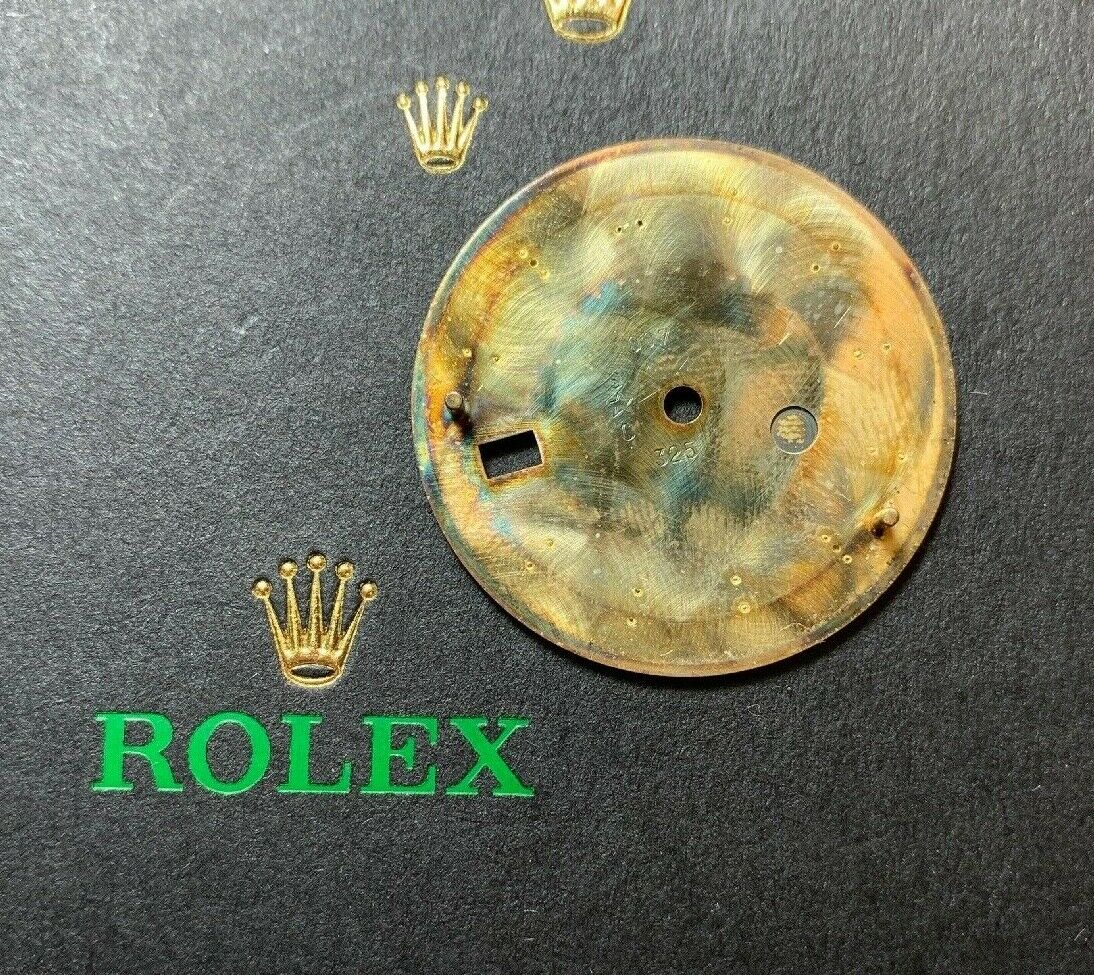

The ETA 2872 has the same feet positions as the 2836, both of which are different from your gen dial. The gen feet will need to be clipped, grinded/sanded flat and then you go from there with your chosen technique.

Oh, good thing you mentioned...Based on the below research, I was sure that this dial shared the feet position because it was the quickset version. See quoted from other forums.

Link to the by Forum Member

lysander from MWR Forum:

https://www.mwrforum.net/forums/showthread.php?6262-Submariner-style-cases-where-to-find

it's 2.50 mm and 11-1/2 l, (the most likely result) you have a little more work to do. Find one of the following movements: ETA 2870, ETA 2872, or ETA 2878 (the ETA 2871, ETA 2873, or ETA 2879 can also be used if you don't mide it operating at 21,600 bph) and then you will have a movement that has the dial feet in the same position as ETA 2824-2/ETA 2892A2, so it accepts all the dials from Mk II, etc, the hand size is the ETA standard of 90/150/25-26, so all the hands will fit, and the stem height is 2.50 mm. Just make sure the original movement was at least 5.50 mm tall (they usually are.)

(Now, don't you go vacuuming up my supply of 2870 series movements off ebay.)

----------------------

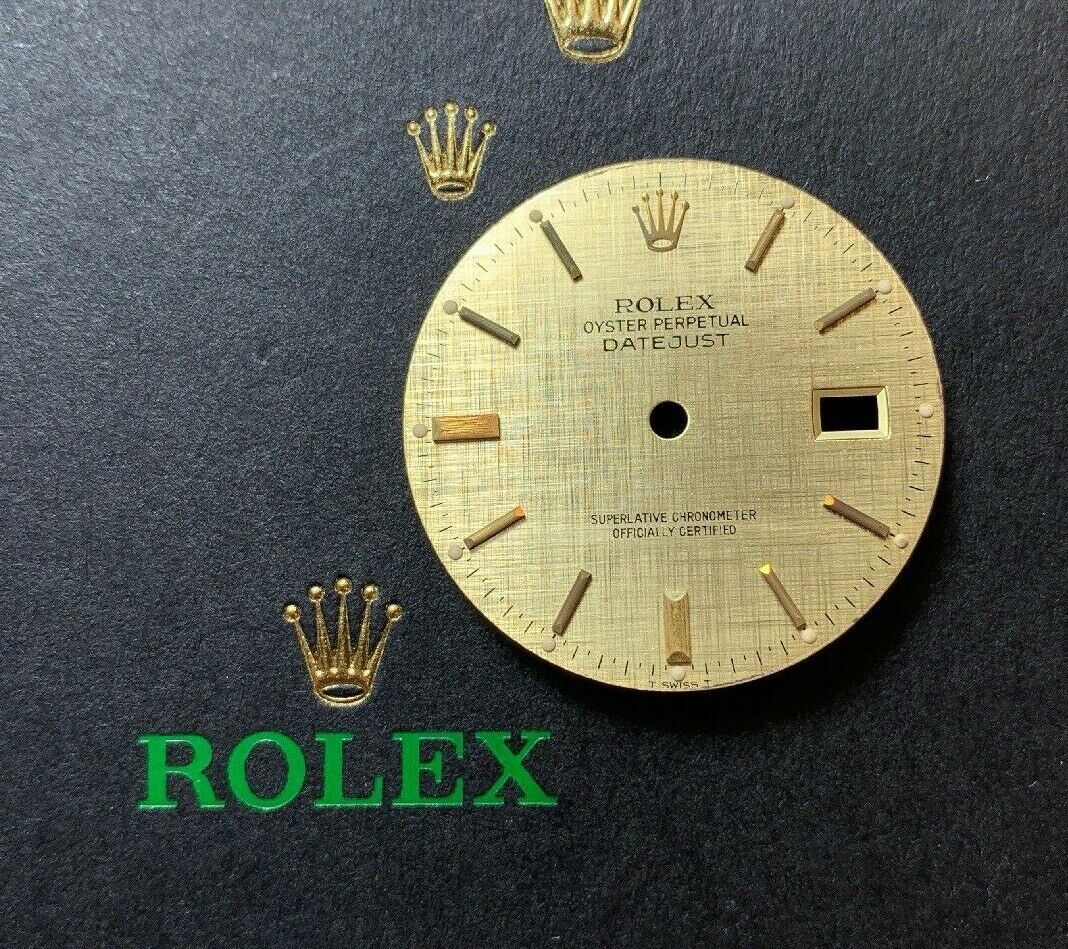

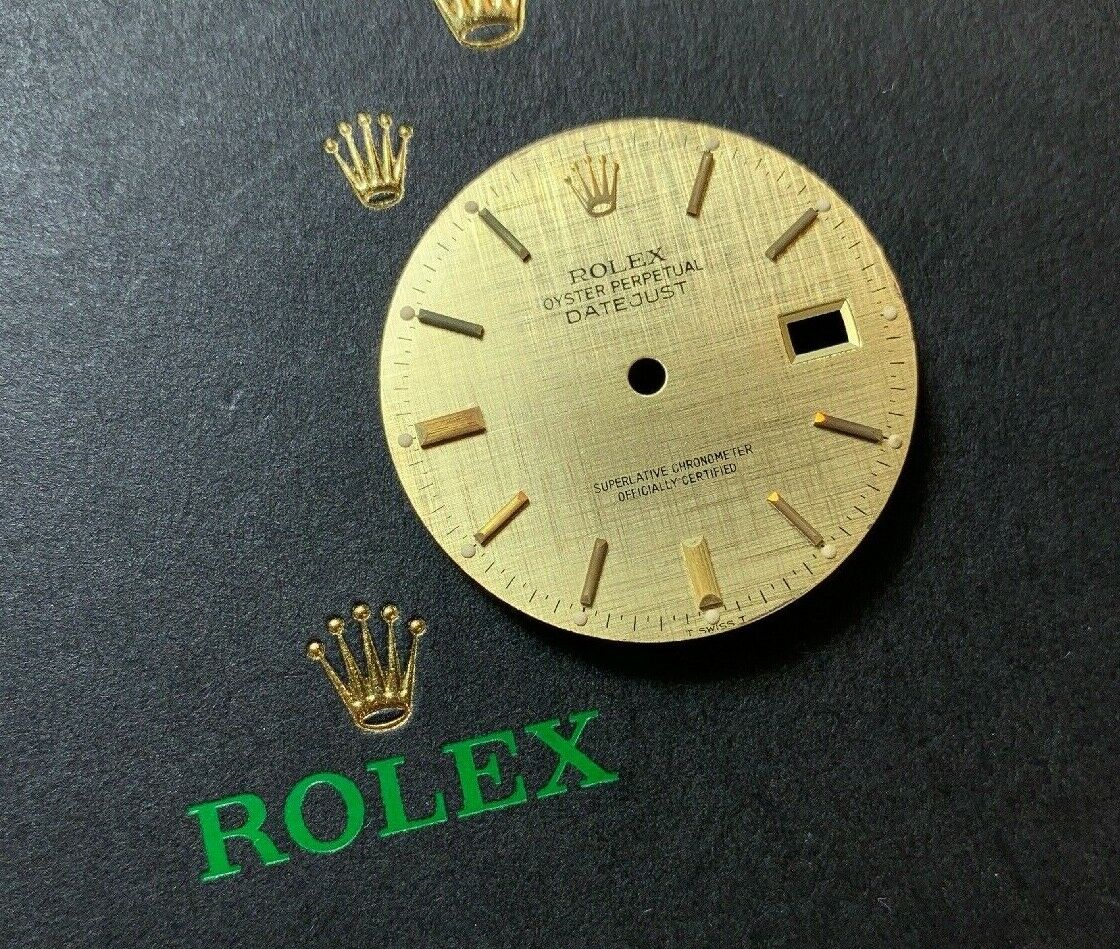

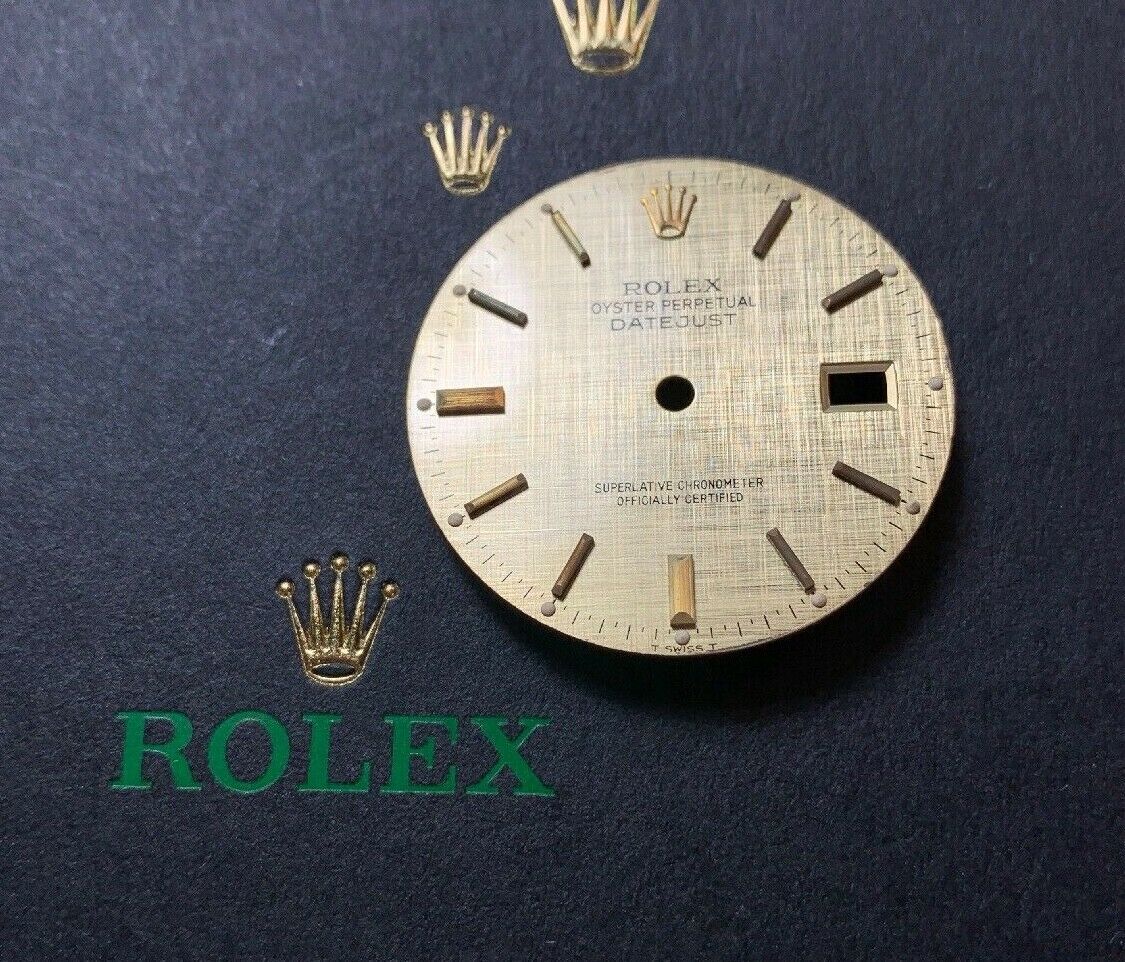

More supporting details that were helpful. Raffle dials also as the 28mm rep datejust dials with the feet positioned in same position as the 2836's. I guess I will find out soon enough.

It would be immensely easier to use an ETA 2872 (or 2878). They are drop in replacements for the Miyota, except they use the 28xx dial and hands.

If you need hand post 0.5 mm longer than standard, you will need: (Bestfit #)

Cannon Pinion: 242/ETA 2801 H6 (245/896)

Sweep second wheel: 227/ETA 2801 H6 (227/752)

Hour wheel: 255/ETA 2600 H6 (255/745)

The big problems you will have using a spacer in between the dial and movement will be 1) if you plan on having the date show, 2) keeping the spacer and dial stable with regards to the movement, and the biggest problem 3) keeping the hour wheel engaged in the minute wheel with 0.5 mm space between the dial and top of the hour wheel. On the 2824, the hour wheel is held in place by just a spring bearing on the back of the dial.