UPDATE: With the completion of my VS3235 gen parts install project, I'm back working on the 4130. Today I figured I'd move ahead with some more re-assembly while I wait for the KIF 3-2 springs to arrive from Cousins (it'll probably take around a week for it to arrive from the UK). I won't install any of the chronograph works until I can sort out the KIF spring on the main train bridge, but there's plenty to assemble before that. And to be honest when I'm not fighting with KIF springs things actually go pretty smoothly. I got the barrel, barrel bridge, click, ratchet, and intermedia crown wheel assembly, all installed without a hitch.

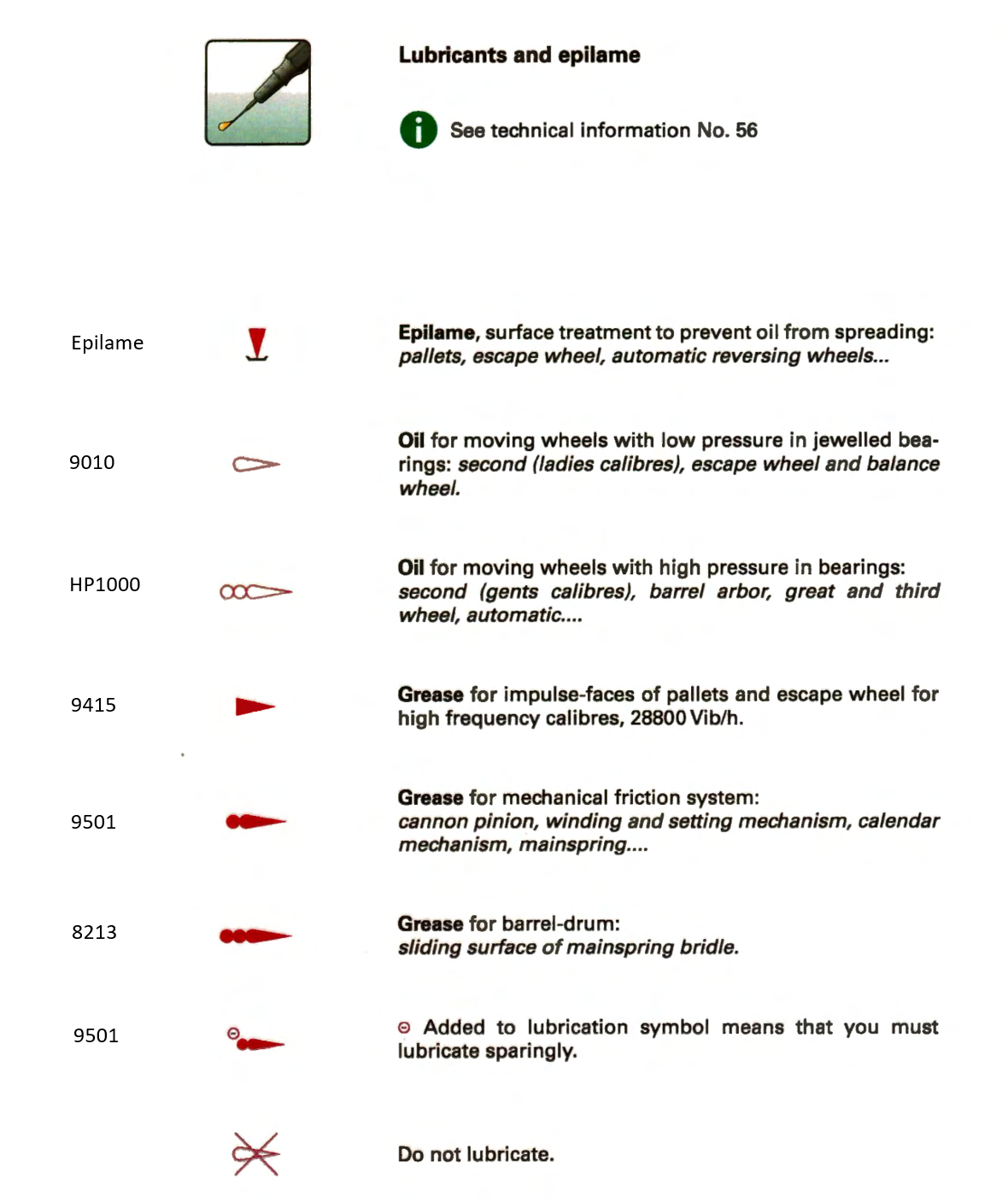

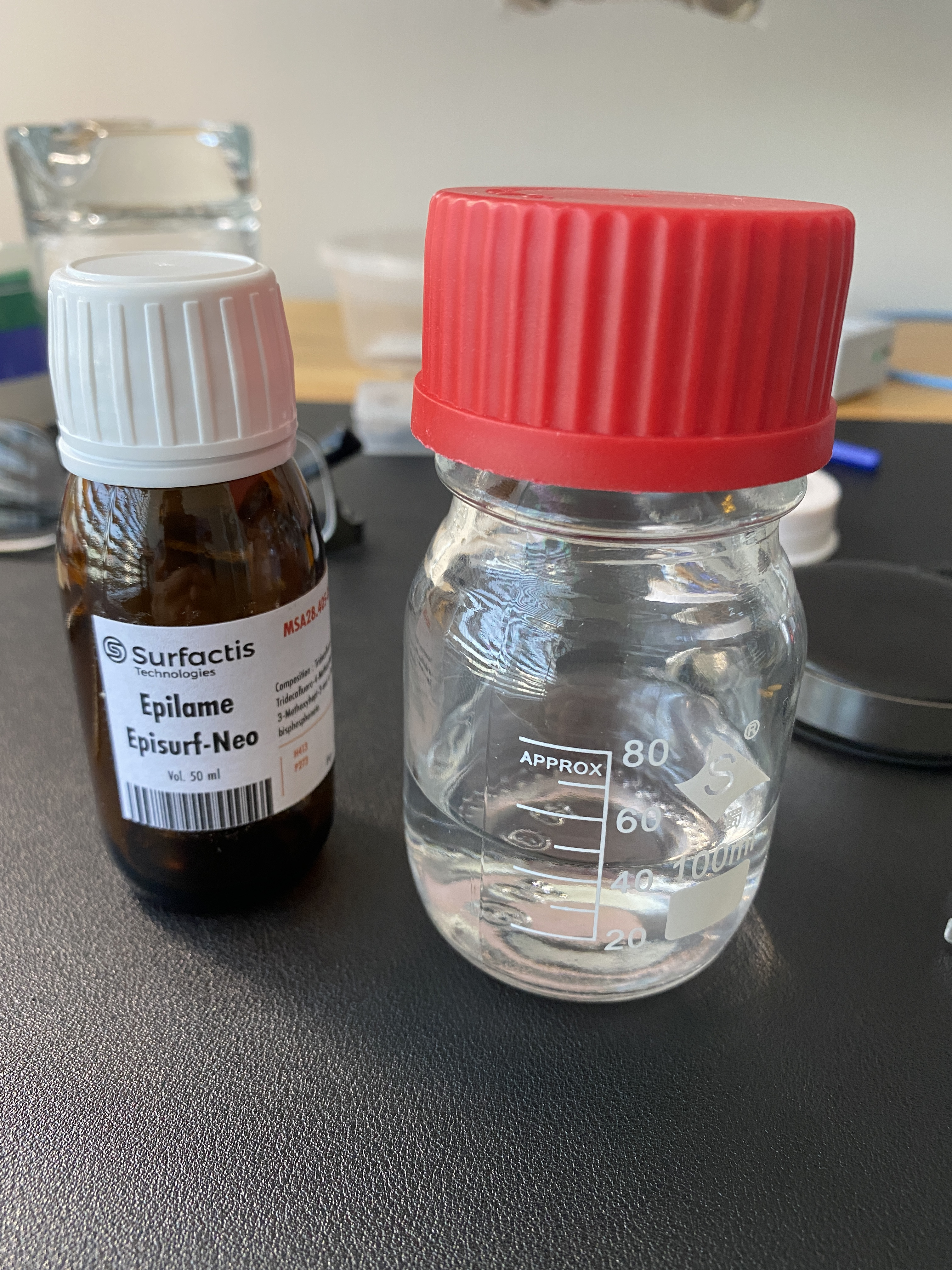

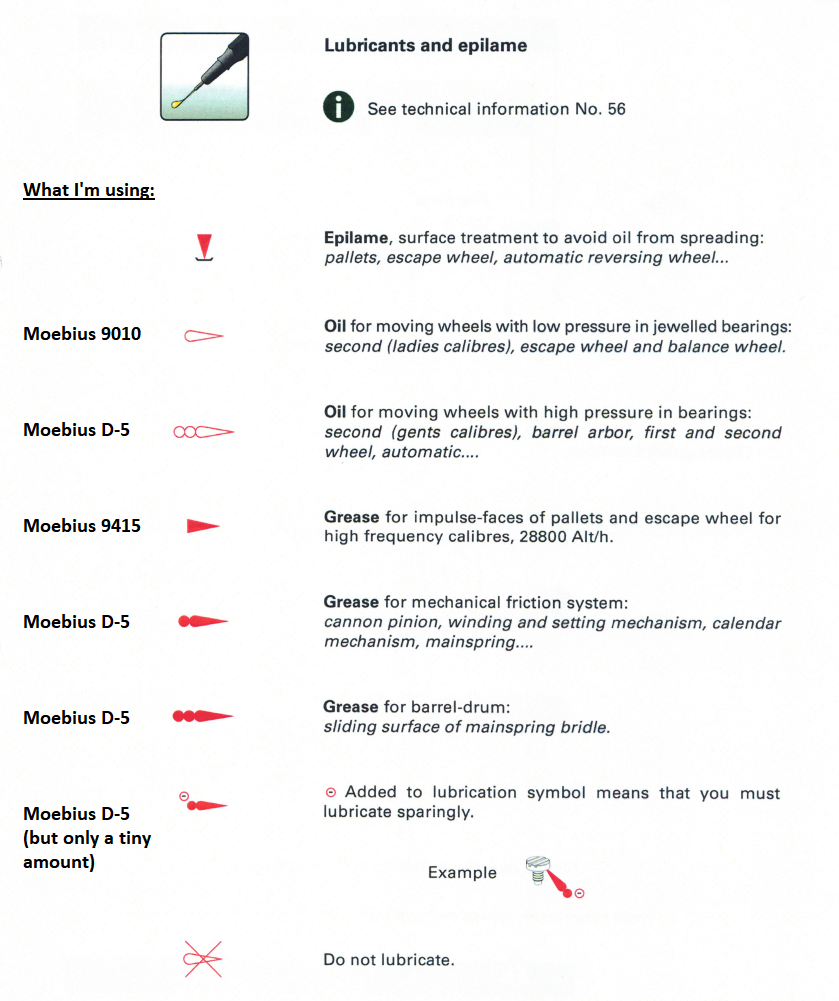

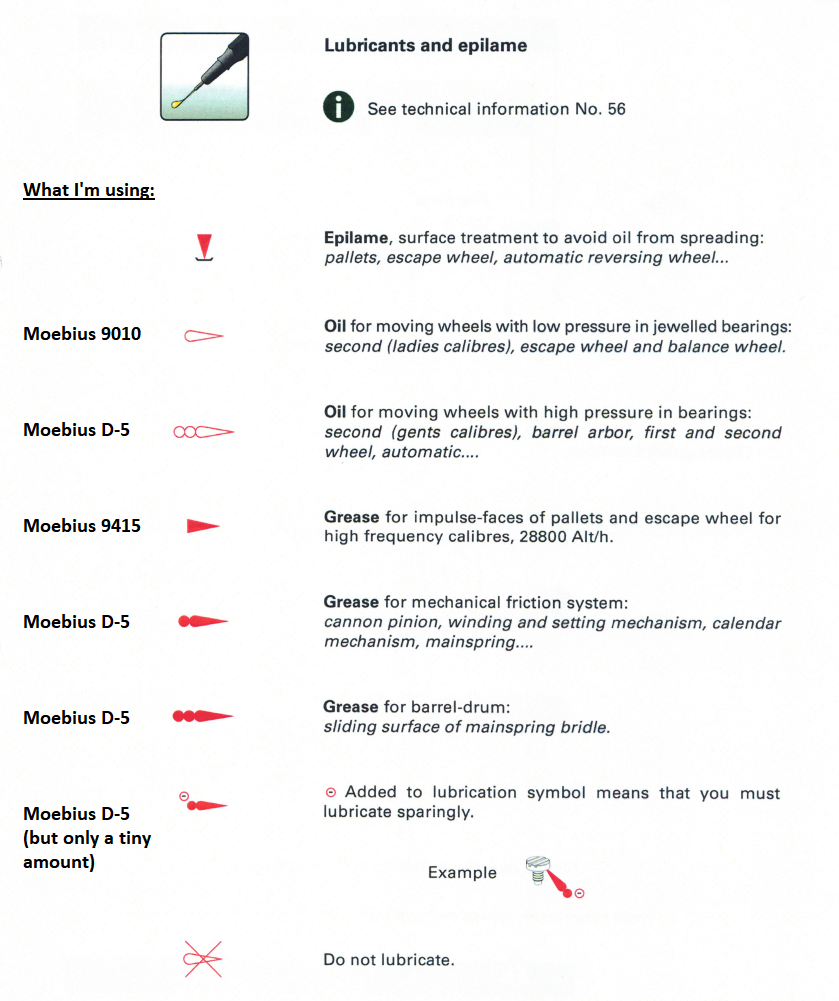

I've been lubricating mostly with D5 except for the shock settings for the balance and escape wheel which I'm using 9010 on, and obviously I'm using 9415 on the pallet stones. I still don't have epilame, so I'm just ignoring that for now. I'm sure I'll take this thing apart again before to long to service it again, and I can do epilame that time. But I do have a question about the use of D5 pretty much everywhere else... Here's a screenshot from the 4130 service guide and I've added what I'm using for each of the lubrication types that are called for. Am I massively screwing up? I have some Molykote, which (if any) of these symbols would I use Molykote for?

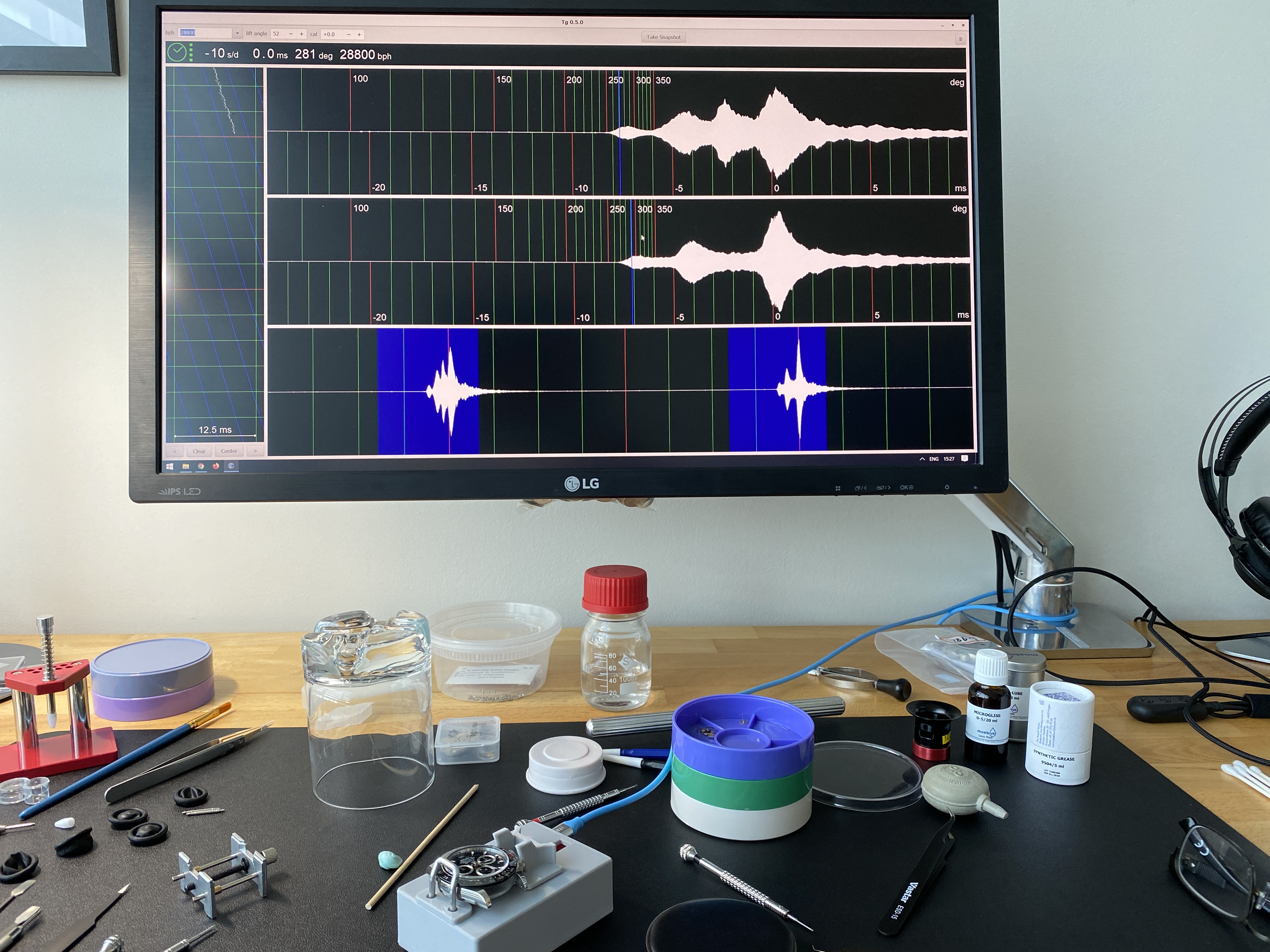

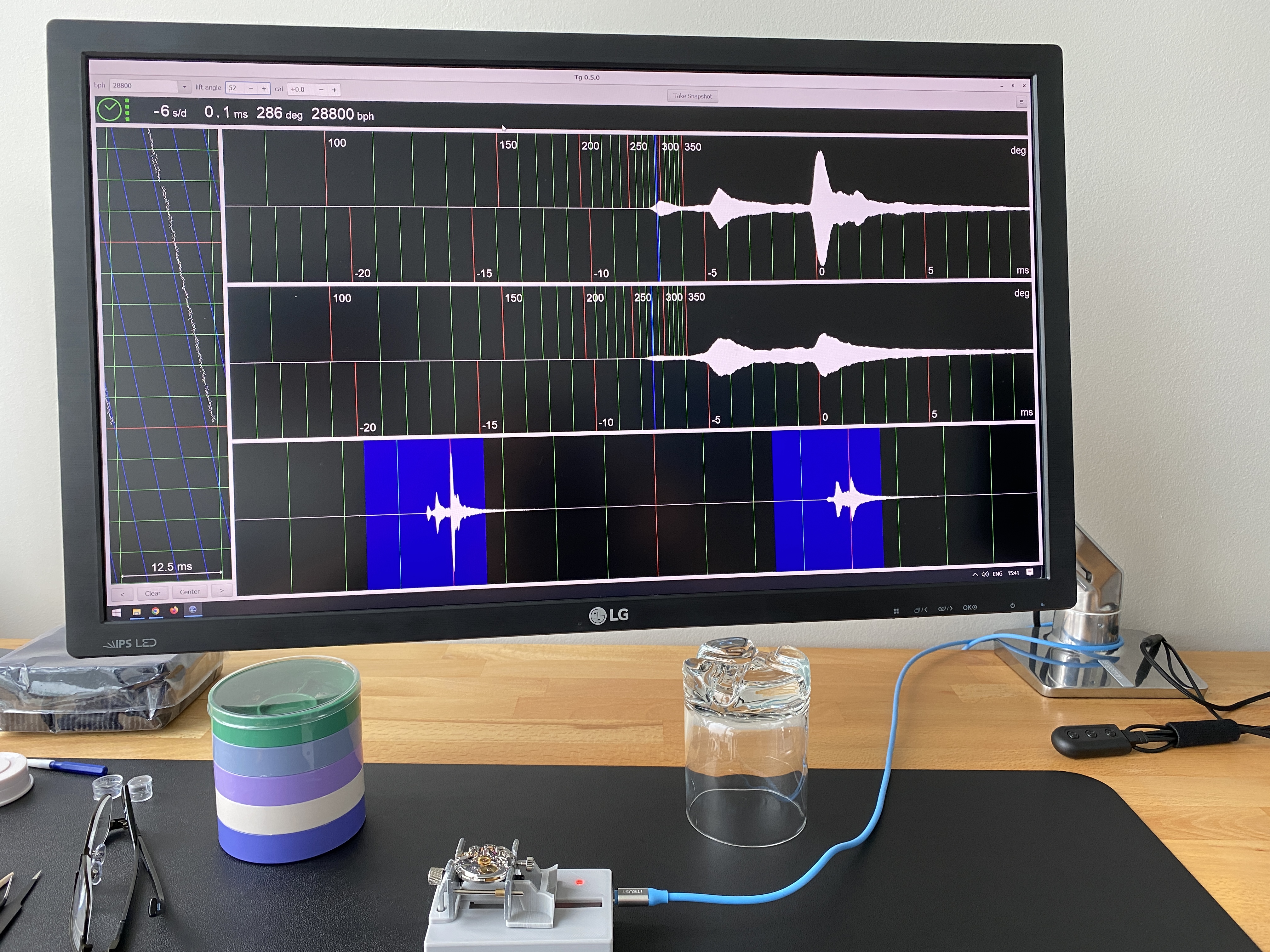

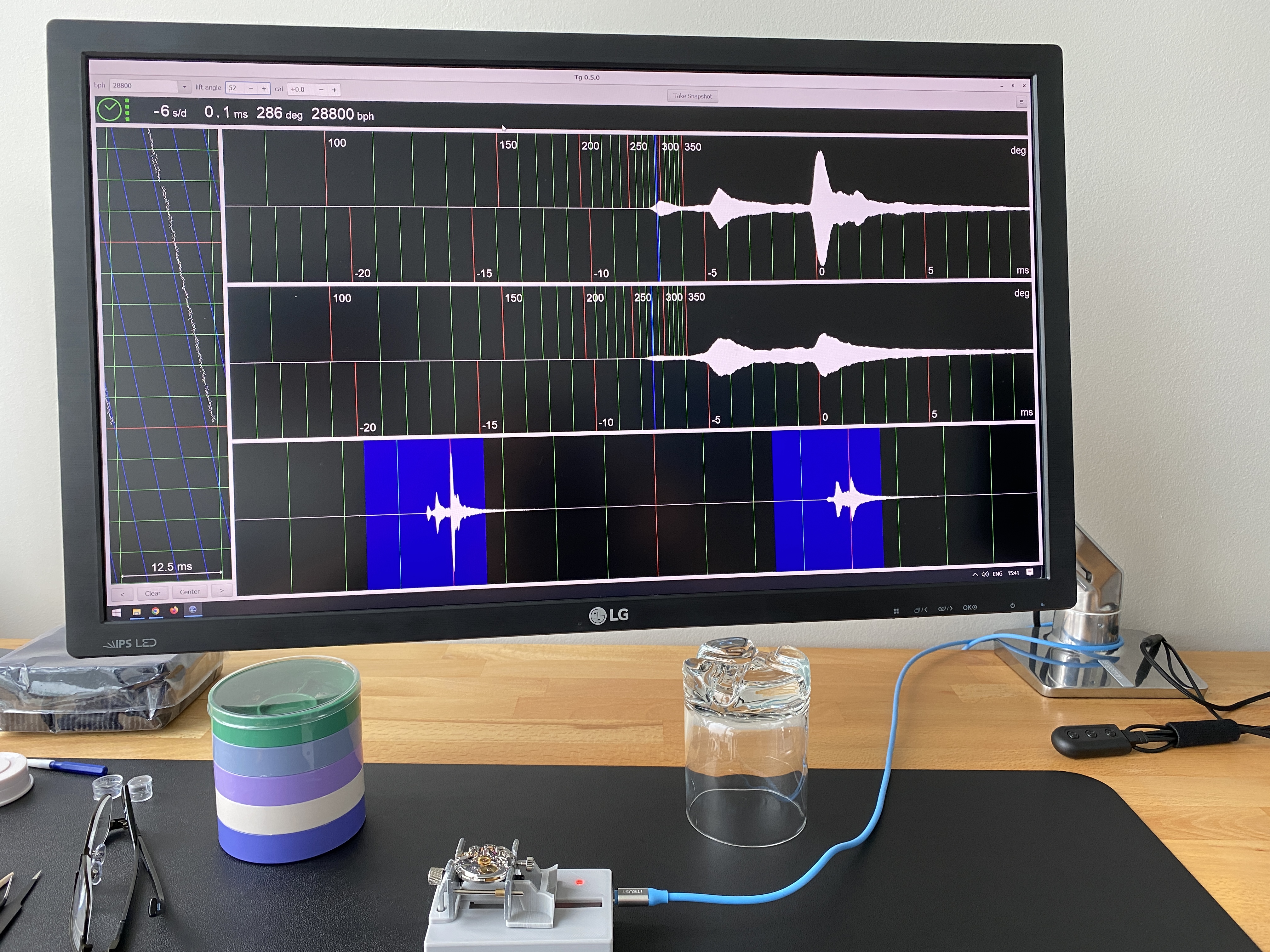

Once I got the barrel side all assembled I put in the pallet fork, pallet bridge, and balance assembly. Everything went together like a charm. Here's what I'm seeing on the timegrapher. I'm actually getting a better amplitude now (286 degrees) vs before I did anything to the movement (see first post... 238 degrees). I call that a win... Is it possible that I took a movement apart and put it back together in better working order than before? (Let's ignore the two broken screws and the broken KIF spring for now...).

I think I'm going to wait for the replacement KIF springs to arrive before I go any further in the reassembly. But I will probably let the movement run in and see if the stability / amplitude changes as the lubrication works its way around the escape wheel / pallet stones.

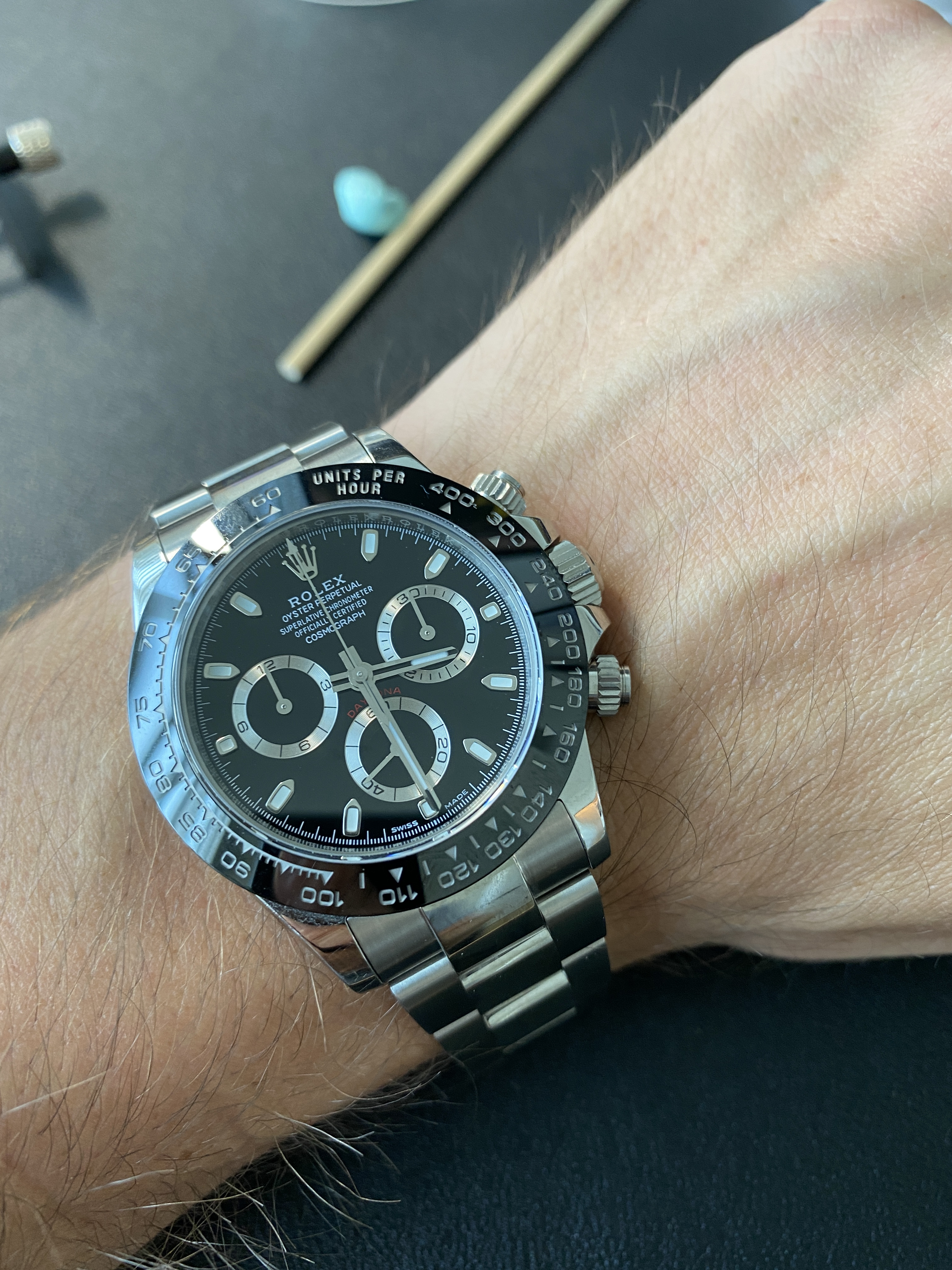

As always thanks for coming along for the ride. Let's hope the rest of the assembly goes as smoothly when the spare parts arrive in a week.

I've been lubricating mostly with D5 except for the shock settings for the balance and escape wheel which I'm using 9010 on, and obviously I'm using 9415 on the pallet stones. I still don't have epilame, so I'm just ignoring that for now. I'm sure I'll take this thing apart again before to long to service it again, and I can do epilame that time. But I do have a question about the use of D5 pretty much everywhere else... Here's a screenshot from the 4130 service guide and I've added what I'm using for each of the lubrication types that are called for. Am I massively screwing up? I have some Molykote, which (if any) of these symbols would I use Molykote for?

Once I got the barrel side all assembled I put in the pallet fork, pallet bridge, and balance assembly. Everything went together like a charm. Here's what I'm seeing on the timegrapher. I'm actually getting a better amplitude now (286 degrees) vs before I did anything to the movement (see first post... 238 degrees). I call that a win... Is it possible that I took a movement apart and put it back together in better working order than before? (Let's ignore the two broken screws and the broken KIF spring for now...).

I think I'm going to wait for the replacement KIF springs to arrive before I go any further in the reassembly. But I will probably let the movement run in and see if the stability / amplitude changes as the lubrication works its way around the escape wheel / pallet stones.

As always thanks for coming along for the ride. Let's hope the rest of the assembly goes as smoothly when the spare parts arrive in a week.