- 21/2/09

- 5,704

- 687

- 113

As soon as I saw JohnG's Combat Luminor PAM homage, I knew I wanted to try to do something similar. I did a TON of reading, searching, more reading, more searching, ordered tools, watch parts, more reading, and finally got the project underway today.

I ordered a mini-fiddy from Getat and in less than 24 hours the crystal exploded. OK, maybe exploded is too strong a word, but it is no longer with us. Tat is sending me another crystal and I got a tip from Hooligan that low dome plexi may be the way to go. So crystal press is on order and probably the plexi soon.

Here's the patient. Cracked glass and all.

Here's my workspace. Actually it's my dad's workspace. I took the day off work to spend with him, since I would need his help and tools as we'll see later. The watch tool kit is a friend's. The hand removers, pressers, and movement holder are mine. Thanks to JMB for the sweeeeeet hand pressers.

OK, case back is off. Good 'ol ball of masking tape.

Crown and stem removed and movement removed from the case. Thanks to Alvinado and Sconehead for their excellent pictorial tutorials.

Ready for hand removal.

Plastic wrap to protect the dial.

Hour and minute hands off. Second hand followed shortly.

Ready to unscrew dial feet holders (if that's what they are called...for the purposes of this post we'll just go with it.)

Original dial is off. Easy peasy.

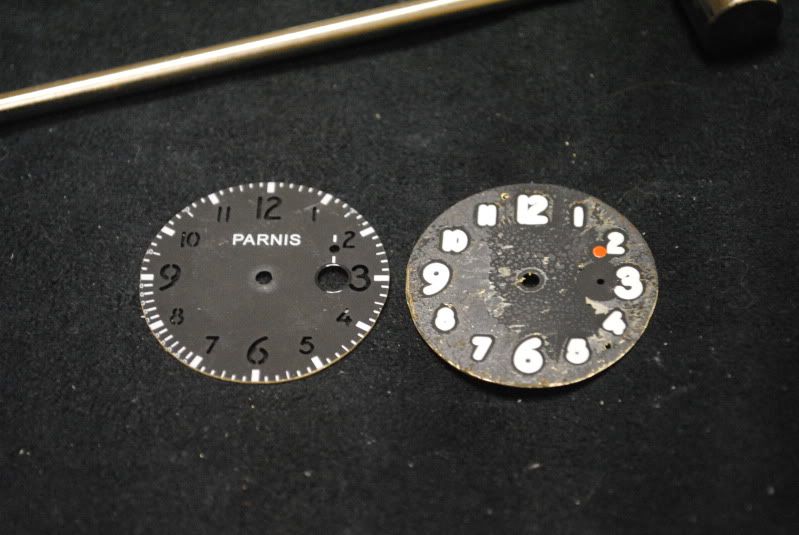

Here's the UBoat homage dial that will replace the MM dial. Uh-oh its considerably larger than the MM dial. Dad's tools come into play in 3...2...1......

I ordered UBoat dials from Tat in case things went hinky with one of them. This is my first go at this. Dad and I had to figure out a way to trim down the dial. I didn't take the camera down to his shop, but I'll give you the cliff notes.

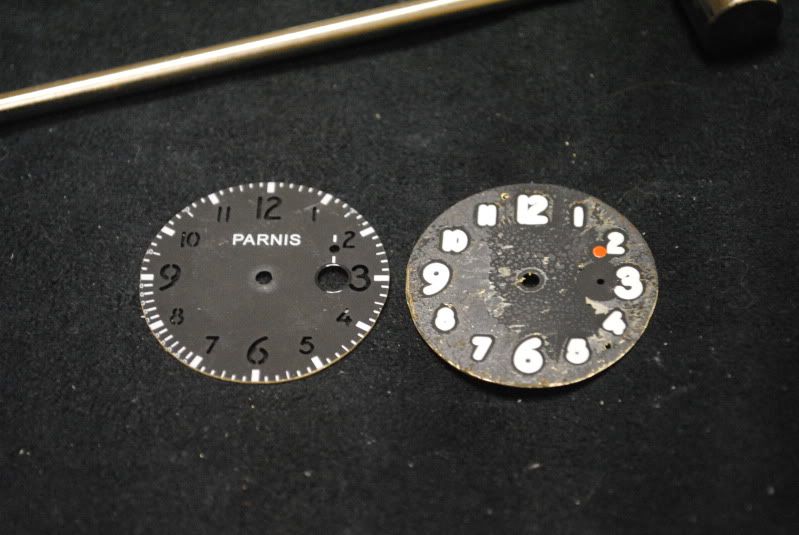

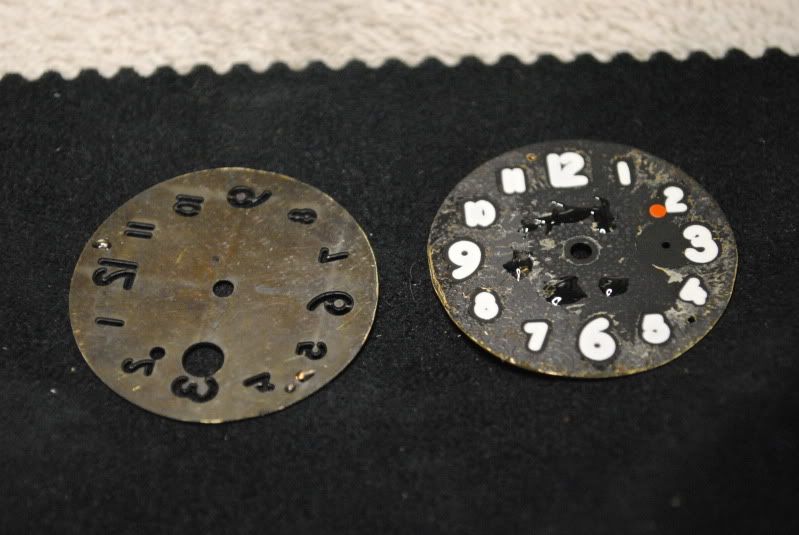

First pass, we tried to use a lathe. Worked well, but we soon saw we were off center slightly due to how we had to mount the dial into the lathe holder thing (again...just go with it). We switched gears and used a Dremel tool with a sanding wheel to take down the excess. Long story short, it worked pretty well, and we decided to go ahead and do the second dial this way. Presto! Here's both dials at the correct size:

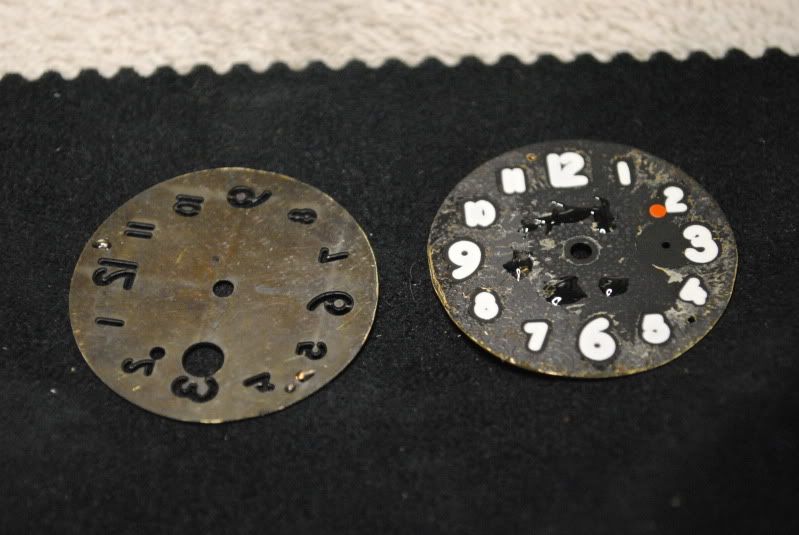

Time to separate the sandwich layers in order to repaint the upper layer. A razor blade, small hammer, and finally a paint scraper did the trick.

Tried using paint thinner to remove the old paint. Not much success. Sand paper? Bingo! Here's the stripped dial.

It took three tries at spray painting the dial to get it free of particles and the correct texture, but it turned out REALLY well (to me, anyway). It was exactly the finish I was going for.

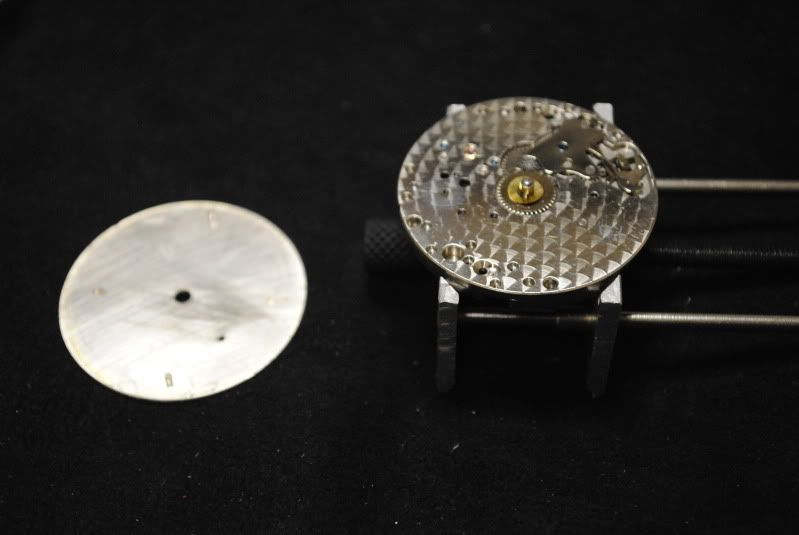

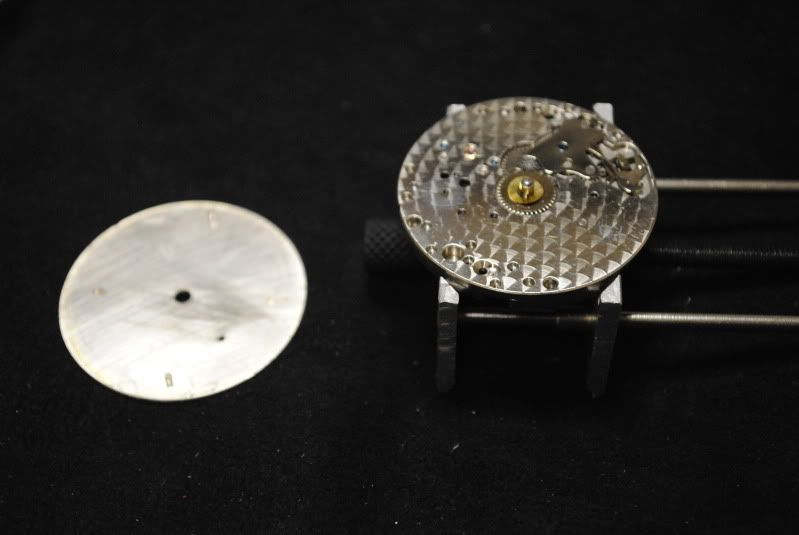

Here's the bottom layer test fitted to the movement. I had to bend one of the dial feet slightly, but it works.

Both dial halves ready for some Gorilla glue.

And we're back together again.

Attached the dial to the movement after the glue dried.

Time for JMB's hand pressers to go to work. Pretty easy to do. The hands rubbed slightly, so they need to be straightened a bit.

At this point, I put the stem and crown back in the watch and rotated the hands around. They look really close, but haven't seen any issues with them rubbing. I still may revisit this before the watch is cased for good. It is currently keeping great time, which is really a plus for a watch project. I'll have to wait on a replacement crystal to arrive before she's ready to be finished up.

As I said before, this is my first pass at this, but I have had a blast doing it. Thanks to RWI, RWG 1.1, RG, RWG, and HomageForum for all the great information. Thanks to Gio, R2D4, Alvinado, JohnG, Sconehead, Coldi, JMB, FakeMaster, Trailboss99, and others for all the inspiration and information. Couldn't have done it without you. I'll post final pics when the crystal arrives (provided I can actually get it into the case). Thanks for looking.

:av007:

I ordered a mini-fiddy from Getat and in less than 24 hours the crystal exploded. OK, maybe exploded is too strong a word, but it is no longer with us. Tat is sending me another crystal and I got a tip from Hooligan that low dome plexi may be the way to go. So crystal press is on order and probably the plexi soon.

Here's the patient. Cracked glass and all.

Here's my workspace. Actually it's my dad's workspace. I took the day off work to spend with him, since I would need his help and tools as we'll see later. The watch tool kit is a friend's. The hand removers, pressers, and movement holder are mine. Thanks to JMB for the sweeeeeet hand pressers.

OK, case back is off. Good 'ol ball of masking tape.

Crown and stem removed and movement removed from the case. Thanks to Alvinado and Sconehead for their excellent pictorial tutorials.

Ready for hand removal.

Plastic wrap to protect the dial.

Hour and minute hands off. Second hand followed shortly.

Ready to unscrew dial feet holders (if that's what they are called...for the purposes of this post we'll just go with it.)

Original dial is off. Easy peasy.

Here's the UBoat homage dial that will replace the MM dial. Uh-oh its considerably larger than the MM dial. Dad's tools come into play in 3...2...1......

I ordered UBoat dials from Tat in case things went hinky with one of them. This is my first go at this. Dad and I had to figure out a way to trim down the dial. I didn't take the camera down to his shop, but I'll give you the cliff notes.

First pass, we tried to use a lathe. Worked well, but we soon saw we were off center slightly due to how we had to mount the dial into the lathe holder thing (again...just go with it). We switched gears and used a Dremel tool with a sanding wheel to take down the excess. Long story short, it worked pretty well, and we decided to go ahead and do the second dial this way. Presto! Here's both dials at the correct size:

Time to separate the sandwich layers in order to repaint the upper layer. A razor blade, small hammer, and finally a paint scraper did the trick.

Tried using paint thinner to remove the old paint. Not much success. Sand paper? Bingo! Here's the stripped dial.

It took three tries at spray painting the dial to get it free of particles and the correct texture, but it turned out REALLY well (to me, anyway). It was exactly the finish I was going for.

Here's the bottom layer test fitted to the movement. I had to bend one of the dial feet slightly, but it works.

Both dial halves ready for some Gorilla glue.

And we're back together again.

Attached the dial to the movement after the glue dried.

Time for JMB's hand pressers to go to work. Pretty easy to do. The hands rubbed slightly, so they need to be straightened a bit.

At this point, I put the stem and crown back in the watch and rotated the hands around. They look really close, but haven't seen any issues with them rubbing. I still may revisit this before the watch is cased for good. It is currently keeping great time, which is really a plus for a watch project. I'll have to wait on a replacement crystal to arrive before she's ready to be finished up.

As I said before, this is my first pass at this, but I have had a blast doing it. Thanks to RWI, RWG 1.1, RG, RWG, and HomageForum for all the great information. Thanks to Gio, R2D4, Alvinado, JohnG, Sconehead, Coldi, JMB, FakeMaster, Trailboss99, and others for all the inspiration and information. Couldn't have done it without you. I'll post final pics when the crystal arrives (provided I can actually get it into the case). Thanks for looking.

:av007: