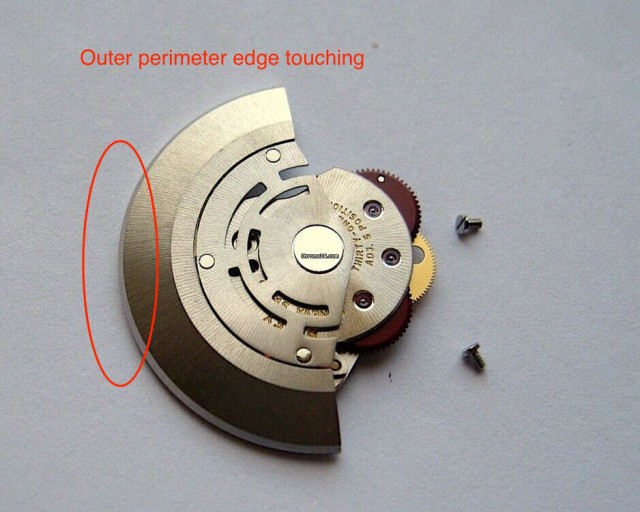

Hello i am currently building a vintage Rolex 15210. When I install the VR3135 movement inside the case it seems to fit nicely, it lines up perfectly with the crown tube etc. But when i mount the caseback, the rotor is slightly hittigt the caseback, which leaves a very unpleasent sound.

I havent got the caseback gasket yet, would this solve the problem? i mean the gasket should extend the distance between the rotor and caseback by a few mm?

I hope someone knows how to fix this.

Thanks in advance and have a lovely day!

I havent got the caseback gasket yet, would this solve the problem? i mean the gasket should extend the distance between the rotor and caseback by a few mm?

I hope someone knows how to fix this.

Thanks in advance and have a lovely day!