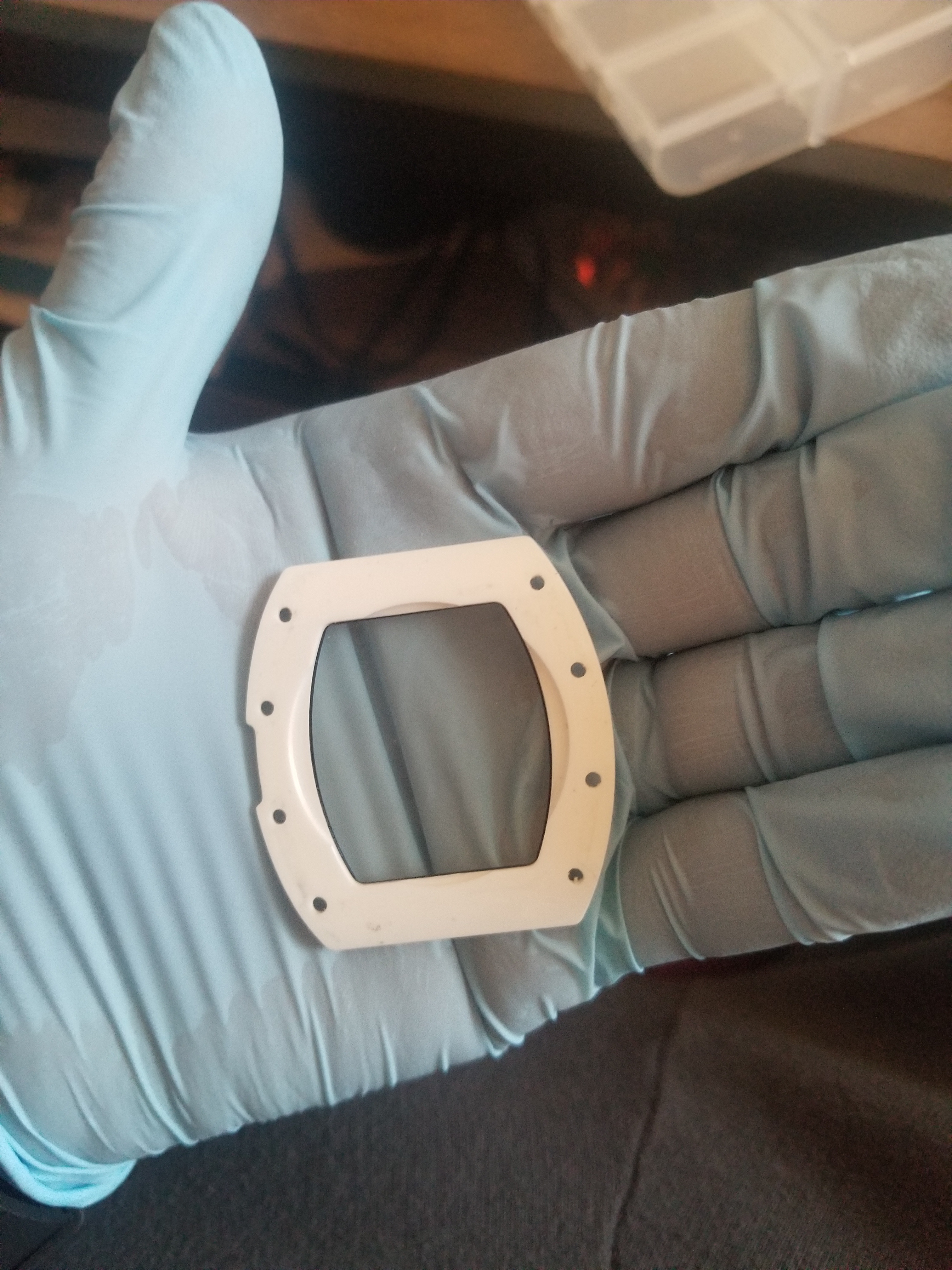

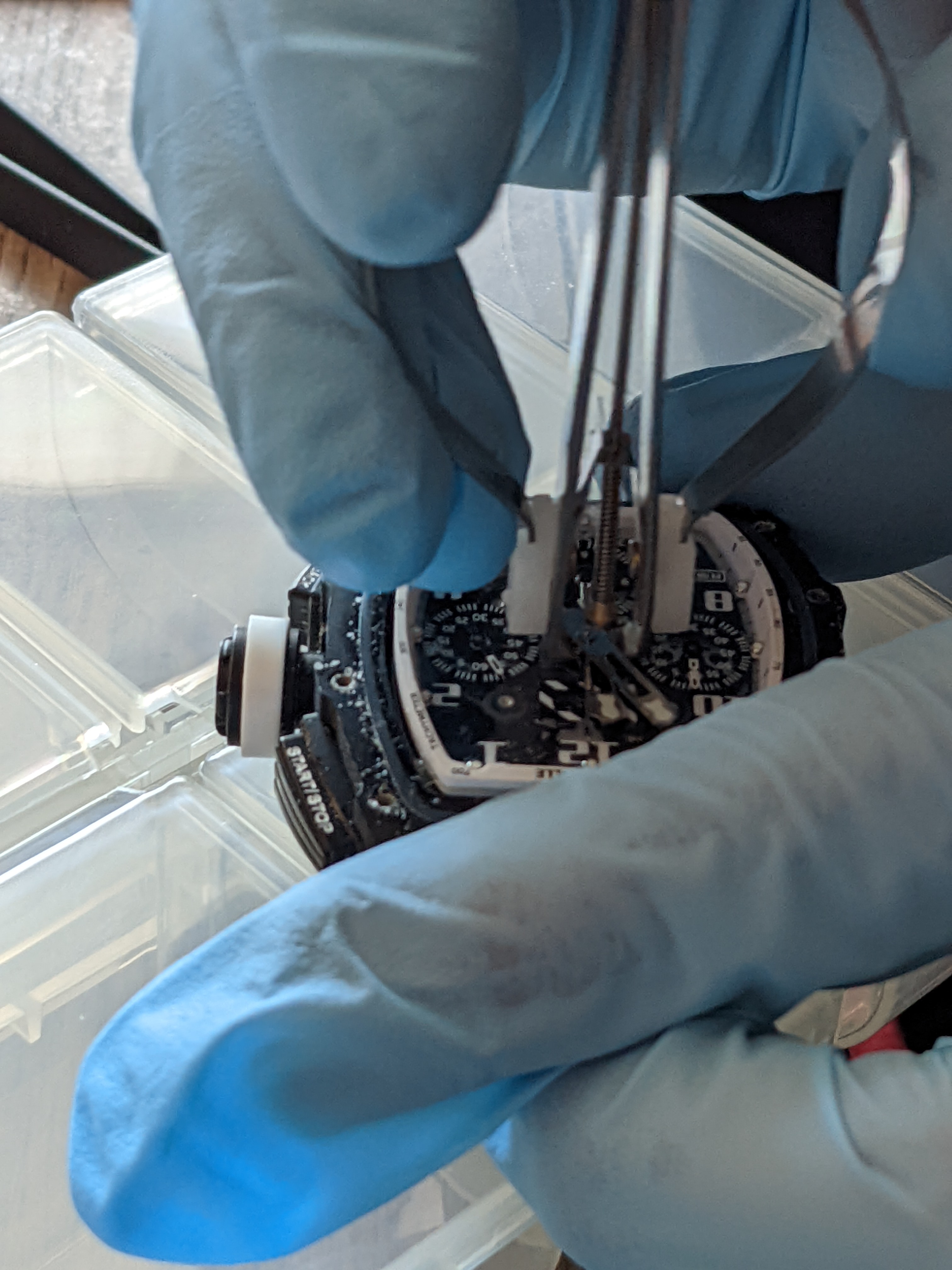

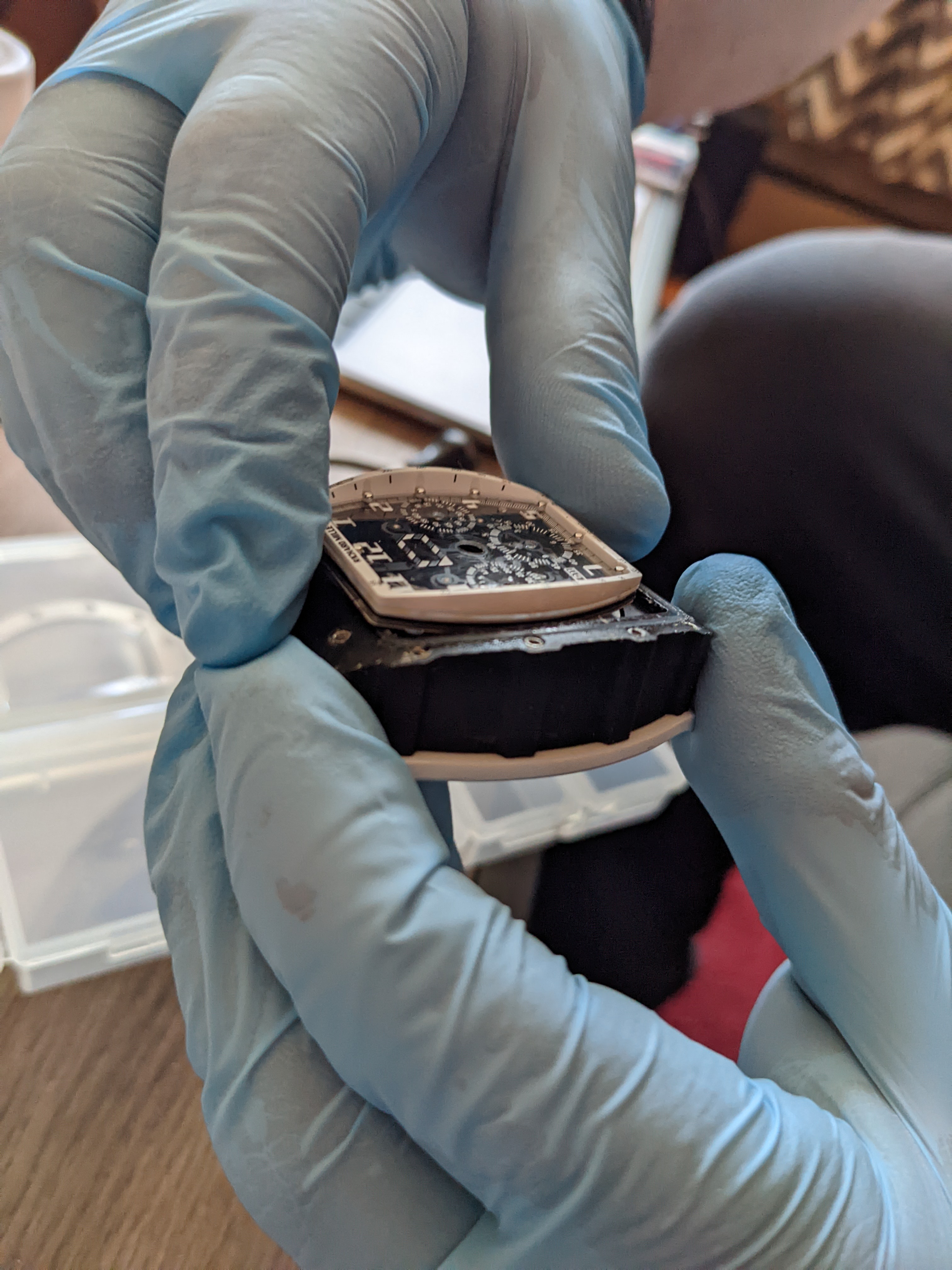

Case - KVF, either 11-03 or 11FM because those seem to be the most widely available. Front and rear bezels for sure, midcase if it can be thinned and still fit the pushers in the right place.

If the midcase needs more extensive modifying, I'd 3d print it, probably in carbon fiber filament.

I'd like to reuse as much of the deco as possible, or if new plates are required ideally they could be lasercut from thin brass and painted or enameled. Hands will have to be custom unless rep parts can be broached out as it's unlikely they'll fit straight out of the box, and the big date font is a back-burner problem.

I'm well aware this is a giant project that might end in total failure, but I figured I'd give it a shot. I've got time, access to tools, and the desire to see if I can make it work.

If anyone is interested in following along, let me know! I'm also looking for a donor KVF case, preferably from a broken watch so I don't destroy a working one. If you've got one, I'd love to figure out how we can come to an agreement! If you're a watchmaker and have feedback (even if it's to tell me I'm wasting my time), I welcome that too!

Thanks for reading my wall-of-text, and if I find enough interest (and a case to play with) I'll keep interested folks updated as it goes.

Here's what I've come up with so far:

Movement - Miyota 6S50. Mecaquartz chronos, big date at 12, with the subdials in the right location (except for subseconds). Other option is a Ronda 5040b, which trades the correct subdial locations for a big date that looks way too high to look proportional. Date font is a problem but more likely to be modifiable on the Miyota.

Case - KVF, either 11-03 or 11FM because those seem to be the most widely available. Front and rear bezels for sure, midcase if it can be thinned and still fit the pushers in the right place.

If the midcase needs more extensive modifying, I'd 3d print it, probably in carbon fiber filament.

I'd like to reuse as much of the deco as possible, or if new plates are required ideally they could be lasercut from thin brass and painted or enameled. Hands will have to be custom unless rep parts can be broached out as it's unlikely they'll fit straight out of the box, and the big date font is a back-burner problem.

I'm well aware this is a giant project that might end in total failure, but I figured I'd give it a shot. I've got time, access to tools, and the desire to see if I can make it work.

If anyone is interested in following along, let me know! I'm also looking for a donor KVF case, preferably from a broken watch so I don't destroy a working one. If you've got one, I'd love to figure out how we can come to an agreement! If you're a watchmaker and have feedback (even if it's to tell me I'm wasting my time), I welcome that too!

Thanks for reading my wall-of-text, and if I find enough interest (and a case to play with) I'll keep interested folks updated as it goes.