Based on some research I’ve found on getting a gen 7030 case tube to fit properly in a rep case (GMF for my situation).

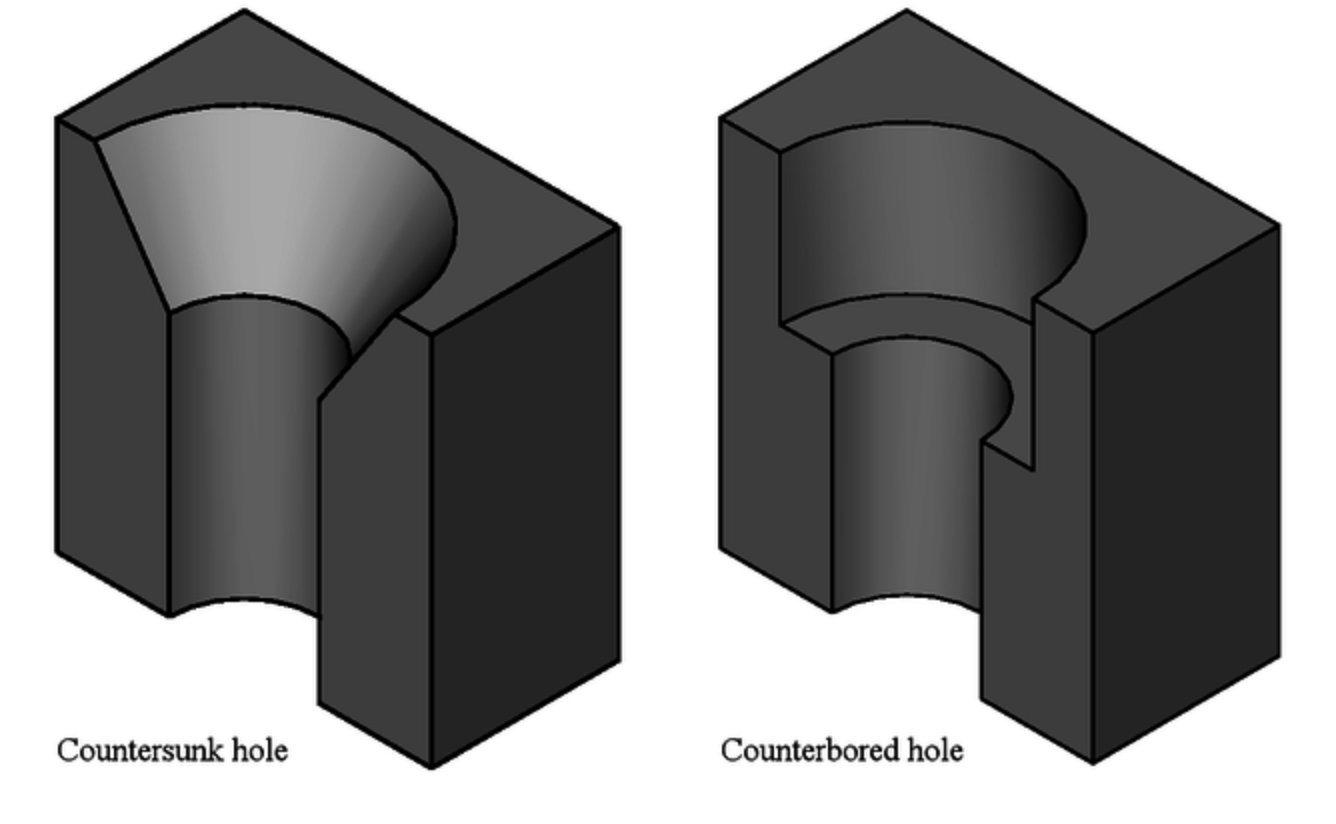

It looks like tube hole has to be counterbored (as opposed to some generically suggesting countersunk).

What I can’t seem to find is:

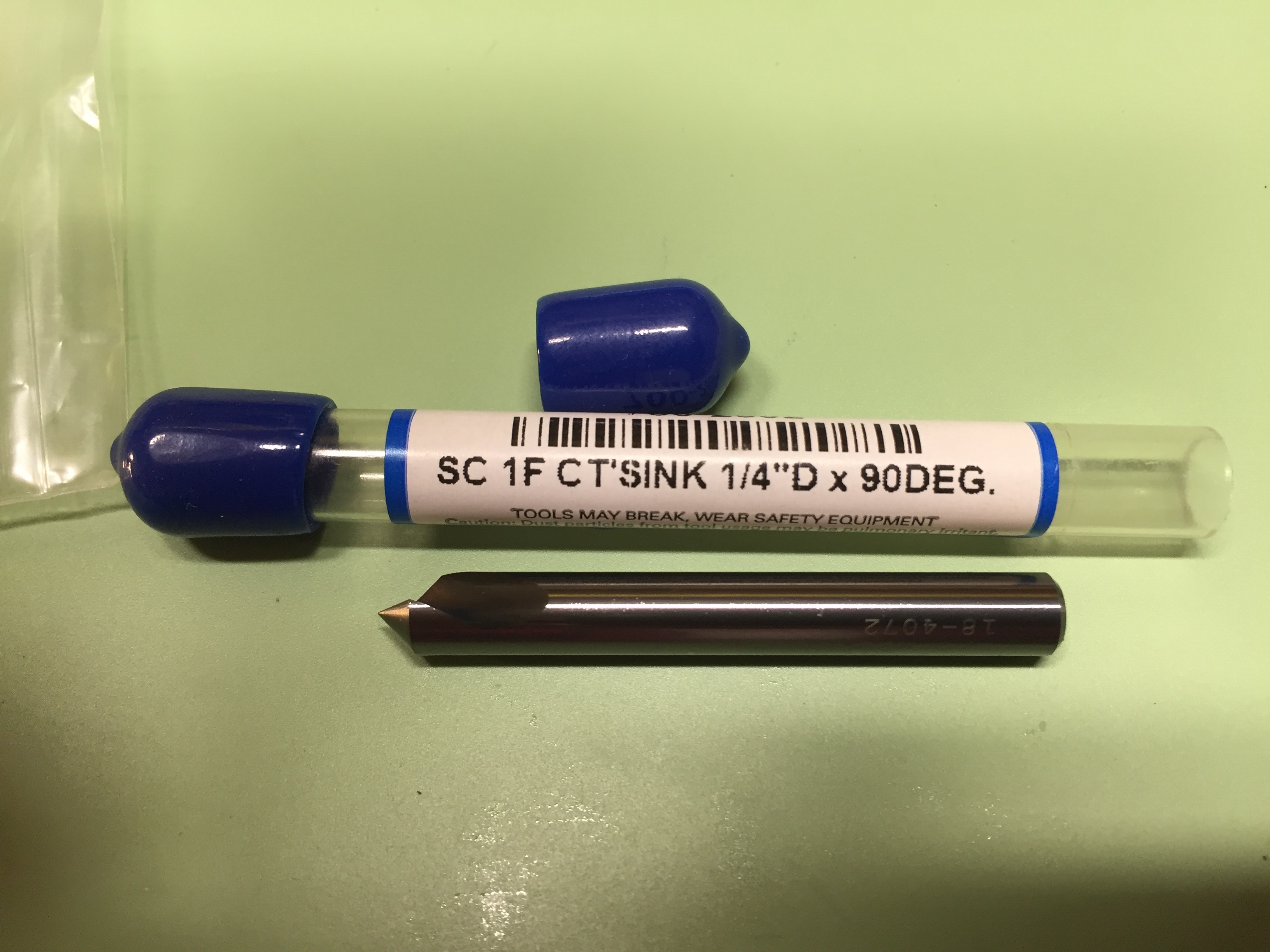

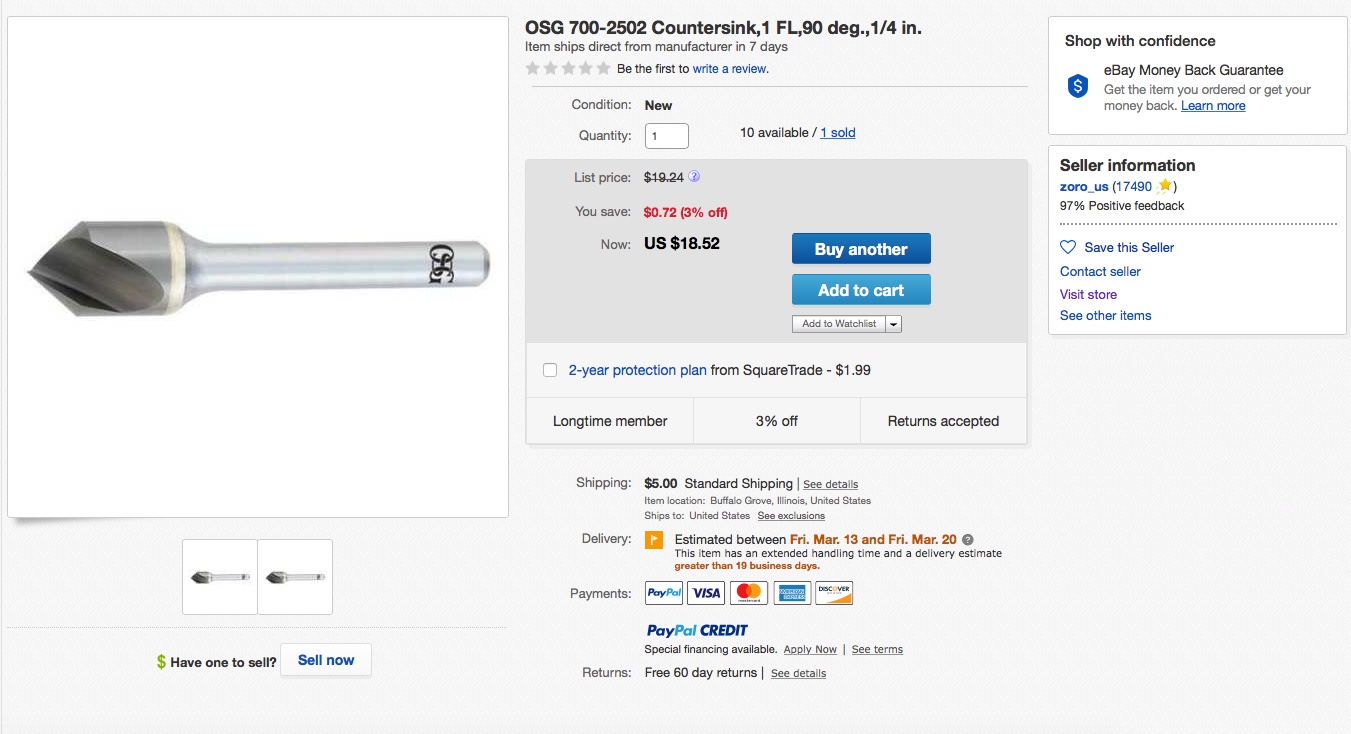

1) Proper counterboring bit to do this

2) A convenient way to do it, if I don’t have a jig to hold the case or a drill press.

Maybe first question should be about feasibility...

It looks like tube hole has to be counterbored (as opposed to some generically suggesting countersunk).

What I can’t seem to find is:

1) Proper counterboring bit to do this

2) A convenient way to do it, if I don’t have a jig to hold the case or a drill press.

Maybe first question should be about feasibility...