- 20/3/13

- 910

- 264

- 63

Because your VN dealer didn't have a clue what they were talking about?

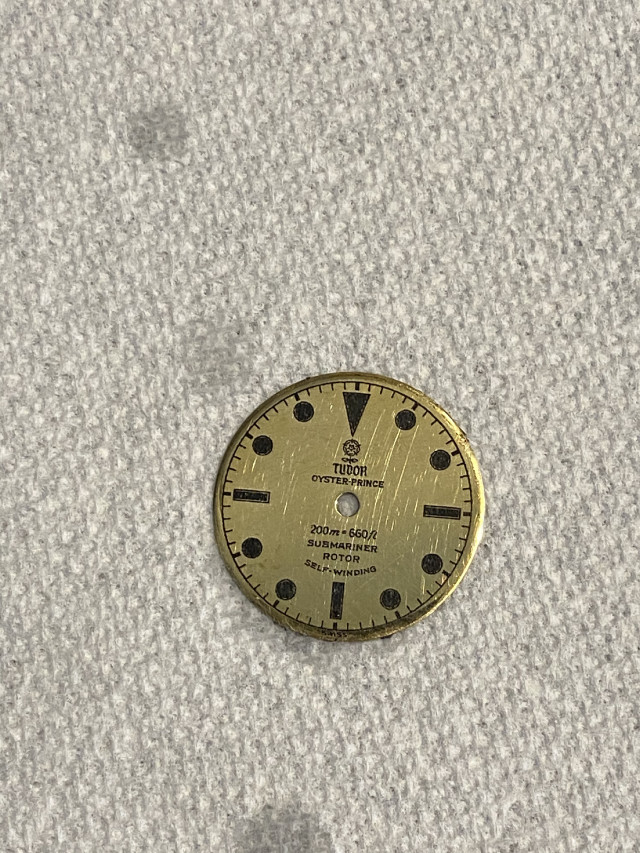

That hydro technique is impractical for watch dials. It's nowhere near precise enough to position a piece of floating dial artwork on a dial less than 30mm diameter. And if this was the technique used to make true gilt dials, then those here who have spent considerable time researching the subject would know that this is how it's done. And it isn't. But hey, that's no reason to dismiss it as a fun technique to try. But as mentioned before, decals (no matter what technique is used to get them on the dial) will not result in print quality as good as the results from using the correct carrier for the printing image - a pad printing plate.

This is not a VN dealer he has made complex customs watch parts for me that includes "simple" parts as movement holders but also 2 complete custom cases out of blue prints, 2 column wheels for gen el primero movements as well as several custom gilt dials and bezels

we have previously talked about modding cases to fit different movements with the valueable aid of tech aspects from alligoat and automatico to mod MBW cases

so not really just a reseller guy as many other dealers

but yes i agree that the way to go seem to be a custom printing pad too

thanks for the view popperini, highly appreciated