Holy crap - OP in "Actual Project Update" Shocker!!

So, Project Raffle Win slowly inches on, and this weekend I embarked on a Herculean effort (for me) to get the watch put together. Prior to this, I've spent several comedic sessions trying to epoxy on dial feet which just fell off again, every time. Anyway, I ditched the Gorilla epoxy for some good old fashioned Araldite, and this weekend achieved a state of successful feet adhesion.

Now, during the process I also decided that my dial foot "footprint" was inadequate, so I switched to dial feet with a bigger "footprint" (what I call the flat plate that you glue to the dial). BUT, these bigger footprints also then fouled the datewheel. BUT, I'd noticed there was plenty of depth to the GMT pinion, and I thought I'd get away with clamping the dial posts so the dial and the big feet footprints hovered over the datewheel. So I proceeded with that cunning plan.

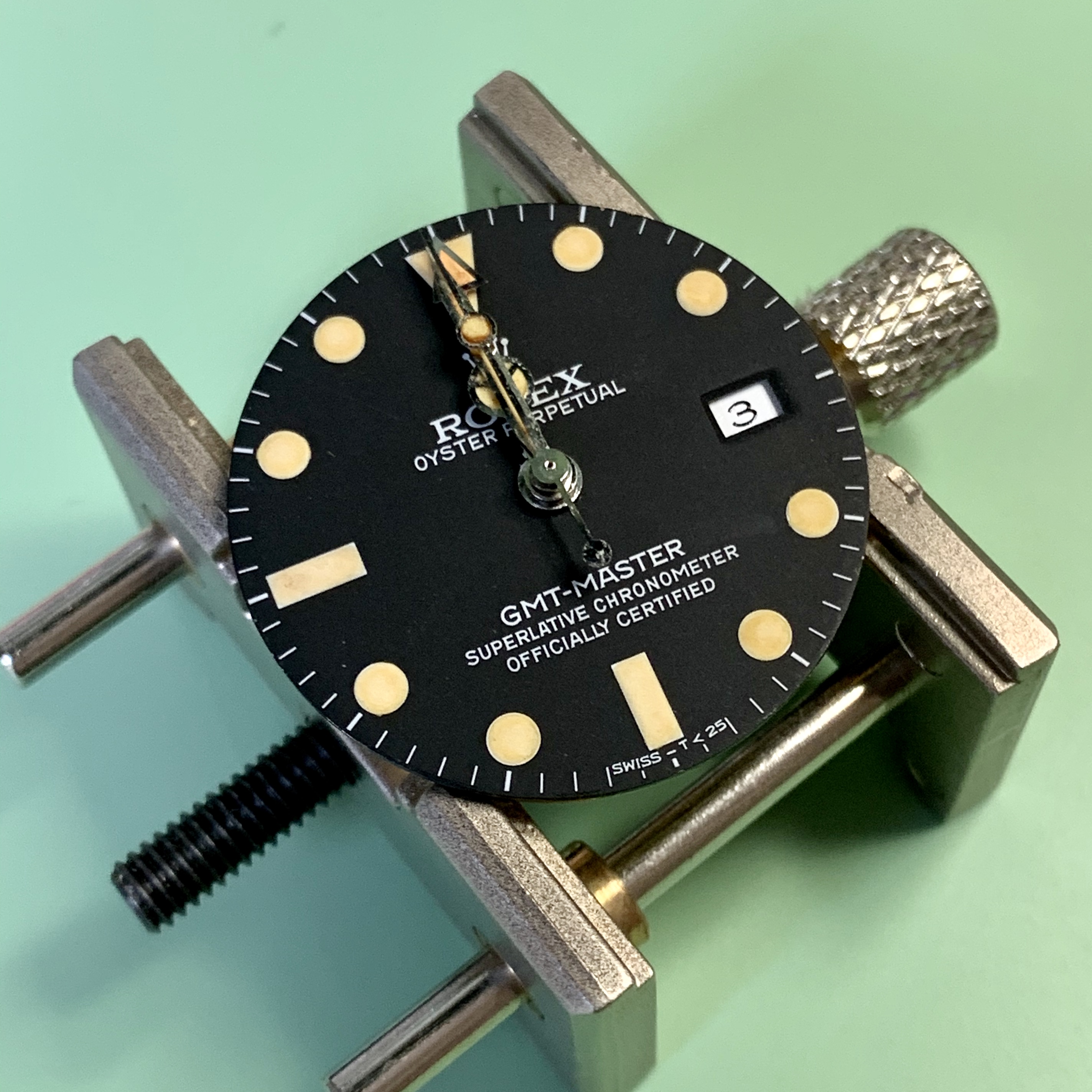

Before assembly, I gave the dial and hands a very light ageing pass with the ol' coffee wash. Just on the lume and hands - I didn't feel the need to work over the dial surface.

And then on to assembly. I attached the dial to the movement, making sure it cleared the datewheel. Checking the operation of the movement, it worked just fine! The GMT hand went on, no problem.

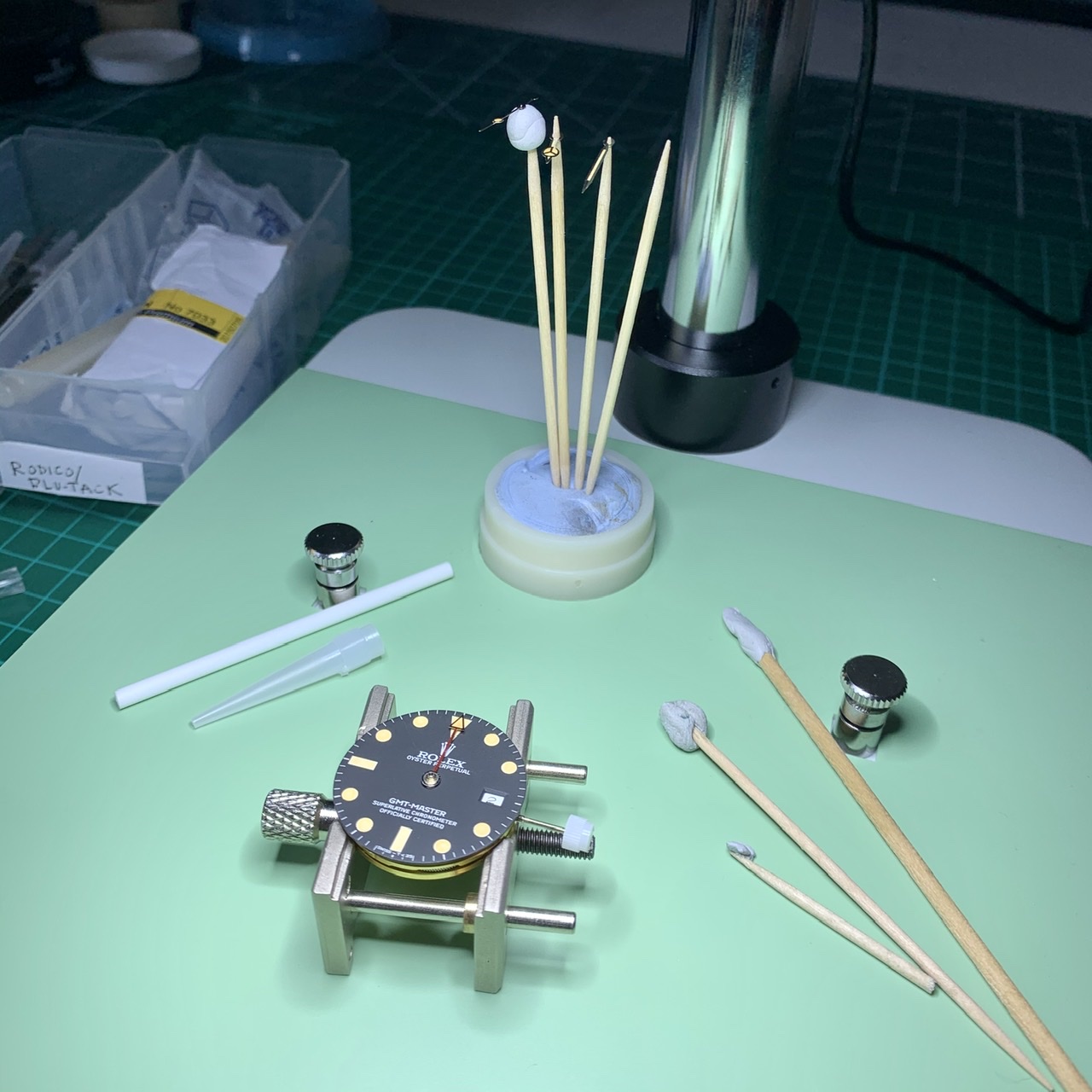

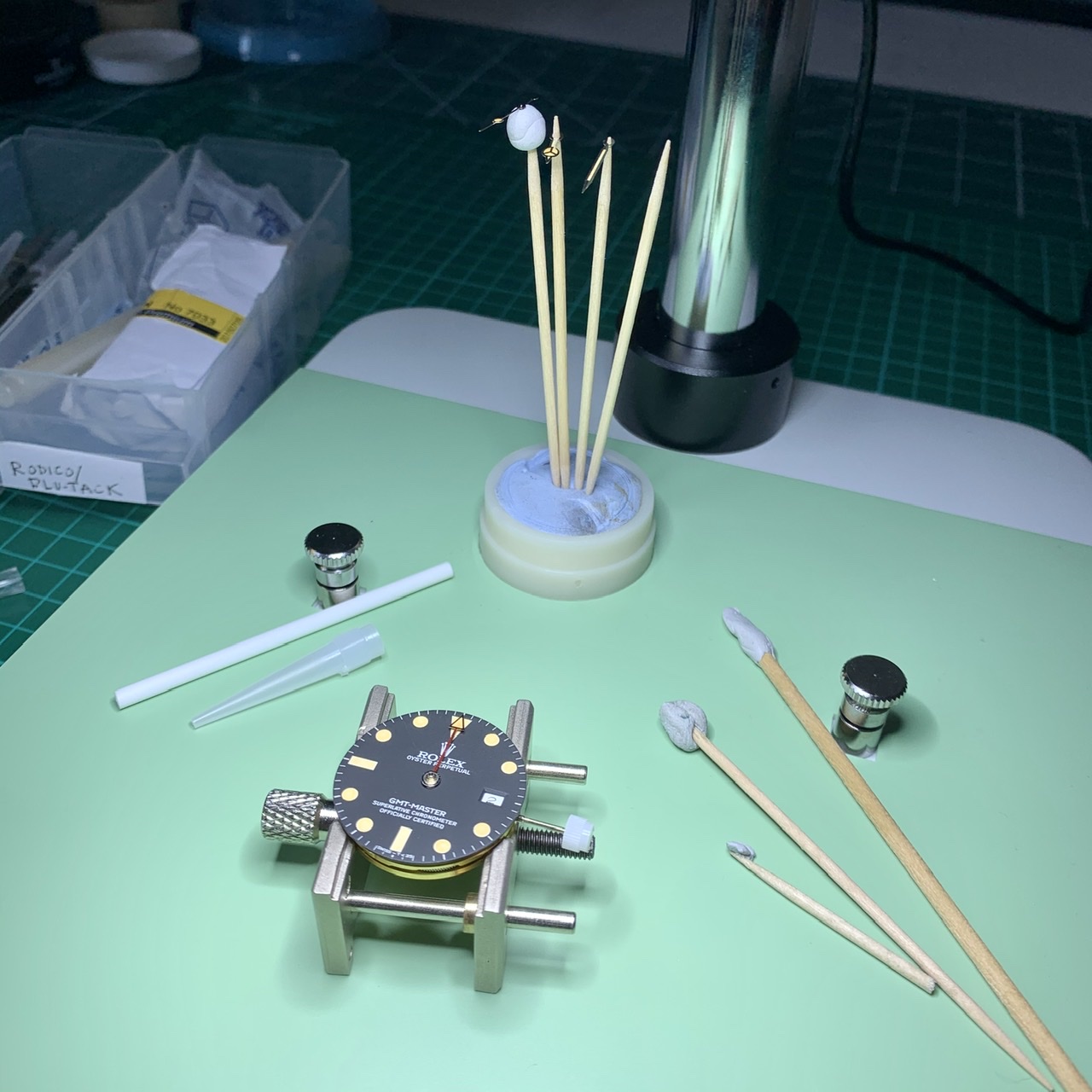

And then I tried to fit my nicely aged hour hand. Oh. It's the wrong size. Okay, so I'd aged a set of hands for a low beat movement. Tits. At this point impatience to get the watch constructed took over, and - having found a set of ETA hands - I went straight ahead and fitted them (I'll give them a very light coffee wash in situ, I thought, because that's the kind of watchmaking rebel I am).

But then in no time at all, I had A COMPLETE WATCH. NEARLY. WOO!

Next - get the gen crown on the stem, and trim the stem to size. Whizz the hands round, slap a bit of coffee on 'em, job's a good 'un.

Crown on, stem in, start to move the hands about... oh. The GMT hand doesn't move at all. And now the date won't change. Hmm. So, clamping the movement into the case has probably caused my big-footed dial feet to press on the datewheel. Oh, and was I meant to use that bendy washer thing between the GMT wheel and the dial..?

Well, I suppose I'd better take it all apart again, and fix the numerous problems I've caused myself. But hey - it's actually nearly done! Apart from all the things that aren't.

So, Project Raffle Win slowly inches on, and this weekend I embarked on a Herculean effort (for me) to get the watch put together. Prior to this, I've spent several comedic sessions trying to epoxy on dial feet which just fell off again, every time. Anyway, I ditched the Gorilla epoxy for some good old fashioned Araldite, and this weekend achieved a state of successful feet adhesion.

Now, during the process I also decided that my dial foot "footprint" was inadequate, so I switched to dial feet with a bigger "footprint" (what I call the flat plate that you glue to the dial). BUT, these bigger footprints also then fouled the datewheel. BUT, I'd noticed there was plenty of depth to the GMT pinion, and I thought I'd get away with clamping the dial posts so the dial and the big feet footprints hovered over the datewheel. So I proceeded with that cunning plan.

Before assembly, I gave the dial and hands a very light ageing pass with the ol' coffee wash. Just on the lume and hands - I didn't feel the need to work over the dial surface.

And then on to assembly. I attached the dial to the movement, making sure it cleared the datewheel. Checking the operation of the movement, it worked just fine! The GMT hand went on, no problem.

And then I tried to fit my nicely aged hour hand. Oh. It's the wrong size. Okay, so I'd aged a set of hands for a low beat movement. Tits. At this point impatience to get the watch constructed took over, and - having found a set of ETA hands - I went straight ahead and fitted them (I'll give them a very light coffee wash in situ, I thought, because that's the kind of watchmaking rebel I am).

But then in no time at all, I had A COMPLETE WATCH. NEARLY. WOO!

Next - get the gen crown on the stem, and trim the stem to size. Whizz the hands round, slap a bit of coffee on 'em, job's a good 'un.

Crown on, stem in, start to move the hands about... oh. The GMT hand doesn't move at all. And now the date won't change. Hmm. So, clamping the movement into the case has probably caused my big-footed dial feet to press on the datewheel. Oh, and was I meant to use that bendy washer thing between the GMT wheel and the dial..?

Well, I suppose I'd better take it all apart again, and fix the numerous problems I've caused myself. But hey - it's actually nearly done! Apart from all the things that aren't.